Best Of

Re: Standby DHW Tank Question

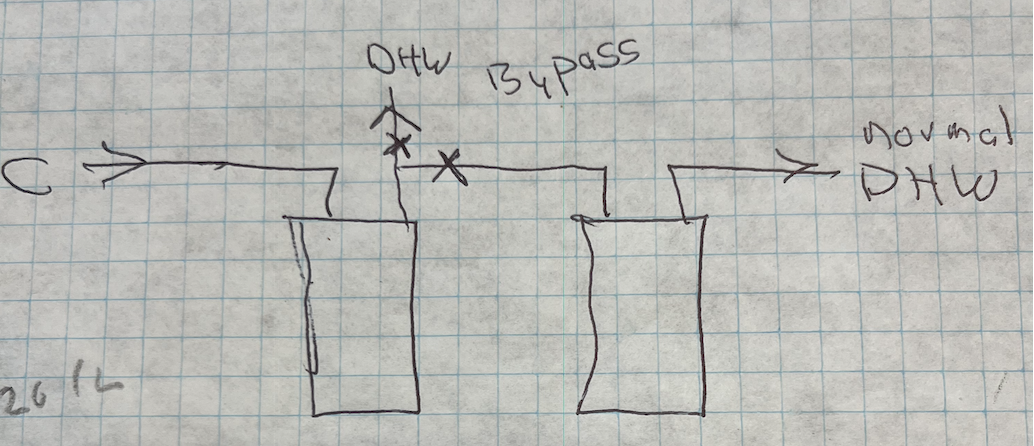

You could valve and series the tanks, so fresh water always flows through the electric tank first. If the indirect is down you could valve it off, flick on the electric tank breaker.

This also give you a small amount of pre-heat the first tank being at ambient room temperature.

hot_rod

hot_rod

Re: Honeywell Zone Valves

TThe valve is only rated for a certain differential, if you exceed that it can leak through. If the radiant loops are very long you could have enough drop over the loop to exceed that differential. Or the valve could just be bad.

Re: Weil McLain Gas Steam Boiler

" I have a brand new Weil McLain gas boiler with a Steam heating system. "

New Boiler !!! Was it ever Skimmed ?

Has this been going on since the the install ?

I'd say the boiler needs Skimming to get the manufacturing oil out of the system.

The oil coating the top of the boiler's water causes eruptions sending the water out of the boiler tripping the LWCO, possibly eventually flooding the boiler due to water being added when the system as a whole (behaving normally) really does not need more water.

Re: Combustion question

What model furnace? I had one recently. New installation no heat on a Boyertown furnace, Beckett AFG with the L head.

Combustion test beautiful. 0 smoke.

It came back in the next day no heat. There's oil on the L head. I reset and it fires right up. Combustion test numbers are different. O2 and excess air went way up. I pulled the burner. Got the T-Gauge and checked the Z dimension. The assembly was 3/4" back from specs. I set the Z and dialed it in. Haven't heard a peep since. Check the Z dimension.

HVACNUT

HVACNUT

Re: oil boiler loud drone when firing

If you open the fire inspection door and the noise stops then its combustion and draft. …

Big Ed_4

Big Ed_4

Re: oil boiler loud drone when firing

To the technical folks @epmiller — your noise description was very specific. I even went online to find a comparison tone. The frequency wasn’t an exact match, but the volume level was close to what I’m hearing.

Regarding oil burners, that is not a normal operating sound. It’s possible the noise is combustion-related. I’ve heard this before when servicing a burner that is not adjusted properly — we call it pulsation.

Pulsation occurs when the rapid expansion of combustion gases creates back pressure against the combustion air fan. That back pressure can cause incomplete combustion, which then reduces chamber pressure and allows more combustion air in. The mixture improves, combustion becomes more complete, pressure builds again — and the cycle repeats.

This expansion and contraction can occur anywhere from about 10 cycles per second to over 30 cycles per second, producing a very distinct and sometimes loud noise.

If the burner is pulsating, that is not normal and should be addressed. A qualified service technician should inspect and correct the issue.

Re: Cost to install Aprilaire 865 whole house steam humidifier with fanpack

without being there there is no way we can tell you.

pecmsg

pecmsg