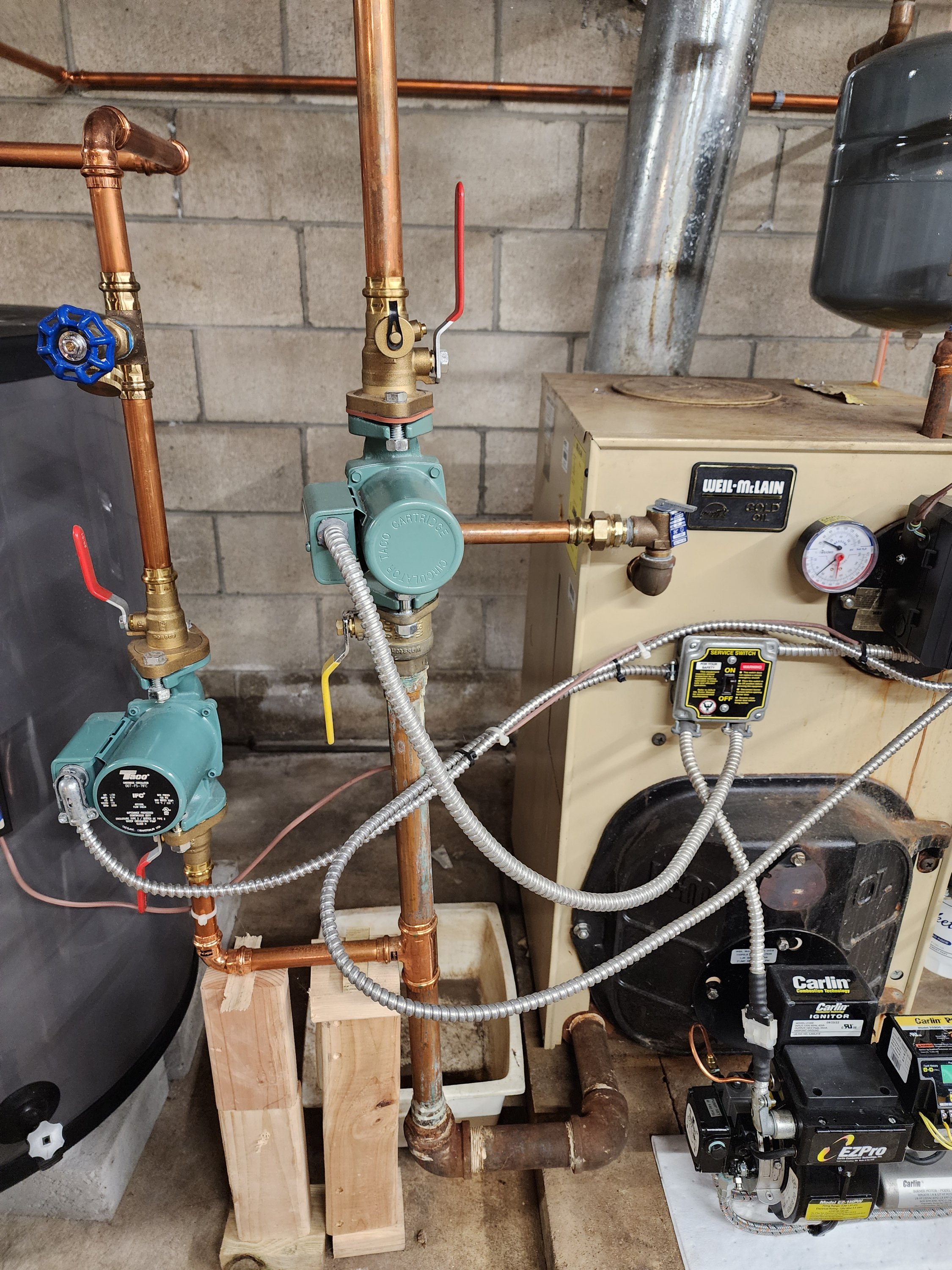

Near boiler piping/replacement boiler

Hi everyone. I have a 20 yr old Weil Mclain 5 section boiler that is oversized for my house.

I'm debating if I should replace it with a smaller boiler such as a Buderus G115WS/3, or keep this boiler and repipe it.

House has three heating zones and an indirect zone. Indirect is wired from the Taco relay to the Hydrostat 3250 using ZC/ZR, and set for indirect priority. Each zone has about 50 ft of fin tube baseboard length. Oil use is about 1,000 gallons a year. House is about 1,800 sq ft.

The existing boiler piping has some of the following issues:

- The circulators for the boiler and indirect are both on the return

- The return pipes for all heating zones connect into 1" pipe, then this goes into 1 1/4" after the circulator and into the boiler at 1 1/2"

- The supply pipe reduces from 1 1/2" into 1 1/4", goes into the spirovent and then to the manifold for the zone valves on 1" pipe. There also appears to be some sort of balancing valve in the manifold pipe before the zone valves.

I figure I have a few options:

1) leave everything as is since the boiler works, and nothing is leaking yet.

2) Replace boiler with Buderus G115WS/3, repipe supply to 1 1/4" manifold reduced to 3/4" for each zone and repipe return to 1". I would plan to still use zone valves instead of individual circulators.

3) Keep existing boiler, install circulators on supply, repipe supply to 1 1/4" manifold reduced to 3/4" for each zone and repipe return to 1 1/4" before it goes back into the boiler at 1 1/2"

I've attached some pictures of the current boiler and piping.

Thanks!

Comments

-

The answer is: 1

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el5 -

-

-

The piping size is adequate for the load you have connected. 100' of fin tube could supply about 55,000 BTU/hr. Seems like plenty for 1800 square feet? No sense in having a boiler sized larger that the fin tube can put into the space. So a 60- 75,000 BTU/hr boiler would be adequate.

If your current boiler is twice that size, 120,000 or larger it probably short cycles and runs 70% efficiency range.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Three zones with 50'/zone = 150' x ~500 BTU/ft. @ 180° = 75,000 BTU. One inch pipe is fine for that load.

If you really want to do something, pipe it primary-secondary to keep the large boiler happy.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab2 -

-

Thanks everyone for your comments and suggestions.

Some of the near boiler piping is looking like it's ready to leak, so that's why I was considering at least having a buddy who's a plumber replace some of the piping for me.

The decision I will need to make is do I just replace what pipes needs to be replaced, or dig deeper by doing stuff such as moving the circulators to the supply, remove that inline purge/balancing valve, and add a 1 1/4" supply manifold to 3/4" to feed the zone valves while the piping is being fixed.

I'm trying to avoid any unexpected breakdowns of the boiler during the winter and be proactive.

The circulators are a little sketchy to me with the way that they're piped into the return, so I put the wood under them to take the weight off of that return pipe.

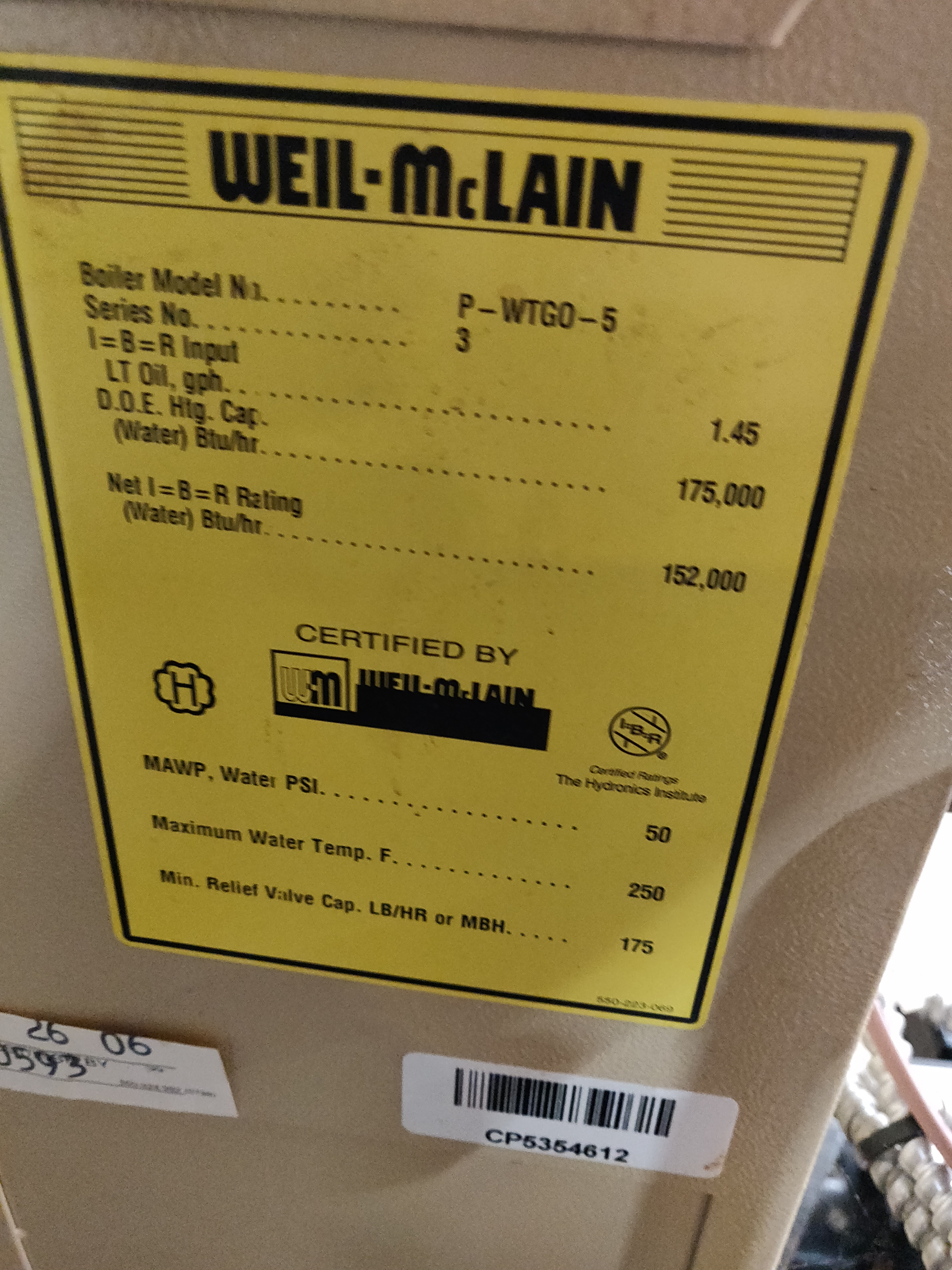

Here are the specs on the boiler:P-WTGO-5

Series no 3

I=B=R Input LT oil, gph 1.45

D.O.E Htg Cap (Water) Btu/hr 175,000

Net I=B=R Rating (Water) Btu/hr 152,000I used to use an outdoor reset with the hydrostat 3250, but the boiler would hit the lowered high limit too quickly.

I then removed the ODR, and set the high limit differential to 30 with a high limit of 175.

This got the boiler to run for about 7-8 minutes while zones are calling before hitting high limit.

The boiler also only runs for about 5 minutes when the indirect is calling before high limit is reached.

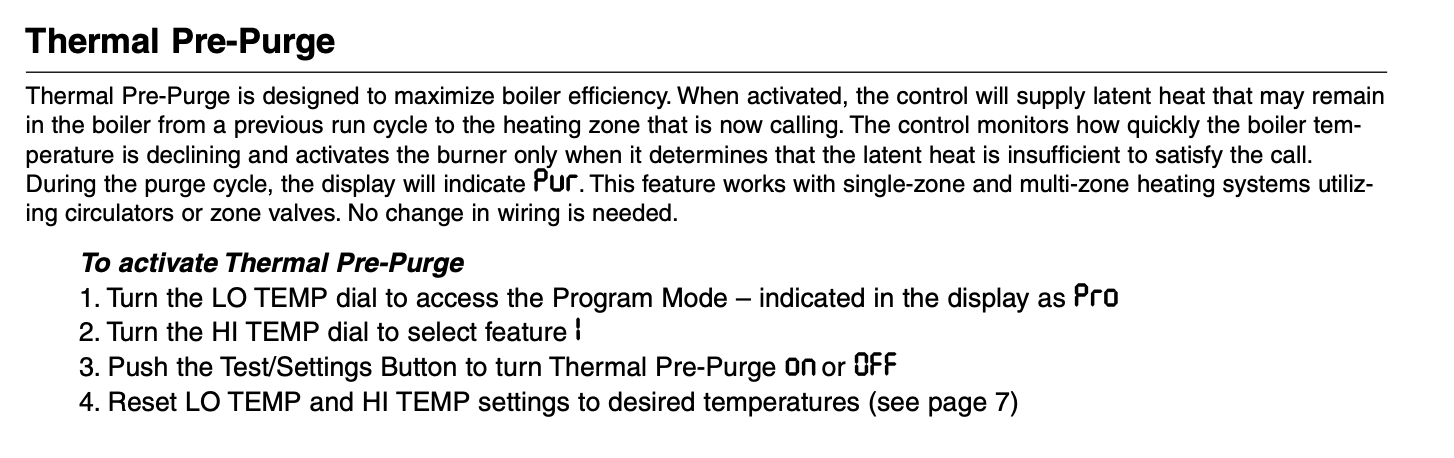

I also have thermal pre-purge enabled on the hydrostat 3250 to make use of the latent heat in the boiler.

I downsized the nozzle from a 1.25 to a 1.10

I'm burning about 1,000 gallons of oil a year.

I know that this short cycling isn't efficient, but I just want to make sure that this won't harm the boiler.

Then again, it is 20 years old and still going……

I replaced a lot of the parts on the carlin burner as well, and the boiler runs good as it is.

I'm going to see if I can find someone in CT who can come see what I have, and give me some consultation on what makes the most sense for me to do.0 -

A heat load would add some more info to the question. 1800 sq ft X 25 btu/ ft guesstimate= 45,000BTU/hr required. That is on the coldest day.

80% of the heating season the load could be in the 30,000 range. So the boiler 152,000 you have could be 3-4 maybe 5 times what you need.

While` not hydronically ideal for that boiler, the circs are not causing efficiency issues on the return, unless the system has noisy air issues?

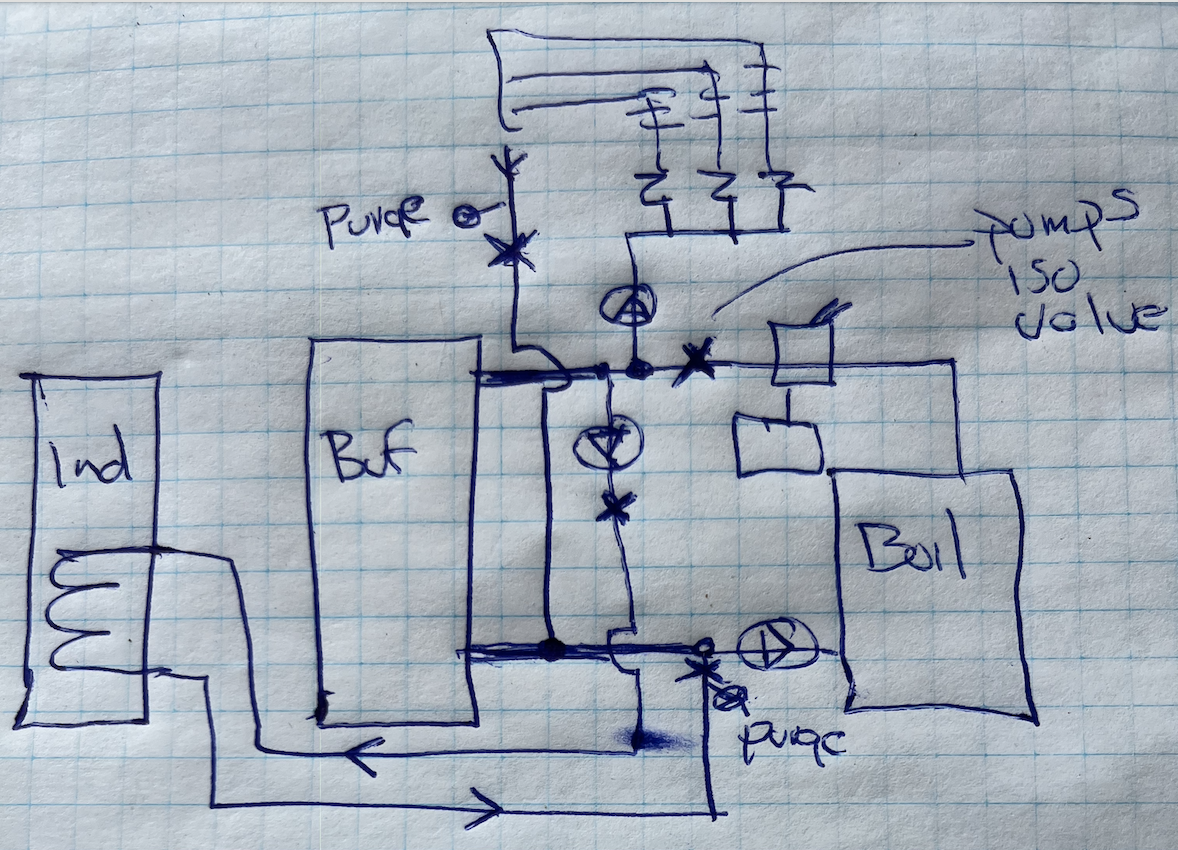

Here is a simple buffer piping, direct to load method. Indirect on priority with its own circ.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream3 -

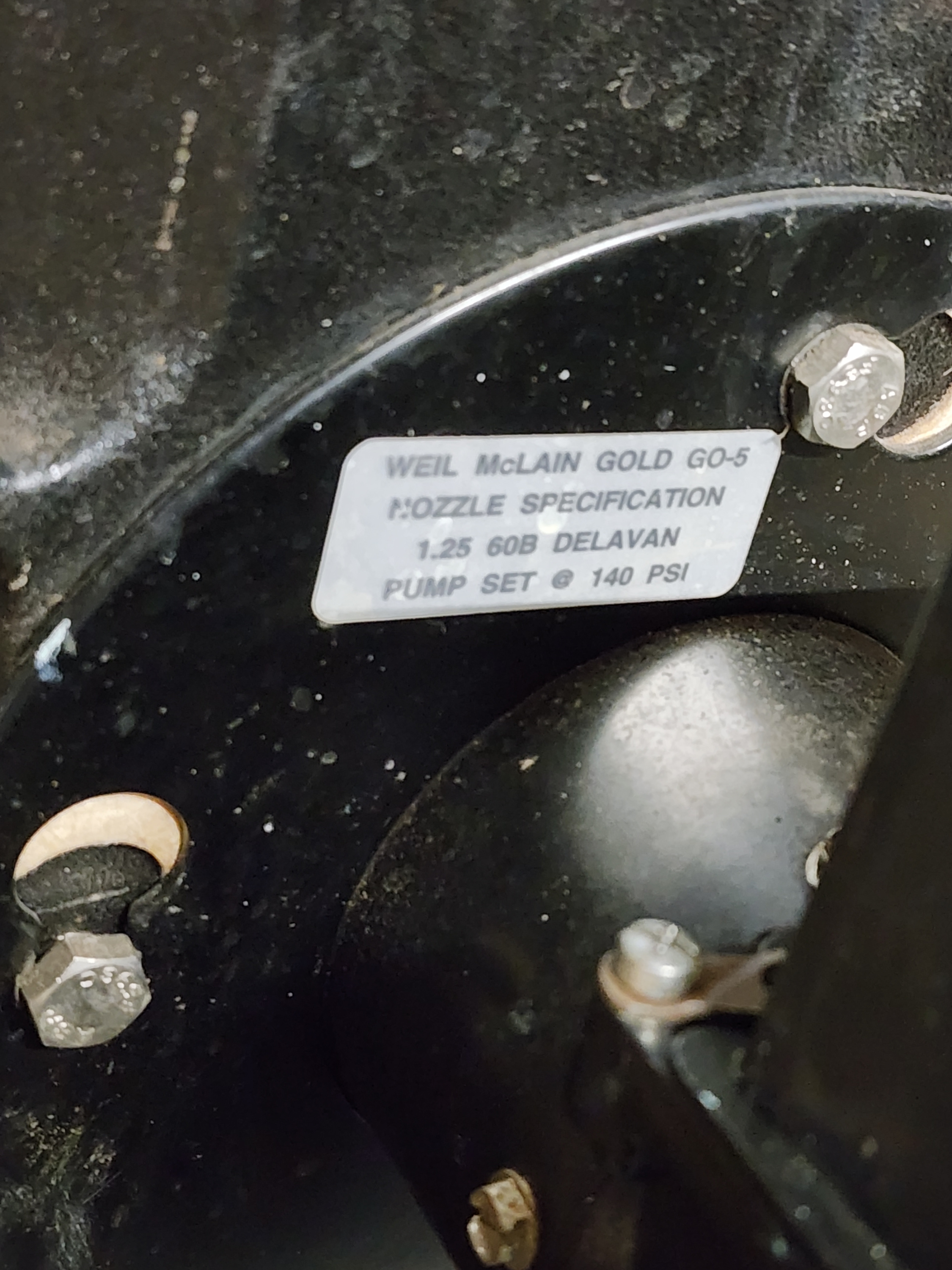

The WM WGO-5 has a rated input of 1.45 GPH. That same boiler can be fired at 1.20GPH when it has a model number of WGO-5RD. That is a 5 section boiler that comes from the factory with a oil burner nozzle of 1.00 GPH and a pump pressure setting at 145 PSI.

Weil McLain allows you to reduce the fire rate by 15% and as much as 20% on most of their boilers by adjusting the gas pressure on Gas Fired units and reduced nozzle size on Oil Fired units. I might attempt to use a .85 GPH nozzle at 45 PSI. After checking the stack temperature and other combustion test numbers, you may find that you can get good numbers with the boiler firing at 1.02 GPH which would end up with a AHRI NET output of 107K BTUh. That will bring you from 3 times too big down to twice as big as needed. That will then reduce your short cycling by 30ish%.

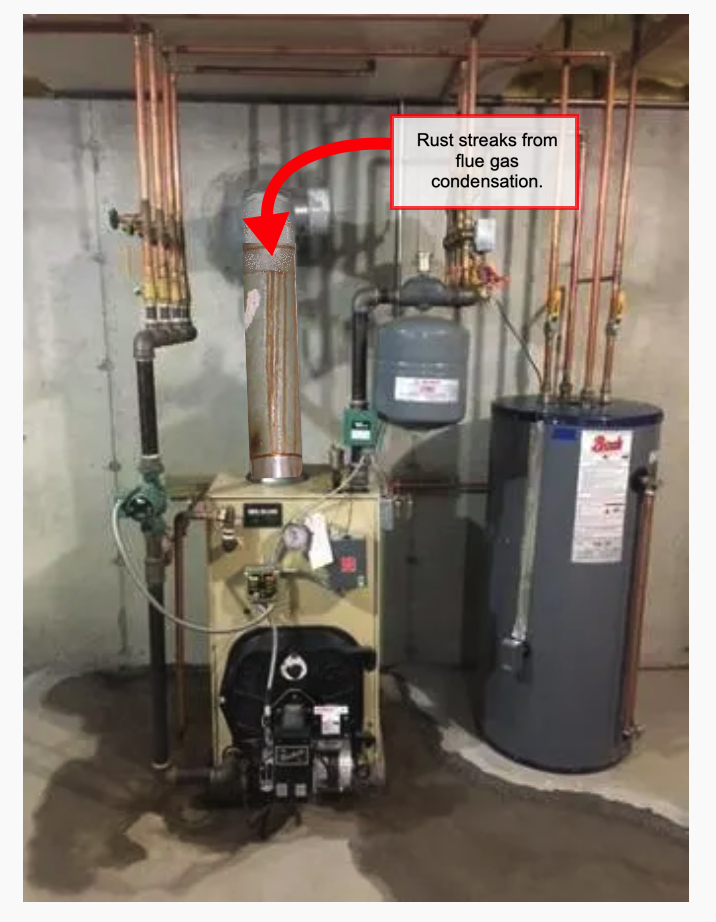

Now you may end up with flue gas condensation as a result of this change, but you may not. If you get the stack temperature to 350° within the first 3 minutes of operation, you will probably be alright. If you can't Then check the return water temperature. Since you are using Baseboard with copper tube/alum fin, you should have no problem getting return water to 140° within the first 5 minutes and the stack temperature should be 350° or more, without a problem. If you end up with Flue Gas Condensation you will notice water droplets that leak out the vent connector pipe and leave rust trails on the vent pipe in a few weeks. If you don't get that, you can leave the boiler operate at the reduced firing rate and save a little on fuel. If you do get the rust trails, then increase the fire rate to 1.1GPH by using a .90 GPH nozzle at 150 PSI.

Don't forget to paint the rust marks away with high heat aluminum or replace the vent connector pipe with new, so you can monitor for new rust streaks. You should be able to get the firing rate down enough so you can keep that oil boiler in operation for another 20 years. That will give you time to sack away enough for a new boiler later on.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thanks Ed. Here's the labels on the boiler:

Tankless coil has been disconnected and replaced with an indirect.

I installed a 1.10 60B nozzle, and set the pump to 140 psi.

I have a Carlin EZ-1HPW burner, so I would have to change the head bar if I go lower than a 1.10 nozzle.

With the 1.10 nozzle, I was originally using the Hydrostat 3250 Outdoor Reset. This led to the boiler only running for maybe 2-3 minutes since the high limit was typically only around 140-150 degrees. My stack temperatures got up to just around 350 degrees or so in the 2-3 minutes.

I disconnected the ODR, and set the high limit to 175, low limit to 135 and the differential to 30.

Once I did this, I could get a burner run time of 5-8 minutes as long as the thermostat stayed calling.

My stack temperatures also went up to around 420-450 degrees.

I did notice that I have the rust trails already on my vent pipes. However, they were there five years ago when I bought the house.Here's my combustion readings with the 1.10 nozzle and the 30 differential:

Having thermal pre-purge enabled on the hydrostat 3250 seems to also help, as this stops the boiler from firing and instead purges the latent heat in the boiler thus saving on cycles. I had to enable this in the settings as it is turned off by default.

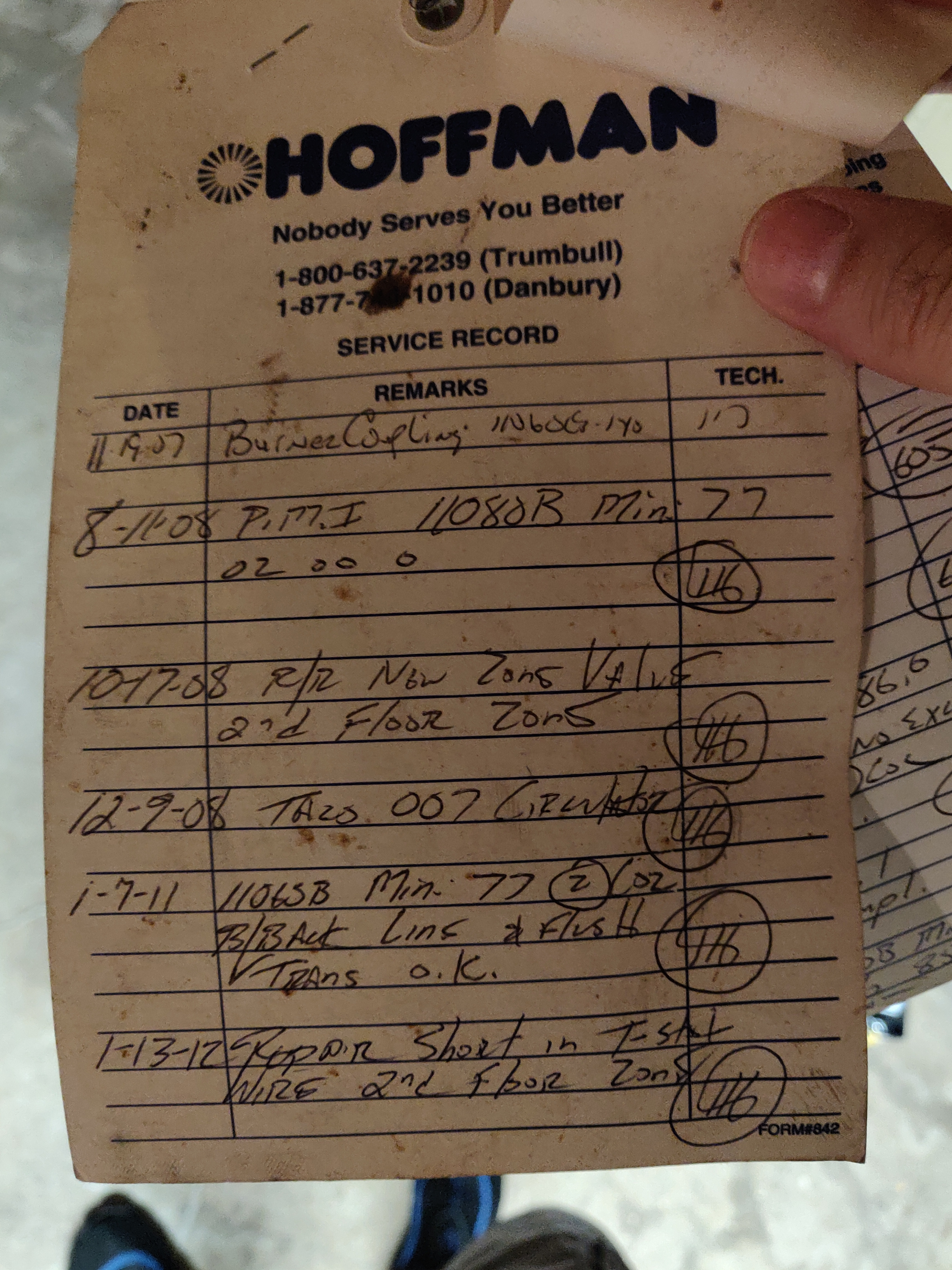

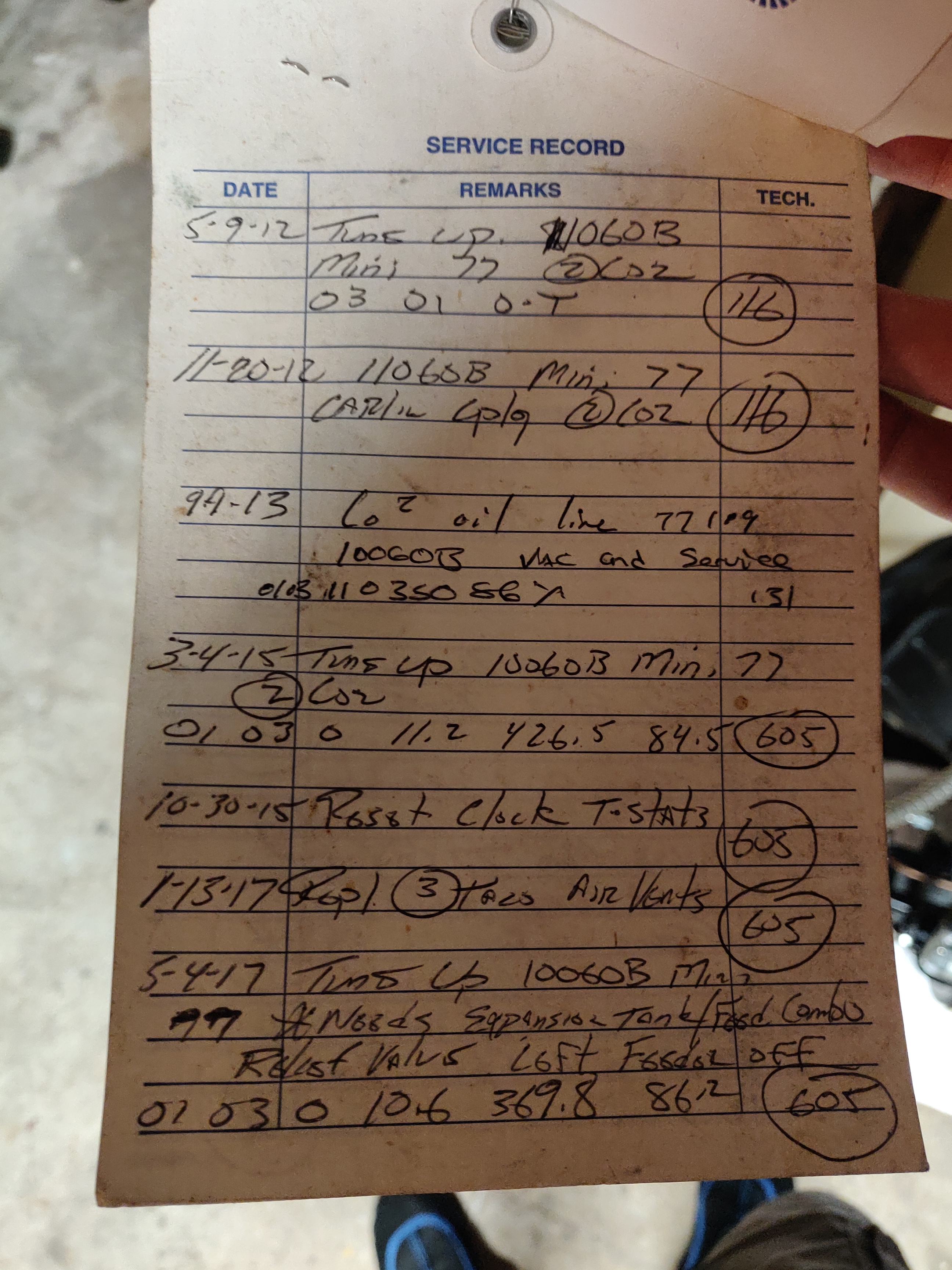

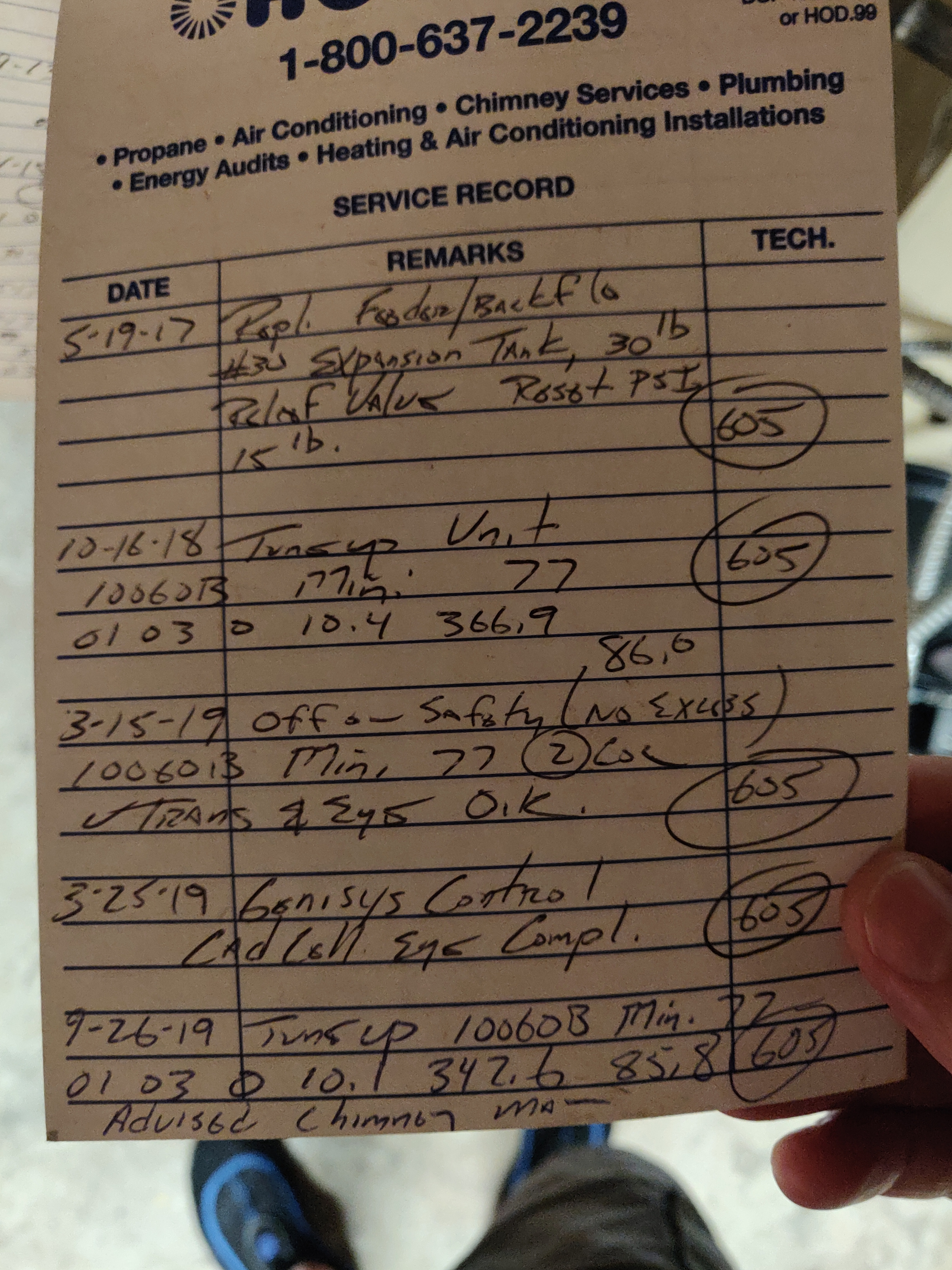

What's interesting is I just found the original service records, and it looks like this boiler was downfired with either a 1.00 and a 1.10 nozzle since new (strange since the head bar is a 1.10/1.25)

Do you think I should start off by trying a 1.00 60B nozzle, raise the pump pressure to 145 psi, and change the head bar to the .85/1.00 and see what kind of numbers I get or just go right for the .85 nozzle at 145 psi first?

Thanks!0 -

-

@katman, The Aquastat that you have, may be the Original Equipment Manufacturer (OEM) specifically designed for WM. That control may not have the ability to operate as a WGO cold start boiler. If your system was originally installed with a WGO boiler and an indirect for DHW, then the control would automatically be set for cold start operation. All that said, since you are no longer using the Coil for DHW, there is no need to maintain any minimum temperature in the boiler when there is no call for heat of call for DHW. Set the control to the lowest temperature for LOW LIMIT as possible. If you can go as low as OFF that is the best setting for your situation. that will result in the lowest fuel usage. In the future, if you ever need to replace the Aquastat Control… Use the universal model that can be set to OFF in order to convert this WTGO to cold start operation like the WGO. Except for the tankless DHW coil, the WGO and WTGO are the same boiler in every other specification.

As far as setting up the burner to fire at 1 GPH with a .85 nozzle, that is where I would start and see if you get the minimum stack temperature of 350° within 5 minutes of cold start operation. If you do, then leave it there and look for signs of flue gas condensation on the vent connector, after several weeks of operating at this lower input. You may be in good shape.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Hi, the original aquastat when it was a tankless was a Honeywell L8124A. This was changed to the hydrostat 3250 when the indirect was installed.

I can turn the low limit completely off on the 3250 - I kept it set to 135 because I thought it might be better for this boiler not to cold start it, and the gate valve on the balancing valve leaks water if the boiler temperature drops. I'm going to remove this balancing valve anyway. I'll also bump the high limit back up to 180 and keep the differential set to 30.

I'll change the head bar to a 1.00/.85 and try out the .85 nozzle at 145 psi and see what the readings are.

Do you guys think I should get a new circulator such as the Grundfos Alpha 15-58F and move it to the supply side along with the indirect circulator while I'm doing some of the piping work, or just keep the existing Taco 007 circulators on the return side?Thanks.

0 -

FYI: If you originally had a WGO boiler of the same series, the OEM control would have been the L8148 aquastat. You would not have the option to set a low limit with that control because there is no low limit. Weil McLain does not see that maintaining a minimum 135° on a cold start boiler has any advantage. Their 66 and 68 series boilers also came with the L8148 aquastats and there are many of those 35 to 50 year old cold start boilers still operating across the country. The only advantage to maintaining 135°F in your boiler is to your fuel oil supplier. They make more $$$ the more oil you burn.

As far as repiping the boiler so the circulator pumps are located on the supply side of the boiler would be: if you are experiencing air problems. If you constantly need to purge air from your system (more that once a year) because you have no heat in a zone or a radiator resulting from air in the system, then you will gain an advantage in that repipe job, if designed correctly. Otherwise, if it ain't broke don't fix it. Lacking any air issues, there is no fuel savings or thermal efficiency to be gained my redesigning the pipes. The only advantage is to eliminate air problems.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

Hi all, I just wanted to give you some updates:

I had some repiping done - supply header is now 1 1/4" and return is 1". Left the circs on the return. Added a Caleffi 573 feed valve. Set low limit to off, so boiler is now a cold start. High limit is set to 180, economy off and differential to 30. Thermal pre-purge is enabled on the hydrostat 3250.

I changed the headbar to 1.00/85 and put in a .85 nozzle at 145 psi pump pressure.

Here are some numbers:

Boiler sat overnight with no calls and dropped to 105 degrees and 10psi water pressure.

I turned on two of the three heating zones to call the boiler on.

This is with the thermostat reading 72 degree house temperature, so it's not really testing at ideal conditions.

3 minutes runtime - stack temp=340, boiler temp=122

4 minutes runtime - stack temp=350, boiler temp=137

5 minutes runtime - stack temp=358, boiler temp=149

6 minutes runtime - stack temp=359, boiler temp=147

7 minutes runtime - stack temp=356, boiler temp=135 - return pipe just getting warm, water feed at 15 psi

8 minutes runtime - stack temp=357, boiler temp=134

9 minutes runtime - stack temp=362, boiler temp=144 - return pipe warm

10 minutes runtime - stack temp=368, boiler temp=155 - baseboard temp=126

11 minutes runtime - stack temp=374, boiler temp=161 17psi water feed, return pipe hot

12 minutes runtime - stack temp=375, boiler temp=165

13 minutes runtime - stack temp=378, boiler temp=171 - baseboard temp=145

14 minutes runtime - stack temp=379, boiler temp=175

15 minutes runtime - stack temp=383, boiler temp=180 - baseboard temp=157

I've never had the boiler run this long, but it might have to do with starting at such a low temperature.

The indirect called about 30 minutes later when the boiler was still at 180 high limit - here are the numbers for that:145 degrees - boiler fires

2 minutes runtime - boiler temp=149

3 minutes runtime - boiler temp=157

4 minutes runtime - stack temp=350, boiler temp=166

5 minutes runtime - stack temp=360, boiler temp=171

6 minutes runtime - stack temp=372, boiler temp=177

6 minutes 30 seconds - boiler hits 180 high limit again with indirect still calling

I have to do a combustion analysis to see where my numbers are with the .85 nozzle.

Do my stack temperatures look good enough to prevent condensation, or should I increase to a .90 or 1.00 nozzle?

I couldn't measure the return pipe temperature exactly to see if I got 140 degrees after 5 minute. My infrared camera was not picking up the return pipe temperature that well.

Thanks!1 -

Stach temp is fine

0 -

At the 10 minute mark, boiler at 155, baseboard at 126°. Is that the return from the baseboard? Hopefully you are not leaving the boiler at 155 arriving at the bb at 126°?

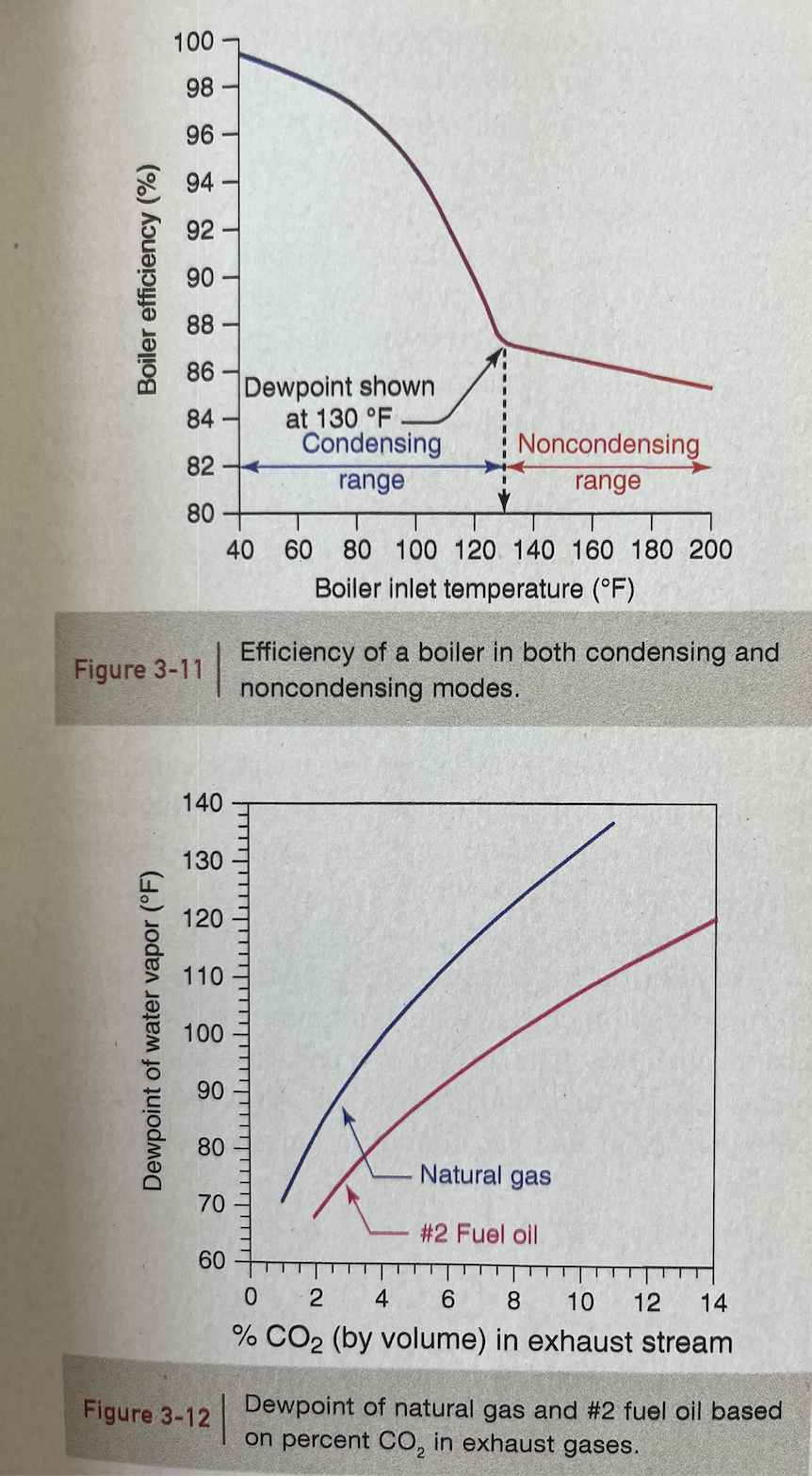

Ideally within 10 minutes or so the return at the boiler should be over the fuel dewpoint. So getting to @130°F within 10 minutes or so is ideal. Burner adjustment CO2 has some to do with dewpoint also.

If the boiler cycles off before warming above 130, you could be getting condensation in the block.2

On the indirect call, boiler hitting high limit at 6 minute tell you that you could be flowing more btu to the indirect so it can absorb full boiler output. Not a dealbreaker if you get adequate DHW and recovery time?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi, the 126 degree baseboard temp is the temp of the baseboard measured with my infrared camera.

That might not be accurate based on where the camera measured the temperature.

I don't know how to measure the boiler return pipe temperature to see the return water temperature as the infrared camera only sees the outside temperature of the pipe. What's the best way to measure return temperature?

The indirect is providing adequate hot water - basically it calls until the boiler reaches high limit, and then calls for a second time when the boiler drops to 145 degrees. Usually the indirect is satisfied when the boiler hits high limit for a second time.

I'm probably going to keep the low limit set to around 110 degrees instead of keeping it off. I'm concerned that since this is a 20 year old boiler that letting it sit at 100 degrees during standby might cause it to leak - is this a valid concern?

Thanks0 -

-

Hi guys, so I got my new combustion analyzer today and took some measurements. I bought a TPI DC710C1, it's so much nicer than the Testo 310.

I also put some black electrical tape on the pipes to get a better temperature reading with my thermal camera.

I setup the airband by eyeing the flame - my smoke test was zero.

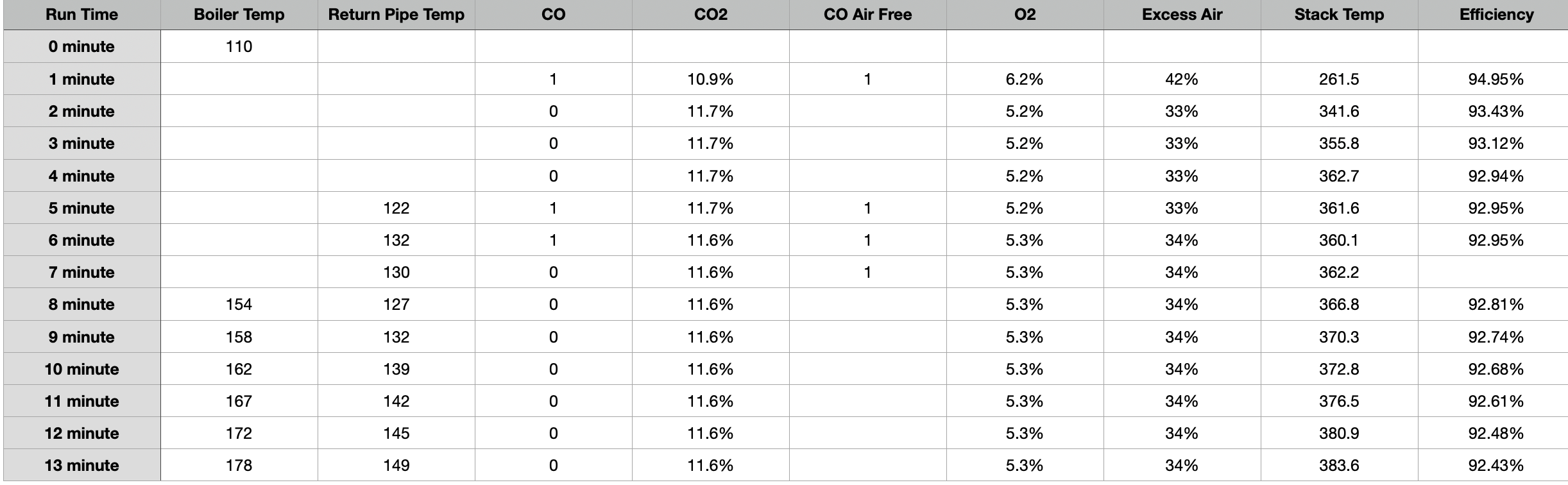

Here are my latest numbers with running the boiler from a cold start of 110 degrees and calling from two heating zones together - note that I didn't capture the boiler temperature and return pipe temperature for every minute run:

Does this look good? My combustion numbers look good to me, I just want to make sure that the stack temperatures and return pipe temperatures look good.

Thanks!

0 -

-

#s look too good. O2 looks ok but did you do a smoke test?

0 -

Looking at the 13 minute numbers here is what I might want to look into

The temperature difference (∆T) between the supply and the return water is a little high. 29°F (almost 30° ∆T) means one of two things. Either the water is staying in the radiators too long, or a new zone just opened and is sending cold water to the boiler and mixing with the hotter return water from the previously operating zone(s). You need to have a more controlled test procedure. Perhaps have all zones calling at once, then check steady state operation after 15 minutes. That will show the real operating ∆T

11.8% CO

2with a gross stack temperature of 383.6°F does not equal 92.43%. When you look on a combustion efficiency chart for #2 heating oil and you take into consideration the NET stack temperature. (383.6° minus 70° room temperature is a net of 313.6°, for example) you will get a combustion efficiency closer to 85%Of course you may get different number if you set your electronic instrument to "LP" or "Nat" gas. Double check your settings

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Yeah, I messed up and selected net instead of gross for the efficiency

Yes, I did a smoke test before using the analyzer and I had zero smoke.

0 -

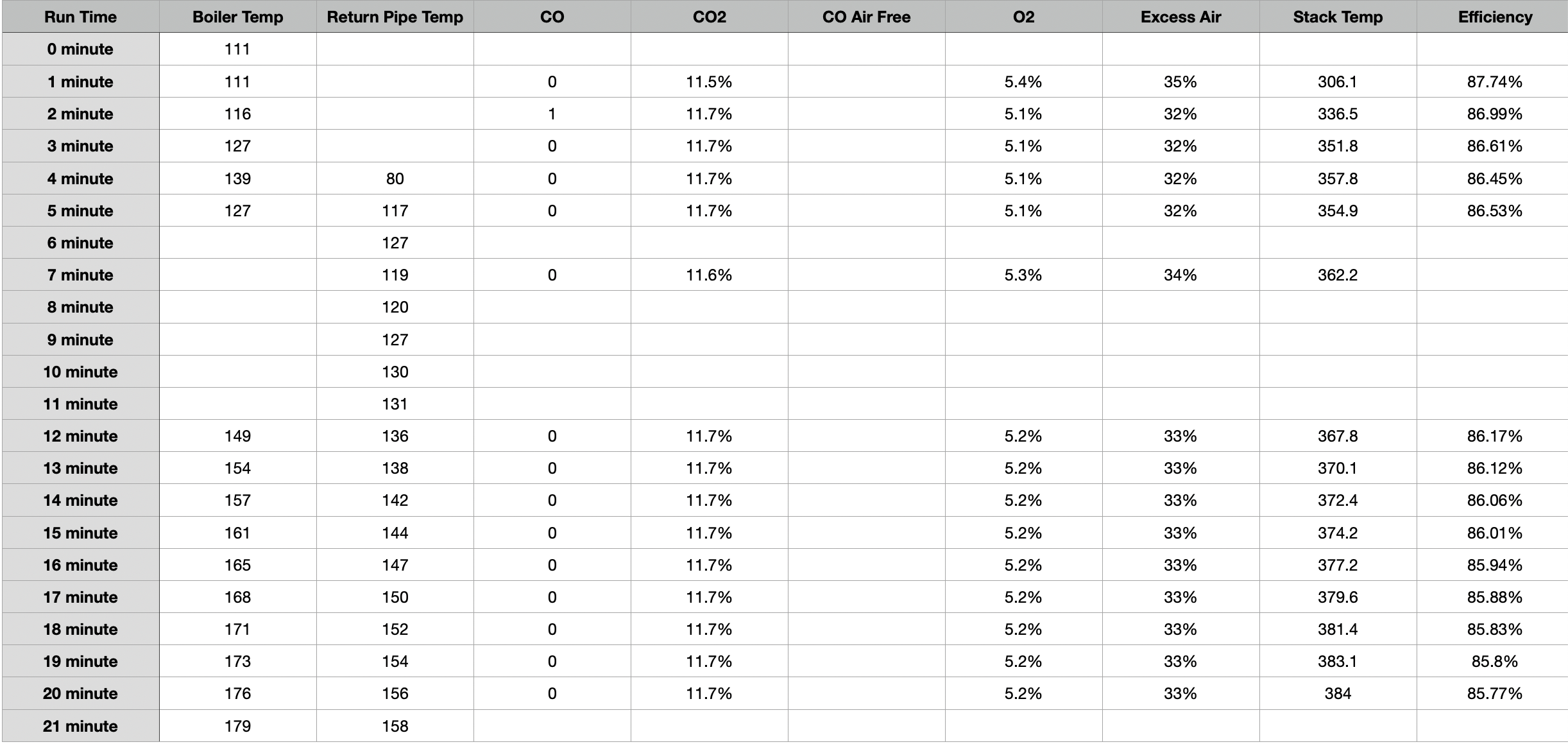

Hi, so I did another test today with all three heating zones calling together starting from 111 degrees boiler temp. I also fixed the analyzer to display gross efficiency as I had this set wrong.

Here are the numbers I got today (some of them are missing as the pictures I took were blurry) - the boiler did drop temp from around the 5 minute mark and then climbed again, and the return temp dropped at around the 7-8 minute mark and climbed again.

This boiler never ran longer than 5 minutes, so it's a big improvement.

I want to see how long it will run until it reaches high limit when the boiler is already up to temperature around 145 degrees. I'm hoping it will run around 10 minutes now during those conditions.

I'll do a few more smoke tests as well to make sure it's still zero smoke.

Thanks

0 -

This was right before the boiler stopped at 180 degree high limit, so I don't know if this has anything to do with the temperature differences.

0 -

-

Thanks. I bought a Klein Type K clamp on temperature probe that I used in my multimeter.

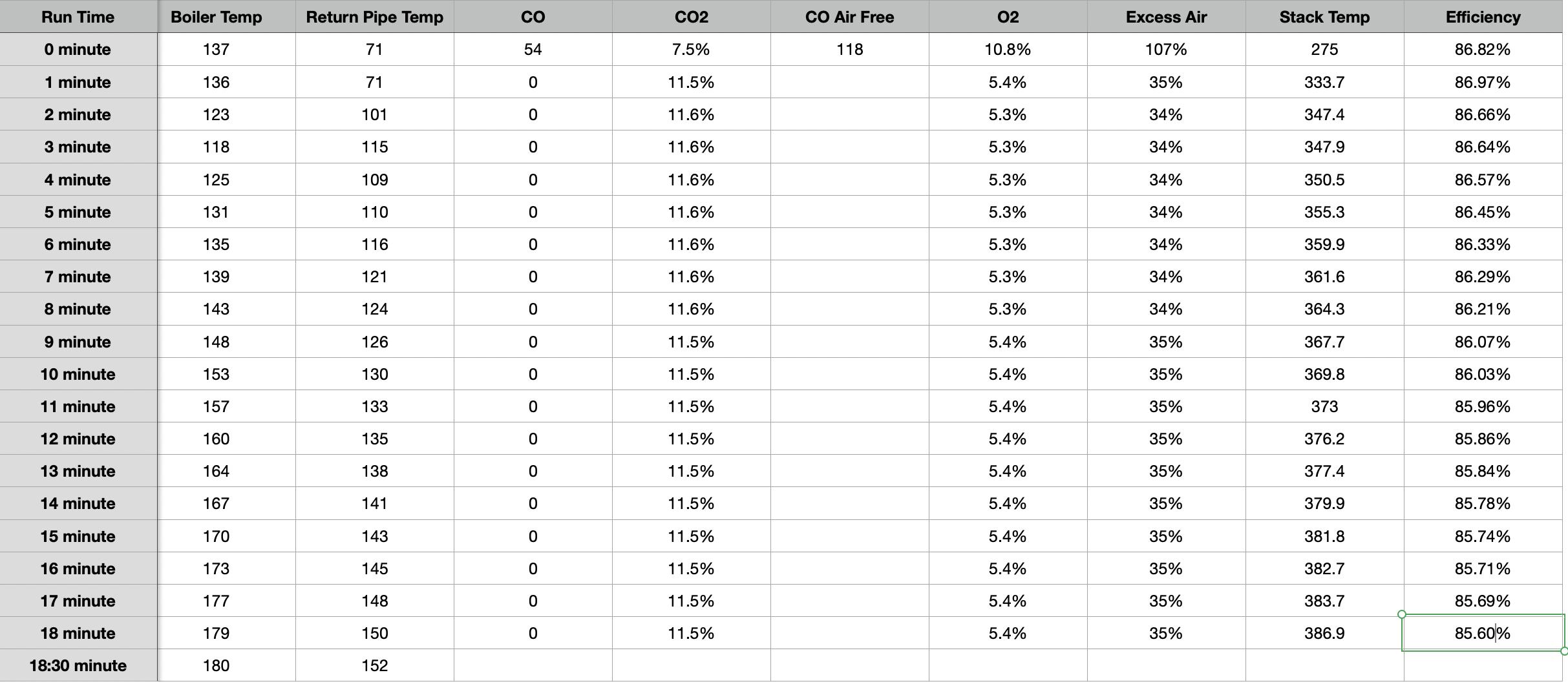

Here is my latest test with the boiler starting this time at 137 degrees, and calling for heat from all three zones together:

0 -

Now that looks correct for an oil fired boiler. Your ∆T is close still close to 25° during the steady temperature increase from minute 10 thru minute 17. There is nothing wrong with that as long as your room temperatures are within your comfort range when you are operating under normal conditions. (Not testing conditions). And the fact that you are making all the zones operate simultaneously for this test may indicate that you should not expect your actual burner run times will ever be over 10 minutes. This is because there will be times that only one zone may call for heat at a time with a run time of 4 to 5 minutes before it is satisfied then 5 minutes later another zone may call for 4 to 6 minutes and be satisfied.

You may be able to use the economy feature on the HydroStat aquastat's economy setting to 3. This may offer you some burner down time if there is enough heat left in the boiler to satisfy the call for heat on another zone by using the left over heated water from the previous call for heat.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks for all of your help Ed. It's not cold enough in CT to see if the room temperatures are good, but I expect them to be good.

I figured there will be instances when the boiler run times will still be short, but downfiring to the .85 nozzle has made a big improvement on getting longer run times.

I configured the Hydrostat 3250 to enable the thermal pre-purge so the latent heat in the boiler can be circulated thereby eliminating unnecessary burner firings:I also disabled the economy feature, and set the differential to 30 to maximize the burner runtime.

I'll do a few more tests once the heating season begins and the boiler is operating under normal heating conditions.

Everyone here has been a tremendous asset with all of your help and suggestions, and I greatly appreciate all of your wisdom and assistance.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements