Best Of

Re: Thermostat for new high efficiency boiler with ODR

Just read that you have infloor heat, boosting the temp for in floor can be tricky, its do-able but you run the risk of floor damage. Either way the floor will take a long time to heat back up. Honestly If I was leaving for the weekend I would say its not worth it at all to turn the heat down on a radiant floor. I would need to be leaving for over a week personally, and then I would still just turn the temp up on a wifi stat about 2 days before I come home. There is no "quickly raise the temperature" or lower the temperature, with most radiant floors, and the ones I am familiar with that are quicker response all use high temp anyway

Leaving the rest of what I wrote here for reference in case it helps someone

You would need a communicating system. thermostats, at least typical variety, do not communicate with your appliance, they are a switch.

Most condensing boilers have some type of ramp delay/boost feature, or a wifi connection that would allow you to boost the heating curve right from your smart phone. ramp delay would increase temperature if the call for heat last a certain amount of time

The other option would be to abandon the internal boiler ODR, use a third party controller with a communicating thermostat (indoor reset) and you would need to control the boiler temp either through a 0-10v signal if it accepts one, or a mixing valve. the mixing valve would lower your efficiency as the boiler would always fire at a higher temp

Some boilers offer a room feedback sensor that provides indoor reset technology to work in tandem with outdoor reset technology (NTI is one, at least the newer models)

I personally recommend for the easiest path of least resistance, either a wifi stat which you turn up before coming home. A boiler app if yours offer one so you can control the curve from your phone when you get home. Or what I do which is to make about 5 button presses on my boiler to turn the curve up, and then turn it back down the next day.

Re: water level after heating cycle

Ed is right. But assume all is built correct, or is not compromised in any way, the system has three states of operation. All on, all off and in between. Off and steady on could show a stabilized level but be different. But there is a time lag between startup steady, to shut down cold. In between is always changing. Given all of this the question asks, what is normal for this? Here is where the most important diagnostic tool is needed that is almost never done. A complete operation report recording all those little details. With this, we can compare new installed to what we see currently. But this will never be done except maybe by Government and a lab. We'd be lucky to even get a combustion test. But its not just design, there are changes in combustion rate and design that can affect steam dynamics. Is it a rolling boil, or a simmer? Does it cool fast or slow? Just changing any component like a boiler, burner or even a few radiators can make a change. Some tweaking is always needed in a new install. So who will set the settings, size the devices, this all will matter. It is why diagnosticians will always be in demand. If we really want to know and spend the coin to find out. But my experience is hearing, "Its working don't touch it!" And then the boiler room door closes and everything changes again.

Lance

Lance

Re: main vent not closing

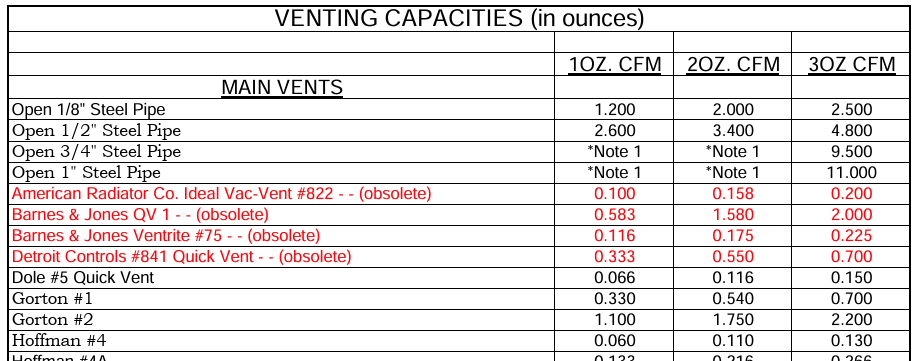

I don't know what the box says, but Gerry Gill and Steve Pajek's tests show otherwise.

https://heatinghelp.com/assets/documents/Balancing-Steam-Systems-Using-a-Vent-Capacity-Chart-1.pdf

ChrisJ

ChrisJ

Re: CGA weil mclain

Unfortunately, the CGAs are having issues with the left cast-iron sections leaking. On cold fires, water leaks directly on to the roll-out. We were forced to change five of them out under warranty. All within a year old.

Re: ChatGPT, AI

@GGross It was a few weeks ago. I don't remember the exact words but it was about a type of plumbing drainage issue that code requirements in my area did not allow for. I remember it was way off topic.

The problem for me is how impressionable some one so young, or any age can be, and take the word of ChatGBT with out questioning it.

Intplm.

Intplm.

Re: ChatGPT, AI

I have user ChatGPT to edit some of my letters to make them sound either more official, or kinder, or friendlier. And that seems to work. Take an angry response to an email that you would like to send and have ChatGPT look at it and ask ChatGPT to make this sound friendly, and you get a great response that gives all the necessary information to that dummy and won't rub the recipient the wrong way.

Example:

What I want to send:

What the f are you thinking, you idiot, you can not put the check in the same envelope with the request. can't you follow instructions? it clearly states that you submit the request then wait for the response before you send the check. how stupid can you be? Wait for the response and then send the stupid check in the envelope provided for checks. Will you ever learn you moron? I am mailing your check back and maybe I might think about forwarding your request to the proper channel

What ChatGPT sent:

Hello,

I want to clarify an issue with the materials you sent.

The instructions require that the request be submitted first, and that you wait for a response before sending a check. The check should only be mailed after approval, using the envelope specifically provided for payments. Including the check with the initial request does not follow the required process.

Because of this, I will be returning your check to you. Once you receive a response to your request, you may then send the check in the appropriate envelope as directed.

Please be sure to follow the instructions carefully going forward, as this helps avoid delays and additional handling.

Thank you for your attention to this matter.

Regards,

I think AI is great for this stuff. It is what it is made for and has clearly learned how to communicate with idiots so they don't get their nose out of joint.

When it comes to technical topics, however, I’ve noticed that some of my own responses about heating equipment have been used by ChatGPT to answer questions for others. The system is constantly learning, but that creates a problem.

ChatGPT gathers information from many contributors across many websites, and it does not reliably distinguish between correct and incorrect answers. As a result, inaccurate information can be treated the same as accurate information and repeated as part of its responses.

Unless errors are clearly pointed out and corrected, ChatGPT may continue to absorb both correct and incorrect explanations as if they are equally valid.

So YES it is learning and it is not always correct.

Re: ChatGPT, AI

AI is very powerful, but you have to know how to use it and it's limitations. If you ask AI a vague question, you will get a vague response - and hallucinations are something you need to be mindful of. Also consider that a lot of data available to AI might not be accurate.

e.g. if you ask AI where you should mount a circulator, AI is going to find a bunch of forum posts where people insist the circulator mounted on the boiler return.

If you ask the same question with a bit more context and tell AI to limit its sources to professional heating publications and boiler installation manuals, you will probably get a different result. The way you instruct AI is called the "Prompt", and the way you do it is critical to the result.

I took a free class called "Google AI Essentials" and I thought it was well worth my time. If nothing else, you can use AI to really speed up the creation of documents that are very similar, and it can be a big help with writing professional communications.

Re: Understanding Plumbing Licensing Suffolk/Nassau

Knowledge and pride in craftsmanship are mutually exclusive. Knowledge of a subject (Continuing Education) keeps one out of big trouble. Pride in craftsmanship is a personal choice of the installer. I have worked with brilliant plumbers and heating guys that are happy doing work with mediocre and minimal pride.

Conversely, I have worked with guys of average intelligence and plumbing IQ that go above and beyond to put out neat, high qaulity work. Makes sense? Mad Dog