Best Of

Re: Wet Steam

”@ethicalpaul Well your reasoning was a secret , until now.”

Haha, nobody can say Paul keeps his ideas secret!

@ethicalpaul - I can imagine you getting a few eye rolls from your wife while briefing her on your findings! Been there!

PC7060

PC7060

Re: Tekmar 356 question

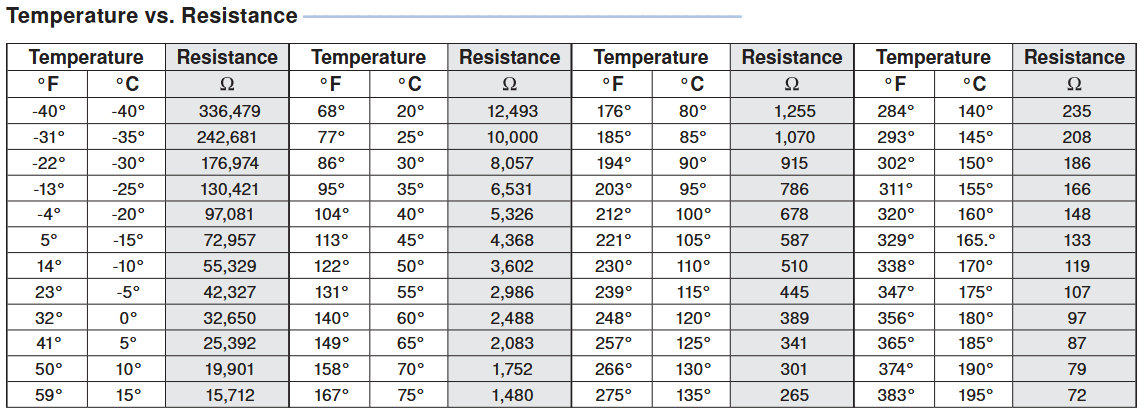

@hot_rod adding fixed value resistors to a potentiometer circuit would most likely limit the simulation range and/or offset the potentiometer's simulated range to a more desired temperature range.

For this application, a 10K at 77 degrees F (25 degrees C) thermistor I like a 10-turn 100K potentiometer. It provides a temperature range of -5 degrees to over 383 degrees simulation. Obviously the resistance range that simulates 212 to 383 is pretty useless, but it is less than 1/10 of one turn (1000 Ohms) of a 10-turn 100K potentiometer (212 F = 678 Ohms, 383 F = 72 Ohms). However, if desired, you could go above the 383 degrees of simulation resistance with less than 72 Ohm and test the Tekmar's short circuit detection functionality.

Also with 10-turn 100K potentiometer you can count the turns 10,000 ohms per turn (easier math for me), in this case so you can loosely keep track of the resistance without using the ohmmeter with simple testing.

I would wire the potentiometer so the resistance increases when turned Clockwise. If you want the potentiometer to increase the simulated temperature by turning the potentiometer Clockwise you could do that too, personal preference.

It's all about knowing how you want your simulator to work, its capabilities and knowing the component values to get that accomplished. Simulators can be as simple as a single potentiometer and some clip leads or in the case of the Tekmar 356 using 3 potentiometers since there are three sensors. Features like WWSD can be verified in the winter, outdoor reset can be verified in the summer, Mix and boiler temperature all at the same time without moving things around.

If it was me and I did a lot of Tekmar work (and the need was there) I'd put three potentiometers in a box with ohmmeter test points and an isolation switch for quick setup and changes. I'd use good test prod wire so I would not be repairing it all the time. I like tools that make my life easier.

Re: Buderus or Viessmann?

rumors on the oil heat site that. Buderus is discontinuing some versions?

It’s hard to get a straight answer these days, but recent events seem to make you wonder about import boilers in general, cast iron specifically.

It seems these decesions happen without much notice to the distribution and rep chain, i.e. SlantFin, TT, Basi.

Oventrop and Adey have left the US market also. Tariff headaches??

