Best Of

Re: bending fuel oil line

Fill the tubing with sand. Then clear out the sand after the bend is completed.

R-22 works good for blowing out fuel lines. Oops did I say that out loud?

Re: A word about Design Day and not-so-warm homes.

I have a customer whose wife smokes one cigarette per day after dinner. He's a professional studio vocalist. His sound board and equipment require near constant cooling in the room because of the heat it emits 24/7.

So, that happens.

Meanwhile, in another part of the house at his insistence, his wife fully opens a 30" wide window while she smokes her nightly cigarette. You can't design for this stuff.

The process of heating a home can be somewhat arbitrary. If you make a science project of it, what you save on fuel you end spending on sweaters like @ethicalpaul does.

Mod-cons made it all a little easier and did wonders for plumbers who ain't too good at math. Still, I'm happy to have some benchmarks, like design temperatures and universal hydronic formulas. We've also got some good rules of thumb to work with: TDH, BTU/psf, etc.

A lot of them work well enough. Is that sacrilege?

JohnNY

JohnNY

Re: A word about Design Day and not-so-warm homes.

But then you may get the homeowner that says they weren't consulted in the design and their system should have been designed for a 100 year low temperature.

Since we can only install condensing equipment here in the Bay Area and since I like to see my boilers condense as much as possible, I size my radiators for low water temperatures. My supplier once told me that I order larger radiators than anyone else. I also design for 4° lower than our local design temperature. That gives me a lot of leeway should conditions change.

I like your writing, @JohnNY.

Re: A word about Design Day and not-so-warm homes.

@HydronicMike I wrote this for a local homeowners' Facebook group after several posts stating their boilers/furnaces were running and seemed fine but their homes weren't reaching thermostat settings.

This recent cold snap was particularly brutal. We must've gone above freezing today because we're fielding calls for floods and burst pipes more than any previous day this season.

JohnNY

JohnNY

Re: Pipe Vise Stand and Bracket

Like the looks of the bigfoot. If I was working, I would get one.

But it takes the fun out of kneeling on a concrete floor with two pipe wrenches

A word about Design Day and not-so-warm homes.

In the world of Heating and Cooling, there is a temperature that gets thrown into the mix of both longhand calculations and computer models that establish the BTU outputs of all our equipment. It’s called a “design temperature” and it varies as we follow typical climate variations going north and south, and up and down in elevation. In our part of the world in 2026, the design temperature is 13°F.

That means that heating systems are designed to maintain an indoor temperature of 70°F when the outdoor temperature is 13°F.

Efficiency is defined many ways by the different industries that use the term but in fuel-burning boilerspeak, peak efficiency means the boiler runs at 100% of its output at design temperature, and never shuts off while hovering around that outdoor temperature, and combustion is steady with minimal standby or flue losses at the boiler which factor heavily into manufacturers' published efficiency ratings. In other words, the two most *efficient* boiler heating cycles will have the boiler never come on, or have the boiler maintain the 70° indoor temperature by never shutting off. We call that a "Design Day" heating condition.

So, what happens when the outdoor temperature drops below design temperature? Like lots of days these past two weeks? Well for us professionals, the first thing that happens is all our online forums and message boards start blowing up with warnings to each other about trouble coming, and stories of engineers on current projects nervously considering supplemental heat sources in their designs.

But the bottom line is design temperature is often an average of the ten coldest days of the year and it is well known and expected that there will be be a handful of days colder than the median or average cold day. And so it is accepted that the internal ambient temperature of some of those structures operating on design have the potential drop below 70°. Does that sound like a failure? Maybe. But what you have to consider is that aside from the heating system, there are plenty of other things in the home or building that give off heat to the space. Cooking a pot of stew adds heat energy to a space for hours. Lights, TVs, computers, cable boxes, solar gain, hair dryers… all these things being in place or running add BTUs to the home and take some of the onus off the boiler or furnace. So, this high-design-temperature-vs-low-outdoor-temperature thing is rarely ever an actual problem. To design a home heating system with significantly higher heating capacity, or to change the design temperature to 5° or less will often change the design greatly, increasing installation costs substantially and operating costs permanently.

If you feel you are getting close a to problem caused by low outdoor temperatures versus your system’s design, you would be well advised to do what you can to close that gap. Literally. A tight building envelope will outperform even the most highly efficient of boilers and furnaces. You heat your home only with the BTUS you keep inside. The rest are gone instantly and forever. A lot of words for a Sunday morning but I hope this helps someone.

(In the photo below, two boilers provide redundancy to make heat and hot water. Multiple smaller boilers tend to burn fuel at higher efficiency than a single larger one due to something called "turn-down-ratio" limitations so each of these units is sized for 75% of the home's peak demand. If the primary boiler can't meet the target temperature, the secondary unit kicks on at 10% intervals. The full capacity of both boilers being 150% of the demand means the home's heating zones are always satisfied in the most efficient way possibly.)

JohnNY

JohnNY

Re: I need help tuning my steam system and thinking about mini-splits

Both. Unlike some trade websites, HeatingHelp has always welcomed non-professionals, both to ask questions and to share experience. So we have professionals helping professionals, professionals helping non-professional, non-professionals helping professionals, and non-professionals helping non-professionals.

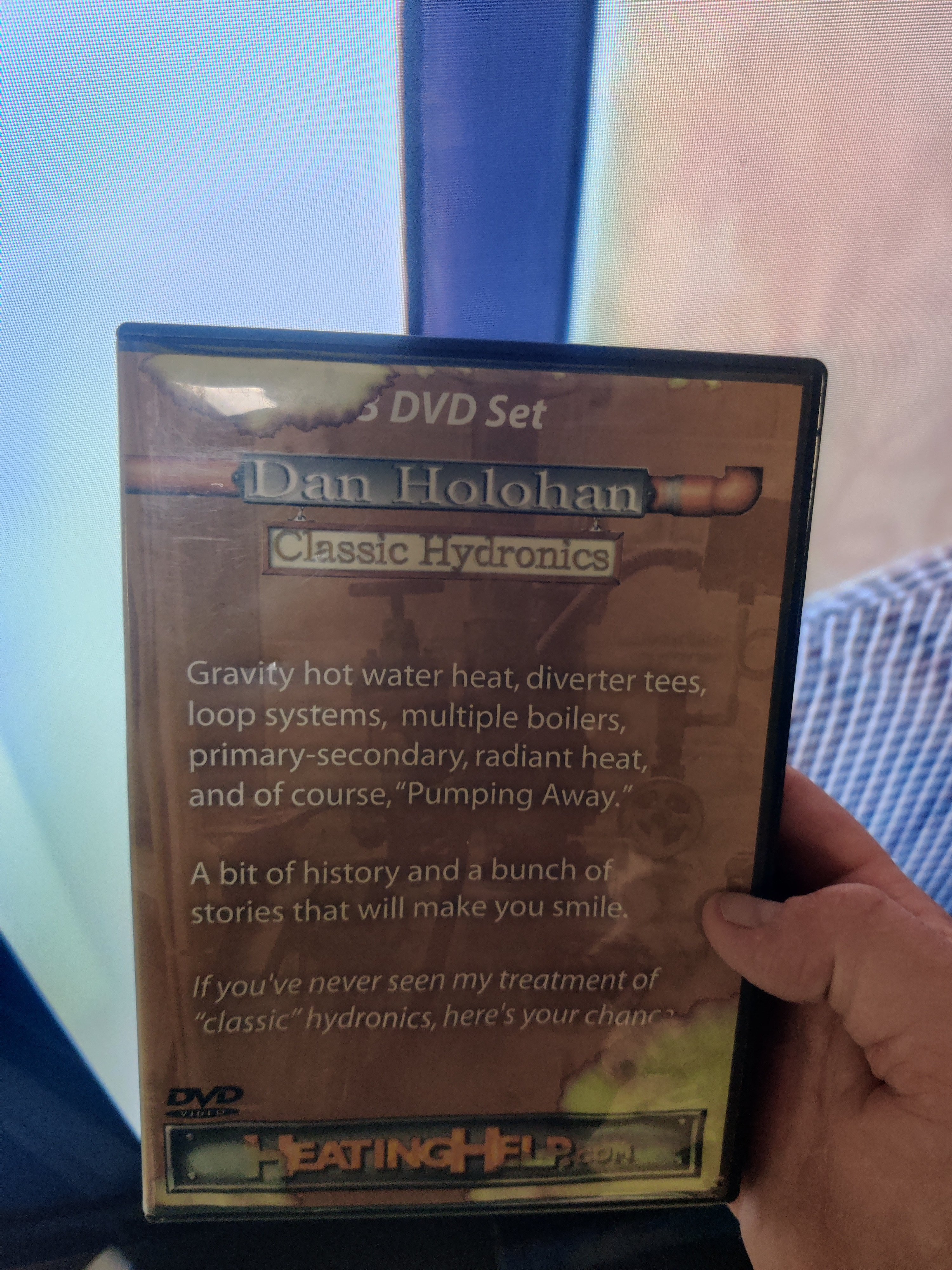

That's what makes this place work so well, and we can thank @DanHolohan and his daughter @Erin Holohan Haskell for the concept and for keeping it that way.

A little history recap

When you are prepping to teach you revisit the trusty beginnings (at least it was for me 20 years ago).

Re: Wet return line called it quits

Used a Rigid diamond circular blade on the Harbor Freight grinder. As expected the pipes would not unscrew from the 45s. Grinder was easier to attack than a blade on a reciprocating saw. $40 worth of black iron. Pipe stands are important. Had to quickly make a couple out of 2x4s. The pegs don't hold the pipe to the wall and once tension is gone after cutting the whole line slips off.

Probably replace most of it in the summer when it's not 1 degree Fahrenheit outside.