Wet Steam

As suggested by @ethicalpaul, I have started this thread to steer the discussion from boiler pipe sizes and carryover to water quality induced wet steam.

Several standards are used to measure wet steam, among them IAPS Industrial Formulation that measures the dryness fraction of steam as a %. The ISO 5167 standard is used to correct steam flow rates by plugging in wetness correction ratios from a pressure table. Then there are inline instruments used to monitor steam dryness, a common one is a mass flow meter for that sets off an alarm when the liquid water content of steam drops below 80%.

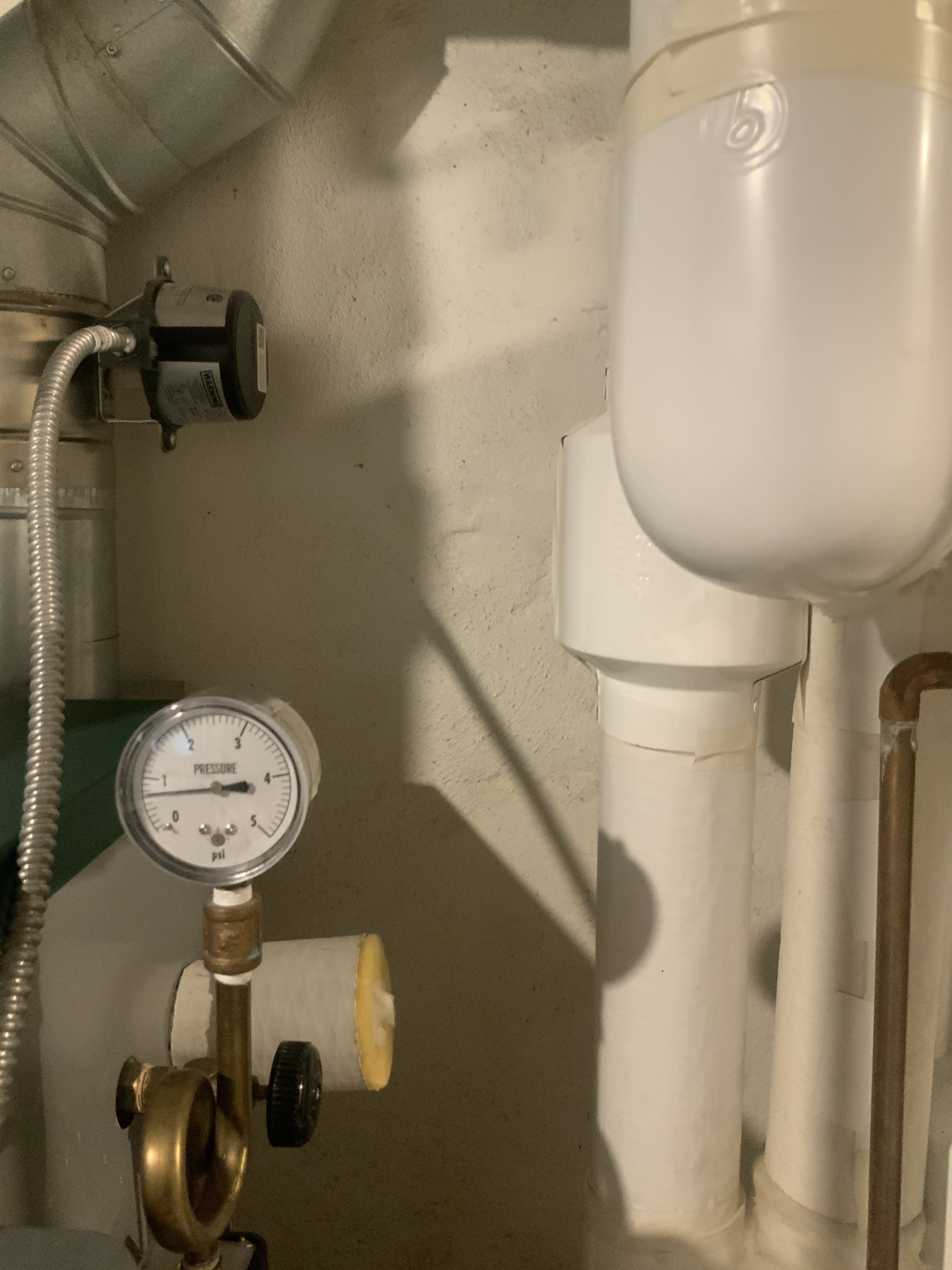

I have attached a pic of the water level in the sight glass shortly after my main vents close. It falls another 1/2” towards the end of the heating cycle-typically 20-25mins. I have also shown my pressure reading and my 3” takeoff for my 63-03. I have one pipe steam with two headers.

Sorry but I am presently jet lagged; I will be glad to address any questions I might have missed.

How do I know I have wet steam? When steam reaches the end of my mains, my Bigmouth lets out two puffs of steam,3-5 secs each, before it closes shut. No water droplets fall out, but if I hold a sheet of paper close to this vent, I see several drops of water that are in the form of a mist. At the remotest rads. my #5 Moms will spit out water just before they shut off and a small amount after they shut off, meaning they open intermittently and will spit some water but for the most part remain closed. On my largest rad I have a #C Mom that seldom shuts off because the stat is satisfied before heating entirely, but the vent, not the rad, makes a gurgling sound.

I have a small rad in a bath that makes a gurgling sound which unfortunately has a 1/2” riser. It’s feed valve has a screw, not a knob, but is wide open. It is pitched but has a lot of water condensing in it. I am attributing this to wet steam.

Finally, I should comment about water quality. I drain the boiler to remove the crud because my vents get frequently clogged by rust particles and stop working. I get most of them to work by washing with vinegar but lose 1-2 each season. This is my 4th heating season with this boiler and I have skimmed it 6 times; 2x with washing soda. I had to skim it myself as my installer simply drained it once and added Surgex to it. When I drain the boiler for rust, I don’t see any oil on the rusty water in the pan or in the sight glass. @ethicalpauls video shows that when you have carryover the water level in the sightglass drops. In my case the drop is substantial despite the oversized takeoff.

By method of deduction/ elimination, if the water is leaving the boiler in such copious amounts, with no leaks,

where is it going? Wet steam?

Comments

-

is your water level at the designated mark when your boiler is at rest?

If so, you are experiencing carryover.

“Wet steam” isn’t a thing you can control in a residential boiler because all the steam created is by definition wet steam.

Your main vent behavior is just normal behavior. A small amount of condensed steam will escape just before it closes.

It is pitched but has a lot of water condensing in it. I am attributing this to wet steam.

all radiators condense a lot of water. If you hear gurgling it is due to something like a mid-pitched pipe or a partially closed or bad valve.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

To reiterate @ethicalpaul 's question slightly modified: does the water level eventually go back to where it was before the cycle? Or are you missing more and more water every cycle due to a leak?

2 -

After draining the boiler to remove rust each month, I have to add 4-5 quarts of water. With each cycle I do lose some water but it only becomes evident after2-3 days of operation. I am estimating that I am drawing down 1+ quarts of rusty water and the rest is water loss from opening and closing of the main and rad vents. I have checked for leaks at the usual places but have yet to find one. During the installation of the boiler three years ago I had the installer check for leaks along the two mains and the wet returns.

I try to keep the boiler level 1” below the factory mark to minimize the carryover. This season, I have one Ventrite that is closed shut and I am using a #4 Mom in its place. I prefer the Ventrites because they have no problem closing with wet steam while the MOMs spit water even at 0.5 PSI when installed on small rads. They are ok on big rads since they seldom have to close.@mattmia2, I have a combination of counterflow and parallel flow mains. I may not have entirely understood your question, but my wet returns are insulated and stay hot between cycles.

@ethicalpaul, you are right on point with the small rad that makes a gurgling sound. It has the steam inlet about a 1/4 distance from one end with a 4” horizontal runout towards the middle of the boiler. I had it pitched like all other rads, yesterday, however, I made it level to see if the water would drain back faster. I want to observe for a couple of days to see if it does. What is the right way to pitch it?

0 -

-

Don't bother trying to pitch radiators, it doesn't matter. Just have them close to level. If interested, see my experiment where I pitched radiators the wrong way.

Here is the one pipe video, but I also did 2-pipe which you can find:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@ethicalpaul I agree from your good experiment that the radiator doesn't have to pitch back to the inlet to avoid hammer, but, if it slightly pitches the other way would you have any concern over long term corrosion at the bottom of the radiator, much like a sag in a return pipe leads to through corrosion over time?

2 -

No because regardless of radiator pitch, radiators hold water at the bottom. The radiator castings have low spots at the bottom that are lower than the supply port, and additionally almost all supply ports have a reducing bushing on them resulting in more captured water.

Have you ever had a radiator not spill water out of it when you disconnect it?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

A couple signs (in my recent experience with new boiler) of surging and carryover besides the dropping level in the sight glass is a very rapid gain in boiler pressure (like an inch of water column every several seconds very early in the cycle, along with vibration in the header. At its worst I could literally see the header oscillating. That is gone now but I often double an old washcloth and but my hand on the reducing elbow of the equalizer to feel for vibration / impacts. What solved this for me has been a combination of skimming and dosing with Hercules boiler cleaner. My skim water is still pretty murky and carrying flecks of pipe dope. I see no oil stain. I think these Teflon dopes seem to cause rough boiling. Not sure why.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

1 -

I agree,

Not only do the sections hold water, many of them are bushed down.

Going by memory here, so don't kill me if I'm wrong, but I think all of my radiators are 1.5" and most are bushed down to 1.25, and the smaller ones are all bushed down to 1". They're all built from the same sections so a 5 section has the same tappings as a 20 section.

Unless the radiator is almost on it's side, it's going to hold water.

Here's one of the many smaller ones that's bushed down to 1". I replaced the riser to it, but the valve is original to that radiator. That's how they've all been since the 1920s.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

Anyone know why my radiator which looks like a Sunrad has a port that has to be piped from the middle rather than from one side? After this post, I have leveled it and it continues to gurgle but heats ok. Not sure why it was bushed down to 1/2”. I found out that until 1976 my house was heated by a central boiler operated by the town and the stats were windows, and I am wondering if that has something to do with a small dia riser.

0 -

" Sunrad has a port that has to be piped from the middle "

Can you post a picture of it ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

<y Sunrad has a pipe that comes up in the middle but goes into a 90 - a valve and then into the end section of the sunrad. Maybe the 1/2" is because it was once used on hot water system?

Bob

Smith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Does your sunrad has a return pipe? Its not trying to drain thru the 1/2" supply i hope. If you have a supply in the middle do you have returns at either end?

0 -

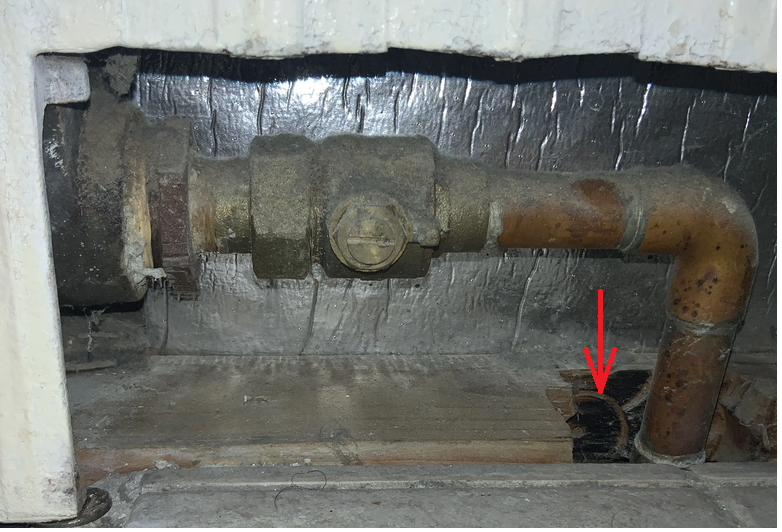

Here are a couple of pics of the small rad-

@pedmec, I have a one pipe steam and only one port shown with a 1/2” copper connection. All others in the system are black iron 1” except the largest which is 1.25”.

0 -

is that pipe somewhere where you can repipe it in 1" black? you can maybe make that work if everything is perfect but a lot of things are against you there. i'd set that sunrad dead level because it will hold the least condensate that way. try to give the actual runnout some pitch if you can

0 -

" Anyone know why my radiator which looks like a Sunrad has a port that has to be piped from the middle rather than from one side? "

I'd say they were designed that way to get the most radiator in a confined space (embedded into a wall).

Is the Red arrow below pointing to a cut off abandoned pipe ? Anyway if it works well enough and you can tolerate the gurgle, I'd leave it alone, if not bigger piping and a new valve is needed.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Don’t know what that pipe is doing there but it is not carrying steam. I will check the rad’s level closely however. Would the copper fittings respond badly if I try to bend them downwards a bit while they are filled with steam? I am thinking about 1/8”, no more.

0 -

-

" Don’t know what that pipe is doing there but it is not carrying steam. "

My point is, maybe it did carry steam at one time and it may be bigger than what is presently there.

I don't think bending the pipe will help much, and you could break something. Depending on how that valve is constructed there may be a bunch of water trapped between the valve and the radiator.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I have a Peerless 63-04L that was very poorly installed by previous owner and I suspect it was with the help of my neighbor/plumber up the street but I can't prove that (lol). Among other things, the Hartford Loop is right at the NWL instead of min. 2 in. below, and the header is less than 24 in. above the NWL and is copper and the boiler is not level but is much higher at the flue end than the front panel end. Many more issues…. Anyway, it is very sensitive to water quality or it will carryover, sometime spectacularly to the point where one particular radiator on the 1st floor will spit water out of the vents.

One of the first clues that it is getting to be time to flush the boiler and that carryover is starting again is that the low pressure gauge will start to show a small amount of pressure very early on in the cycle when boiling has just begun. That is because of the slug of water that is going up into the header causing back pressure. Should just see the needle bouncing slightly on zero peg when all is well. I will also see the water drop in the sight glass further on in the cycle to well below the NWL, fully exposing the Hartford Loop, which is a no no. You could calculate how much steam volume it should take to fill your radiators and mains and the water volume equivalent of that and that is the most you should ever see your sight glass go down, barring some sort of tilting waterline issues, which I probably do have with my bad install because I will see my waterline actually go up when the boiler water is freshly cleaned when boiling is imminent and before steaming (single riser used on near boiler piping and it is the one nearest the sight glass). It goes up lots more than would be happening with expansion due to temperature. When it is carrying over badly this never happens so I don't mind seeing it happen.

I suggest installing a full port ball valve drain valve on the boiler and draining it through that. Then back flush it (several gallons maybe until it appears at bottom of sight glass) by hooking up a hose to that and drain again and keep repeating that maybe 5 times or so until the drain water is pretty clear. I then fill it with preboiled distilled water treated with 2 oz. of Rectorseal 8-way per gallon. That's more than they say on the label. I shoot for pH 9.5 to 10.0. That should give me pretty consistently excellent performance for the entire season but the pipes and radiators are 100 years old and very dirty.

I plan to start draining 1 to 2 gallons every month or so and putting fresh preboiled distilled treated with the 8-way to see if I can improve the season long performance that way by keeping the intra season particulates down a bit more.

Wet steam is very real and residential steam boiler systems are not somehow immune to that. It is simply saturated steam with entrained water droplets (ie. two phase mixture). The more liquid water present the wetter it is. You will get a significant efficiency loss with that happening.

1 -

@captain who, thanks for your sharing your wet steam experience. My installation was up to factory specs except for a larger and taller riser as shown in the pics. Additional work I had done was to install the drips.

I don’t get a lot of rust from my wet return and apart from boiler rust there is no oil or anything else in the water I drain, yet I have fairly wet steam. I do have a ball valve to drain the boiler and the wet return separately, and yes, I too have been using 8-Way, this being my 3rd season with it. This winter I have been adding store bought distilled water, but I think it does little to reduce oxidation in the boiler or in the pipes since there is no way to keep oxygen out of a system that is open to the atmosphere. My 63-03 manual has an annual limit of 16 gallons for fresh boiler water( that I remember) and I try to stay under that limit.

All told, steam is forgiving.

0 -

You're welcome although we have a secret dissenter with my post LOL. I'm just giving my personal hard knocks experiences; ones that people with perfect and new installations might not be able to relate to. If someone disagrees tell me why.

Let me know how I can help further if I can.

Store bought distilled water is very oxygenated. I don't have a DO meter (yet) but when I boil it there are tons of bubbles on the sides of the pot. They don't bottle it hot. It might not be quite as oxygenated as distilled water collected on the coils of a dehumidifier but it has lots of air. What it doesn't have is minerals and chlorides, both of which are way over acceptable limits in my tap water in my town.

I didn't mention my returns. I have single pipe steam as you do. I have mostly dry returns that are brass or copper so they are not contributing the rust particulates that seems to plague my system, first causing efficiency drop due to wetter steam, and then eventually causing carry over, and eventually catastrophic carry over (lol) that spills out the vent of that one radiator I mentioned.

However, unlike your case (which surprises me), when I drain my return it is very rusty, just like the boiler water. I don't believe that my rust is mostly coming from my boiler but from the steel pipes, cast iron radiators, and cast iron fittings.

If you are getting an anomalous high pressure reading early in the cycle when steaming has just begun and well before radiator vents are closed, that screams carryover to me. The fact that your sight glass water is going so low just confirms it. By the way, check the Hoffman Loop and make sure the boiler water level is not going below that. That will just compound the problems.

Edit to add - When I looked at your pictures I saw that you did a fantastic neat job of insulating the near boiler piping. But, even though your riser is very high, it seemed to me that the takeoff for the main was almost horizontal instead of what I thought was proper which is a 45deg upward or even vertical upward tee. Just FWIW. That could help carryover up into the main even with the high takeoff riser out of the boiler.

If you could, pleas post another picture that shows the Hartford Loop relative to the NWL of the boiler. The picture that shows it is not a good angle but it seems high.

0 -

It's not a secret, I think it shows my icon with the "disagree" mark. Residential boilers don't entrain water droplets in the steam. What most people call "wet steam" is carryover, usually caused by oil on the water or other water problem.

My advice is don't bother adding any 8-way or other boiler additive until your water is clean and not carrying over.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

@ethicalpaul Well your reasoning for disagreeing was a secret, until now (edit to add - to me and within this thread). I disagree with your disagree. Wet steam in residential boilers is a spectrum, with carryover being the extreme end of that spectrum. I've experienced the whole spectrum so I know, and my lousy installation makes it a great testing bed. The one radiator that is on a main all by it's lonesome (since prev. owner stupidly removed the 2nd radiator on that main) and is on the first floor basically has no header and even though the riser from the boiler is very tall like the OP's situation, it will carry over but before that happens it doesn't heat as well when it is getting wet steam due to the particulate count being too high in my water but not high enough for catastrophic carryover.

How Rust Particulates Cause Foaming and Increased Entrainment

Rust and sediment act as suspended solids that increase the total dissolved/suspended solids (TDS/TSS) concentration in boiler water. At high levels (e.g., >10–50 ppm in low-pressure systems), these particulates contribute to carryover in two main ways:

- Foaming: Solids like rust can adsorb onto bubble films, stabilizing them and preventing quick bursting at the water surface. This creates a persistent foam layer (many small bubbles) that rises into the steam space and entrains liquid water droplets as steam flows through. Resources note that high solids from corrosion products (like iron oxides) promote this, especially when combined with alkalinity forming soap-like compounds.

- Priming (Violent Boiling): Particulates provide heterogeneous nucleation sites—tiny surfaces where steam bubbles form more easily during boiling. In clean water, boiling might be smoother or delayed (superheating), but rust particles lower the energy barrier for bubble initiation, leading to rapid, explosive bubble growth and collapse. This "violent ebullition" ejects slugs or sprays of water upward into the steam space, entraining droplets directly into the steam flow. The result is a foam-like or surging condition where more liquid is carried over, making the steam wetter.

In residential boilers, this is often "sometimes severe" due to factors like startup surges, high steaming rates, or accumulated rust from poor feedwater treatment or oxygen ingress. It's not just "water problems" like oil—solids from internal corrosion are a classic cause, and prevention involves regular blowdown to flush particulates.

0 -

I wouldn’t call my thoughts on this secret since I’ve been promoting my videos on this topic here for years.

Here’s a recent one where I forced my steam to go through a 1” supply pipe to see if that kind of incorrect piping could produce “wet steam”.

https://youtu.be/Uz-8TWtbpiM?si=N1tHJ1tK-gkBY5Pc

It doesn’t. I have so many other videos and they all show there is no such thing as “wet steam”, only carryover/surging due to water quality issues.

From everything I have seen (and I actually see it unlike you and others who are guessing what’s in your pipes), there is almost no bad piping that can cause carryover or surging. Again, I’m talking about residential steam production rates and pressures.

A direct pipe to the main with no header or equalizer works fine and exists in many installations, for one example.

I haven’t seen your piping that I recall but based on all the ways I’ve purposely tried to create “wet steam” I can say with confidence that your piping isn’t the cause of any problems

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

”@ethicalpaul Well your reasoning was a secret , until now.”

Haha, nobody can say Paul keeps his ideas secret!

@ethicalpaul - I can imagine you getting a few eye rolls from your wife while briefing her on your findings! Been there!

2 -

"From everything I have seen (and I actually see it unlike you and others who are guessing what’s in your pipes)"

I don't want to take away from the purpose of my posting which was not to debate you but to help the OP, since we have similar issues, but seriously dude, how can you read my posts and say that I am guessing what is going on inside my pipes? To reiterate: When the water is freshly flushed and treated my problematic radiator heats fantastically. This progresses during the season to where towards the end of the season it is not getting very hot anymore and I didn't mention it but I will also hear all sorts of untoward sounds in the radiator due to the excess water. I've learned this from the school of hard knocks and it is not just the water quality but the bad installation of boiler (tilted forward towards the takeoff riser putting water level closer to that exit), very high non correct Hartford Loop, bad install where the one main does not have any header to help with carryover removal towards the equalizer and back into boiler, etc.. This progresses to catastrophic carryover which, to be honest, probably takes more than one season of neglect to get to that point but it will be muddy water on the carpet time.

I have seen your videos and I think you know I have been commenting and interacting with you and have been largely complimentary, but so far, and I'm not trying to be rude, you haven't done anything rigorously scientific enough to even come close to measuring dryness or wetness of steam. You are going against the textbooks. In science you have to try to disprove your own hypotheses and the hypotheses of others especially when you are trying to go against known experts like Dan Halohan.

For the OP mainly since you have your mind made up lol, there are qualitative ways to do it. You can put ball valves between your sight glass and the boiler at the top and the bottom. Also put a ball valve at the bottom of the glass. Close both valves between the boiler and the sight glass. Drain the water out of the glass. Then open the top ball valve and observe what the steam looks like. It will be readily apparent if you can observe the two ends of the spectrum of dry steam vs. wet steam.

Another more quantitative way which would work with a problematic radiator that I have in my system, would be to use a non contact thermometer and measure the amount of time it takes between when the entry neck of the radiator hits 180F and the radiator at the base of the vent hits 180F. The wetter the steam is (like as the season progress in my system with the particulate count increasing will do), the longer that delta amount of time you will measure. Wet steam doesn't heat as well. It is the latent heat of vaporization of dry steam that does the most heating.

1 -

yes I’m sorry, I wasn’t trying to fight.

I’m with you on the water quality. That is what makes carryover. Near boiler piping can’t affect supposedly invisible “wet steam”. A couple 90 degree turns aren’t going to create dry steam by removing sub-visible particles of liquid water that are supposedly making BTUs of heat cease to exist

What science did Dan do? He did thought experiments and observations, just like I do. Or show me the data I guess if I’m incorrect.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I kind of don't usually continue to debate when someone clearly disregards most of what I say, and I don't want the OP to feel like this is about you and me and not him and disappear due to cringe, but I'll say this:

Wet steam isn't "sub-visible" in problematic amounts—droplets are often visible as mist or spray in tests, and even trace wetness (1–3%) causes measurable efficiency loss (longer radiator heat-up, higher pressure drops).It's not "ceasing to exist BTUs"; it's wasted sensible heat evaporating the liquid instead of delivering latent heat in radiators.

Also, I think Dan Halohan would rightfully feel slighted by your comments. I mean, you are suggesting that he just conducted thought experiments and didn't do any research. I guess it is true that his writings aren't scientifically rigorous in the respect that he footnoted everything with references but come on! Some quick research online gave me this:

In articles like "Dry Steam Is The Goal" and "The Subtlety of Steam":

- "If the steam goes too fast as it leaves the boiler, it will tornado-suck the liquid water right out of the boiler. That gives birth to wet steam, which is steam that contains more than 2% liquid water."

- "The slower the steam goes, the less boiler water it will take with it."

- Larger headers slow velocity, giving carryover water time to drop back → "Drop headers leave the carryover water back in the boiler and the results are remarkable."

- Wet steam increases system pressure drop (water burdens the steam) → longer run times, higher fuel use.

- Poor piping on replacements leads to callbacks: wet steam causes water hammer, uneven heating, high bills.

1 -

Captain Who, you have asked several questions and I will try to address them all. The first re water quality.

You said “When the water is freshly flushed and treated my problematic radiator heats fantastically”. This is my situation too. I had said in my earlier posts, not in this thread, that without the 8-way I have a lot less carryover and dryer steam. Allow me to summarize:

Without 8-Way:

Boiler pressure 0 psi. Cycles on pressure when ambient drops to 25 or below.

Water level drops 1.5” in the sight glass

Lot of rust in the boiler at end of the month

Remove and clean rads clogged with rust at least once a month

Lost 3 rad vents last year

With 8-Way and store bought distilled water:Boiler pressure .6 psi. Still cycles on pressure when ambient drops to 25 or below.

Water level drops 4.5 “ as pressure rises to .6psi but does not trigger the LWCO.

Less rust in the boiler but more wet steam

Lost one Ventrite early in the season. Rest of the vents are operating without any cleaningMy use of distilled water is for the most part experimental, I will use it for the rest of this season and then decide if I want to continue. It is inexpensive, but I get your point.

I replaced my wet returns 24 yrs ago but I see very little rust when I drain them partially each October. This might be because I have hybrid counterflow and parallel mains and some of the rust in the counterflow sections is being brought into the boiler from the two drips. Mine are black iron. I have attached a couple of pics of the piping near the Hartford Loop and the ball valves.

My boiler is well matched to my radiation and pressure is not a problem at all. It takes 5-6 mins for the pressure to reach .6psi from a warm start and with fresh water, the boiler operates at 0 pressure for most of the winter. If you have gripes against poor boiler installs, then you are on this forum for the right reasons. Few contractors can install them correctly even when the installation schematic is taped on the wall in front of them. More fly fishermen have read books on steam systems than installers with 30+ years experience. A wise man once said “A funeral is better than a failed heating system”

1 -

OK so it looks like the top of your Hartford Loop Short Nipple or Street Ell is about even with the bottom of the Safgard? That looks like it is plenty low enough.

Carryover worse with 8-Way.

What is the pH when you add the 8-Way? Alkalinity can contribute to foaming if you still have rust particles. Maybe you are not getting very much of the sediment and rust out of the boiler in your draining and refilling process? I had to back flush mine several times this year through the full port ball drain valve. Last year I did it for over an hour with a hose supplying water via the pressure relief valve nipple location, with a little pump taking the water out through the full port drain valve (a pump which I returned because they said it was the complete kit with floor strainer etc. and it wasn't….long story) and I often turned the water on and off trying to disturb as much sediment and rust as possible. I also removed the problematic radiator last year and took it outside and flushed it out. While it was disconnected I flushed water down through it's piping through the dry and wet return and out the return drain valve.

0 -

I would like to say that the term "Wet Steam" is not a good term. There is steam which is water that is converted by boiling to a gaseous state. Then there is "Wet Steam" which describes a mixture of steam and water droplets [small]. There is also a dryness fraction which is used to describe the ratio of water to steam by mass in a container or system. It was my understanding that when a steam system had a dryness fraction of more than 2%, the steam in that system or container was considered "wet". There was a reference to this according to my notes in Heating help February 11 2019. Please keep this in mind when using the term.

1 -

@Captain Who, my boiler is running at a Ph of 10. My utility water is very nearly a Ph 7. My blowdowns are not that drastic, perhaps because my boiler is relatively new(<4yrs). I stop draining when the water runs clear.

0 -

Your utility water? So you filled it with tap water? From the water heater? What about total hardness and chlorides? I looked at a report from my water utility company for my service area.

What happens when you take a sample of the calm water well after a boiler cycle through the skim port? Does it look oily?

So did you back flush the boiler repeatedly like I did?

Honestly, I don't see how anybody's return water can be free of rust in a single pipe system. How old is it?

0 -

return water is crystal clear in a 1 pipe system.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Sorry if I confused you@ Captain Who. The water in the boiler is distilled water + 8-Way and has a Ph of 10. I included the Ph of my tap water merely as a reference since with no additive and tap water, I get dryer steam, meaning less carryover, but end up with more rust in the boiler.

@ARobertson13, I am using the term “wet steam” to describe a mixture of water in two phases- liquid and gas. I am also using it in a relative context to describe my system which creates steam with a greater percentage of liquid water than gas compared to other systems. So when Paul says all steam is wet, few if any would disagree. That is like saying all alcoholic drinks have alcohol, but the percentage of alcohol can vary. The same goes for steam. The percentage of water in the liquid phase suspended in its gaseous phase is a measurable quantity, also expressed as a %.

My goal( call it my 2026 new year’ resolution) is to improve the boiler water quality. Paul’s videos show that even a little oil in the boiler water is a no no. I am pretty sanguine I have eliminated the oil for the most part, but I have long ways to go in controlling rust. For now, I am betting on 8-Way, despite its side effects.1 -

My research recently has shown me that you can have TDS (total dissolved solids, ie. minerals etc.) too low and too high, and should shoot for about 1000 to 2000 ppm measured with a TDS meter for stable boiling rather than more superheated explosive style boiling which could lead to surging leading to priming with too pure water, whereas TSS (Total suspended solids) should be very low; less than 10 ppm achieved by regular blowdown and return flushing, to reduce nucleation causing too many bubbles causing foaming which can lead to priming and contribute to surging.

Maybe you should get a TDS meter and add some tap water to get into that range, and perhaps lower pH a bit to 9 to 9.5 to reduce possible foaming caused by higher alkalinity.

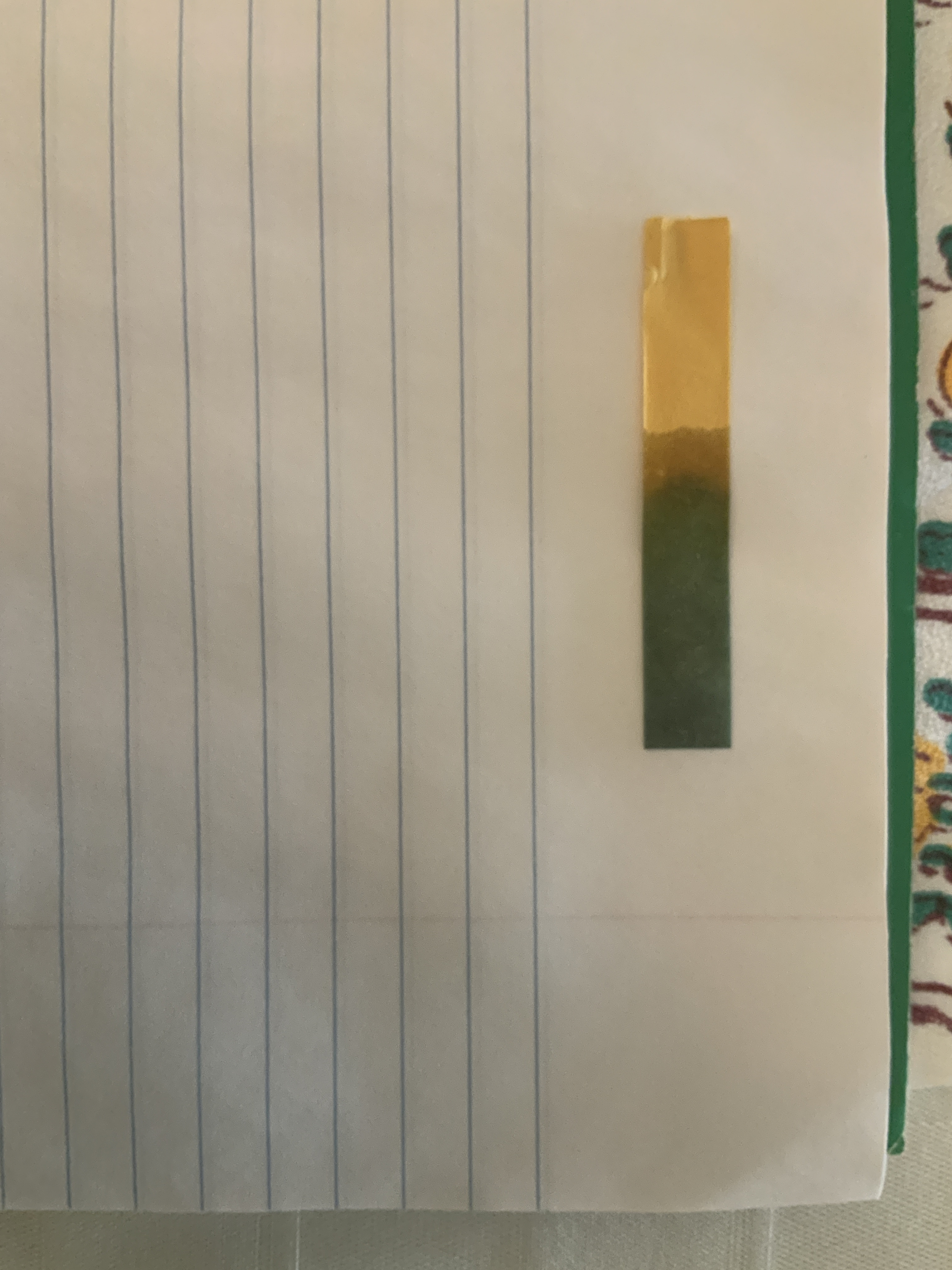

I found this for trying to assess TSS and will try this on my system by sampling some boiler water while steaming from the bottom of my sight glass (I have a mini ball valve there):

Practical Alternatives Most Steam Owners Use

- Visual + jar test(very common on Heating Help):

- Fill a clear glass jar with hot boiler water and let it settle 24 h

- Crystal clear with no sediment at the bottom → TSS < 10ppm (excellent).

- Slight haze or thin layer of rust → 10–30 ppm (monitor,blowdown soon).

- Cloudy or thick sludge → >50 ppm (definitely causing issues — blowdown now)

- <1 mm of sediment = TSS probably <10–20 ppm.

- Visible rust layer = TSS likely>50 ppm.

- TDS meter + visual clarity:

- High TDS with cloudy/murky water→ high TSS.

- High TDS with crystal-clear water→ TSS is low (most solids are dissolved, not suspended).

- Commercial water-test strips or kits that claim TSS usually only estimate turbidity, not true TSS.

I'm still wondering about your takeoff from the header that looks to me like it is almost horizontal in orientation and whether that is contributing to the problem.

0 - Visual + jar test(very common on Heating Help):

-

surging is caused by a lack of nucleation, the steam formation has trouble getting started then the water becomes superheated and it suddenly erupts violently.

0 -

Guidelines for Total Suspended Solids (TSS) in Residential Steam Boiler Water

Yes, the general rule for TSS in low-pressure residential steam boilers is as low as possible — ideally <10ppm, and never above 50 ppm for prolonged periods. High TSS is one of the main causes of foaming, priming, surging, and carryover (wet steam), because suspended particles:

- Provide excessive nucleation sites→ violent boiling / priming.

- Stabilize bubble films → persistent foam layer that gets carried over.

TSS Level (ppm)

Effect on System

Recommendation

< 10

Excellent – minimal risk of foaming/priming

Target range

10 – 30

Acceptable if water is otherwise clean

Monitor closely, blow down more often

30 – 50

Elevated risk of occasional carryover

Blow down / skim frequently

> 50

High risk of foaming, surging, wet steam

Immediate corrective action (blowdown, flush returns, skim)

These numbers come from boiler water treatment literature (e.g.,Rectorseal / 8-Way guidelines, Veolia, Chem-Aqua, and numerous Heating Help threads where pros report carryover starting around 30–50ppm TSS).

How to Measure TSS (and TDS)

There is no inexpensive handheld meter that directly measures TSS in real time the way a TDS meter measures conductivity. TSS requires a laboratory-style filtration and weighing method:

- Take a known volume of boiler water (e.g., 500–1000 ml).

- Filter through a pre-weighed 0.45µm filter paper (or Whatman GF/C glass-fiber filter).

- Dry and re-weigh the filter.

- TSS (ppm) = (weight gain in mg) / (volume in liters).

This is accurate but not convenient for routine checks.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements