Best Of

Re: Weeping PRV.

Hi, Agree with what @hot_rod just said. I've tested thousands of T&P valves, and in my area one in forty is plugged solid with mineral. It could easily be considered negligence to not test them. 🤔

Yours, Larry

Re: leak in pex tubing in concrete slab

fix the discovered leak and air it up to 80 psi. It will drop as the air from the compressor cools down. But if it drops to zero, time to start looking.

Any framing that was anchored down is the first places to look. Check the gauge with spray soap also, if it ever had moisture in it maybe it froze?

It is repairable once you find it. Is the slab the final finish? Or are you going over it with tile or wood?

hot_rod

hot_rod

Re: ChatGPT, AI

another issue coming up with AI replacing people is that AI doesn’t pay taxes like workers do. So when you start replacing millions of employed humans with AI?? Who makes up the shortfall?

AI is already hitting our electric rates for its needed generation and infrastructure requirements.

Around here the AI companies nice tax breaks and incentives to move to State. Seems to even be a bidding war going in for AI businesses

hot_rod

hot_rod

Re: A word about Design Day and not-so-warm homes.

For me, I usually stuck to the book when it came to heat loss and design days, but I can’t tell you the amount of customers I had within the City of Chicago who kept their thermostats at 84 degrees all winter long and that would be their expectation on the new boiler, usually older folks.

Then, at some point, someone else moves into that house and complains that some knucklehead installed a grossly oversized boiler. These were in poorer neighborhoods where cast iron was the only option so modulation or multiple smaller boilers weren’t an option. Outdoor reset can only do so much.

Re: SuperStor SS-40 Aquastat Immersion Well LEAKING

Hi, A little trick I've learned about using the conventional thin teflon tape is to use at least six turns of it rather than the suggested three. I put enough onto the threads so the tops of the threads appear rounded. This nearly always gives me a tight connection without having to really torque things down too much… And I'd consider adding the heat transfer paste/grease just so you know you have a responsive sensor.

Yours, Larry

Re: Heatnglow TownsendII-LP

Something else just came to mind. You said LP in the subject. Any chance your tank is cold enough that you're fractionating & not getting the right mixture to burn properly with your pilot assembly?

Re: Another Smart Thermostat Question

Good. The 18 gauge (or rarely 16) — which often had a cloth wrap — has two possible problems: first, if it's really old it can actually get brittle and break, which is tiresome. The other is that the insulation can degrade and give shorts — sometimes pesky intermittent shorts.

However, if it's a decent gauge and otherwise seems intact, you aren't dealing with high voltage so that if you test it with a good miultimeter and it tests good for continuity and no shorts I don't see why it wouldn't be OK if it has enough conductors.

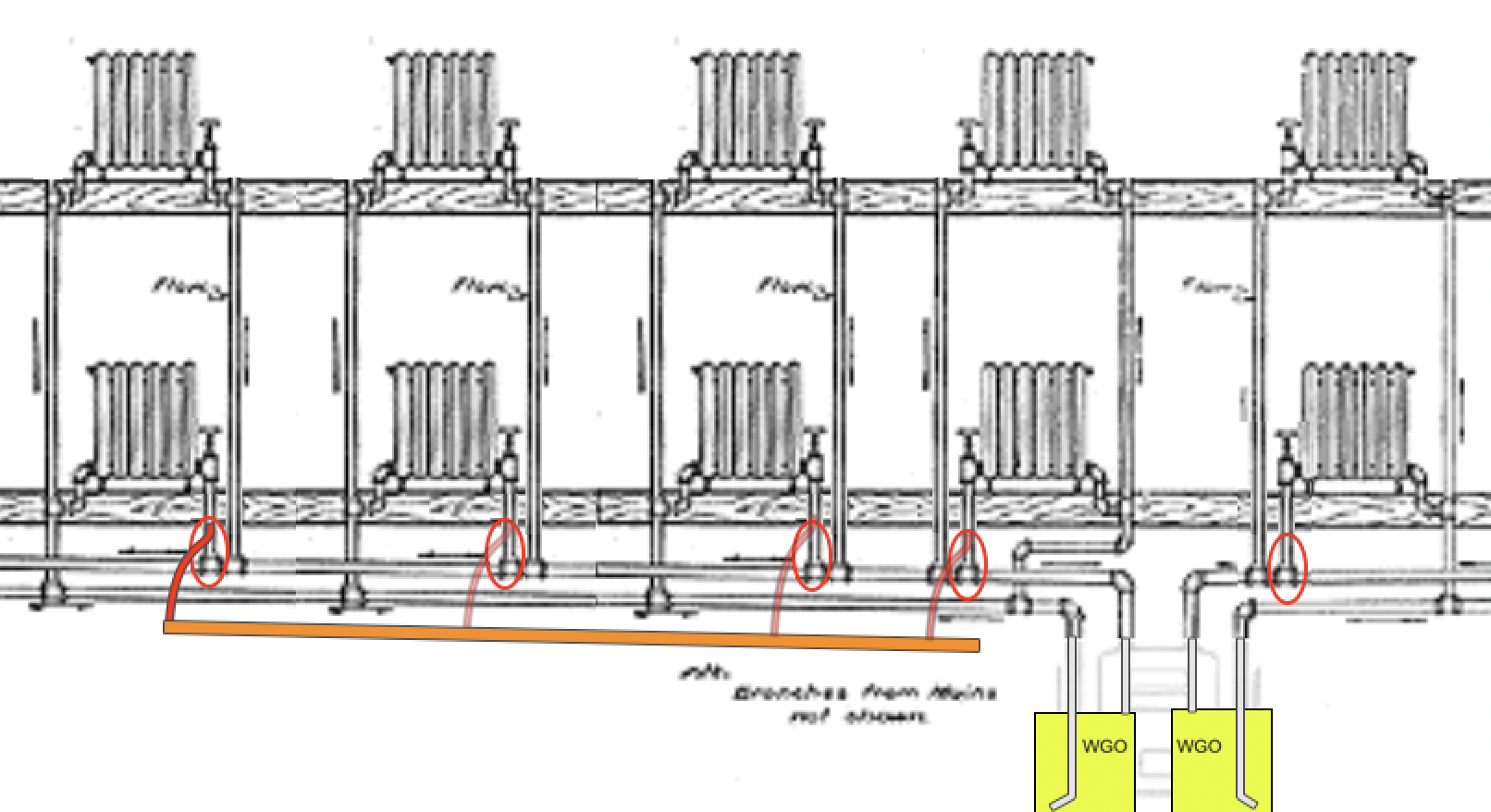

Re: Two boiler repipe for primary/secondary

@jesmed1 said: We'd need to rip out and repipe all the large diameter piping, and that would cost mucho dinero.

and that is not necessarily true. If you look closely at the diagram, you will see the red piping is all that needs to be changed to zone the first from the second floor.

You leave ALL the old pipes from the return and All the pipes from the supply. All you need to do is to disconnect the first floor radiator supply pipes from the large supply main. Plug those openings. Run a 1” copper supply from the 90° corner to the radiators that you disconnected. Connect those radiators with ¾” PEX to that copper main.

How many radiators are we talking about? 5 or so from each side? Not such a big piping job at all.

That is a lot less piping than the project you are talking about.

Ono of my first jobs when I went into business for myself was for the owner of a 4 unit building just like you have. Two upstairs and two downstairs long before wireless thermostats and sensors were available. He had one oil fired boiler and one thermostat in one of the hallways. Always got complaints from tenants about too hot or too cold.

I purchased 3 gas boilers, 4 gas water heaters and a ton of copper pipe and fittings from my local supply house and all of that was able to fit into this one service van.

The guys at the supply house couldn't believe it all fit. I drove less that a mile to the job and took 2 days to complete the job.

You might be thinking, “Only three boilers?!”

Yes. My original proposal was to install four new gas boilers, but the owner wanted to save money and asked, “What if we install only three and leave the old oil boiler serving one apartment?” So that’s what I did.

The system was laid out much like yours: all the radiators on the left side were on one main, and all the radiators on the right side were on another. To separate things, I removed the first-floor radiators from each main and connected them to a new gas boiler. On the left and the right sides. The second-floor radiators remained connected to the existing mains on the left . On the right side, the old oil boiler continued to serve the remaining second-floor system.

As you might expect, that oversized oil boiler burned significantly more fuel than the three gas boilers so the tenant complained in a big way. The following summer, I went back and replaced it with a fourth gas boiler.

That experience showed me this can be done with very little new piping. In your case, you only need to modify the supply side. The returns can all remain as they are, since they’re still returning to the same boiler.

Re: SuperStor SS-40 Aquastat Immersion Well LEAKING

Re: Down Firing Oversized Boiler

@Jamie Hall makes a solid point .

I once had a customer who was convinced they needed a bigger boiler because the house wouldn’t stay warm on the coldest winter days. Three different contractors quoted them for a replacement boiler. That would not fix the problem. The existing boiler was already oversized.

Years earlier, the original cast-iron radiators had frozen and someone replaced them with baseboard. They installed 96 feet of baseboard on a single 3/4" loop running through the entire house. That’s a lot of footage on one small loop. The issue wasn’t boiler capacity — it was poor distribution.

Instead of replacing the boiler, I split the 96 feet into two separate loops, with a 1" common return back to the boiler room. One loop had 50 feet, the other 46 feet. I also reworked the near-boiler piping with 1" shared piping to improve flow.

The result? Even heat throughout the house — and the total cost was less than half of the lowest boiler replacement quote.

I’m sharing this because sometimes the issue isn’t the boiler at all. It’s worth taking a close look at how the piping is arranged between the boiler and the radiation. In your home, rezoning the kitchen made a huge difference in comfort.

You might have a similar distribution problem rather than a boiler sizing problem.