Best Of

Re: Replacing cast iron radiator with smaller one

That's a gorgeous radiator. As dabrakeman said, remove, sandblast, powder coat....it needs to have its dignity and beauty showcased. Add a TRV if better temperature control. Mad Dog

Re: Evaluating Ductless Install Quotes

there’s a lot to do to install these. Get a bad contractor and throw the entire system out in a few years.

forget what you see on line as a price for equipment there is so much more that’s needed.

pecmsg

pecmsg

Re: Need help with new install of radiant with Buderus cast iron boiler

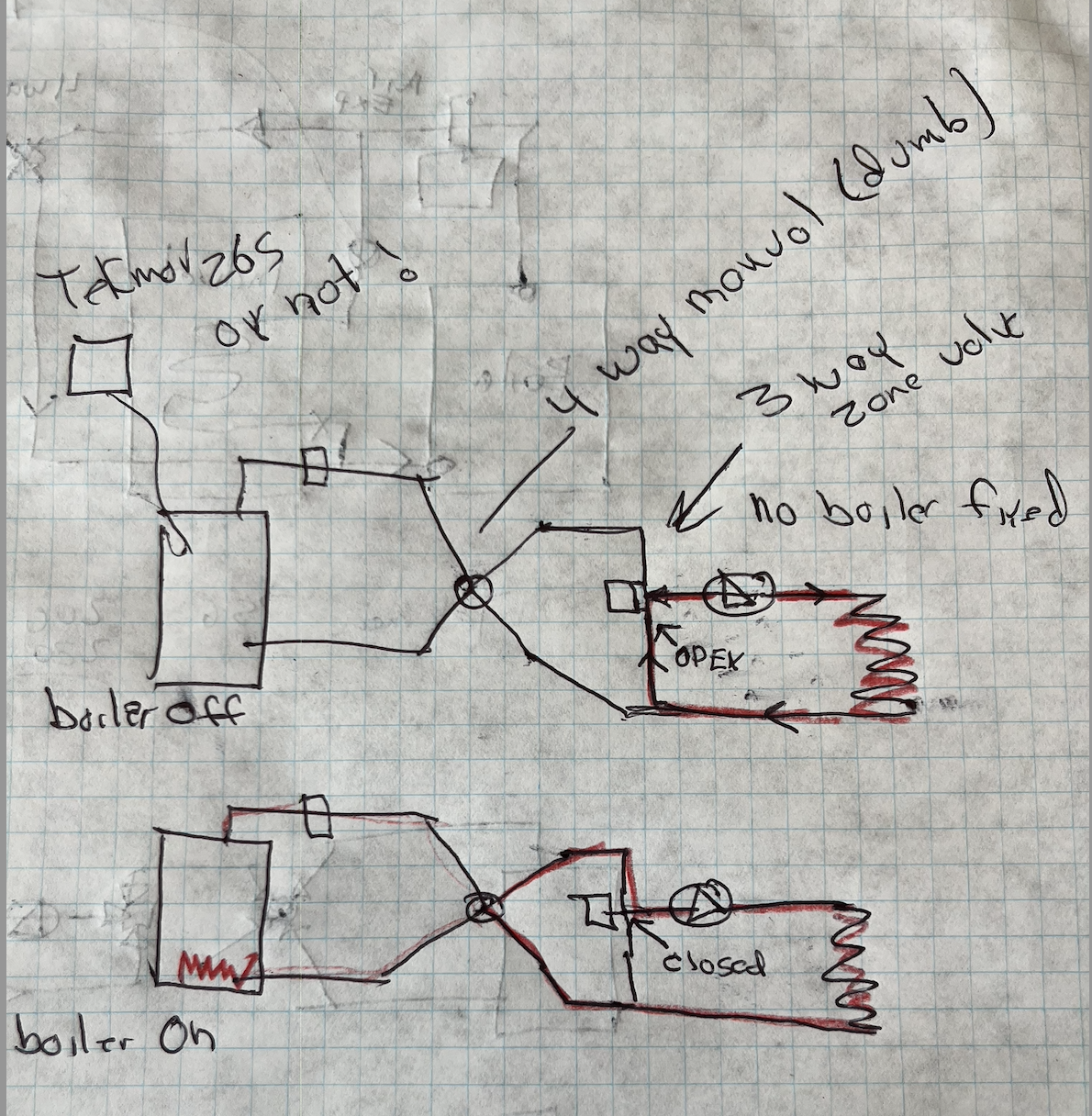

The proper 4-way setup with an actuator (mechanical actuator, not thermostatic) and outdoor reset, will aim to protect the boiler, and also aim for the correct mix outlet temp based on the outdoor temperature.

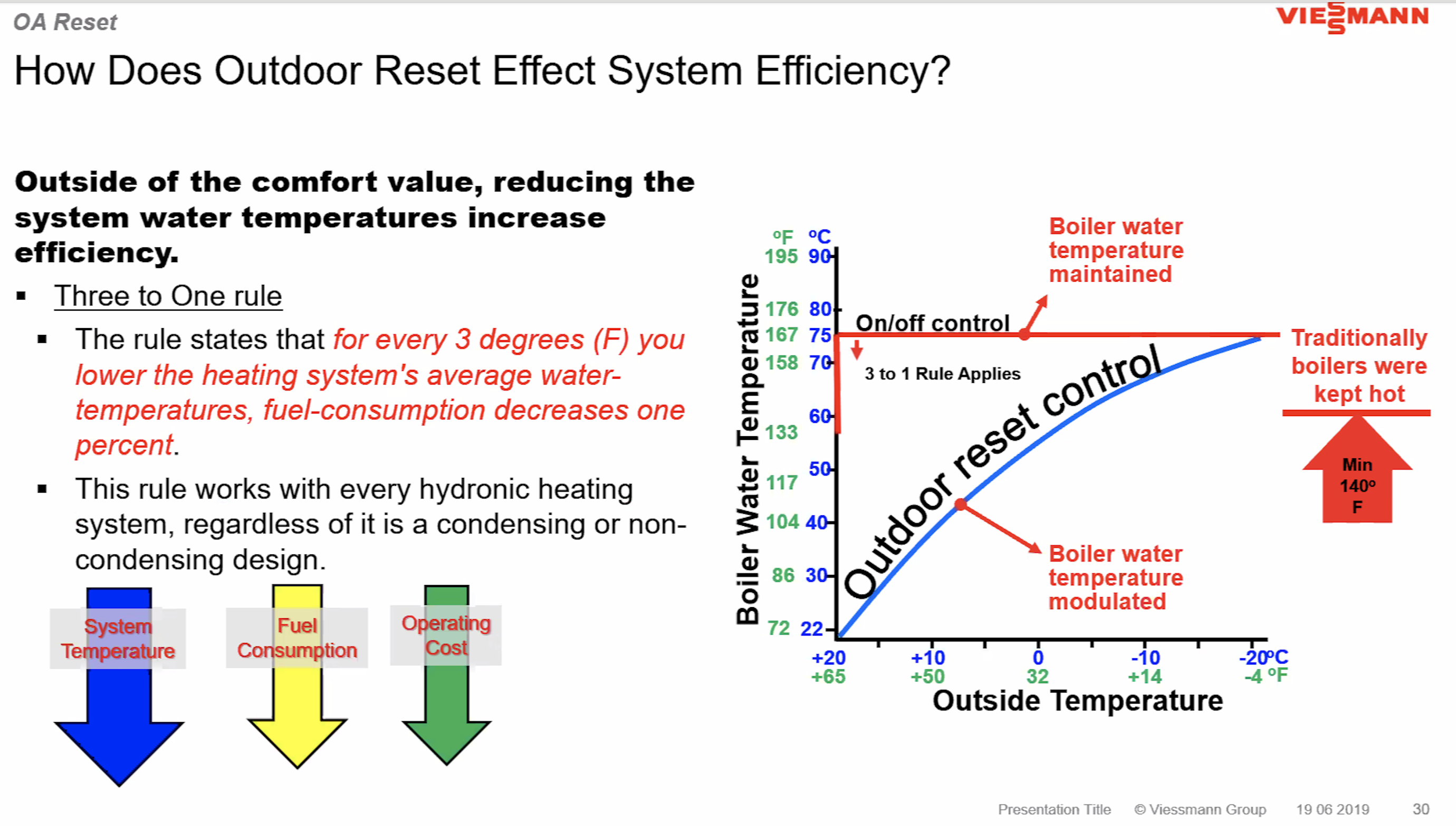

Let's do a hypthetical. Consider how much concrete you have on your floor. Now lets assume that you could heat your space to the exact indoor comfort you are looking for, while the outside temp is -10, by supplying a constant 110f supply to your manifold. Now let's fast forward to a day it is 35f outside. With a thermostatic mix valve you are still going to be supplying 110f water to your slab (a "dumb" miux valve just set by hand will also do this assuming the boiler setpoint remains constant, though it will eventually overheat even more), by the time the temp reaches the desired comfort level, the slab is hot, and the heat in the mass of your slab will continue transferring to the space thus over shooting the temperature you are looking for inside. Now let's say you only need 80f water on that 35f day, with a mechanically actuated mixing valve, and properly setup ODR control, you will be supplying the exact temp water needed to maintain the comfort level in your space. In theory you can match the load precisely and the system runs constantly, to maintain a perfect comfort level in the space.

These are features that are basically built in to modulating condensing boilers, no mix valve needed for those with a single temp system, and no worry of cool return water temp. and all of the above is ignoring the potential damage that overheating a big concrete slab can cause

Re: Need help with new install of radiant with Buderus cast iron boiler

I guess I just wasn't understanding the concept or advantage of the "dumb" 4 way vs going with a thermostatic valve like Kaos was showing in his setup. The thermostatic would keep a constant/regulated temp going to the system, It seems like with the 4 way it would fluctuate as the boiler cycles? Or does that just not matter if it was being controlled with ODR from the 256?

I like where we are heading though!

Re: Evaluating Ductless Install Quotes

And gas for the truck and truck insurance and and liability insurance and workers comp insurance and the time it take to put a quote together, run the office, do the billing and payroll and bookkeeping, truck repairs, employee training on you system. He also has to make a profit to stay in business

If you don't like the pricing don't complain to the contractor, Massachusetts is one of the most over regulated states in the country. i know, I have lived here 72 years.

Re: Evaluating Ductless Install Quotes

TL;DR: You're buying a lot more than the equipment.

I can't say much about your particular installers, but while it doesn't take much skill to slap a mini split on the wall & cash a check, a good install takes quite a bit of skill and experience. And not especially cheap tools. And insurance. And licensing. And training. And warranty.

Re: I get all the weird ones...

redesign the whole job,

keep the conveyor warm inside,

put the feed hopper outside, maybe under a shed roof if snow or rain matters, have a small opening for the feed conveyor, air curtain that,

Re: Thin Tube Steam/Hot water in Barre VT

i kind of lumped the inspection door and hanger iron and furnace cement in with the corrosion.

Re: I get all the weird ones...

I appreciate most of the comments guys. I did have a conversation with them verbal and through email, that discussed their expectations. I told them that no matter what we do that building wont maintain a satisfactory temp if any of the 3 overhead doors remain open for prolonged periods.

The best I can offer is at startup in the morning, the space will be 70 degrees, but within mins of the door opening, all bets are off. They understood and think they can manage as long as the conveyor and hydraulic oil get warmed up and rolling. I said keep it on through lunch then!

I dont think I will walk away from this job but I will have enough disclaimers and exceptions it'll make a lawyer wanna high five me!

Re: Need help with new install of radiant with Buderus cast iron boiler

A 3 way thermostatic can only send the adjusted temperature to the slab. It is a smart valve with a one track mind :)

So if you set it to 110F for example, and the weather warms, heatload goes down, it is sending water that is too warm and you will over-shoot the thermostat setting. Remember the slab needs some, maybe hours to respond to a load change. So it could take 2, 4 maybe more hours for the slab to cool down and bring room temperature down.

This is called the flywheel effect. It works in both directions, warming or cooling down the slab. One of the very few downsides to a high mass radiant emitter.

We try to minimize that by 1) adjusting the supply water temperature based on outdoor temperature, called ODR outdoor reset.

Not to overwhelm you with options, Constant circulation is another nice function. In my shop the pump runs 24/7 durning heating season. The thermostat connects to a 3 way zone valve. It pulses heat into the slab. It also takes the passive solar gain I get in the south end of my shop and moves it to the back, north (colder) part. So my slab across the room stays very consistent. I'm connected to a mod con with ODR, so mostly it sends between 90- 110 temperature. But you add another 150 bucks or so for the 3 way zone valve.

A manual 4 port valve gives you a few options. You can go down and manually turn the knob during a cold or warming spell and fine tune it. Maybe 3- 4 times a season as you get large outdoor temperature changes.

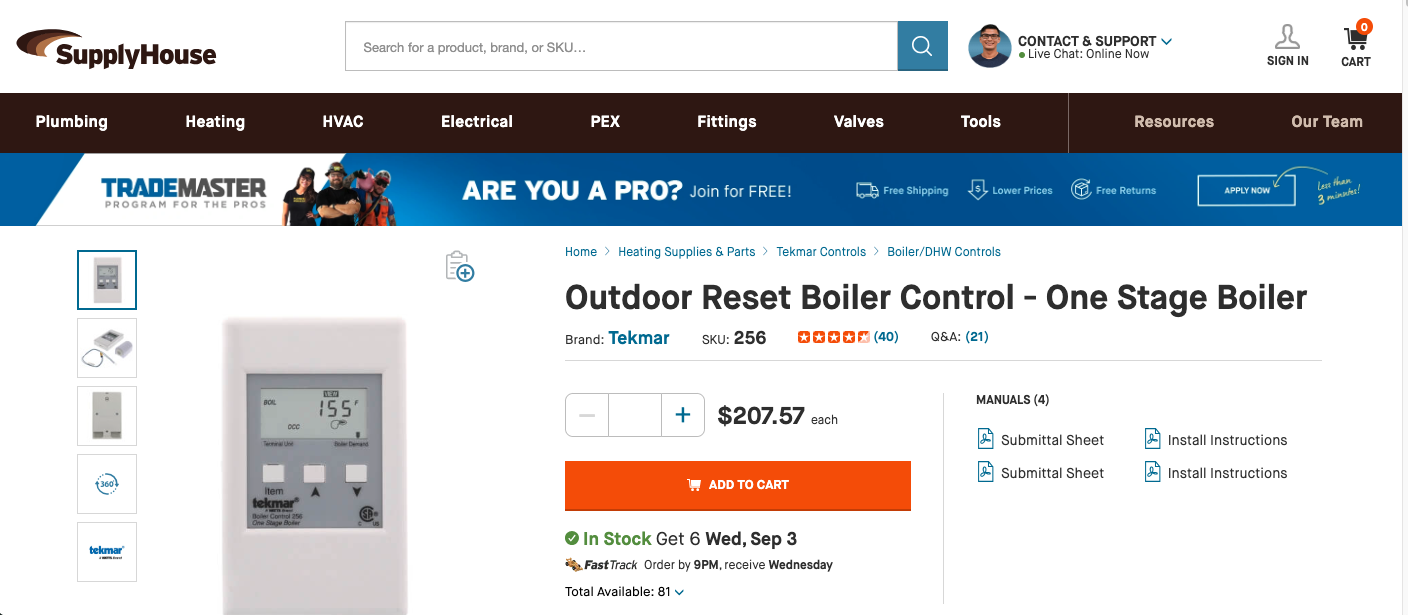

IF you add the tekmar 265 to the boiler it could run maybe 160 on coldest day, modulate down to maybe 140 even 130 with that particular boiler.

As the boiler modulates down, the hot supply to the dumb, manual mix valve decreases by default, so it get a bit of what we call proportional mixing. The manual mix valves tracks a bit with the boiler reset curve and temperature.

While not as accurate as a mix valve with a sensor and actuator, it would modulate water temperature a bit more accurately than a thermostatic mix that only knows 1 condition, the setting on the knob.

The 4 way is always slipping some flow back to the boiler to help keep it in a safe condition. A 3 way does not allow two mixing points as a 4 way can. Price wise about the same.

Pipe it with a manual 4 way. Try and see if it is being controlled well enough for your use habits.

If not add the 256 later to get more control, higher efficiency. The lower the boiler operating temperature, the more efficient it runs.

Viessmann claims for every 3 degrees you reduce the boiler temperature fuel consumption decreases 1%. So ODR controls actually can pay for themselves over a few years based on your energy costs and consumption, of course.

200 bucks or so seems like a good investment for temperature control, fuel savings. Even on a "free" boiler :) Pretty much all boilers come with some version of this now.

As far as the boiler protection, running them cold for extended periods causes condensation corrosion in the flue and at worse case excessive CO from the flame. It's not just about saving the boiler, but allowing it to run safely, efficiently.

I think we are all try to get you a safe, comfortable, efficient system with the pieces you have and the least additional $$

hot_rod

hot_rod