Best Of

Re: A lower main from another basement

I love Jamie's response but I will give you a little more wiggle room if this system is 1-pipe (I can't tell if yours is):

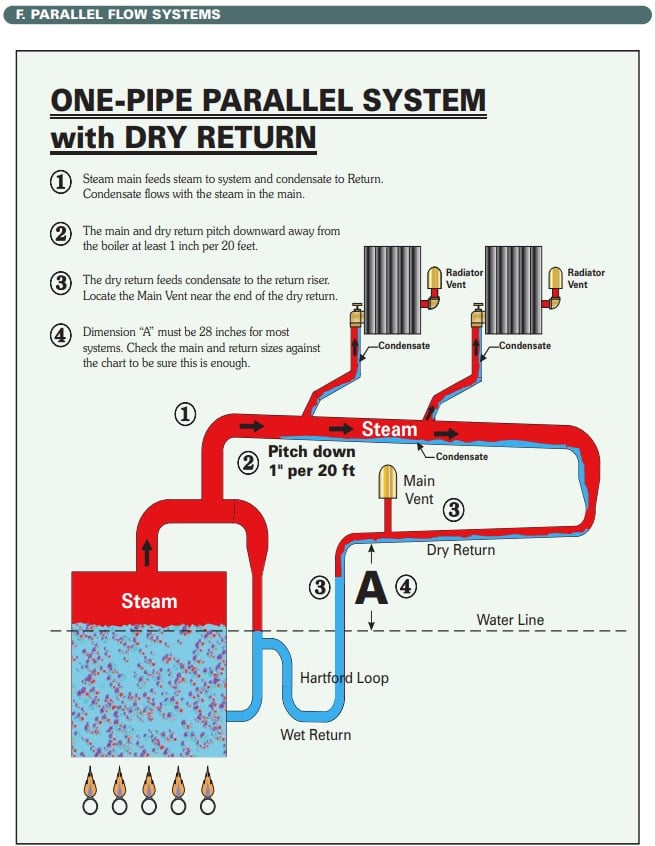

If the dry return isn't well above ("well above" depends on the operating pressure — at least 14 inches, if you can operate at half a pound)

What Jamie wrote above only comes into play in a 2-pipe system. In a 1-pipe system, there is no concern about additional height requirements due to pressure. In a 1-pipe system, no matter what the pressure is, the water line will not rise either at the boiler, or at the far end of the main. But still, keep the pressure low regardless for other reasons!

Re: One pipe steam system main vent

I used to wonder about this too but I'm glad I never moved my vents from the end of the dry returns to the end of the main. You don't want an air bound dry return. Vents are supposed to remove as much air from horizontal piping that can carry steam as possible. If you didn't it would cause more back pressure and hinder flow of condensate to the returns and it might even interfere with the A Dimension and possibly result in more noise and gurgling. From one pipe steam pdf by peerlessboilers:

Re: At last! Or... not quite!

Right, I know what causes water hammer but how does steam advance down there when there is nowhere for it to flow? (It doesn’t)

Re: At last! Or... not quite!

the height of the Hartford loop shouldn’t matter (within reason).

I know the thought is out there that it can cause water hammer, but I don’t see how steam can get down there.

Maybe I’m missing something 🤷🏻♂️

Re: A lower main from another basement

Yes. If you'd like to talk about it more I will make a new discussion post so as not to distract from this gentleman's topic. Click "agree" below if you'd like me to do that.

Re: Equalizer

From my videos you can see that the amount of condensate in the header is minuscule—even uninsulated ones.

And a lot of it gets re-evaporated by steam going by.

Pitch on the header gets you nothing.

Re: Water hammer - novice question

was it on a 1 pipe system? i can see it on 2 pipe under just all the wrong circumstances coming together just the right way.

if it can happen there then on 1 pipe it could also happen on a drip.

Re: At last! Or... not quite!

the steam will rise to the top of the header and push the air around. it won't rise to the bottom of the equalizer.

Re: At last! Or... not quite!

air can't get out of the equalizer so no steam gets in, in a 1 pipe system. if the radiator doesn't vent no steam gets in. in a 2 pipe system if the equalizer ends up equalizing then it could push the air in to the return and get full of steam. in a gravity return 1 pipe system the mains and returns are connected so they can't get out of balance pressure wise. the equalizer will be hot because it is partially filled with the near boiling water in the boiler but it shouldn't have steam in it with a 1 pipe gravity return system.