Tekmar 356 question

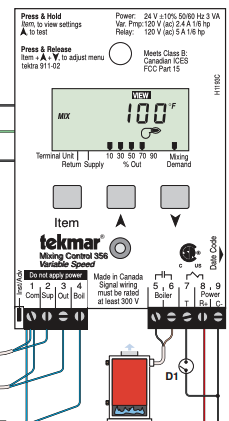

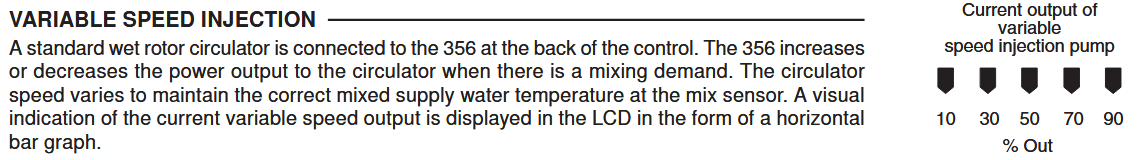

Tekmar 356 is showing the mix demand icon in lower right screen. It however doesn't show any pump percentage in the bar graph. Is this normal?

Comments

-

Scroll through all the parameters, with the item button I believe, what is the supply temperature. Is the system heating? Supply to the system warm?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Customer is stating floors aren't as hot as they used to be. We replaced the Tekmar about 3 weeks ago because the screen was blank and the inject ion pump wasn't working. Customer sent screen shot of display, will be going there Monday.

Mix temp- 113

Boiler supply 183

Outdoor ambient 52 (Chicago in January)!

Thank you

0 -

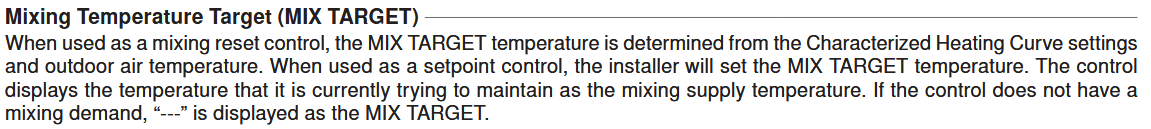

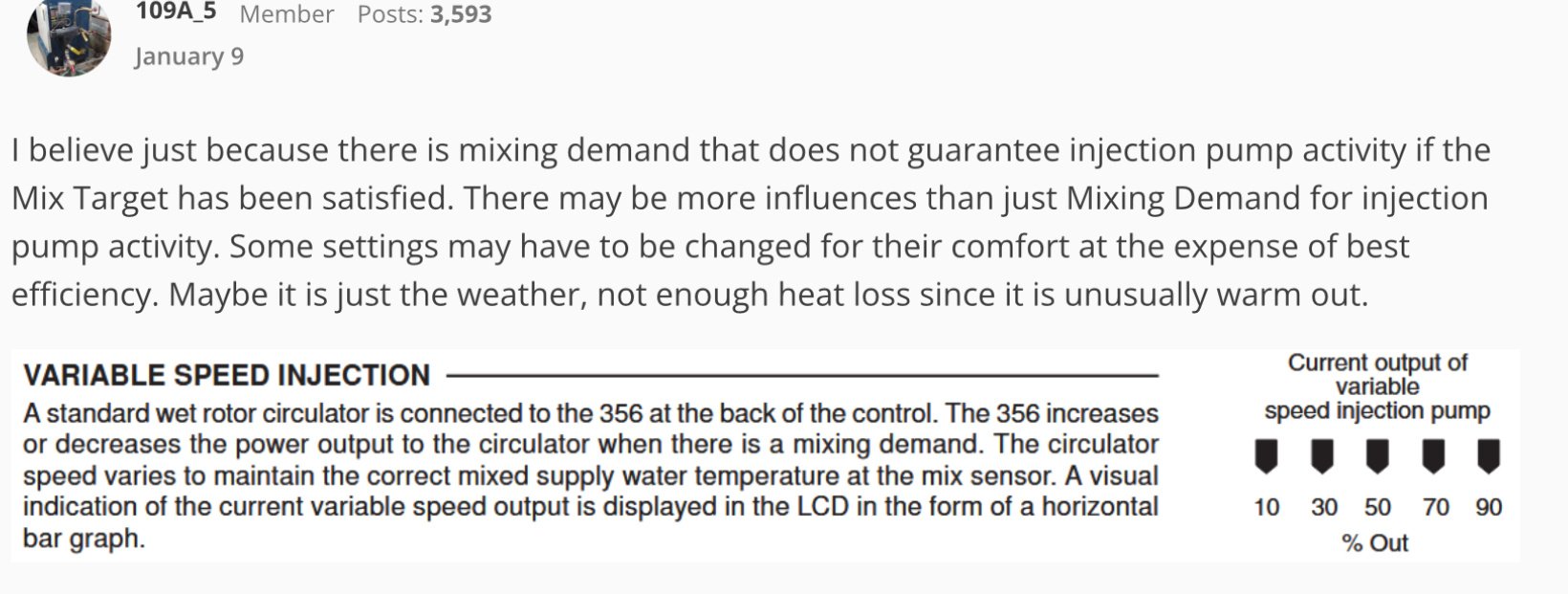

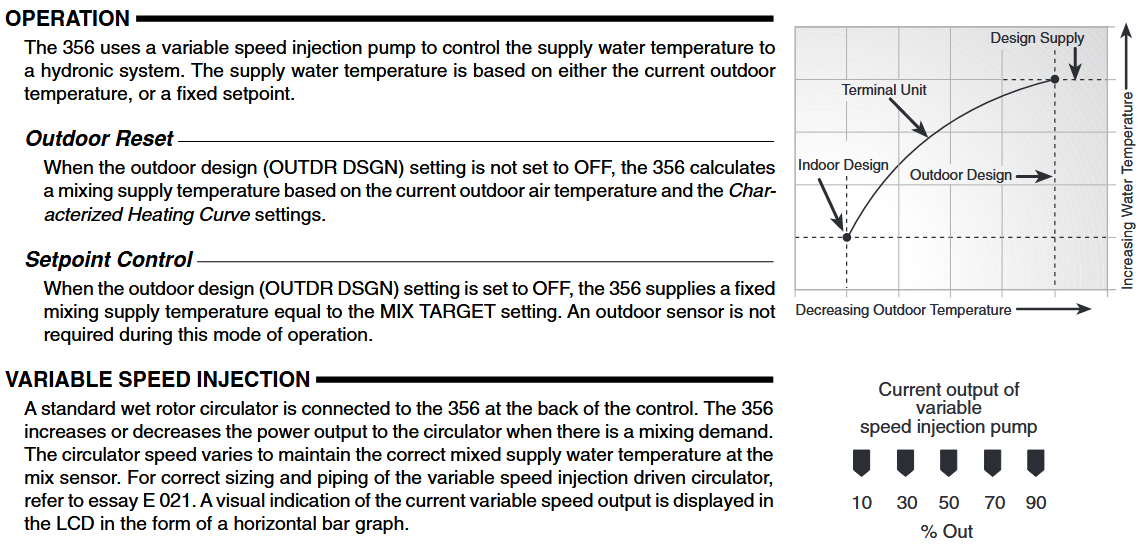

I believe just because there is mixing demand that does not guarantee injection pump activity if the Mix Target has been satisfied. There may be more influences than just Mixing Demand for injection pump activity. Some settings may have to be changed for their comfort at the expense of best efficiency. Maybe it is just the weather, not enough heat loss since it is unusually warm out.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Thank you for the responses thus far, really appreciated! Went to customer today, Jan. 13. Still not heating enough. Since installing the control, have yet to ever see the pump running. Test button does actuate pump. Jumpered the injection pump and manifolds warm nicely, supply and return which tells me IF the injection pump runs, they will have heat. I have set this up as a reset control. Couple of points I'd like to note.

1-Set outdoor Design to 0 degrees- Chicago. Room temp to 75

2- Looking at the manual one would believe that jumpering terminals 7 and 9 would actuate pump. However I now realize that other criteria must be met for that to happen (supply temp and boiler return temp).

3-As a test I'm considering changing terminal unit setting to fin tube or cast iron radiator, see if the inject ion pump runs (briefly).

4-Supply sensor reads 113 degrees tho a thermometer reads supply as 89-90. Possible incorrect placement of sensor? System has worked perfect ly past 22 years however…

Sorry for the rambling, frustrated.

0 -

Your Item " 4-Supply sensor reads 113 degrees " This does not agree with previously posted information.

If there is demand and the boiler is running what is controlling the boiler's circulator ? If the boiler is running and the boiler's circulator is running, 113 degrees (Supply sensor) seems low and 89-90 would be even worse.

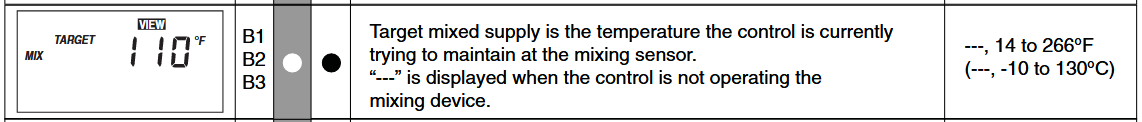

What is the Target Mixed supply set for ?

Maybe the sensor is bad.

Another thread (link below), long read, but may help you.

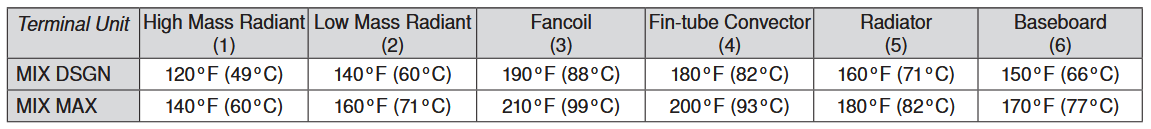

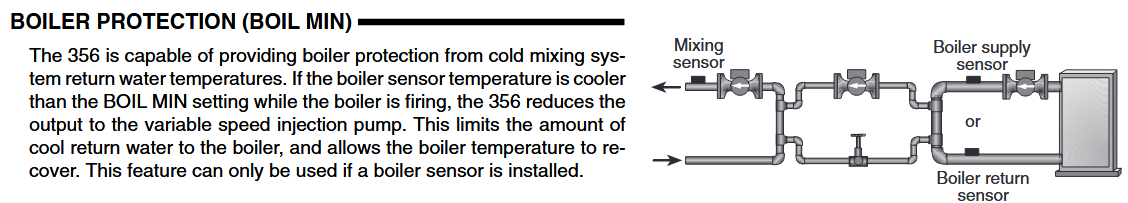

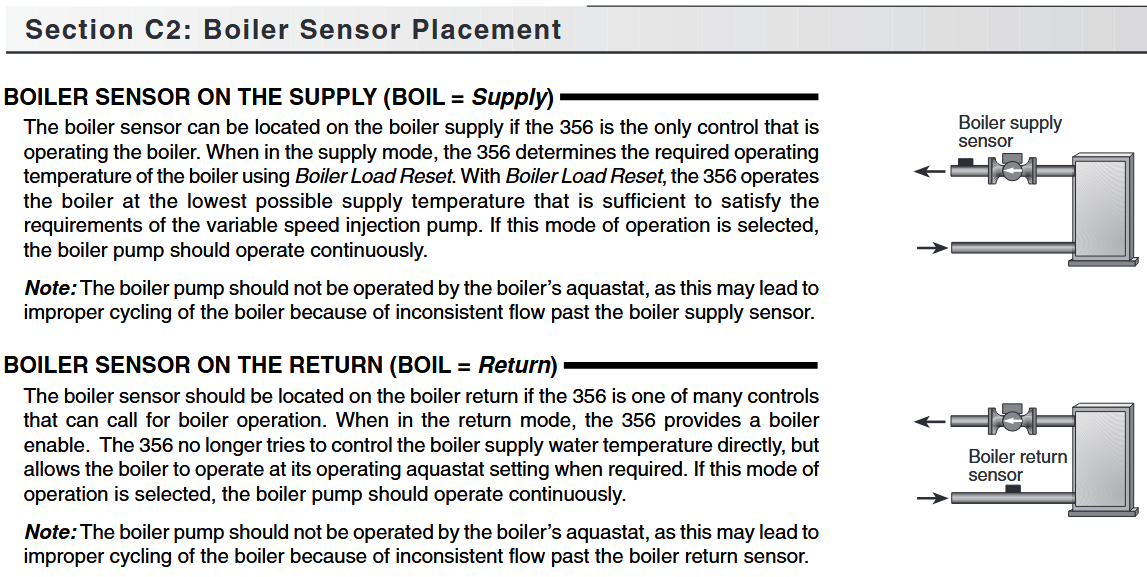

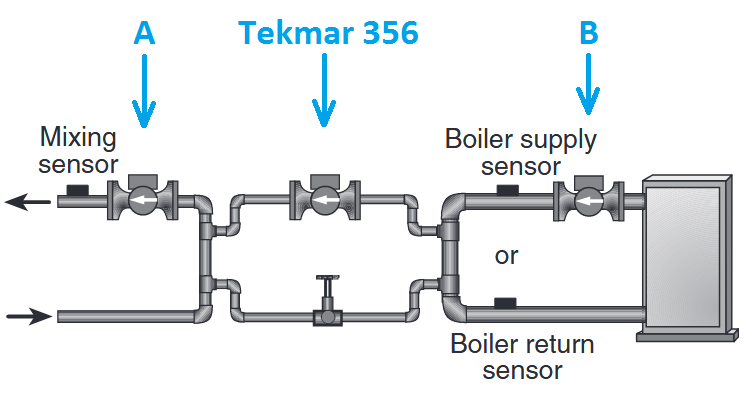

Claimed it worked for 21 years, and then something changed, it was resolved (long story short), the boiler pump was not wired into the system correctly. In this case when the Tekmar 356 sensed the boiler was hot enough it would end the call to the boiler and that would turn off the boiler's circulator. So no more heat to the system until the Boiler Supply sensor cooled enough. Tekmar's note below warns about that situation. In that case the system's drawings helped a lot.

https://forum.heatinghelp.com/discussion/comment/1869060

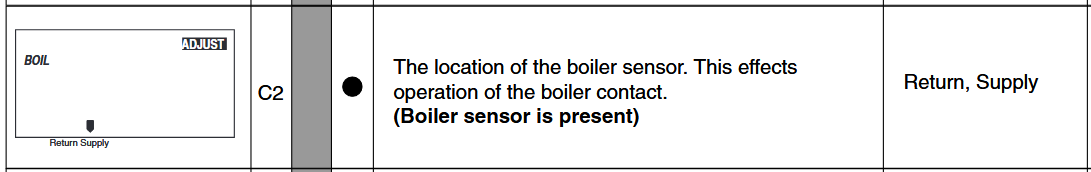

Is this set correctly ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

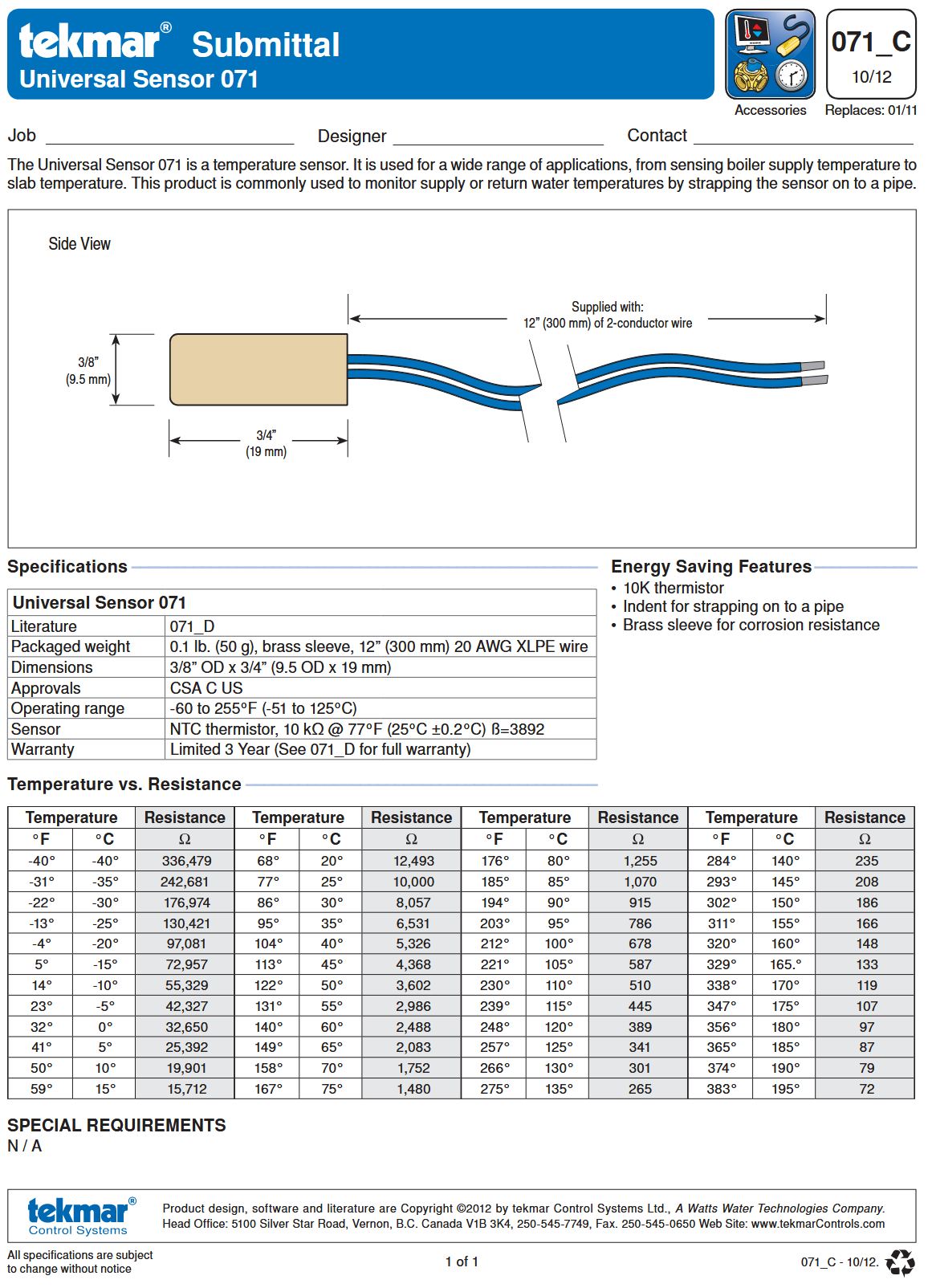

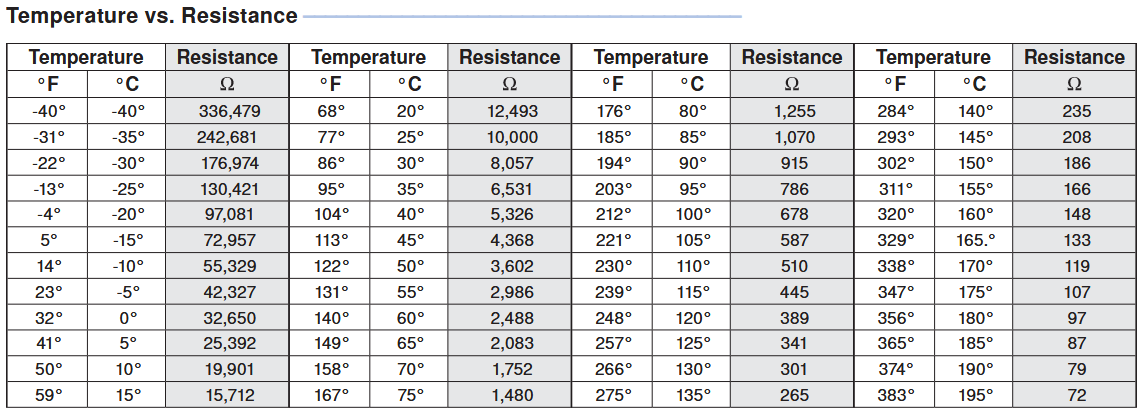

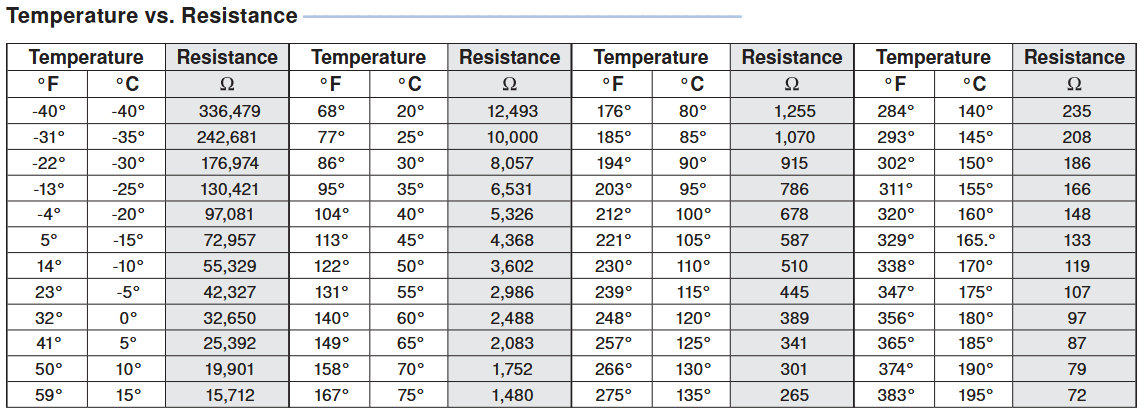

Looks like the Boiler Supply / Boiler Return, Mixing and the Outdoor Reset Sensors have the same resistance properties.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

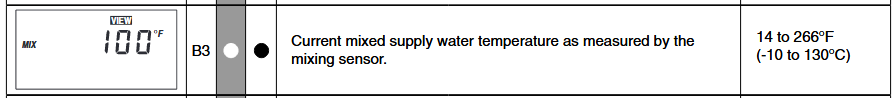

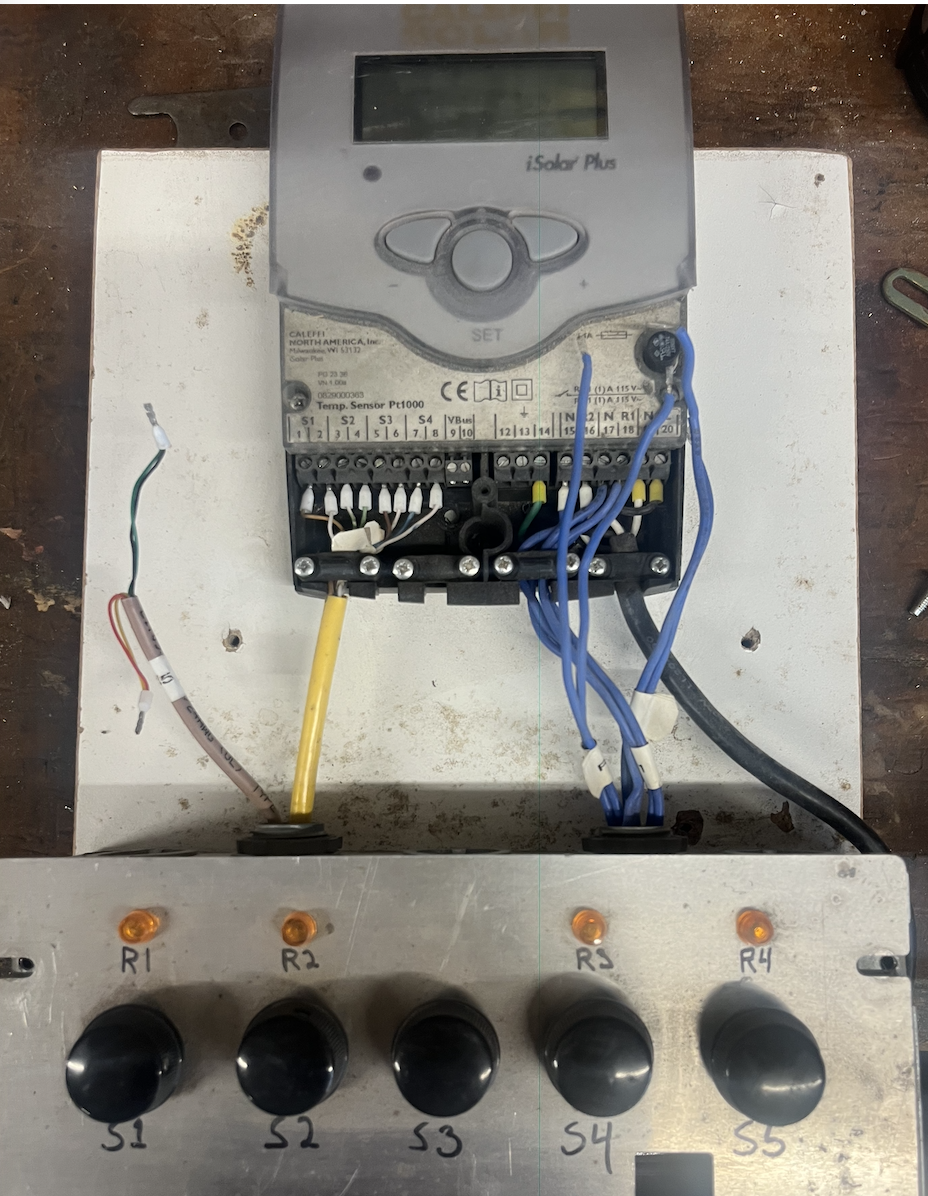

Sorry for the confusion on item #4 in previous post. "Mix" temp was 113. Attached photos sent by customer. Supply mix temp is at default for the terminal units (120). Reset mode sets 113 given the ambient temp? Thermometer on supply pipe going to garage zone reads 89/90. Need to see what sensor actually reads AND must check resistance vs temp on the sensor. Crux of the matter again aside from not enough heat, I have Never seen the injection pump run at ANY percentage, yet on its own.

0 -

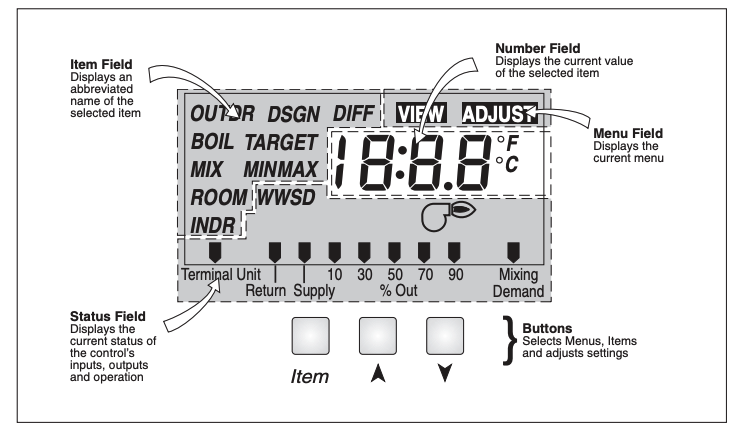

so this light bar graph never lights or shows any movement?

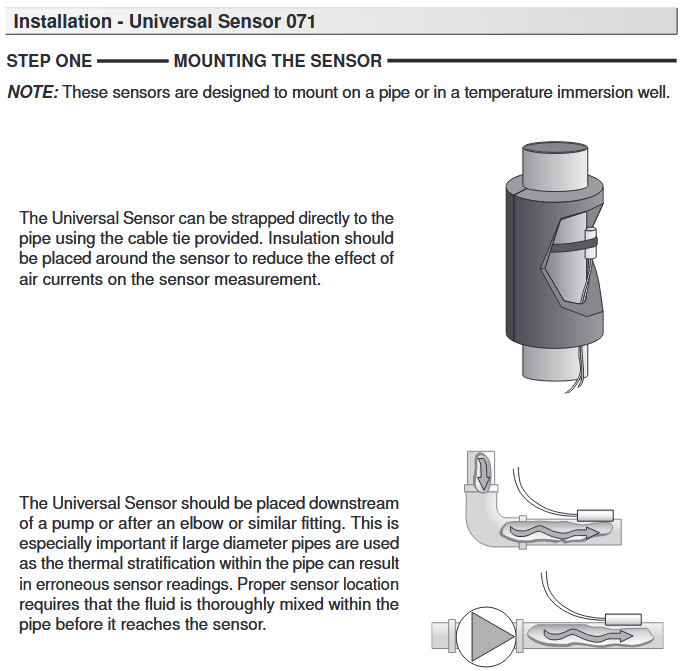

if you had a spare tekmar sensor you could wire it to #2&3 and put an ice cube on it. Or an ice cube on the outdoor sensor. The actual sensor is under the white cover.That would tell the control to ramp up the pump speed.

One way that you test sensors is a glass of ice water, and a cup of boiling water, two known or close temperatures, then look for 32 and 212 degrees resistance readings.

But it is easy enough to check all the sensors resistance., right on the control. You will need to know the temperature at the sensor to see if it matches the resistance.

Remove the leads from the control to measure the resistance of the sensors

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

They say the floor is too cool, is the room temp too cold also ?

So there is no written records of the previous settings ?

Since you don't know what the old setting were maybe the outdoor reset was off (disabled). I'd verify the Mix sensor is accurate. Maybe there is a bit of ghost flow going on and that satisfies the mix temp, so the mixing circulator won't run.

Well it looks like Chicago won't be 52 degrees at least for a week. The injection pump should be running when it hits 6 degrees on Monday.

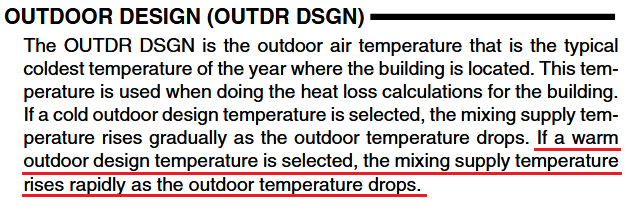

I found 2 degrees for the design day temp for the Chicago area, so I agree with your setting of 0 degrees. Maybe it was set warmer.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

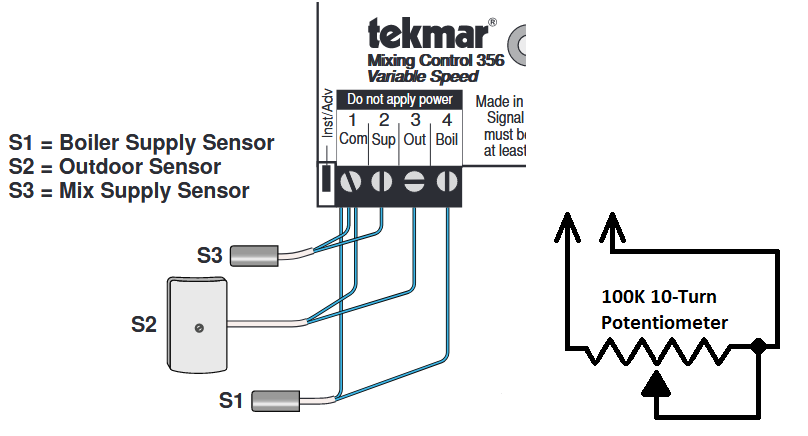

If I was a Tech that wanted to verify the operation of the Tekmar and other like controllers I would have a 100,000 Ohm 10-Turn Potentiometer (-5 degrees to over 383 degrees simulation) and/or a resistor decade box I could substitute for the sensor(s).

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Building on my last post with thermistor simulation with a variable resistance you control. Changing the outdoor reset resistance to 42,327 ohms to make the Tekmar thinks it is 23 degrees outside should raise the Mix temperature target and the injector circulator should start.

Also if you raise the Mix Supply Sensor simulated resistance value to 10,000 Ohms so the Tekmar thinks it is 77 degrees at the Mix Supply Sensor the injector circulator should start.

I would think this would be faster than guessing or waiting for colder weather and actually it could be done as a test in the summer time.

What I don't know in this case is if there is any delay to act upon the new resistance values. Or if the resistance change is too rapid or erratic if the Tekmar thinks there is a thermistor problem. It may not care as long as the circuit is not open or shorted.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

There is no written record of original settings. I would normally have noted settings from original tekmar but the reason for change was no pump activity AND blank screen. The garage always held 70 degrees, currently 60. Separate thermometer showed 62. Going to ask customer for picture of current screen now that temps are really cold. Will visit Saturday, test the thermistors. Also considering disable reset and operate in set point mode.

0 -

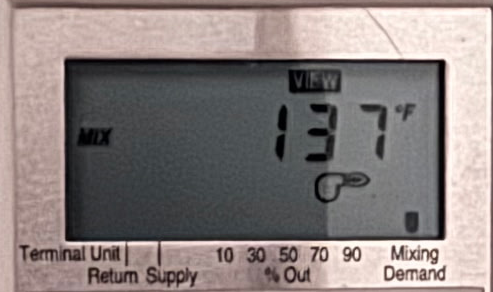

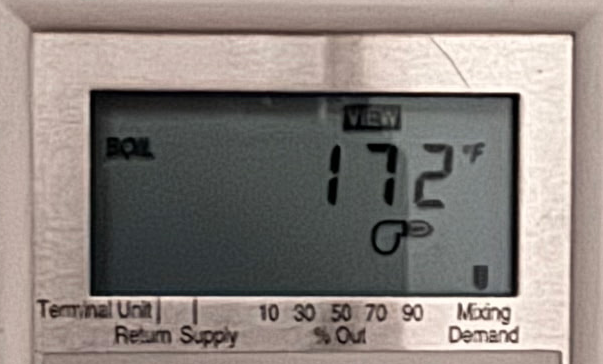

Attached are later photos of the troublesome Tekmar on a colder day. Will be onsite tomorrow armed with variable pot, sensors and new 356 IF all goes south. Customers have been exceedingly patient. I am nearly 2 hours from site.

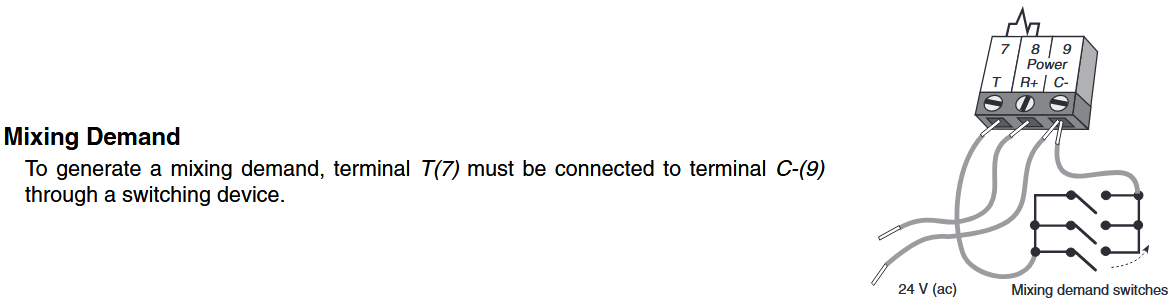

Question? (1)- The "mix" icon in lower right is generated when terminals 7 & 9 make, or on a call for heat? I do understand that doesn't necessarily mean pump will run, other criteria must be met. Thanks a lot!

0 -

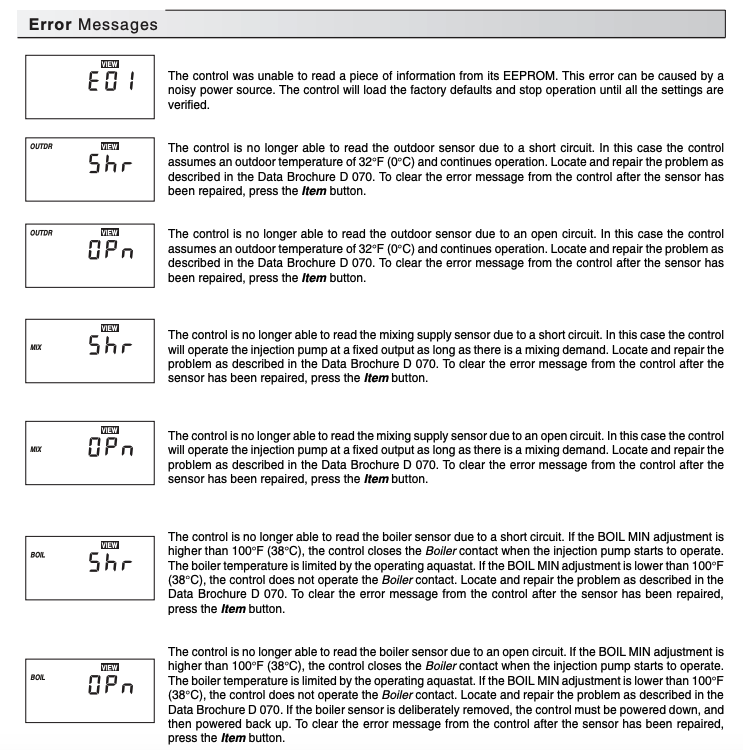

That control usually tells you if and what is wrong via error codes on the screen.

If you are not seeing error codes, test the sensors for resistance, and scroll thru settings.

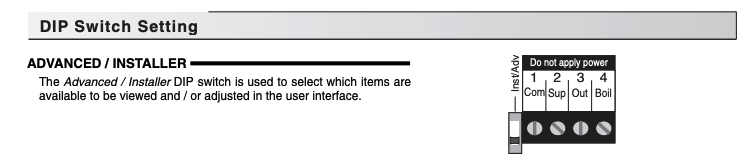

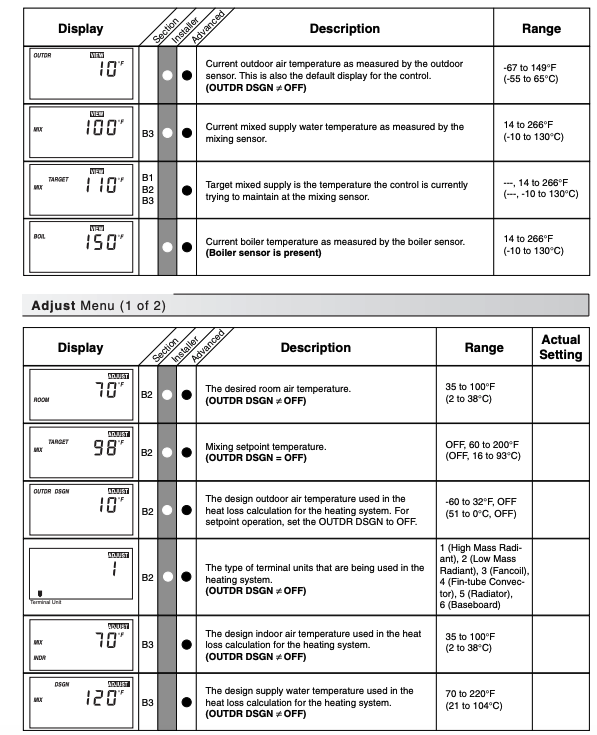

The small DIP (toggle) switch left of the terminal strip is easy to miss, make sure you are in advanced to change settings. The chart below shows what screens are available in Advanced/ Installer mode. Adjust appears in the upper right screen in advanced mode

It only needs a few pieces of info to start working, the manual walks you through typical settings and how to apply them. Basically outdoor temperature for when it starts thinking, 68- 70 typically then the temperature you want to maintain at the system sensor location.

If you don't have original design numbers just pick something, like 0° for a design day temperature, 70 for design indoor temperature. The control then calculates and displays mx target, after the boiler fires it

After that lights and icons tell you what the control is doing.

If you can, take a spare sensor the 082 is a universal sensor it can be used anywhere.

If you have a spare circulator wire it to the control, hold the pump in your hand and you will feel it ramp up as the % lights come on. If you press the test button the pump will ramp up regardless of what the sensors are telling it to do. If the lights sequence up the pump on the system should also, maybe you will hear it revving up., It could be a stuck or failed pump. So having a spare pump serves as a troubleshoot and replacement should the system pump be bad.

With a 2 hour drive I would have all the options along with you. Pump, sensors, ohm meter, new wire connectors. It's not a super expensive control compared to multiple 2 hour trips, to have a spare with you. If you don't break the seal on the box, your supplier would probably take it back.

Often times it is best to be in front of the control when you have a support person on the phone. Facetime is a great troubleshooting tool that we use, it let me see the screen as you make adjustments.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

2 hours that is a hike.

Interesting; Could they be missing the injection circulator activity ? Although I would think it would modulate and not just shut off although if the Mix temperature of the curve has been met it may shut off. It seems here at 23 degrees outside the Mix water temperature is at 137 degrees, that is higher than the earlier 113 degrees and the boiler is active at 172 degrees where before the boiler water was 184 degrees and the boiler was off. Kind of wondering if the Tekmar is basically working just the Variable % part of the display is not.

" Question? (1)- The "mix" icon in lower right is generated when terminals 7 & 9 make, or on a call for heat? I do understand that doesn't necessarily mean pump will run, other criteria must be met. Thanks a lot! "

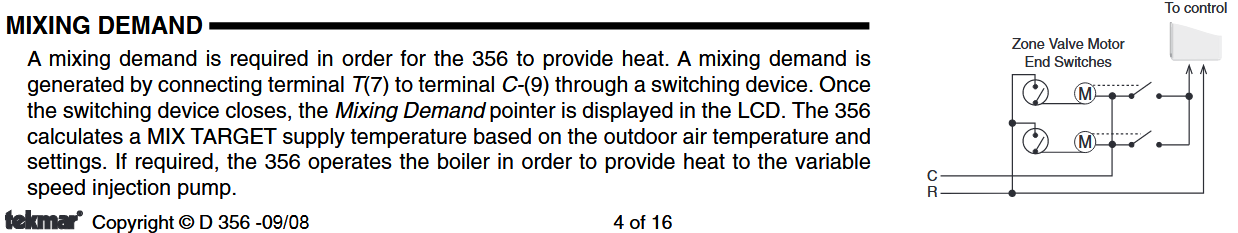

The way I understand this control; The Tekmat 356 has control over the boiler for space heat. So if you want space heat you have to close 7 to 9 (Demand). How that is actually done depends on how the system control is built or configured.

It could be as simple as a thermostat. But more likely it is a contact closure from a relay (or other equipment) since there may be other circulators involved that need to be controlled (On or Off, but not variably modulated) when the actual thermostat calls for heat. There could be multiple zones controlled by zone valves the zone valves are controlled by their own thermostat, so in that case both circulators A and B need to be both active during the call for heat.

So the calling thermostat activates the zone valve, the zone valve's end switch via relay for one example would have to activate both the A and B circulators and provide a demand signal to the Tekmar 356.

No zones, you most likely still need a relay with isolated contacts, one contact set for the Tekmar 356 demand (low voltage) and one for the A and B circulators. During a call for heat the Tekmar has control over the boiler temperature and the Mix temperature, hopefully for best efficiency and comfort. Once the call for heat ceases it all shuts down.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I think you mentioned that you hit the test button and the light bar did ramp up. But did the pump?

With no errors on the screen sensors should all be connected, but certainly one could be out of spec and not sending proper info. The screen or the resistance test confirms sensor accuracy. Every sensor connected can be read in the view screen.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

When pressing the test button the bar graph showed all bars. I could hear the pump come on. On a prior visit I jumpered out the pump and zone began heating.

0 -

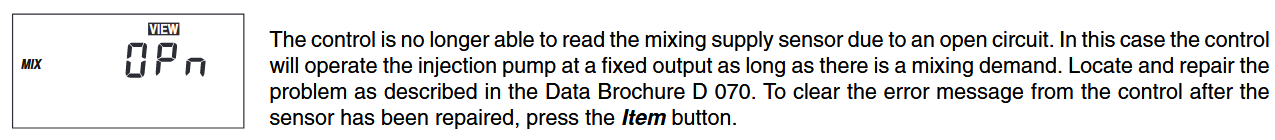

Thinking a quick and dirty test would be to disconnect supply sensor. Pump should go into a "limp" mode and run at some predetermined speed. As per troubleshooting section.

0 -

could be as simple as bumping up the target temperature if they need more heat output

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

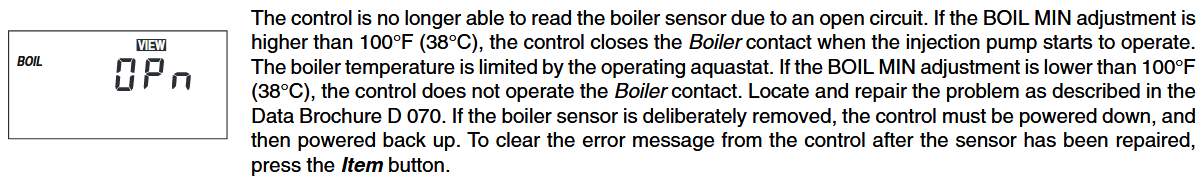

Mix supply sensor, doing that with the Boiler supply sensor is contingent on the BOIL MIN adjustment and could be confusing. Sure add that to your testing tool box.

In my mind, using the substitute resistance for a sensor is a complete test of the Tekmar 356 and its settings. and you can easily simulate other temperature conditions. As previously mentioned the sensors can be verified with an ohmmeter (multi-meter) if the sensor's temperature is known.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

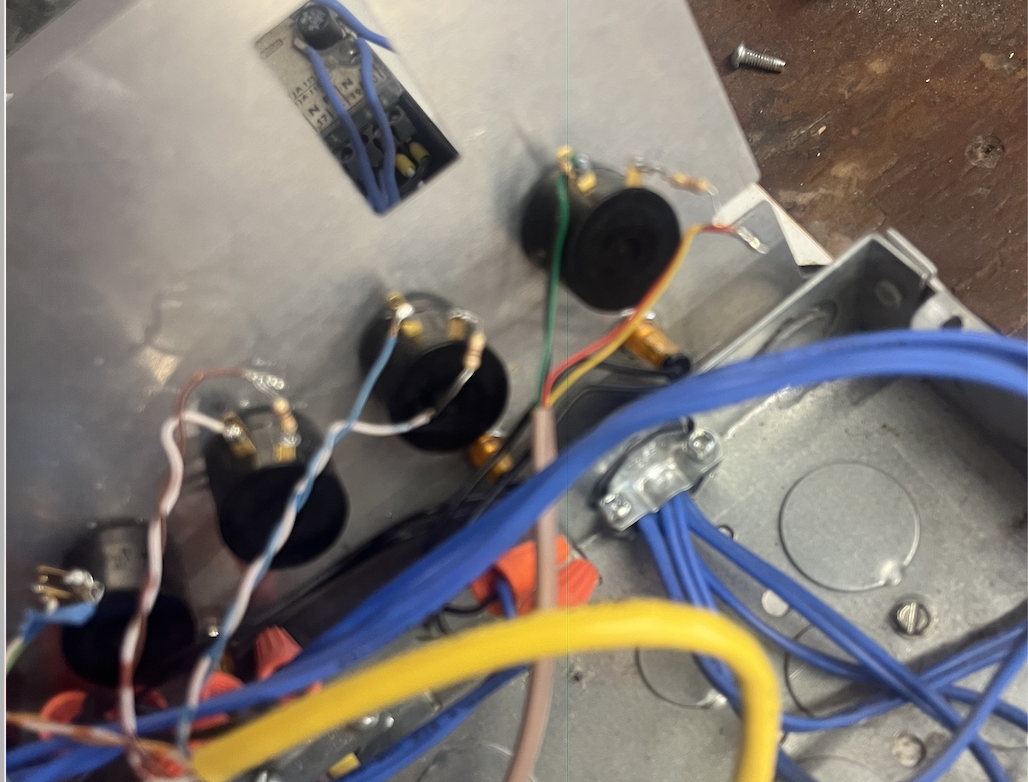

I build a number of simulators for our solar controllers. The engineer that came up with the design had me put a little rebel resistor in series with the POT. As I recall is serves several functions, allowing more range and prevented a short when cranked all the way down? Is that the intent?

These controls uses 1000 ohm sensors.

These were 20 turn POTS.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Have you confirmed that you it is 10k sensor mounted on the mix sensor location. Any chance that someone installed the wrong resistor, like a 5k. Its obvious that the tekmar is satisfied based on the temperatures the 356 is showing. And when you test the Tekmar to jockey the injection pump it comes on. confirm Your mix sensor is in the correct location on the mix and confirm that its wired to the correct terminals

0 -

@hot_rod adding fixed value resistors to a potentiometer circuit would most likely limit the simulation range and/or offset the potentiometer's simulated range to a more desired temperature range.

For this application, a 10K at 77 degrees F (25 degrees C) thermistor I like a 10-turn 100K potentiometer. It provides a temperature range of -5 degrees to over 383 degrees simulation. Obviously the resistance range that simulates 212 to 383 is pretty useless, but it is less than 1/10 of one turn (1000 Ohms) of a 10-turn 100K potentiometer (212 F = 678 Ohms, 383 F = 72 Ohms). However, if desired, you could go above the 383 degrees of simulation resistance with less than 72 Ohm and test the Tekmar's short circuit detection functionality.

Also with 10-turn 100K potentiometer you can count the turns 10,000 ohms per turn (easier math for me), in this case so you can loosely keep track of the resistance without using the ohmmeter with simple testing.

I would wire the potentiometer so the resistance increases when turned Clockwise. If you want the potentiometer to increase the simulated temperature by turning the potentiometer Clockwise you could do that too, personal preference.

It's all about knowing how you want your simulator to work, its capabilities and knowing the component values to get that accomplished. Simulators can be as simple as a single potentiometer and some clip leads or in the case of the Tekmar 356 using 3 potentiometers since there are three sensors. Features like WWSD can be verified in the winter, outdoor reset can be verified in the summer, Mix and boiler temperature all at the same time without moving things around.

If it was me and I did a lot of Tekmar work (and the need was there) I'd put three potentiometers in a box with ohmmeter test points and an isolation switch for quick setup and changes. I'd use good test prod wire so I would not be repairing it all the time. I like tools that make my life easier.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements