Best Of

Re: near toilet floor constantly wet

Is the shower in regular use or just idle? If it's in use, avoid using it for a while like @MikeL_2 suggests and see if the water dries up

It would also be worth popping the shower handle escutcheon off and seeing if you can see any visible leaks from the shower handle body

Re: Equalizer

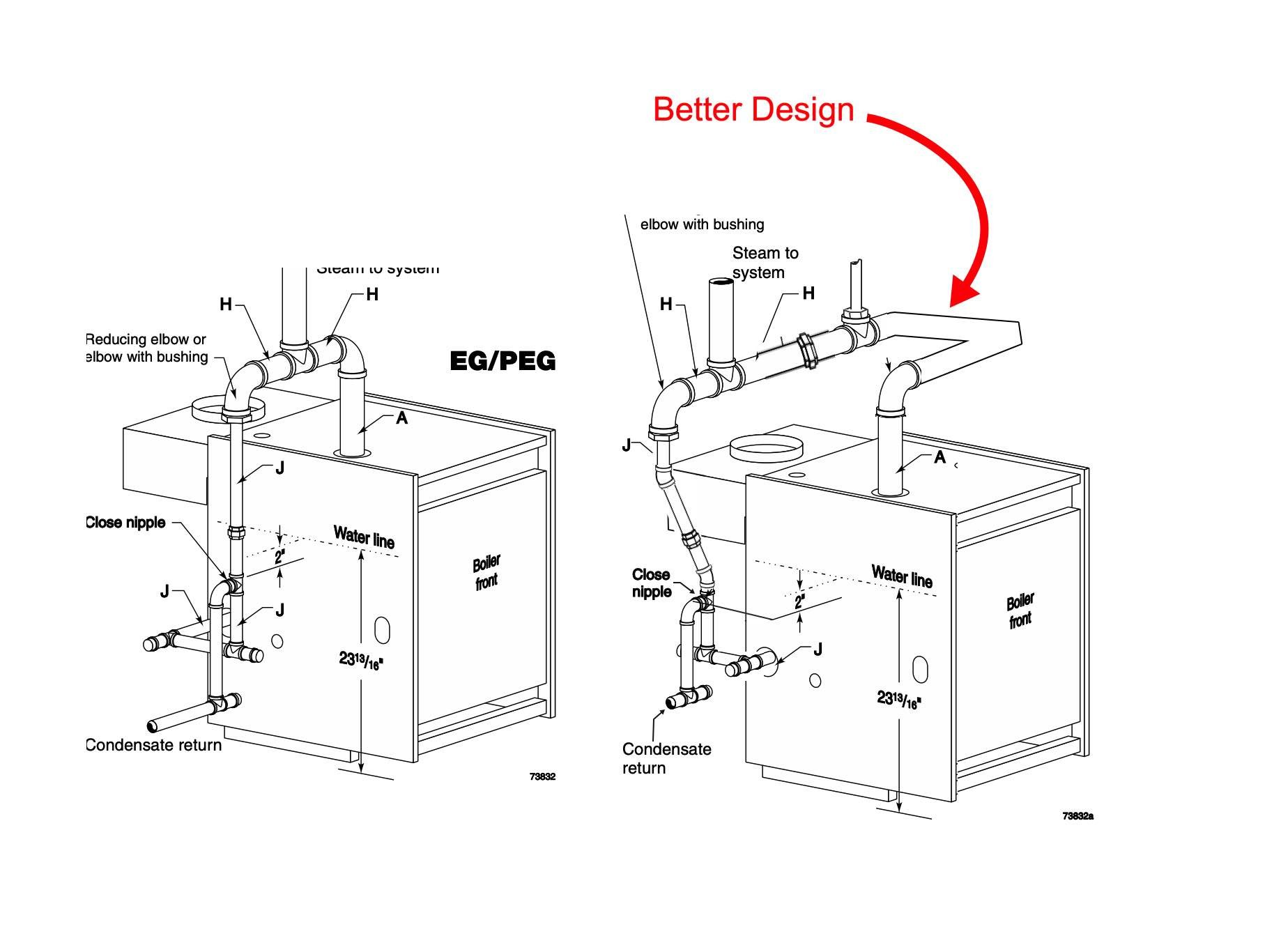

We have all been taught, the higher the velocity, the more water gets carried out from the boiler. The lower the velocity, the less water gets carried out of the boiler. If you follow through with that equation, that means that the larger the boiler steam piping and header coming out of the boiler, the less water there will actually be in the header. Which means, the drain function of the equalizer, can be reduced.

Re: American Standard Acroliner - varying hot water temp

WOW… you still have an RA117A primary safety control? That is obsolete and has poor safety performance. You should think about removing that from the system completely if it is still connected. Replce it with a much safer primary safety control like the Carlin 70200 PRO. It is a much safer control for your oil heat system, and it should be installed by a professional.

The black covered box installed just below the vent connector (smoke pipe) is your circulator/burner relay. The thermostat wire connects tothat control and should turn on the circulator pump and also the oil burner by way of the RA117A primary safety control, Honeywell called the primary safety control a "Protectorelay®". I would strongly recommend upgrading that control. The Honeywell version of the Carlin 70200 is the model number R7184U protectorelay. But I would still recommend the Carlin control because it has the most safety and diagnostic features.

Re: Too Hot Upstairs When Cold Outside

That is probably your main vent issue. The main is trying to mostly vent through that one radiator since the other radiators are now venting more slowly and it all rushing toward that radiator is enough velocity to pull some of the condensate with it in addition to not getting the air out at the same time as the other radiators.

you also seem to have 3 mains at the boiler but 2 of them are teed together just above the boiler, that can cause balance issues between those 2 mains.

Re: American Standard Acroliner - varying hot water temp

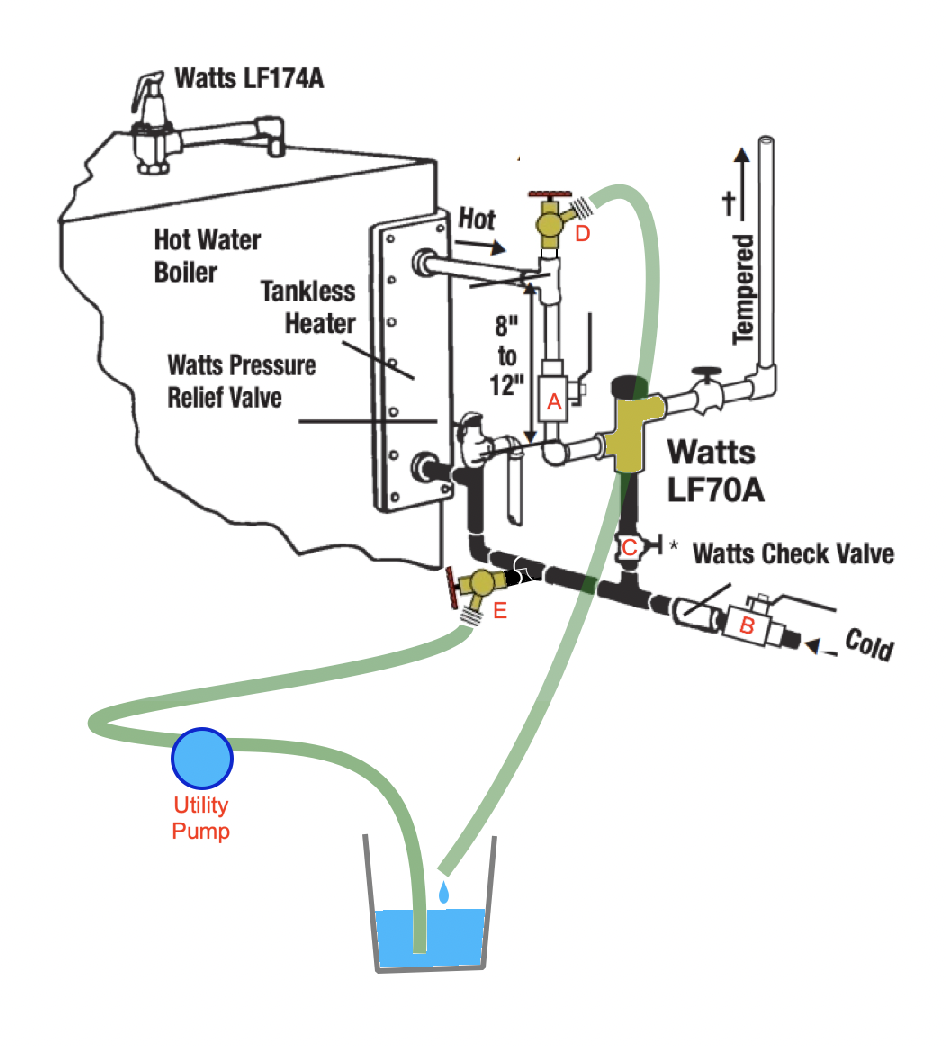

This is the piping arrangement you ahould be looking for. You should already have Valve B. You may need to add Valve A and C. Then you must add draw off valves (also called boileer drain valves) D and E and get an inexpensive utility pump. We used to use a really economical pump that you attach to an electric drill.

Close valve A B and C then attach hoses as shown to D and E and open those valves. Pump the cleaning chemical thru the coil for about 30 minutes. Then close E and open B to flush out the chemical. close D whan the water runs clear and open A and C. You should be good to go.

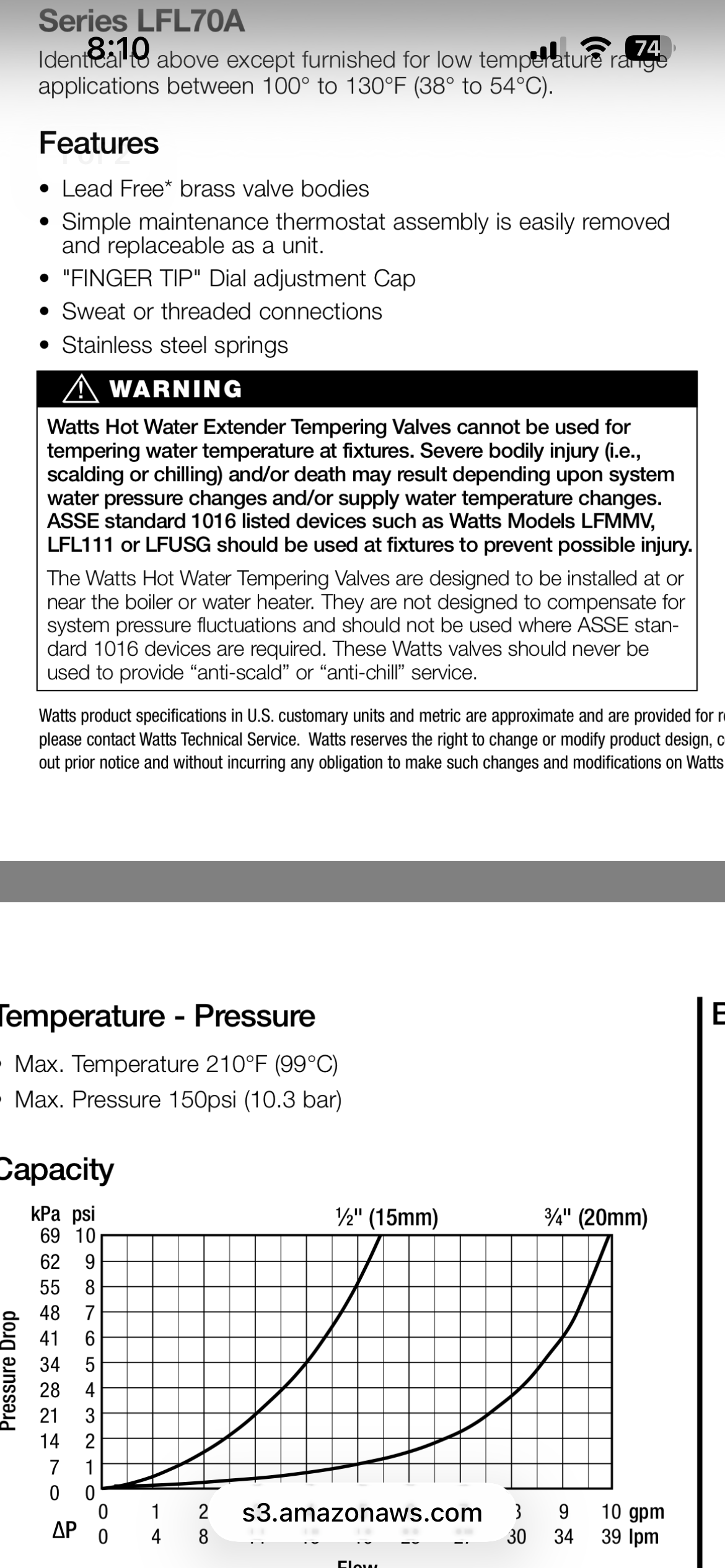

Agree with @hot_rod on upgrading to a ASME 1070 listed valve while repiping for the flushing valves

Re: The Model K Mystery

Nicely told. No doubt this is still happening across NYC.

Re: American Standard Acroliner - varying hot water temp

More and more states are requiring ASME 1070 listed mixing valves on any water heater

If you do a repipe to add flush valves, consider upgrading that mixer. It may not be much more $$ than a rebuild kit for that hw extender valve

hot_rod

hot_rod

Re: Two boiler repipe for primary/secondary

The custom wheels didn’t seem so much like you😉You’re to practical to spend on outside impression. The $$ is in the tools inside!

hot_rod

hot_rod

Re: Water hammer - novice question

i doubt that is where whatever they were trying to fix was…