Help with Goodman GSXC16 Error code 04

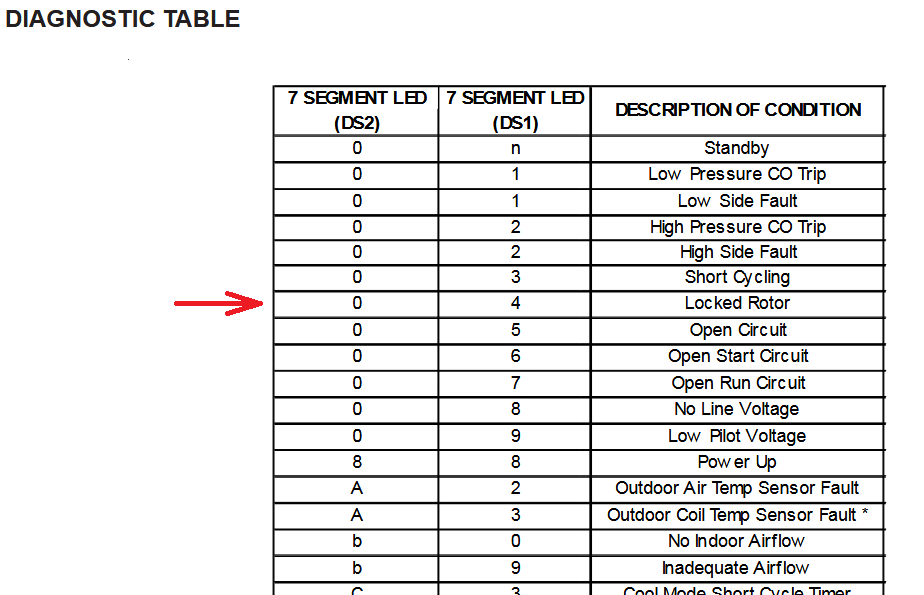

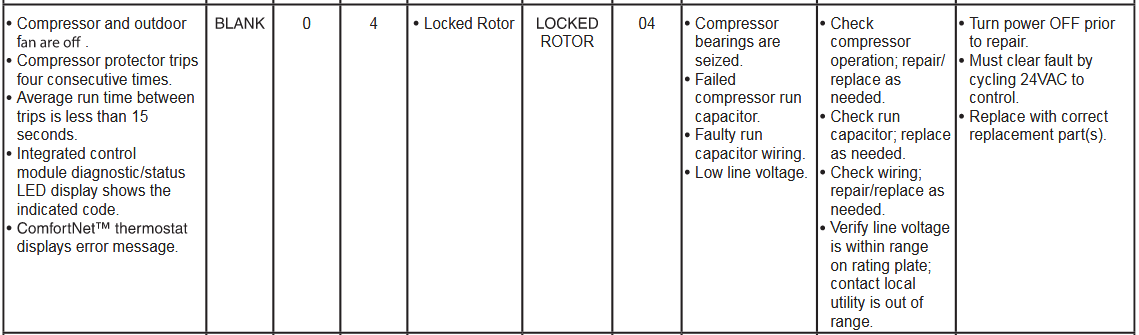

3 years ago my son installed a new Goodman GSXC16024 that has been working fine for the first two summers, and the beginning of this summer. About 3 weeks ago there was no AC and he found error code 04 on the condensing unit PCB display. I wanted to look up the technical documents for this unit and I am unable to find the IO manual or Trouble shooting info online. Does anyone here (other than @pecmsg) have info that might help? Is there a technical bulletin on this particular issue?

Cycling the 220 vac off to the outdoor unit and the indoor unit will bring the system back to operation. It will operate for several days and the stop. Now it is becoming more frequent.

There was a discussion on this same issue in 2021 on HVACTechTalk, but I did not see any resolution on that thread.

I think that he may need to call goodman tech support when he is at the equipment in order to get the answers, but I seem to be his GoTo tech support person on all things automotive, Oil Heat and HVAC, so that is why I'm asking

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

Comments

-

-

Goodman uses the CoreSense module.

0 -

The dates are interesting and this unit may be much newer so it may be different than either of these documents posted.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Check easy things first. Electrical connections, capacitors, start components.

If those are all good, let the system cool off completely. Reset by cycling power. Measure the suction temp and discharge temp at the compressor, as well as the amp draw/voltage.

If the superheat across the compressor is high and amp draw low, you aren't moving enough refrigerant to cool the compressor and it will trip the common internal overload after a longer run time. That can come from low refrigerant, high head pressure ( dirty condenser, blockage or malfunctioning fan).

If the compressor superheat is low and the amp draw is high, that would mean it's pumping to much gas and overloading the motor to the point of tripping the internal overload. This scenario would be most common in a horizontal right airhandler application where the txv bulb is in the return Airstream and not properly insulated or loose from the pipe.

And lastly, it could be a bad compressor.

2 -

-

-

Capacitance measured is 34.4 uf, capacitance rated is 35.0 uf. is that within 6% plus or minus.

Testing that possibility. first step is to re do all the wiring connections. Seems that all the failures happen around 3 PM when the setback ends and the system starts to recover. If redressing the wiring does not fix the problem, then removing the setback to see if that is the cause of the problem. I don't want to change too many things all at once. Then we won't know what one of the many fixes worked.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I've dealt with this a lot. In my experience the causes are either a dirty condenser coil or the system needs a good 5-2-1 hard start kit installed. Goodman and Amana units really need to have the hail guards removed to be able to clean the coil effectively. And if the system has TXV I would definitely check the superheat. 3/4 of them need some adjustment to set the superheat correctly.

1 -

I'd probably put a soft starter on it instead of a hard start if it really has a power issue that keeps it from starting sometimes.

Does it have a time delay in the condenser? Is it possible something happens control wise trying to start it before it has equalized under some condition?

0 -

Another thing to check is if the system has a positive shutoff TXV to prevent refrigerant migration during the off cycle. If it is designed that way and the txv is slowly leaking, you could have liquid migrating to the suction side of the compressor. That would overload it on startup. You need to measure the inrush current after a long off cycle to see if this is when the trips occur. If the inrush current is to high, look up the OEM start components listed by the manufacturer (Copeland) and install those.

You really need to get guages on this thing as well. Wait to long to get it fixed and there's a good chance you'll loose the compressor.

0 -

How does that work? Isn't the txv going to go wide open trying to bring the superheat down when there is no supply of liquid refrigerant?

0 -

No because the pressure on the suction side goes up. When pressure is equalized the txv is shut tight.

0 -

I installed a Goodman Dsxc18 a few years ago that ran fine for two years and then started alarming out with I think the same locked rotor error

Voltage as far as I know was always fine and the system was running perfect. I had set the superheat when I installed it and it was still fine. Replaced the cap and it still happened randomly. From what I recall the solution was a hardstart and I think there's comments about certain compressors from 2022? being borderline.

It's been running fine with the hardstart for a year now.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Hard starts are fine-ish. As long as you compare the actual specs on the capacitor and relay to what the manufacture has designed for. That's all they are, a start cap and pot relay in 1 container. The ratings they give them, like 1-5 tons, ect. are garbage.

The compressors are not borderline. The HVAC manufacturer puts them in a borderline envirnment. The Copeland data sheet will tell you exactly what components to use dependant on application.

I recently had to replace a 3 ton compressor out of a York HP. It was an electrical burnout out. As I did my research to determine cause, I found the generic hardstart kit on it had over twice the capacitance allowed by copeland for that compressor. Unit was only like 5 yrs old.

1 -

like i said earlier, i'd go with a soft starter rather than a herd start.

0 -

Compressors have a high starting torque requirement. Also frequent cycling. Using a voltage limiting soft start on compressors is extremely risky and requires careful design. In most cases should be avoided altogether IMO.

0 -

As was explained to me, apparently the larger the capacitor the more current it can pass but the less phase shift you get. A hard start just adds another capacitor to give the start winding more current. Apparently it needs to be pulled out because you end up with less phase shift so the motor runs worse. I guess it's a balancing act to get enough current with the right, or as close as you can to the right amount of phase shift.

It's not going to pull any more current starting than it wants just because you add capacitance regardless of it's name. It should probably be called an easy start, but I guess it's name comes from being used on motors that have a hard time starting.

This info was given to me by an engineer with a PhD in electrical engineering about 8 years ago, so I might remember slightly off.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

-

"In a capacitor, the current leads the voltage by 90 degrees. When an AC voltage is applied, the capacitor charges and discharges in response to the changing voltage. As the voltage rises, the capacitor begins to charge, allowing current to flow immediately. However, the voltage across the capacitor builds up more slowly, reaching its peak after the current has already started flowing. Conversely, when the voltage decreases, the capacitor discharges, pushing current out before the voltage drops fully. This creates a phase shift where the current waveform precedes the voltage waveform by a quarter cycle (90 degrees) in an ideal capacitor."

The angle of the phase shift is determined by the interaction of the winding resistance, capacitance, and hertz. This allows the start cap to dump current into the start winding until the voltage reaches the preset level on the start relay. The start relay then drops out the start cap and leaves the run cap in the circuit.

So if the the start cap is to large, it will dump more current than the start winding is rated for before the voltage reaches the required drop out level.

2 -

Update. My son is working full time as a welder, so he does the family trade as a side gig. Since everyone is asking for the fall tune up of their oil burners and other service calls as needed, he has been busy after work and on weekends. He has just finished looking at just about every possibility all of you have been so helpful contributing, but it has taken some time to get there.

Finally contacted Goodman Tech support on Tuesday, and they asked him to get a megger and test the compressor windings. (locked rotor and stuff like that may have caused winding insulation deterioration). Since I sold the business and no longer have a megger, he needed to borrow one from the guy I sold mine to. That test indicated that the compressor is just fine with over 1000 megs. (anything less than 700, Goodman would have condemned the compressor). So, Goodman told him to get a new circuit board under warranty. And just so happens that the counterman from the supply house where he purchased the equipment stopped by for a beer and to see how Ed Jr. was making out, and he heard the Goodman tech support guy tell him that. Case number and all!

So on Monday, there will be an order for a replacement board placed if they don't have any in stock.

Future updates to follow. Thanks for all the help everyone. Since this is newer technology on this compressor, I will keep you all updated on the progress. As of now the 04 code is a daily occurrence.

May be related to this issue:

The lights have been dimming on occasion when two appliances are operated at the same time, like the washing machine and the garbage disposal. and the Comcast Cable repairman has also needed to come look ar some of the reasons for poor performance of the cable and internet. His findings have indicated that some of the components having to do with the cable were showing signs of partial failure. although there was no actual "fried cable" He said top call the electric company and tell them the the cable guy (Not Larry) said he had to replace a fried cable and that will get them out to do some testing for electrical problems.

The electric company did diagnose a problem that was effecting Ed's home and several customers further down the main. There was a work crew that spend most of the night, in to the wee hours of the morning working on the underground electrical service lines. they were gone bu the morning when he went to work. That evenoing when he came home he did some testing of appliances by operating several appliances at the same time that were known to cause the dimming lights. The problem with the "Dirty Electric" was gone. no lights dimming anymore. Perhaps the electrical problem was playing havoc with the software chips and diodes in the circuit board of the Goodman Equipment. ????

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

I agree with @mattmia2 a possible bad neutral (don't tell Goodman)

I would clamp an amprobe on the underground water line (if its metal) and also on the grounding electrode conductor the bare wire leaving the panel and going to the water pipe or ground rods etc..

If the neutral is bad or compromised the neutral current will try to get back to the source (transformer) by any means and on parallel paths like:

Ground rods

water pipes (if metal)

grounded cable wire

Underground gas pipe (if it has a path)

Turn on a bunch of loads in the house. Take an amprobe and check load on L1 and L2 then neutral and grounds.

The neutral carries the imbalance. 30 amps on L1 and 20 amps on L2 neutral should be 30-20=10amps.

But if neutral is compromised it could go through ground. A bad neutral will give you funny voltages maybe 130 on one leg to N and 110 on the other leg to N. And a disconnected N is real bad puts appliances in a 240 volt series circuit

0 -

If it is burning the shield of the coax then it has to be a bad neutral somewhere and either a nonmetallic water service or main or the service bond to a metallic water main and service is missing.

0 -

Why would Goodman care about a bad neutral?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Does that AC have a hard start kit currently installed?? Or, if there is one, is the potential relay working? Sorry if I missed that info.

Just an FYI, that unit has to have a hard start kit or you will get that exact error code. At the time that unit was manufactured I don't believe they came with a hard start, they had to be field installed. We learned this lesson the hard way. I can't remember the exact date, but Goodman did start sending them out with "factory installed" hard start kits. I believe there was a bulletin issued from the factory about this.

If I were you I'd skip the board for now and get a hard start kit like the 5-2-1 on it.

0 -

Probably to deny a warranty claim.

0 -

What would be the reasoning behind that on a unit that doesn't use the neutral (center tap of transformer on the pole) ?

I'm not saying they wouldn't, but I am curious how they'd justify it.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

The control xfmr does.

0 -

Depends.

My airhandler, as most is 240v.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Bad neutral with unequal loads on each leg of the 240 volt supply (they are never 100% = will put the loads in series without the neutral. The voltage on each leg will be all over the place depending on the load. The 240 volt stuff will probably be ok but the 120 volt stuff (air handler if 120 or furnace) will be compromised.

0 -

All this talk about the electric service is moot. The electric company fixed the problem and now we are just waiting on the warranty replacement parts. Other neighbors on the same underground service past my son's home also experienced electrical problems and their light dimming problems have also stopped. Many problems solved. Still getting error 04. Now we will see if the replacement board will correct that problem.

I'm just giving all here an update now that I believe that the issue will be corrected as soon as the PCB in replaced. I believe that some hard to solve problems here never reach a conclusion because once it is fixed, there is no need to post anything here and we all would like to know what happened. Did the problem get fixed? Did the the equipment get replaced? Did the wrong steam piping get repiped correctly? Did the house blow up? Did the OP die in the explosion? Just wanted everyone to know that I'm still alive!🤣

Stay tuned to this channel for more updates after station identification.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

4

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements