Best Of

Re: Heatnglow TownsendII-LP

Some Heat & Glo products are designed for non-vented (vent-free) applications. In those models, the flame input is typically limited — often under 30,000 BTU/hr — because vent-free appliances must meet strict combustion and safety standards.

What model number is your gas log?

If you have a vent-free model, it can generally be installed in a vented fireplace behind glass doors, but it is specifically engineered to operate without a chimney draft. In order to be approved as a vent-free gas appliance, it must include a safety device that shuts down the burner if oxygen levels in the room drop below a safe threshold.

That safety device is called an Oxygen Depletion Sensor (ODS).

The ODS system typically consists of a precisely engineered pilot burner and a carefully calibrated orifice. It works in combination with a thermocouple (or thermopile). As the oxygen level in the room decreases, the pilot flame characteristics change — it becomes smaller and lifts slightly off the burner. When the flame can no longer properly heat the thermocouple, the millivolt signal drops, the gas valve closes, and the appliance shuts down.

It does not wait until all breathable oxygen is consumed. The shutdown occurs well before dangerous oxygen deprivation levels are reached. It is a preventive safety measure.

Given the location of your gas log inside the fireplace — particularly if glass doors are closed or airflow is restricted — is it possible that the oxygen level around the burner is dropping during a 30-minute burn? If so, the ODS may simply be doing exactly what it was designed to do.

Re: Equalizer

steam has no trouble going in 2 directions. the issue is that any water that is with that steam has no place to go but up the riser with the steam. that is why the equalizer is beyond the tee going up to the mains, any water with the steam having a higher mass than the water will tend to continue moving horizontally toward the equalizer rather than up the tee to the main with the steam. the height of the riser to the main and to the header both also help let the water fall out of the steam.

if the water quality is good it isn't likely to be a problem. while the system is forst operating and oil from the boiler and piping is causing the water to surge, it will be more tempremental until you get the oil out.

Re: Equalizer

I mostly did commercial. The boiler headers were all 4" and up. 5", 6" 8" etc.

In my 46 years in the business, I have NEVER seen a boiler header pitched. Totally ridiculous. you don't pitch 8" welded pipe.

Plus pitching the header looks like crap.

I really don't know how we survived all these years with no drop headers and no pitched headers

Re: Anode rod aluminum vs. magnesium

Hi, If you promise never to cook with or drink the hot water, and always rinse it from the faucet before using cold water, than it might be okay. Aluminum is a neurotoxin and I'd always remove those rods and replace with magnesium when servicing water heaters. There is an old document written by a doctor in the archives here, which goes into much more detail.

Yours, Larry

Re: Hydronic closed loop question

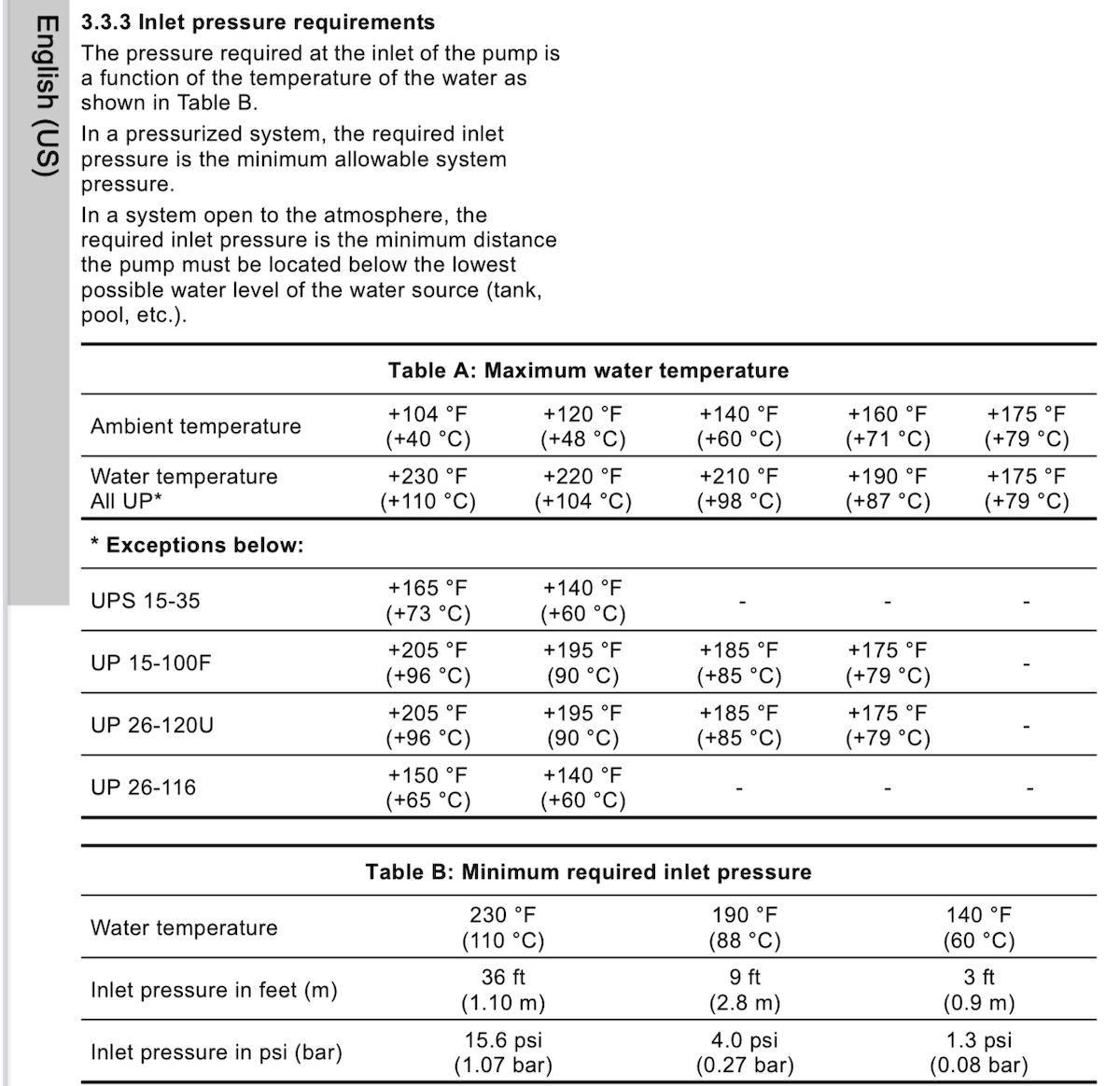

A similar condition happens on unpressurized wood boilers OWF. The circs depend on a temperature pressure relationship to prevent cavitation. Here are Grundfos recommendations.

So with 190°F water you would want 4 psi. Higher temperatures require higher pressure. Notice the big jump at 230° water, 15.6 psi!

To get 4 psi you would need a water lever about 9' above the circ intake.

hot_rod

hot_rod

Re: Steam System sizing

One reason they heated the colder outside air was it was denser which improved circulation.

Re: Replacing wet return on 1-pipe steam system

not sure what blue block is but rtv or hardening sealer or ball wicking should do it, there is little pressure there.

Re: Replacing wet return on 1-pipe steam system

Clean it with alcohol, spray the nipple that is going in there with dry lube, let it dry, put a noodle of JB Weld Epoxy putty in there, screw in the nipple about 1 or 2 turns past the finger tight point (premarked on both pipes), let it cure and disassemble. That's what I'd do because that is a pretty deep cut.