Best Of

Re: Strange device on one pipe steam system

@Mad Dog_2 and @STEAM DOCTOR are right. The earliest steam systems had manual vents because automatic vents as we know them today had not been invented yet. I still occasionally see these in the field.

How does that vent fit into the system?

Re: Unbalanced system or Wrong piping near boiler??

Oh most certainly. Steam doesn't like to go through small pipes and passages where there is lots of water. I'm surprised you aren't hearing any banging. Probably would be a heck of a lot worse if you didn't get a good near boiler piping installation like you did, as far as I can tell anyway.

Re: Unbalanced system or Wrong piping near boiler??

Sounds like you are getting carryover, probably due to bad water, and it triggers the LWCO to shut off the burner. After a time, enough water returns to the boiler and the LWCO signals the burner to turn back on as long as the thermostat is still calling for heat.

Re: Adding main vent to steam zone

Banging and knocking is almost always water hammer (rarely expansion — that's gentler). And water hammer is always water pooling where it shouldn't be, or failing to drain properly.

Venting problems have little or nothing to do with it.

BUT

Pipe pitch and possibly partly closed or failed supply valves most assuredly do. If you can locate the noise to one particular pipe or radiator that tells you where to begin looking at least. The most common problem is a pipe which has inadequate pitch to drain, allowing water to pool; somewhere between a quarter inch per foot and half an inch per foot is a real minimum, and the pipe must drain towards the boiler or a drip to a wet (floor level) return. Sags can be a villain — not only the end to end pitch of the pipe but the pipe must be straight.

So… a real quicky is to start with making certain all the service valves on all the radiators are fully open. Then go into the basement and make sure that all the pipes have decent pitch.

Re: Weeping PRV.

temperature and pressure relief valves are what you put on domestic water heaters. boilers have a pressure relief valve, discharges on pressure only.

Re: Unbalanced system or Wrong piping near boiler??

That is very odd. The actual way to determine this would be to be looking at the pressure and the water level when the boiler shuts down.

If the water level is low, it is probably due to water level. (and a light would light up on the LWCO)

If the pressure is high, it is probably due to the pressuretrol cutting out on high pressure.

I wish you good luck and possibly don't call that guy back.

Re: Unbalanced system or Wrong piping near boiler??

he said he was overriding the pressuretrol when the boiler was cycling so that’s how he concluded it was due to low water not pressure….

Re: Using an indirect water heater as a buffer tank.

The outdoor reset fuction is your best bet to lessen thermal expansion/ contraction noise. Properly set up you get near constant circulation. This helps for comfort, efficiency as well as most noise problems.

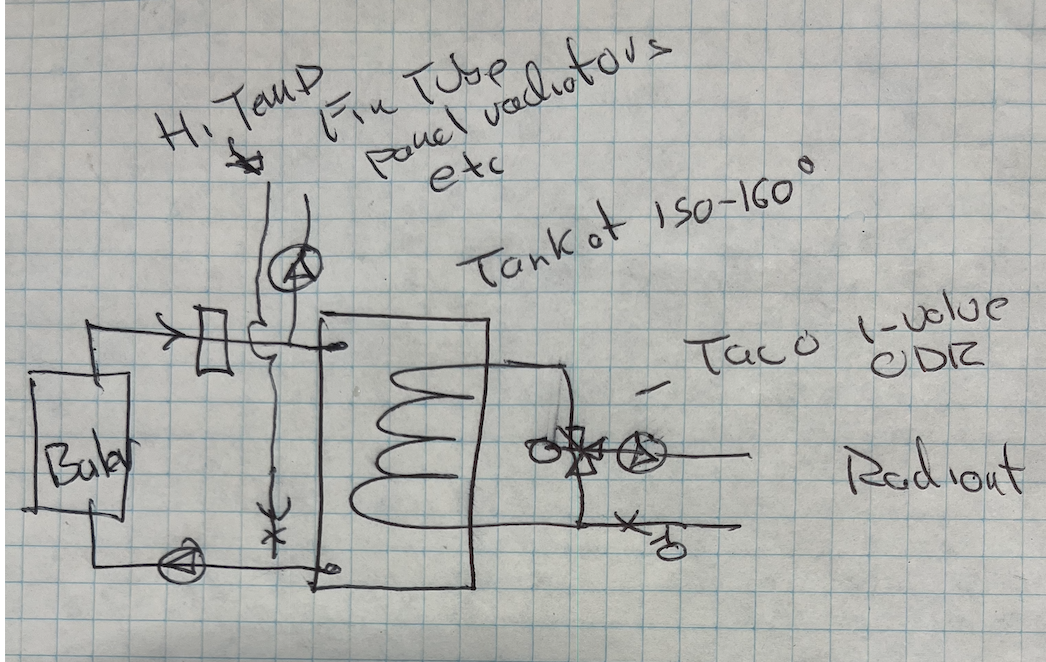

You have two choices. Simplest is just run the boiler and tank on the ODR, so the tank temperature is always modulating to the heat load.

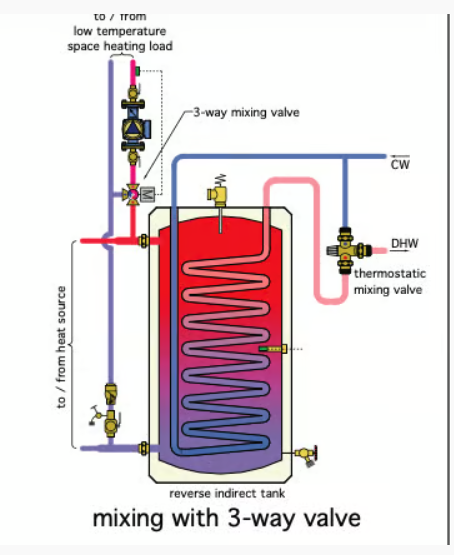

Or run the tank to a set temperature, maybe 150 or so and use a mixing valve off the tank on ODR.

This Taco 3 way valve is a crowd pleaser, it has the ODR function built in, comes with the various sensors.

If you wanted to run the tank at higher temperature for fin tube or panel radiators in those under radiated rooms. This option covers all the potentials

hot_rod

hot_rod