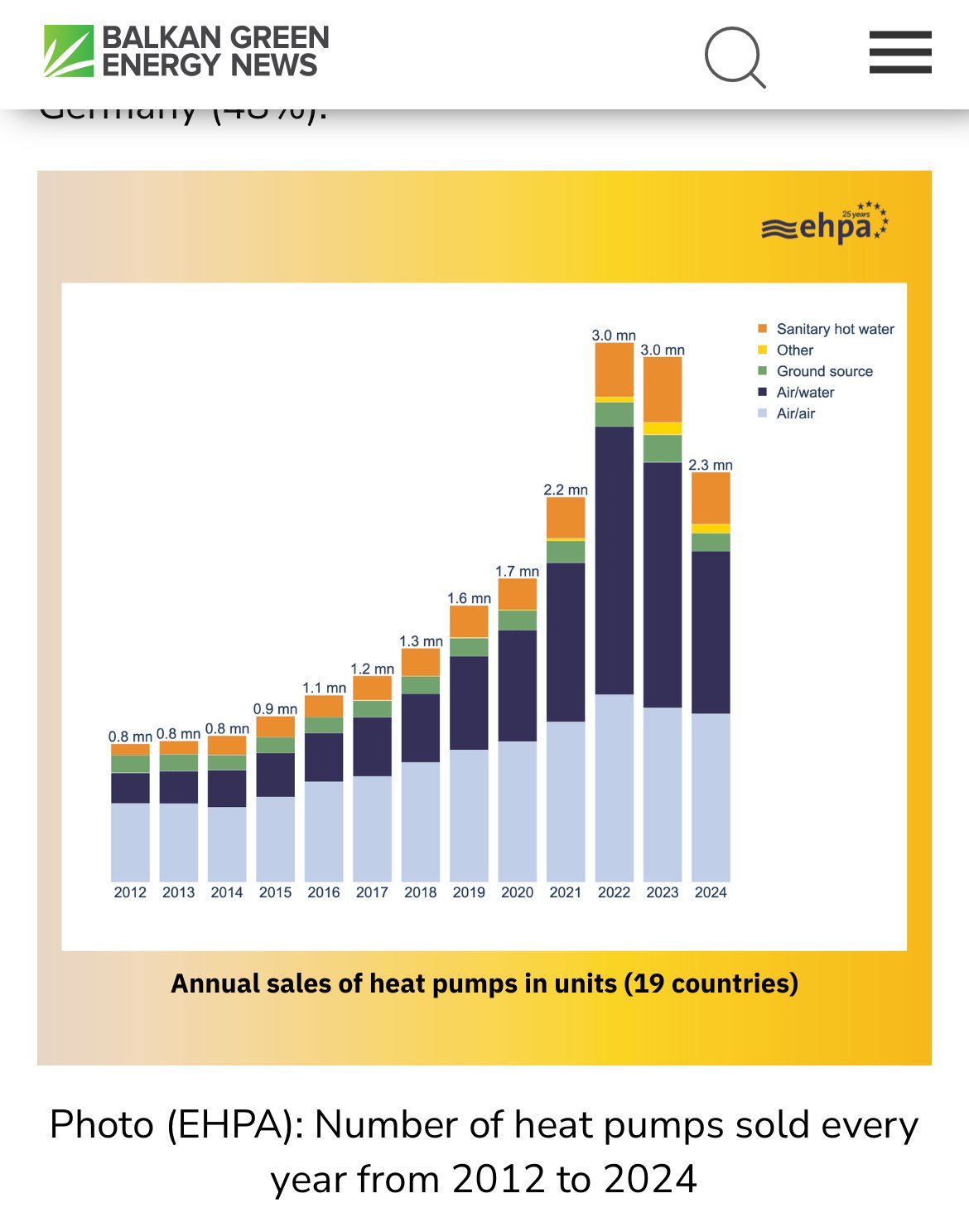

Data suggest heat pumps have surpassed boiler sales in France, Germany and Italy

Trade shows indicate all the big boiler manufacturers continue to promote HP offerings.

hot_rod

hot_rod

Re: Buderus or Viessmann?

Nolo Contendere! I have installed both brands. Buderus is excellent. Viessman is The Gold Standard. Mad Dog

Re: Anybody have an opinion on HTproducts Super Stor Ultra Max?

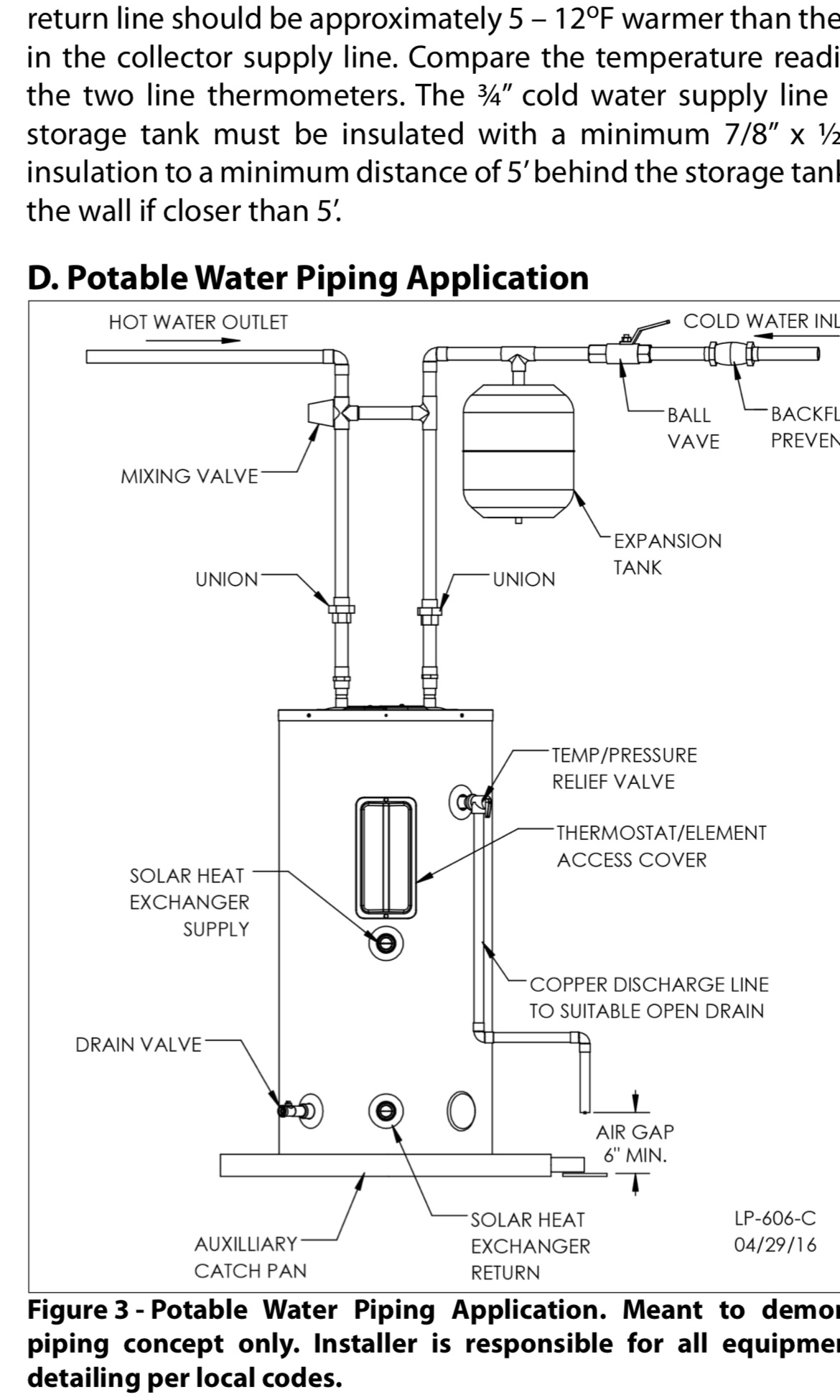

the electric element in solar tanks is 1/2 the way up the tank, sometimes in the upper 1/3

So when it is heated by just the element you get 1/2 the tanks capacity of hot water

I would go with an 80 gallon tank so you get about 40 gallons of useable hot water

another tip is to run the tank hot, maybe 150- 160 on the solar control, use a good quality mix valve set to 120 as shown in this piping. That way you maximize the solar and extend the drawdown

If you have an evac tube array you nay get more solar than you need in the warm summer month

Most of the digital solar controllers have over heat function in them, as well as evac tube settings

hot_rod

hot_rod

Re: Wet Steam

I wouldn’t call my thoughts on this secret since I’ve been promoting my videos on this topic here for years.

Here’s a recent one where I forced my steam to go through a 1” supply pipe to see if that kind of incorrect piping could produce “wet steam”.

https://youtu.be/Uz-8TWtbpiM?si=N1tHJ1tK-gkBY5Pc

It doesn’t. I have so many other videos and they all show there is no such thing as “wet steam”, only carryover/surging due to water quality issues.

From everything I have seen (and I actually see it unlike you and others who are guessing what’s in your pipes), there is almost no bad piping that can cause carryover or surging. Again, I’m talking about residential steam production rates and pressures.

A direct pipe to the main with no header or equalizer works fine and exists in many installations, for one example.

I haven’t seen your piping that I recall but based on all the ways I’ve purposely tried to create “wet steam” I can say with confidence that your piping isn’t the cause of any problems

Re: Question on the size of Daikin heat pump for new install

Any tool that just goes off of square footage, like that one does, is going to be garbage. For my house that tool gave four times the actual heating load.

A few posts up Bjohnny posted a link to a technique using past fuel usage. This is an accurate way of getting a ballpark number. It only takes a few minutes.

Re: It has been recommened that I contact New England Steamworks for a new steam boiler.

Re: Is the boiler oversized?

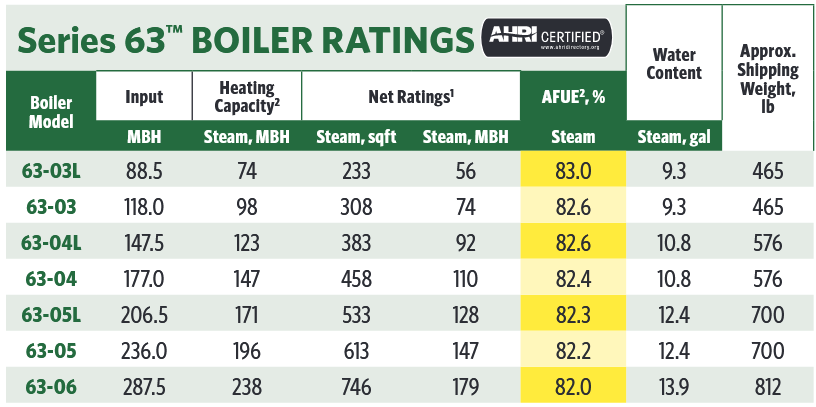

In a perfect world the EDR (Equivalent Direct Radiation, the radiators) should match the boiler's Square Foot rating.

What was the old boiler's ratings ? Was there a pressure issue then ? I understand that information may be long gone.

Going to a smaller gas boiler would probably help but may not totally solve the pressure issue unless the EDR matches the boiler size. Example Peerless only goes down to 233 Sq. Ft. You could add radiators (or increase their size), but that may not be very practical either.

If the contractor bails out and puts the whole expense for a Gas down sized conversion on the customer, I'd use a timer. To me the boiler size and type should have been worked out before the boiler change.

The timer is inexpensive and disables the excessive cycling that is really not needed to heat the home. The timer method is controversial and obviously not optimum or best practice, but it will eliminate the excessive cycling. And even with a timer there are different methods to implement it. And it needs someone capable of wiring it into the boiler control system correctly.