Best Of

Re: F&T oddity

Collum of water 28" tall is 1 psi. So, if you had to lift the condensate 1 foot you would need the steam pressure to be .42psi" higher than the return pressure (if any).

In reality you need a little more to open the check valve and overcome any trap resistance which is minor.

Re: Small baseboard zones

I have never found any info on why 20 is used, @DanHolohan might know.

Most agree it is to make the math simple as you indicated.

Much of the rest of the world heats with panel rads, they tend to use 25- 40 ∆ in their design. Wider ∆ allows small 11 mm tube, for example, to be used for S&R piping

hot_rod

hot_rod

Re: TT Excellence DHW Tank Replacement

The hardest part was making the boiler water connections. The old tank nipples had thick walls at the nipple ends which were a nice shelf for the fiber washers to sit secure, but the new connection points didn't have that thickened end and the washers would slip into the pipe as you tightened the nut.

A properly sized brass friction ring would have kept the washer in place, but we eventually hit on some thick Viessmann washers that worked well. I know now why I never throw unused washers away.

Re: I get all the weird ones...

I second Harvey suggestion. Walk away. This sounds like a no win situation.

Re: Steam kettle trap

@Steamhead is right of course about the bucket trap

What kind of steam pressure are you running?

Most of the trap MFGS are all ok not much difference. I am partial to Watson-McDaniel but that is what our local pipe supplier sold.

If you need specific advice Tunstall in Chicopee, MA is good with traps (you can google them)

other than that

Sarco

Barnes & Jones

Hoffman

Armstrong

……….and the list goes on.

Re: How Do I Connect This Wire?

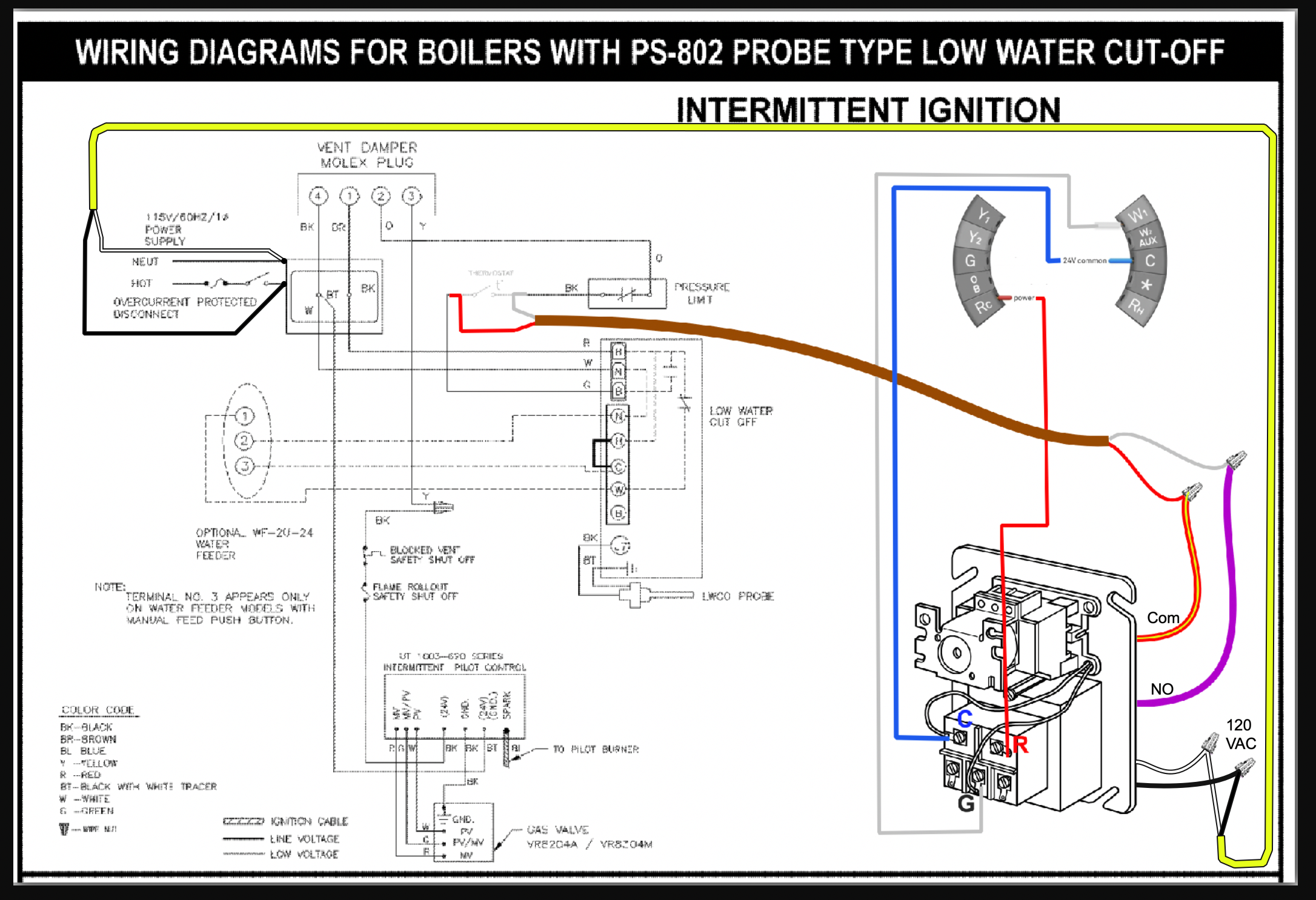

This past month I assisted several using private message and I just wanted to save the wiring diagrams so I can find then in the future.

Steam with Nest

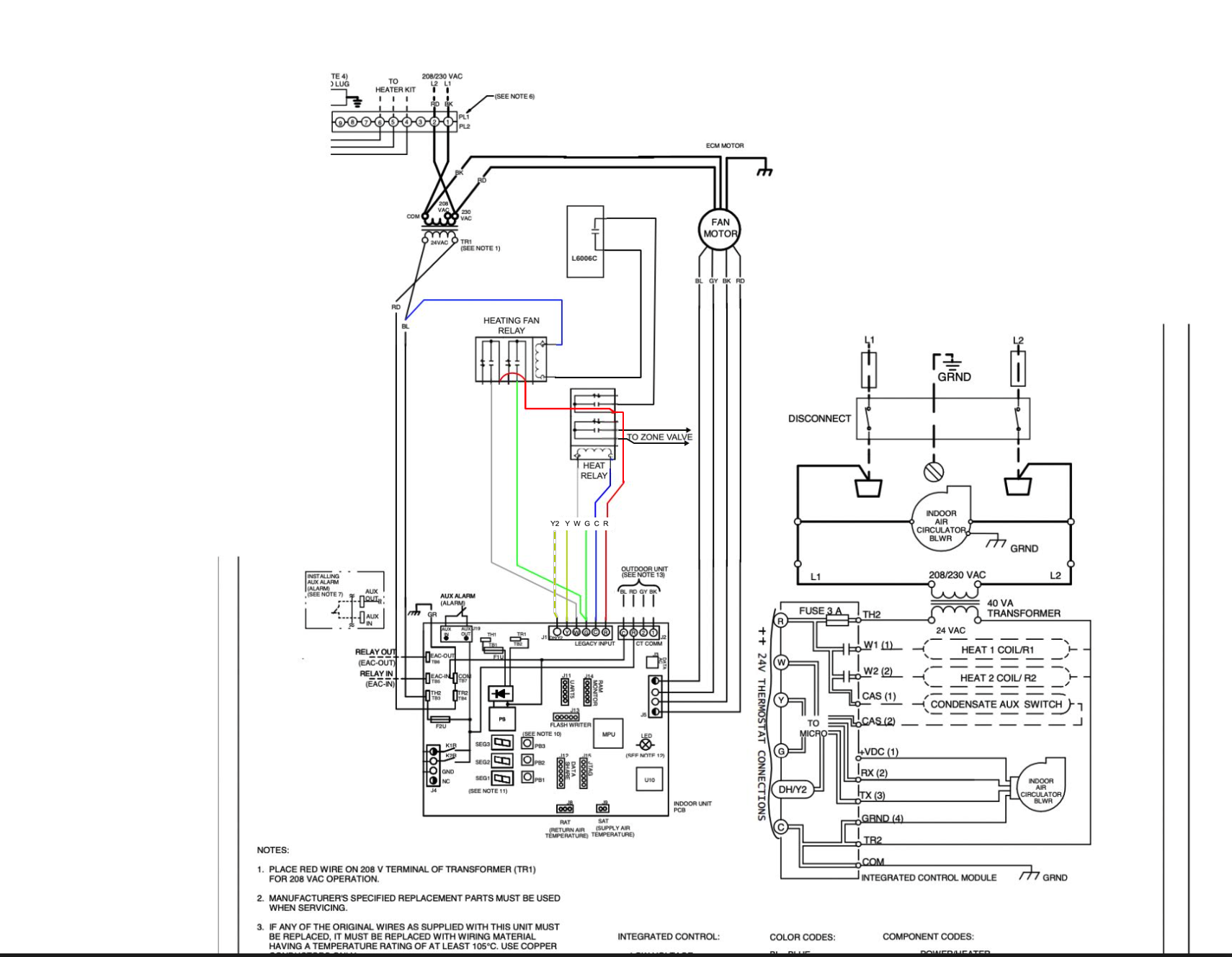

Add on Hydro coil for heat on variable speed air handler using a ZVC 404 for the zone valve control

This diagram uses the Heat Relay C an NO contacts to operate a zone on the ZVC 403. (Not powered) like an end switch.

There is a similar diagram that uses the 24v. transformer from the air handler to operate the zone valve.

Same concept but the zone valve is powered differently. we are looking to fool the variable speed fan by using the G and the W on the AHU control PCB to get both a call for heat and a call for fan simultaneously. Otherwise a call for fan only (G) may indicate that variable speed fan to operate at a 10% or 15% IAQ filtering speed which will not be enough to circulate heat from the Hydro coil to the conditioned space. Any questions? just ask me.

Re: Steam kettle trap

Might not be a bad idea to replace the bucket trap with an F&T. Bucket traps don't vent air that well, and if the air can't get out of the kettle, the steam can't get in.

Re: Near boiler piping/replacement boiler

A thermometer with a clamp type probe will give you more accurate readings.

Re: Near boiler piping/replacement boiler

Looking at the 13 minute numbers here is what I might want to look into

The temperature difference (∆T) between the supply and the return water is a little high. 29°F (almost 30° ∆T) means one of two things. Either the water is staying in the radiators too long, or a new zone just opened and is sending cold water to the boiler and mixing with the hotter return water from the previously operating zone(s). You need to have a more controlled test procedure. Perhaps have all zones calling at once, then check steady state operation after 15 minutes. That will show the real operating ∆T

11.8% CO2 with a gross stack temperature of 383.6°F does not equal 92.43%. When you look on a combustion efficiency chart for #2 heating oil and you take into consideration the NET stack temperature. (383.6° minus 70° room temperature is a net of 313.6°, for example) you will get a combustion efficiency closer to 85%

Of course you may get different number if you set your electronic instrument to "LP" or "Nat" gas. Double check your settings

Re: Radiant flow not pushing fast enough

A very hot pump could indicate an air lock, it is not moving adequate or any water to cool the motor.

hot_rod

hot_rod