Is the boiler oversized?

Hi,

A family member recently had an 80 year old oil burning steam boiler replaced in her 1000sf home and the new boiler is running 15 minutes when cold then less and less with each subsequent cycle. It ends up running for only 2-3 minutes then turning back off for one minute. It comes on and off this way until the set point is eventually reached. It’s going off on high pressure. The pressure cutout is set for 2psi.

My research suggests the boiler is oversized. We had the installer measure the 6 radiators and they came up with 180EDR but the boiler is 396. They should have measured before selecting but here we are. I was not involved in the selection, only after there were issues. I understand smaller steam boilers only come in gas now, which is not an issue if a conversion is the best route.

We challenged their selection and they tried to defend it blaming the vents. They replaced all 6 vents at the radiators and the 2 main vents in the basement and the performance was the same.

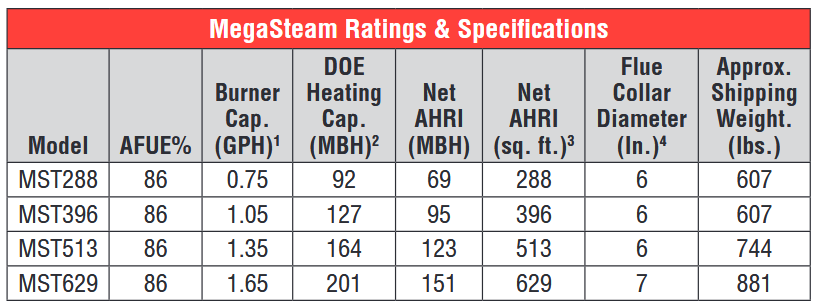

Then they changed the burner to a 288 and it got a little better but not much change. Same boiler block.

I’m pretty sure we need something in the 200-210 range and that we are still significantly oversized. By I’m not fully confident in what the pickup factor should be for a small house. Is 10-15% ok?

They still want to test more things (they have been vague about what else there is to test) but I’m at a loss for what other possible explanations there could be for this. I want to make a hard push to swap in a smaller replacement boiler, but looking for some reassurance before doing so.

The distribution piping and radiators are all existing so the only part that’s new is the boiler itself and the near boiler piping.

Greatly appreciate any feedback from the helpful and knowledgeable folks here!

Comments

-

In a perfect world the EDR (Equivalent Direct Radiation, the radiators) should match the boiler's Square Foot rating.

What was the old boiler's ratings ? Was there a pressure issue then ? I understand that information may be long gone.

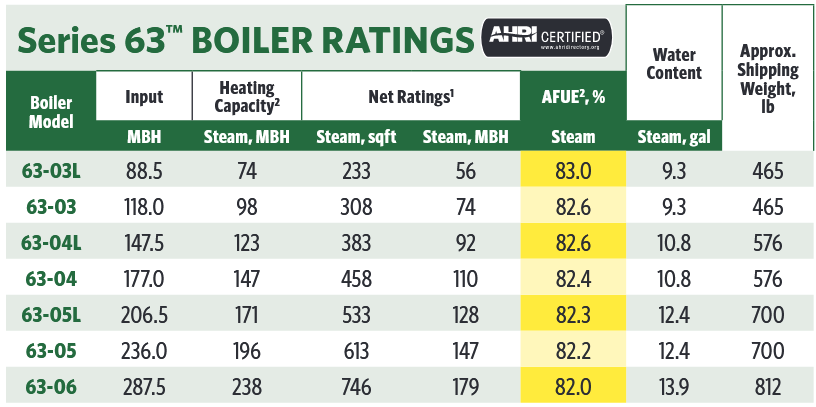

Going to a smaller gas boiler would probably help but may not totally solve the pressure issue unless the EDR matches the boiler size. Example Peerless only goes down to 233 Sq. Ft. You could add radiators (or increase their size), but that may not be very practical either.

If the contractor bails out and puts the whole expense for a Gas down sized conversion on the customer, I'd use a timer. To me the boiler size and type should have been worked out before the boiler change.

The timer is inexpensive and disables the excessive cycling that is really not needed to heat the home. The timer method is controversial and obviously not optimum or best practice, but it will eliminate the excessive cycling. And even with a timer there are different methods to implement it. And it needs someone capable of wiring it into the boiler control system correctly.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

a 30% pickup factor is subtracted from the number on the boiler so if the boiler is rated 180 it is actually outputting 240 ft^2 of steam. in reality you probably need more like 10% pickup factor so you probably need a boiler rated for more like 150 ft^2 of steam. You might not be able to find a boiler that small, but the closest you can get the better the system will run.

are the radiators all heating fully? if the whole radiator is heating the system is consuming as much steam as it can. the boiler is going to cycle off on pressure if it is bigger than the connected load.

you can downfire oil some in most cases but not by over 100%.

0 -

looks like there is a weil mcclain and burnham steam max that is close, probably is a peerless too.oops, i was looking at oil boilers but there were gas boilers mixed in too. there are small enough gas boilers, the smallest oil boilers look to be about 50% oversized

0 -

When it comes to oil heat, the smallest boiler is sometimes too big for a small home. There is nothing you can do about that in most cases. Some oil fired boilers have a minimum and maximum firing rate. If it is possible to reduce the nozzle input to the combustion chamber without compromising operating functionality and efficiency you can get a little better performance. If, however, they put in the smallest heater and it is too big, there is nothing you can do about it. You can't install anything smaller than the smallest heater.

Your old coal converted oil heater may have had longer operating cycles because it was grossly inefficient. Now with a more efficient heating plan, you can't count on that inefficiency to make your system operate better. You can however place some electronic time delays on the thermostat/limit circuit to make the on cycles longer. Can we know the make and model number of the boiler you have now?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Yes the boiler is oversized significantly. It seems like you know this, but that's the question in your post's subject so I'm answering you.

What is the boiler that is installed now? It sounds like it is oil but you didn't say directly I think. Can they downsize the burner even further?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

If the 180 EDR is correct the boiler is double the size it needs to be. But as others have mentioned you probably can't buy an oil boiler that small.

The smallest oil boiler is a Peerless which is about 288 square feet of steam.

When comparing boiler sizes don't look at BTUs it just confuses things. If you have 180 EDR you pick a boiler with the square ft of steam rating #. The mfg already include the PU factor in the boiler sq ft of steam rating

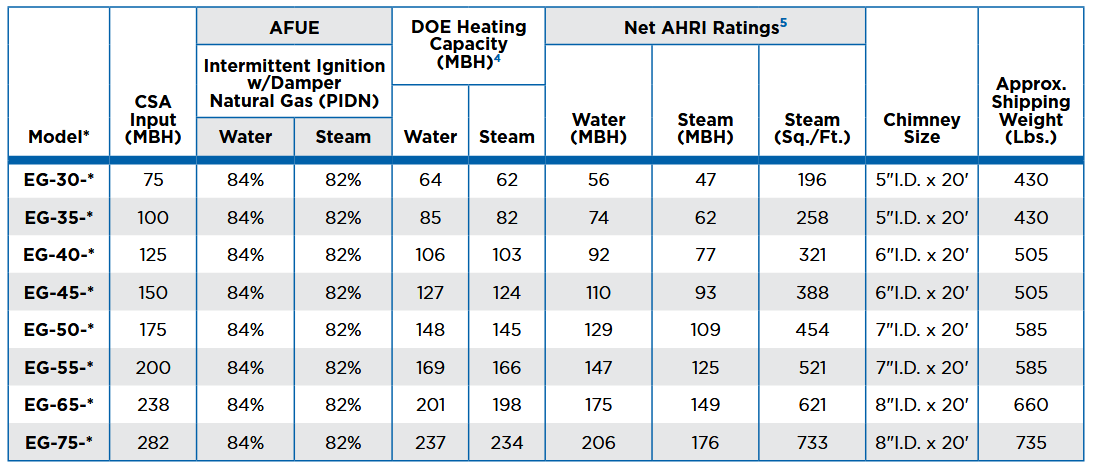

Weil McLain has the gas fired EG-30 which is rated at 196 sq feet which would be the right size.

If you stuck with what you have you could install a timer as others have mentioned. It doesn't cost much. just need someone who can wire it. The way it works it the boiler runs until it goes off on pressure. Then the timer starts to time out and you delay the boiler from restarting for say 20 min. The rads continue to give off heat. 20 min later the boiler will refire unless the stat is satisfied.

Lets see a few pics of the install so we can see if the installer knows what they are doing

1 -

The smallest Weil-McClain oil boiler is still oversized — but not anywhere near as wildly. From the way your contractor is behaving they either are completely clueless or trying to cover that they made a serious mistake in sizing the replacement.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Wow, thanks everyone for the fast and helpful responses, I am so grateful to have found this community today!

@109A_5 Yes, unfortunately the old boiler is out and I didn't a chance to look for a nameplate before it was removed, I was late to the party. It sounds like the system would run two cycles pretty regularly when trying to overcome a typical delta T of 6 degrees or so, and occasionally a brief 3rd cycle if it had gotten colder overnight and it was ~8 degrees below setpoint in the morning. So it was probably oversized but it may have been less apparent due to inefficiency as someone on this thread noted. The timer idea is clever, it just feels like a big concession when this was our opportunity to get it right. I understand the idea in principal though, and I won't rule it out, thanks for suggesting it.

@mattmia2 I did not know pickup factors were baked in, wow, thanks! Yes, all radiators heating fully.

@EdTheHeaterMan Understood about oil. The burner on there is the smallest they make and I'm told it already has the smallest nozzle on it so can't go lower than 288. It's a megasteam MST288. It sounds like my family member expressed a preference for oil-burning since that is what the old one was, and the installer was so eager to get the order that they quickly made the sale rather than taking care to match the capacity to the load. I wish I'd been involved sooner, I could have pushed for a right-sized gas fired selection instead.

@ethicalpaul Yes, oil MST288 and it's down-fired as much as possible now. Thanks for the validation!

@EBEBRATT-Ed Thank you I will look into the EG-30, sounds like it could be a suitable option. My preference would be a straight swap for something like this, hopefully we can make it happen. The timer is a solid backup plan. I'll see about getting some pics.

@Jamie Hall Yes, I think they are covering at this point and dragging it out. If they were dealing in good faith, they would state the remaining hypotheses they intend to check or test, but they are unwilling or unable to do so, so it's a dead end. And so far everyone hear has been in agreement, and with the collective experience of this group, I now have the conviction to push appropriately here.

Thanks Everyone!

0 -

you say that the new boiler is 396 ft^2 of steam but the mst 288 is 288 ft^2 of steam. It is still about 1.5 x the size it needs to be but it isn't as bad as if it were 396 ft^2.

We see a lot of boilers that are very oversized although if it is the mst288 there aren't really better options for oil.

1 -

I might have been unclear there. It was originally the MST396 and after we went back and forth about it for several weeks, we were able to get them to put the MST288 burner on it instead, which we understand is the lowest they can go for this boiler. It's more important to size it correctly than to commit to a particular fuel source.

0 -

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

When a replacement boiler costs a lot over $10,000 and you already paid a lot over $10,000 for a new boiler recently, then you may want to rethink your statement "It's more important to size it correctly than to commit to a particular fuel source." Remember not everyone has the option to change fuel at a reasonable price. To get a Gas boiler in some of the homes that I used to service you needed to get LP gas and that has about 30% less BTU per gallon and costs 50% more per gallon. That is not an option for folks on a fixed income.

You have the ability to get natural gas but is it worth purchasing a complete new boiler? This is not rocket surgery. You have a steam boiler that is properly heating the home. And the manufacturer says not to fire the boiler lower than 0.75 GPH. I have more than once put a smaller nozzle in a heating system that is rated for 0.75 GPH and had it operate properly. You need an oil heat mechanic with experience that can try to fire it at 0.65 GPH and see if the stack temperature is above 400° with good combustion readings. Get that and you will be even closer to the Sq Feet of steam that your radiators can handle. Add to that some electronic timers to extend the cycle time and you will be as good as any gas boiler will get for a lot less than the price of a new gas boiler.

Making this contractor replace the oil boiler with a gas boiler without getting paid for installing it is not a great idea in my opinion. If however you are willing to pay for a replacement gas boiler then more power to you.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

In addition to the hints above, if you keep the thermostat at the same setting you will have much less cycling than if you set it back at night.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

You have the boiler. Now the question is how to tame it. I and others have made some suggestions. One thing doesn't seem to have gotten said explicitly is that the fuel type makes no difference at all — only the heating capacity (BTUh rating).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Even a correctly, or exactly sized boiler is going to short cycle as 80% of the heating season you are below design conditions. Not much you can do about that with a fixed output boiler.

The more a system is zoned, the ore potential for short cycling of the boiler.

Buffer tanks are one option, controls to hold the boiler from firing, as long as you are not trading comfort for that option. High mass distribution maybe handles that forced off time better.

Once it is up and running observe the cycling on a mild day to see the frequency.

A few posters here have built data loggers to track the cycling.

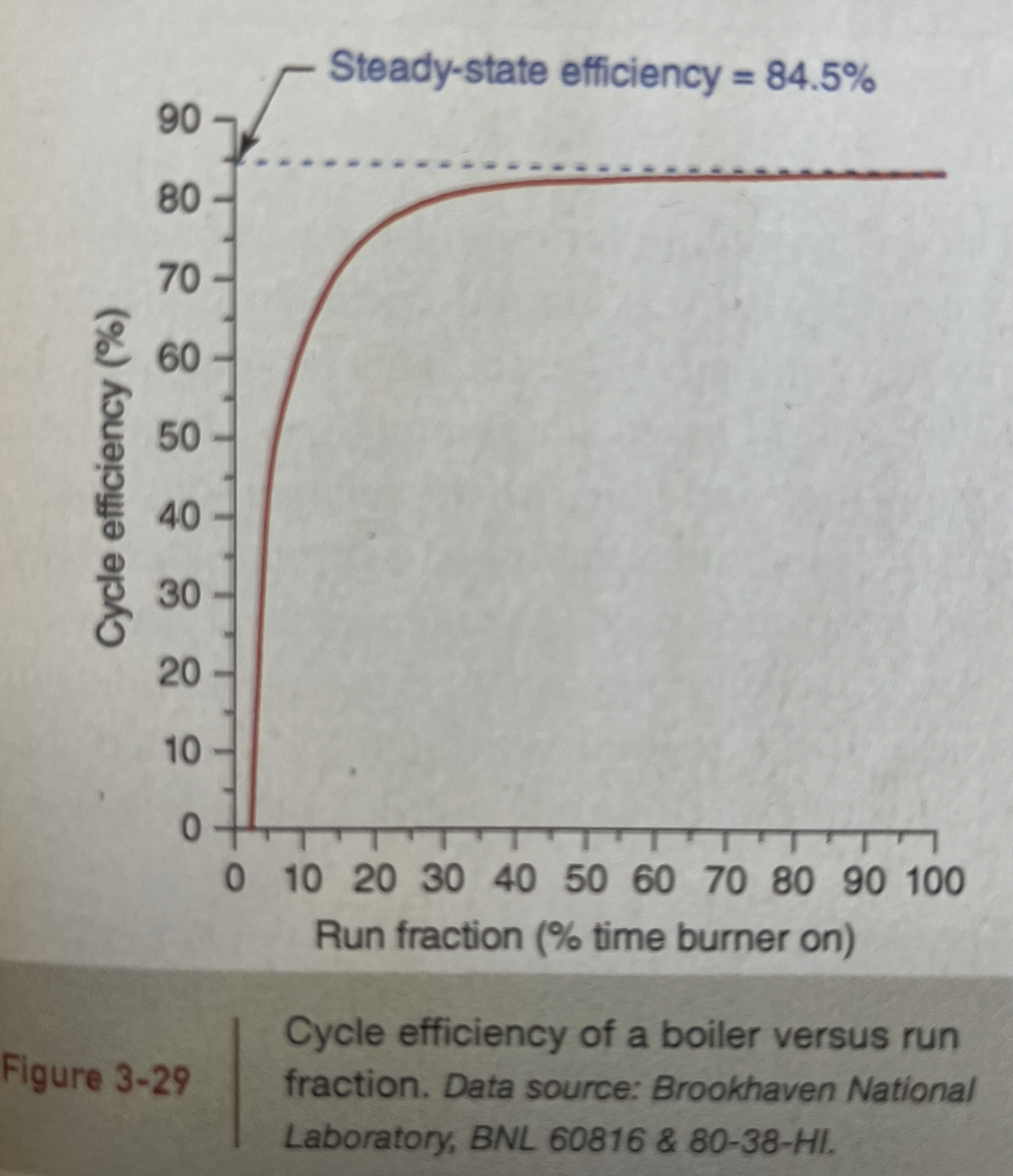

Excessive cycling drives down the boilers efficiency.

The math looks like this if you are interested. Run Time minutes the boiler is firing/ minutes it is off before next on cycle

8 minutes on, 15 minutes off = 23 minute time period 8÷23= .34 or 34% Run Fraction

Plug that into this graph to determine the boilers efficiency. 84.5% being about the best efficiency. So that puts you at or just under 80% efficiency

So boilers with 5 minute on, 5 minute off, 5%as an example, really drive efficiency down.

A modulating oil fired boiler is what the industry needs :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Uncommonly useful graph — hadn't seen that before. Thanks, @hot_rod !

It also helps illustrate my point that a steam boiler which is cycling on pressure, provided that duty cycle is at least 50% on, isn't losing much efficiency during a given thermostat cycle. and provided the off time is short enough that the boiler doesn't cool.

Now if you hold the boiler off long enough for it to cool down — even as little as 10 minutes or so for a smaller boiler — then you start over…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@hot_rod it is residential (single family home ?) Zoned steam, buffer tanks ??? Was this meant for another thread ?

When the boiler is matched to the EDR it should not short cycle on pressure, the radiators can condense all the boiler has to give. During the 80% it simply runs less since the heat loss is less, the radiators probably never fill completely. To me 'short cycling' and simply 'running less' since it is warmer outside is two very different things.

@Jamie Hall The fuel type in this scenario is of interest since you can get smaller BTU boiler in NG than with Oil.

To me that should have been an option presented to the customer before the way oversized Oil boiler was installed. May have been a big screw up on the contractors part.

If the option was given to the customer and the down sides were explained to the customer and they still chose Oil the contractor is off the hook IMO. They should have that in writing.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

since this is steam you are cycling on pressure within the cycling because it isn't design conditions (and steam systems usually need a boiler that matches the full output of the system but they system itself is usually bigger than the design conditions so you are losing some efficiency on 3 levels).

0 -

I'm thinking any boiler that cycles on and off excessively, multiple times per hour, per day, per season, will be less efficient, have more component cycle wear, and basically drive a person nuts if they are hearing it click on and off every 5 minutes. I think we have seen examples of under 5 minute run times systems come across HH.

Does it matter if it is a hydronic system, steam, radiant, etc. ?

My thought is you can calculate and closely predict the boilers behavior, or connect it and data log it as several posters on the list are currently doing.

If the goal is to optimize the system for efficiency and longevity, then the calculations, and best boiler selection, are worth the effort. I think that is what the OP asked.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I'm not well versed in steam, is it possible that if the boiler and radiation match, that on a design condition the boiler runs non stop?

If so any cycling below a continuous run lowers efficiency. As it would on a hydronic boiler operating at maybe 200°?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

With a steam system that the boiler matches the EDR, if at design day temperatures the boiler runs 100%, I would not expect any significant pressure build up since the radiation can condense all the boiler can produce. Actual design day steam boiler duty cycle 'best practice' is unknown to me. I can say mine only runs maybe 70% and it is undersized for the radiation.

To me cycling at any duty cycle due only to outdoor temperature and not steam pressure is as good as it going to get. I agree if the run time of an oversized boiler is less the efficiency is probably less. That's why the boiler should match the radiation and the radiation probably should match the buildings heat loss.

Although I understand the radiation with steam systems may be oversized, the radiation may be greater than the heat loss due to system sizing with windows open for fresh air for health issues. Fuel got expensive, health concerns went out the window and the window was slammed shut.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

things like solar gain, wind, and even usage of the space will change the heat loss at a given outdoor temp significantly, you cant go off of just outdoor temp. Even the rate of change of the outdoor temp changes the heating load significantly.

0 -

In this case the choice of fuel does matter somewhat. Gas steam boilers are available in smaller sizes than oil fired as a rule.

1 -

Let's at least try not to get confused between modulating the heating system to match the heat load of the house with modulating a heat source — hydronic or steam or even some forced air — to match the heat emitters (radiators or what have you).

These are two very different things! And, as a result, have different possible control strategies and devices. And these strategies have very different impacts on efficiency — and comfort.

Perhaps even more confusing, there are two very different approaches to modulation, both of which work just fine and but which also have different impacts on efficiency and comfort, again depending on how they are implemented.

And furthermore… the modulation strategies can be mixed!

And no, I'm not going to write a long essay on it all here. Suffice it to say that it would be entirely possible to take a given system — let's talk steam here — with a somewhat oversized boiler (say half again as big as needed for the radiation) and more radiation than is needed because of building upgrades, and vary the overall system efficiency and hence the cost of operation over a range of from perhaps as low as 60% to as high as 85% (steam, remember) — just by changing the control strategies with very little if any change in the system (possibly you might need one or two additional electrical controls in there).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

which is ironic because you could order an oil boiler without a burner and put a gas power burner on it but you can't convert a gas boiler to oil.

0 -

So many great comments here, not sure where to begin. Thanks everyone! I'll comment and expand on a few points that left an impression, and share an update on the project for anyone interested.

Jamie's point was well put: We have the boiler, now we just need to tame it! That's the spirit in which I led off the conference call with the installer and their technical folks, giving them the benefit of the doubt that the goal is achievable, and the opportunity to explain what they would be looking to do in their next troubleshooting on site. They want to make sure all the air is getting out of the system, but they already changed all 6 radiator vents and 2 main vents, so where else would air be getting trapped? They want to take some readings on the controls, but it seems clear to me that the system is cutting out on high pressure, as it is not achieving temp setpoint, or triggering the low water cutoff, or losing control power. And we can see the pressure rising to 2psig. Lastly, they said they could reduce the nozzle from .75gph to 0.65, which is consistent with what Ed suggested. This sounds directionally helpful, but I expected the reduction from 396 sf EDR to 288 to have more of an impact on the performance than it did, so it's hard to get a sense of what another ~10%—15% reduction will do. Anyway, we will try it so no need to guess, only to manage expectations. Nothing else they shared on the call felt particularly compelling, and tensions were high, but I felt it was important to give them every opportunity to right the problem before taking the next step.

As for the next step, a smaller boiler feels more and more like the correct answer the more we learn. It's a one pipe, counterflow system, and I read in Dan Holohan's book that it's especially important not to oversize boilers for counterflow systems. It always is, but in particular for this design. I also learned that when the mains are insulated, as they are here, a pickup factor of 33% may be generous, and 20% is suggested as being adequate. So the 288 net (after downfiring) would have given us 383 gross when we probably need something like 185*1.2 = 222 gross. All in all we may still be 72% oversized, and if we're lucky we will get down to 50% after the smaller nozzle goes in.

With something like the EG30 suggested by EBEBERATT, we would 260 gross compared to 222, or 17% over. This feels spot on.

Stepping back, the distinction between matching the radiation to the building's heat loss vs matching the boiler capacity to the connected radiation is clear. I can see how that might have gotten confusing but I'm with you. We're not changing radiators, they are being treated as part of the house. And yes, they are probably a bit oversized as is often the case.

Lastly, my position aligns with 109A, that the selection was not correct and we should not bear the burden of the replacement. And Ed's point is also valid, would we really want the same company to do the swap? Trust and incentives are broken down. That's probably outside the scope of this technical thread. But I have enough conviction from the discussion here to take it in the right direction.

Let me know if I missed anything glaring. I'll share an update if there are any eureka moments on site next week. Thanks again!

0 -

Update:

During the last site visit, we learned about cycle guard which is a safety control that automatically shuts the burner off every 15 minutes for a brief “probing” period to ensure stable water level and prevent dangerous foaming or false low-water readings, as many of you may know. So if we ignore the first 2 brief down periods, the initial run is truly 30+ minutes, which is a much better story than 15! We were delighted to learn this, though it is a bit disturbing that we talked past each other for 2 months without this being identified. There are only so many ways to turn off the boiler, and this one was missed. It was not obvious to me, but I understand why it's there now. I was operating under the assumption that it was hitting the pressure cut out in only 15 minutes. I should have noticed the timing was too consistent to be a coincidence, oh well!

We still have the issue of short cycling after the first time the unit goes off on high pressure, but we are more open to using a timer and allowing the system to release its stored energy before making another call to the boiler. Curious if anyone has recommendations on an appropriate delay setting. I'm thinking the final answer will be in the 10-20 minute range, but interested in the group's thoughts. If we go too long, recovery time will extend and it will take longer to get to the setpoint. Too short and we run a greater number of cycles (nuisance, wear and tear). Maybe there is a radiator surface temperature threshold we could look at, like when it drops below 150F (we can take the average of a few radiators) then go ahead and make the boiler call at that point. Or we could just pick a number and move on!

They also proposed replacing the pressuretrol with a vaporstat which I thought was a fantastic idea. We can run at ~14oz + 6oz rather than 2psi - 0.5psi as we are now. I noticed the gauge was getting up near 3psi so I don't trust the pressuretrol operating so far on the low end of its range.

In summary, the good news for us and the installer is that we won't have to rip the unit out, and while we can all agree it is probably still oversized by a fair amount, this approach should get it to control reasonably well without a major loss in efficiency, and the time to first steam will be a bit less than it would be with a 200EDR boiler. And my family member is happy to avoid the gas conversion which was their original preference.

0 -

If you use a timer strategy, you will have to figure out what delay time is best for your system. I'd make the delay as short as possible, but still minimize the short cycling issue. It may only need a few minutes.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I'm using 8 minutes. After that much time a decent amount of heat has been given up by the radiators, but they are still warm to hot so there is a feeling of "the room is still being heated".

But do note this: When it gets close to design temperature (mine is 0F I think) as we saw the last couple weeks, sometimes the system can't hold the thermostat at a temperature of around 70F

So in the morning, even with no setback, due to the cold overnight temps, the house might be 68F. When it warms up to 10-20F during the day, the system is able to catch back up.

I don't mind this because I am happy that my system is running a nice low pressure all the time, but my wife isn't the biggest fan. The two heated floors help her mood tremendously though.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@109A_5 OK, thanks for the guidance.

@ethicalpaul Great data point thank you. Makes perfect sense about the setback. I suppose you could shorten your delay, but it sounds perfect for overnight anyway. Like an externally-driven setback as opposed to a user-defined setback. And it's only on those rare design days anyway. Heated floors sound awesome, nice compromise you found! :)

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements