Need help with new install of radiant with Buderus cast iron boiler

Comments

-

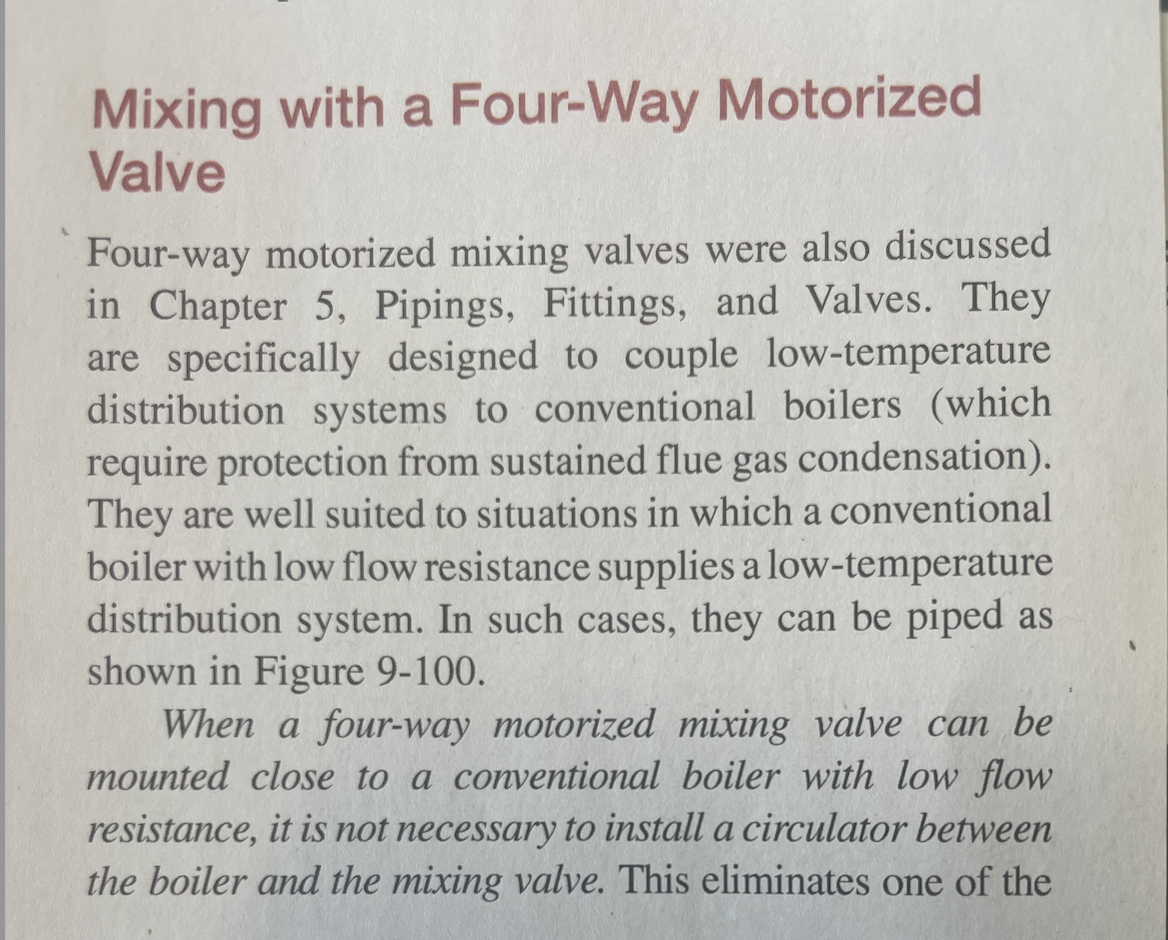

Is it the cost of the 4 way that prevents you from considering that route?

The 4 way both mixes down the radiant and gives you boiler return temperature protection. Return protection could be a concern with a high temperature boiler connected to a high mass low temperature slab. A one pump solution. Two pumps if you add the indirect.

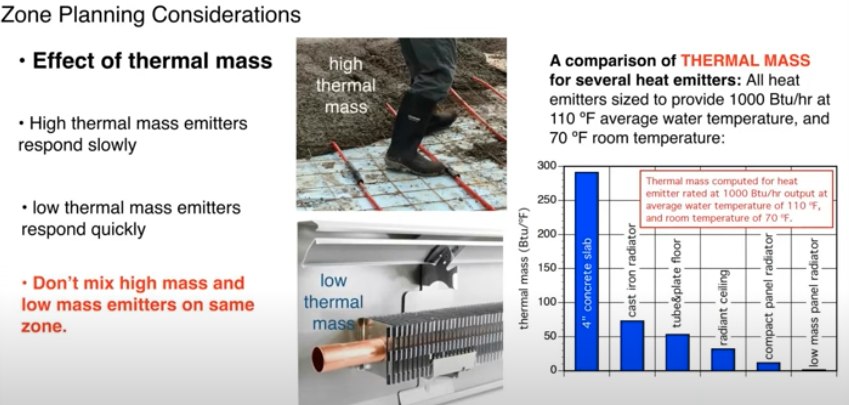

If total slab is 2000 sq ft? At 4" thickness that is around 15 yards of concrete, 60,000 lbs of thermal mass. A boiler, even your oversized one, cannot quickly change the temperature of that mass. As such the boiler needs something to protect it from extended cold running cycles.

With an oversized boiler you will have short cycles that could prevent the boiler from warming up adequately.

So the 4 way solution addresses all the conditions you will experience.

Two choices for ODR, add it onto the boiler as @Ironman suggested or onto a 4 way valve.

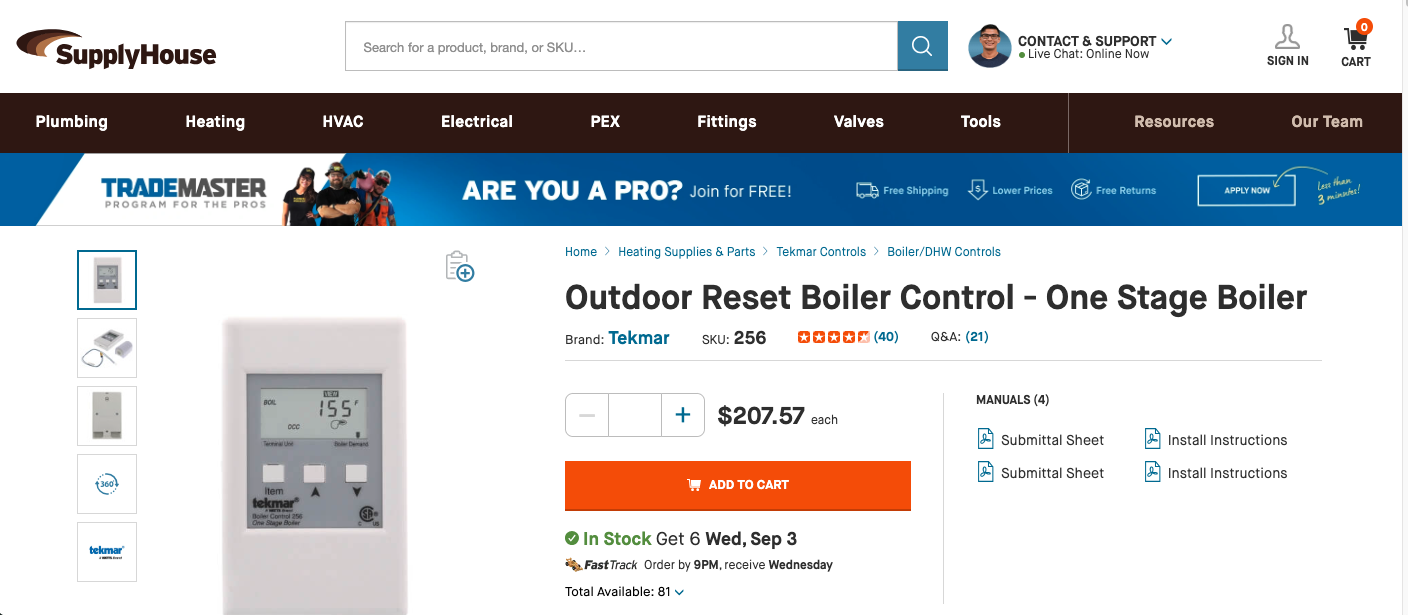

A tekmar 256 around 200 bucks is an inexpensive way to get boiler ODR with good features. Then a "dumb mix valve, around 230 bucks. The 256 protects the boiler return.

This gives you a safe, efficient, controllable system.

With two zone valves, a basic off the shelf hydronic relay box is all the control you need to have.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I guess I just wasn't understanding the concept or advantage of the "dumb" 4 way vs going with a thermostatic valve like Kaos was showing in his setup. The thermostatic would keep a constant/regulated temp going to the system, It seems like with the 4 way it would fluctuate as the boiler cycles? Or does that just not matter if it was being controlled with ODR from the 256?

I like where we are heading though!

1 -

The proper 4-way setup with an actuator (mechanical actuator, not thermostatic) and outdoor reset, will aim to protect the boiler, and also aim for the correct mix outlet temp based on the outdoor temperature.

Let's do a hypthetical. Consider how much concrete you have on your floor. Now lets assume that you could heat your space to the exact indoor comfort you are looking for, while the outside temp is -10, by supplying a constant 110f supply to your manifold. Now let's fast forward to a day it is 35f outside. With a thermostatic mix valve you are still going to be supplying 110f water to your slab (a "dumb" miux valve just set by hand will also do this assuming the boiler setpoint remains constant, though it will eventually overheat even more), by the time the temp reaches the desired comfort level, the slab is hot, and the heat in the mass of your slab will continue transferring to the space thus over shooting the temperature you are looking for inside. Now let's say you only need 80f water on that 35f day, with a mechanically actuated mixing valve, and properly setup ODR control, you will be supplying the exact temp water needed to maintain the comfort level in your space. In theory you can match the load precisely and the system runs constantly, to maintain a perfect comfort level in the space.

These are features that are basically built in to modulating condensing boilers, no mix valve needed for those with a single temp system, and no worry of cool return water temp. and all of the above is ignoring the potential damage that overheating a big concrete slab can cause

1 -

Oh I fully understand the benefits of a "proper" setup, but it's not in the budget. If it was, I'd just go buy a modcon.

I'm just trying to get by for a winter or two until we can finish the rest of the build, then likely upgrade to a modcon system.

So essentially any type of electronically controlled modulation system is off the table.

That being said, I'm trying to figure out if there would be any advantage of using a manual 4 way mixing valve over a thermostatic. With either I would use the Tekmar 256 to get some ODR functionality.

In my mind and I could be wrong, a thermostatic valve guarantees my slab won't be seeing any high temps.

I'm not as concerned about protecting a 15 year old boiler I got for free as I am a $25,000 slab.

0 -

A 3 way thermostatic can only send the adjusted temperature to the slab. It is a smart valve with a one track mind :)

So if you set it to 110F for example, and the weather warms, heatload goes down, it is sending water that is too warm and you will over-shoot the thermostat setting. Remember the slab needs some, maybe hours to respond to a load change. So it could take 2, 4 maybe more hours for the slab to cool down and bring room temperature down.

This is called the flywheel effect. It works in both directions, warming or cooling down the slab. One of the very few downsides to a high mass radiant emitter.

We try to minimize that by 1) adjusting the supply water temperature based on outdoor temperature, called ODR outdoor reset.

Not to overwhelm you with options, Constant circulation is another nice function. In my shop the pump runs 24/7 durning heating season. The thermostat connects to a 3 way zone valve. It pulses heat into the slab. It also takes the passive solar gain I get in the south end of my shop and moves it to the back, north (colder) part. So my slab across the room stays very consistent. I'm connected to a mod con with ODR, so mostly it sends between 90- 110 temperature. But you add another 150 bucks or so for the 3 way zone valve.

A manual 4 port valve gives you a few options. You can go down and manually turn the knob during a cold or warming spell and fine tune it. Maybe 3- 4 times a season as you get large outdoor temperature changes.

IF you add the tekmar 265 to the boiler it could run maybe 160 on coldest day, modulate down to maybe 140 even 130 with that particular boiler.

As the boiler modulates down, the hot supply to the dumb, manual mix valve decreases by default, so it get a bit of what we call proportional mixing. The manual mix valves tracks a bit with the boiler reset curve and temperature.

While not as accurate as a mix valve with a sensor and actuator, it would modulate water temperature a bit more accurately than a thermostatic mix that only knows 1 condition, the setting on the knob.

The 4 way is always slipping some flow back to the boiler to help keep it in a safe condition. A 3 way does not allow two mixing points as a 4 way can. Price wise about the same.

Pipe it with a manual 4 way. Try and see if it is being controlled well enough for your use habits.

If not add the 256 later to get more control, higher efficiency. The lower the boiler operating temperature, the more efficient it runs.

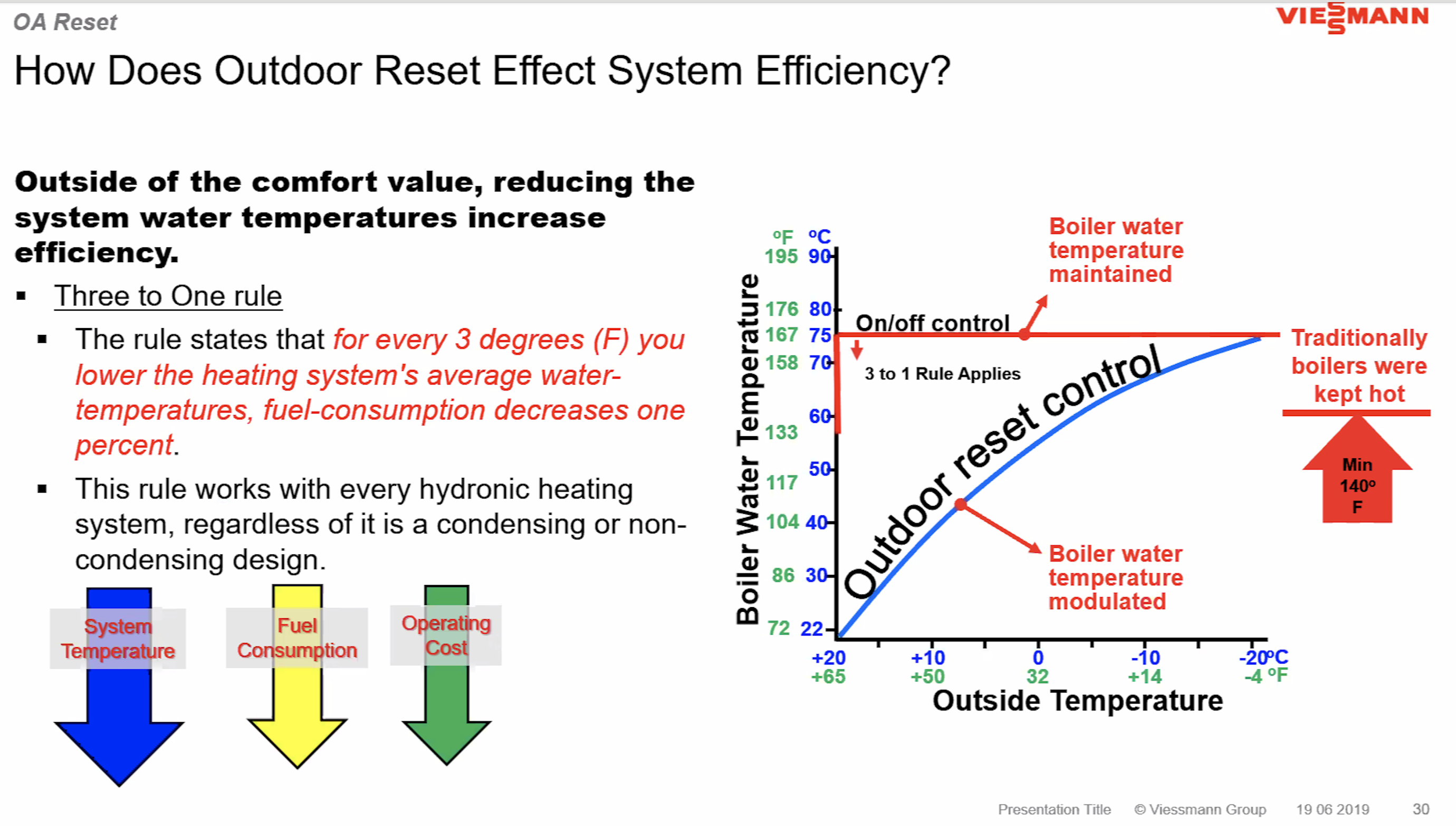

Viessmann claims for every 3 degrees you reduce the boiler temperature fuel consumption decreases 1%. So ODR controls actually can pay for themselves over a few years based on your energy costs and consumption, of course.

200 bucks or so seems like a good investment for temperature control, fuel savings. Even on a "free" boiler :) Pretty much all boilers come with some version of this now.

As far as the boiler protection, running them cold for extended periods causes condensation corrosion in the flue and at worse case excessive CO from the flame. It's not just about saving the boiler, but allowing it to run safely, efficiently.

I think we are all try to get you a safe, comfortable, efficient system with the pieces you have and the least additional $$

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

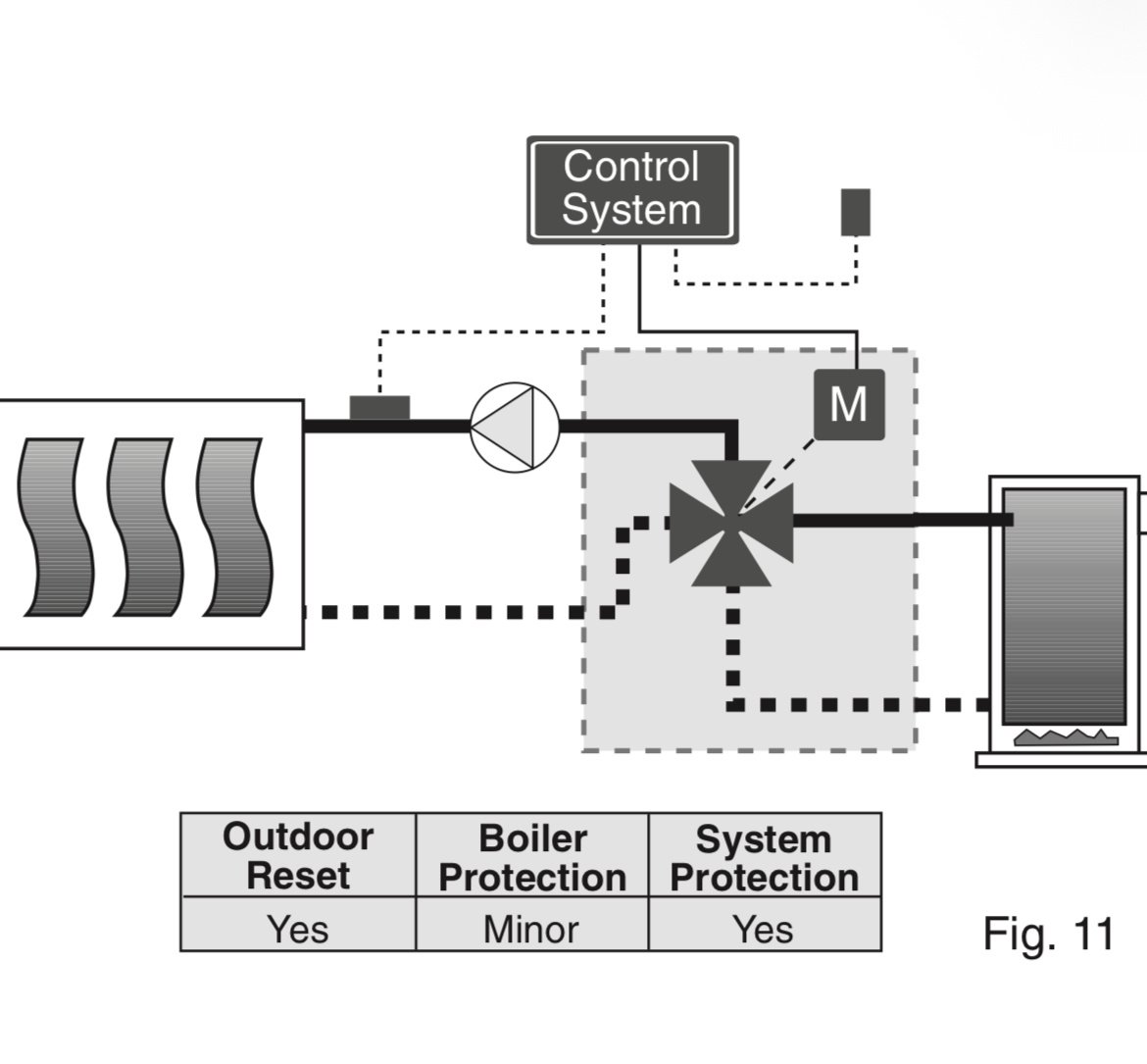

@hot_rod Unless I'm missing something, I don't think a single pump 4 way mix works. It only flows through both loops in the zero bypass position. Dual pump does work though and with a bit of adjustment of 4 way and pump flow rates, you can get a reasonably good temperature control if there is no zoning. I don't think a 3 way mix is even needed.

Sample of a couple, but I have had no issues with no outdoor reset on heated floors except the slow response is slow with any slab. As long as slab temp is limited to reasonable max, the system is somewhat self regulating (as the room heats up, slab output drops). Fixed mix set to low temp has been good enough.

@ajping3830 Your boiler has basic controls, anything fancier adds cost which might not be worth it for a temporary solution. I would try to run as is, if you see a lot of condensation you can add better controls like a Hydrostat 3200 that does outdoor reset and boiler pump hold off.

The ones spot that is worth spending extra money on is getting ECM pumps. These will stay even if you swap out the boiler and they do use significantly less power.

0 -

one pumping 4 way is limited in boiler protection and a high mass boiler is preferred.

Im looking for budget options for the OP. An oversized high temperature boiler presents additional options.

Setting it, operating a 4 way manually you need to never close it completely. They used to have an adjustable stop screw to limit the stroke, when used as a manual valve.I remember doing these systems with older Burnham and Weil boilers when the still had mass and some 8, 10 or more gallon water content. It may not be an option for todays small low water content cast.

I think that Buderus would work fine. It was always promoted as being ideal on low er temperature systems.

Im more concerned that the load on that 800 sq ft could be in the teens or single digits (btu/sq ft) Then the boiler is massively oversized. More suited for a 50 gallon 35,000 btu tank water heater🤔With 7- 1/2” loops he is looking st some low flow rates, less than 4 gpm when all zones are flowing. I think that boiler can handle that. Ill look for the spec sheet

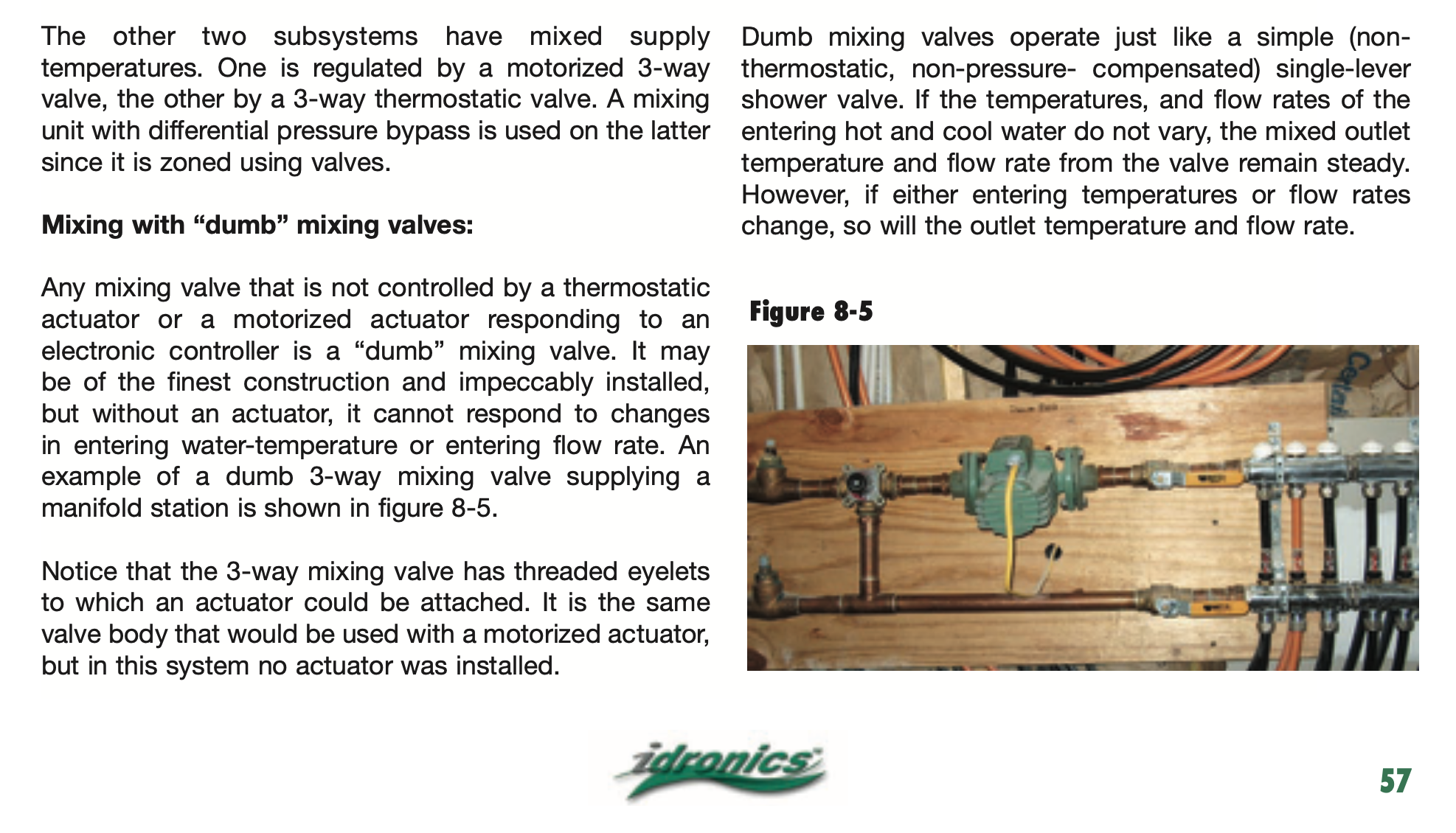

Here is the single pump option from the tekmar manual , and the essay describing its operation and limitations

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

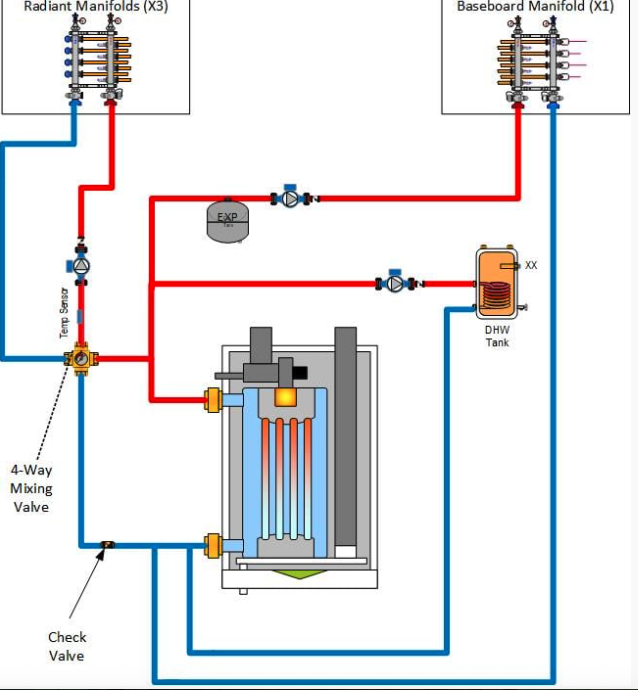

Viessmann 4 way piping for Atola CI boilers. A two temperature system, with indirect as a parallel circuit. example.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Again thanks for all the info!

One thing I didn't mention about the 800sq/ft living space is that it's a much higher ceiling with a loft and a LOT more glass! There will be a bedroom in the loft so in reality it's more like 1,200sq ft of living space. What's that do to the heat load?

Also, my 1,500sq foot well insulated house house has been running on a 100k/80k CI boiler for 20 years with forced water baseboard without a hitch and there's never been any signs of short cycling.

0 -

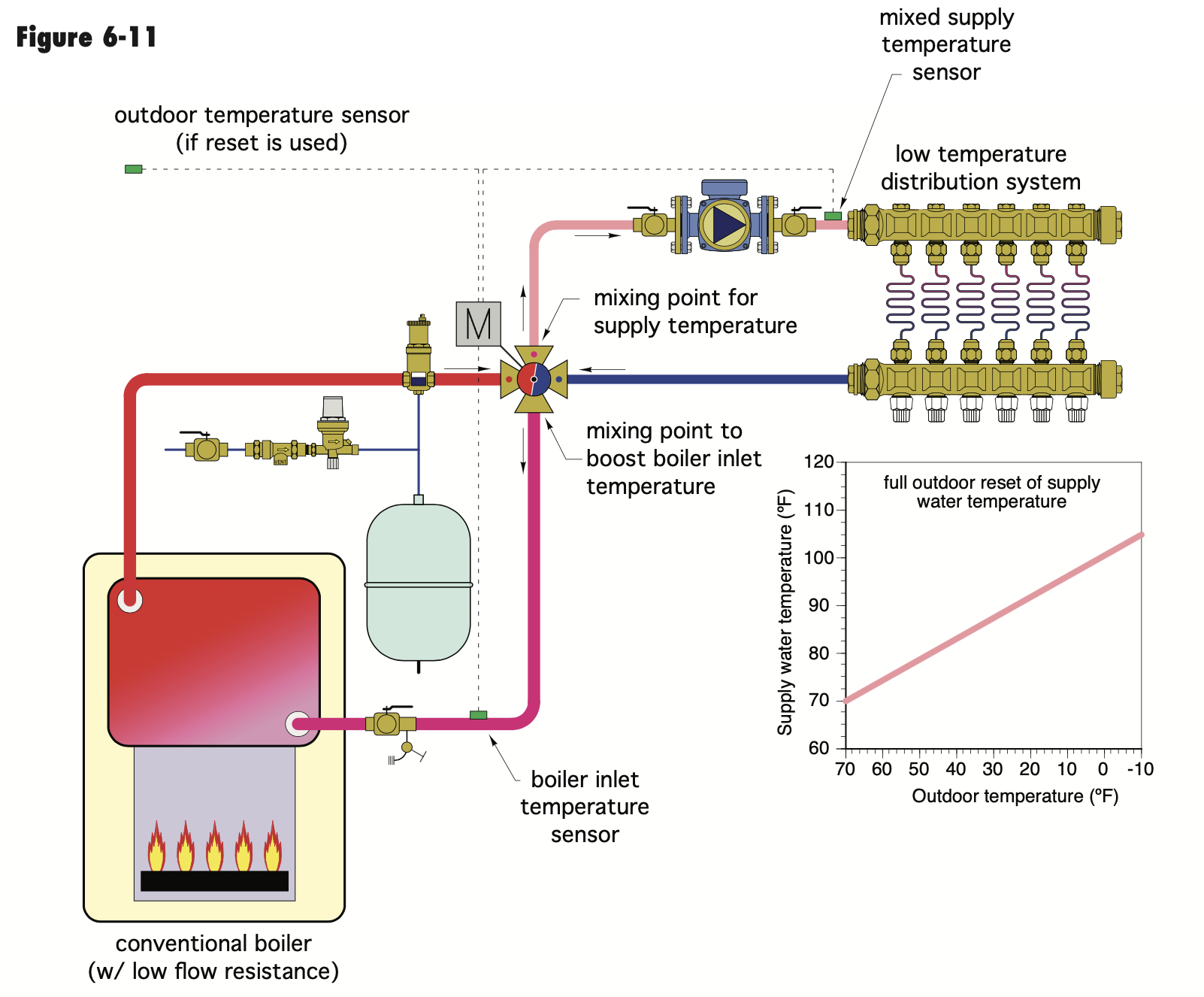

I see that note on the drawing in Modern Hydronics

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Speaking as a homeowner,

now that I have seen the rest of your build I am even more convinced that you need a bulk milk tank for hot water storage OR a small coal stoker boiler like a keystoker kaa-4 to heat it using it with or without a buffer tank and a mixing valve.

You have enough floor to justify summer operating temperatures of 140 degrees Fahrenheit low limit and 160 degrees Fahrenheit high limit using a simple mixing valve.

Short of this you could use a 300 gallon narrow oval livestock watering tank as a buffering tank covering it with a piece of marine plywood and using a hot water rated float valve to keep the amount of water near 300 gallons at all times and piping the circulator suction line and return lines through the plywood sheet rather than using the drain tapping in the side of the tank.

You have the head room to use a large steel compression tank, gauge glass and an airtrol valve for the point of no pressure change. I have a 54 gallon-+ hot water heating system using a keystoker kaa-4-1 coal stoker boiler with 15 gallon steel compression tank with a gauge glass and airtrol valve and I do not have deal with bleeding air out of my hot water baseboard(which I hate) ever again.

In my opinion you have a great deal of open air space that will bleed heat with the great room and you need the thermal mass from a buffer tank.

I hope you will be using fire resistant latex paint to cover the oriented strand board sheets.

0 -

Again thanks for all the info!

One thing I didn't mention about the 800sq/ft living space is that it's a much higher ceiling with a loft and a LOT more glass! There will be a bedroom in the loft so in reality it's more like 1,200sq ft of living space. What's that do to the heat load?

Also, my 1,500sq foot well insulated house house has been running on a 100k/80k CI boiler for 20 years with forced water baseboard without a hitch and there's never been any signs of short cycling.

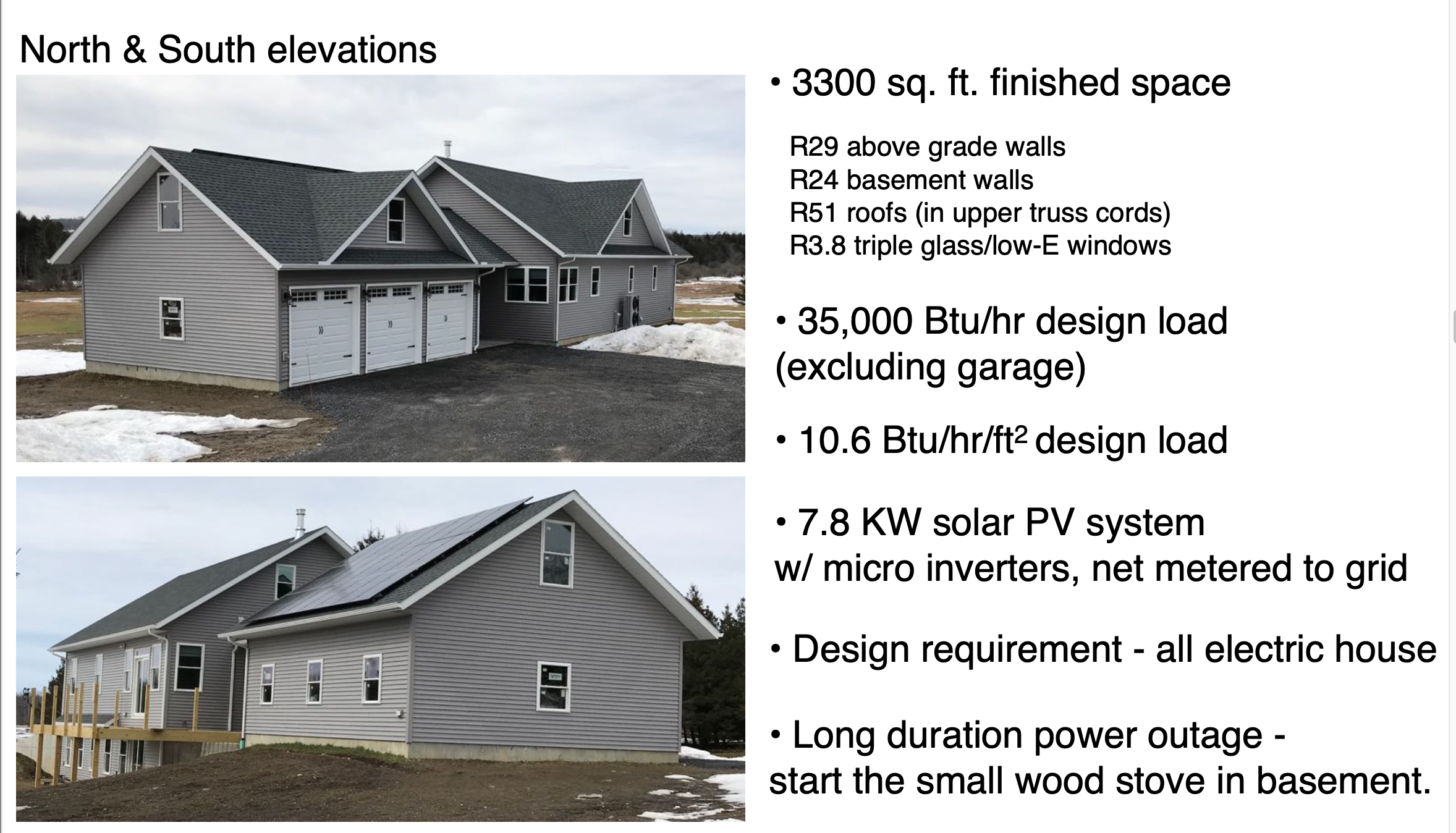

A classic example of why you want a heat load calculation.

Exposed wall, volume, glass, infiltration all have to do with the load.

Here is a recent home built near Utica, NY. Note the 10 btu/sq.ft load! Looks like you have 2x4 walls, double pane windows? So your loads will be a bit higher no doubt.

You design for worse case condition, but you may never see that condition, or rarely.

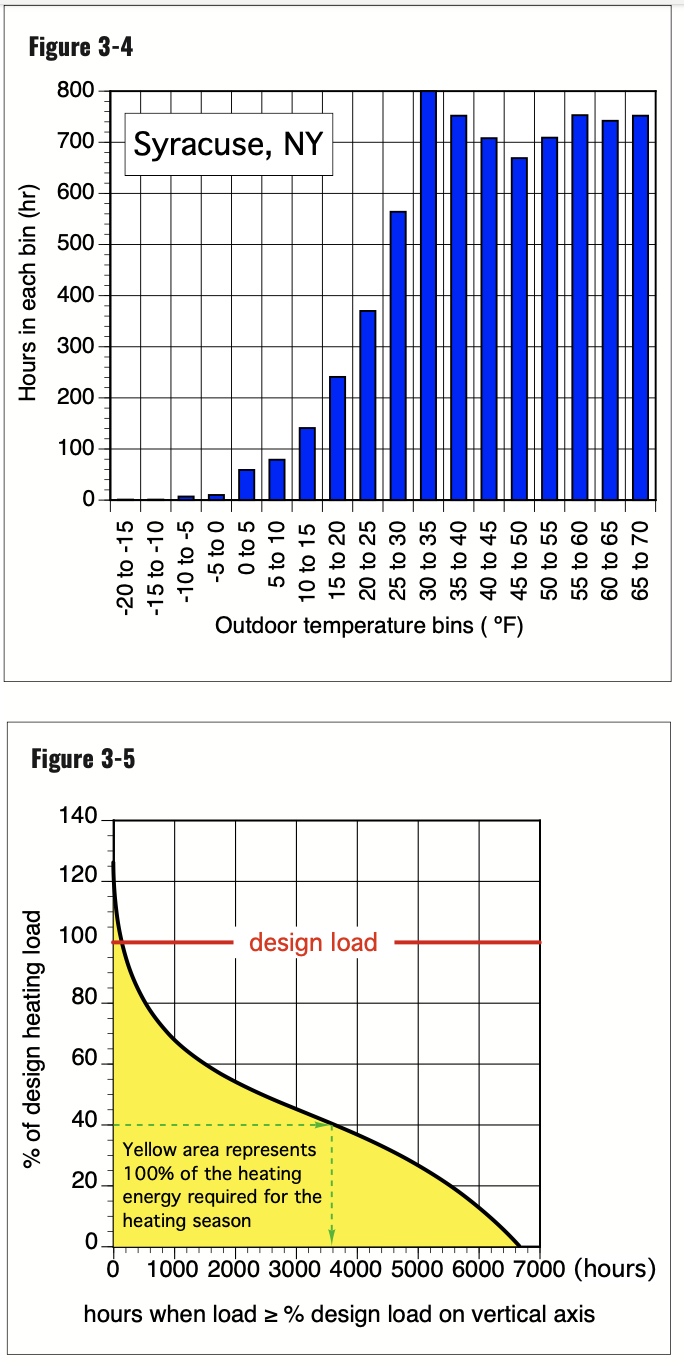

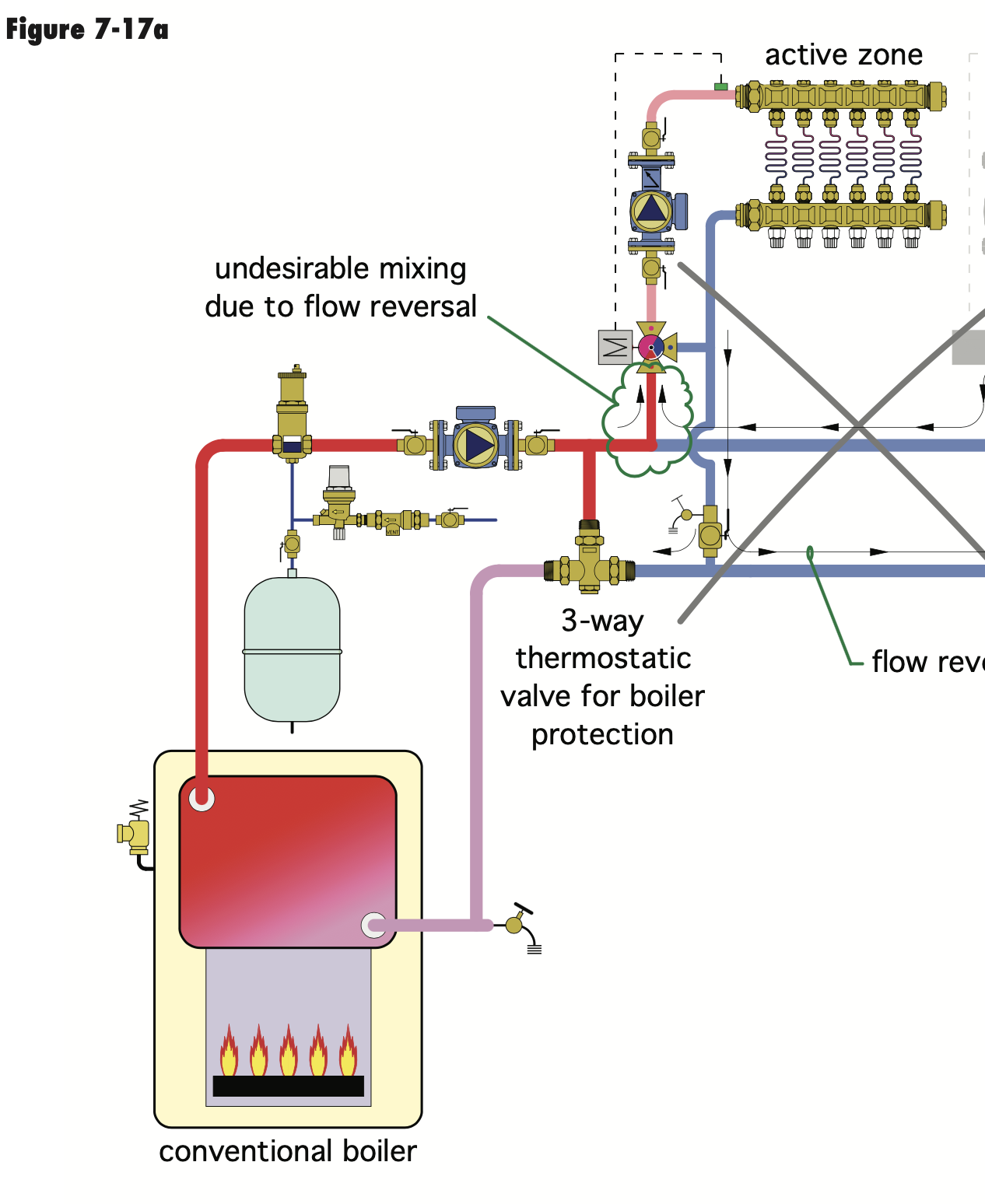

The BIN data for Syracuse shows how seldom you might expect design conditions. About 70 hours at design. Both Buffalo and Syracuse get lake effect weather, high winds, lots oif snow potential. BIN data for Buffalo is available if you want to do some more pencil pushing to get a better picture of what you may be up against.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The exterior walls are 2x6 so there will be R19 in those, and will be blowing in around R40 in the ceiling once it's up.

0 -

If you have an oval livestock watering tank for a buffer tank you will have much more thermal mass to make use of.

Short of putting a coal stoker stove in the living space you are going to have a very cold home.

0 -

Ok I've been camping over the long holiday weekend so I'm looking back at this now.

Hotrod I stumbled across this old video of yours, I'm curious why no one mentioned just using a boiler protection valve like this?

That for boiler protection, and another hydrostatic valve for the supply mix.

https://youtu.be/yfEyGy50P20?si=quM_VZakgRYoaxeD

0 -

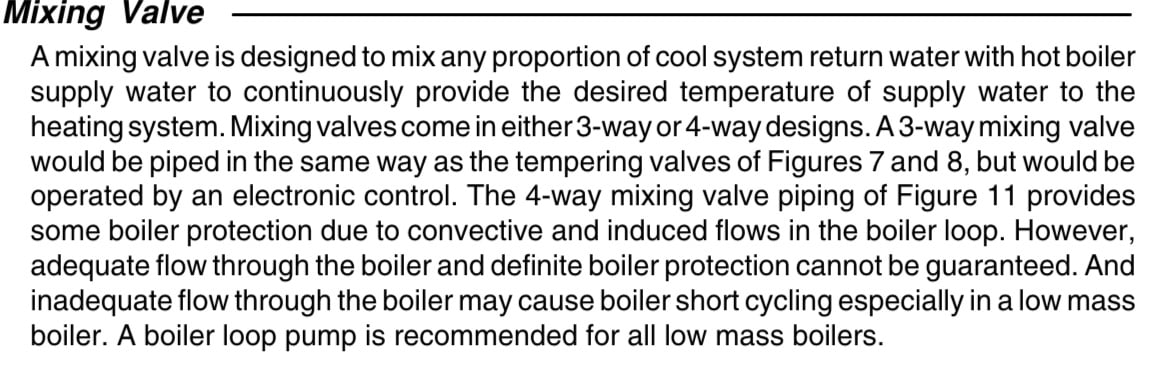

That valve is yet another way to protect a boiler from getting cold return water. It blends some output from the boiler with the return.

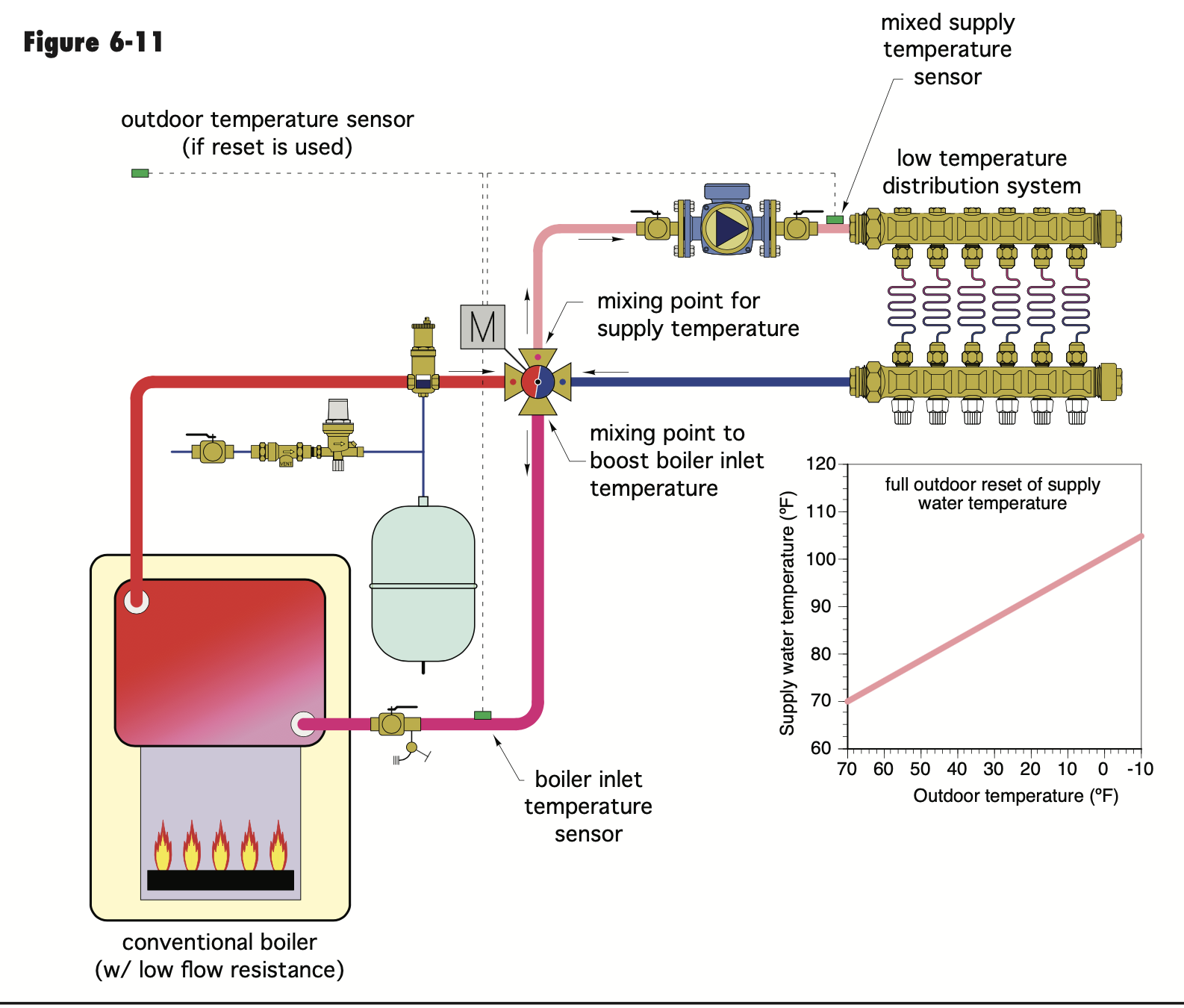

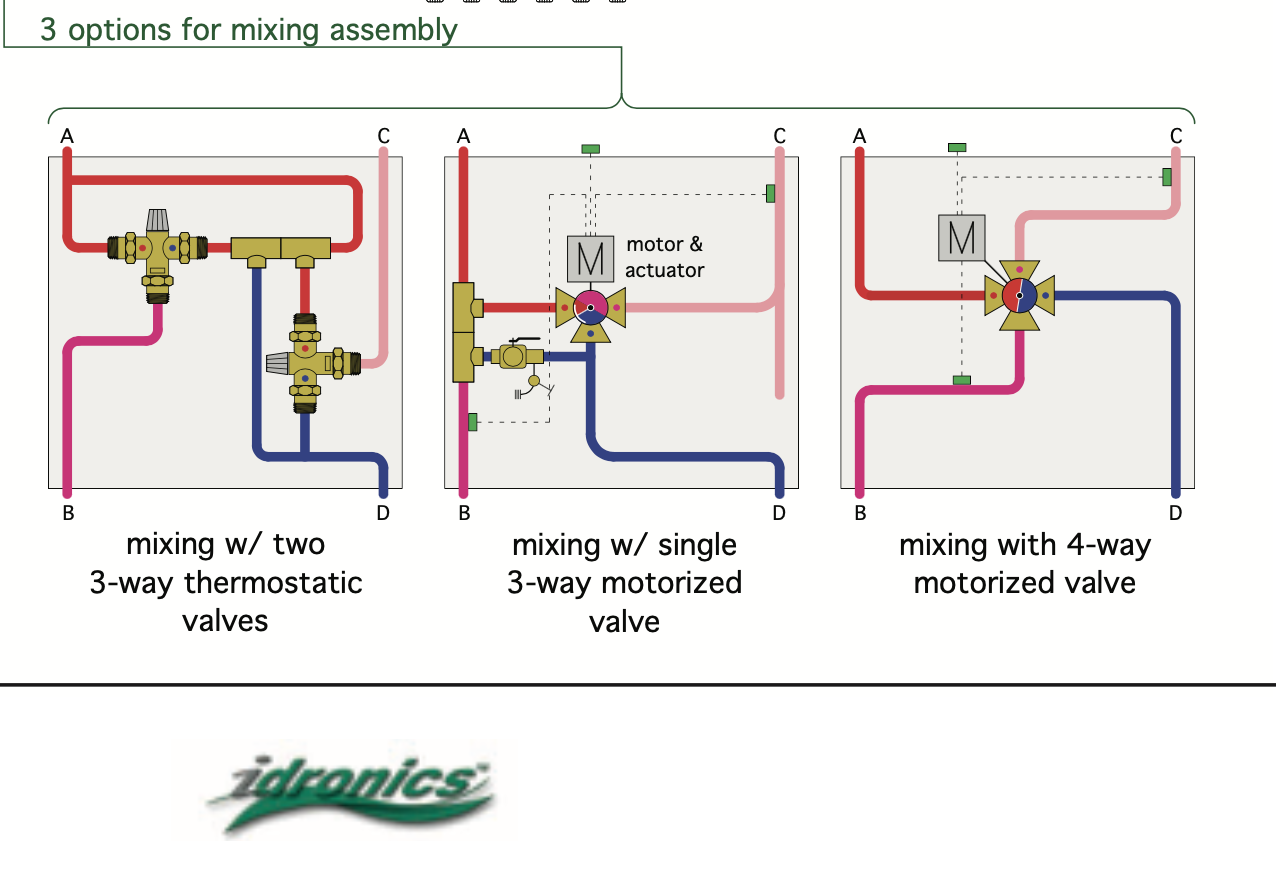

In this pic it shows a non electric valve being used to protect the boiler, the 280, and a 3 way motorized valve to mix down the radiant.

There are probably a dozen ways to pipe a system like yours as far as temperature mix down, boiler protection, buffering the over-sized boiler, etc.

Some use electronic controls, like the tekmar options. So use thermostatic valves shown here.

Some use motorized valves. Some use a combination of the above.

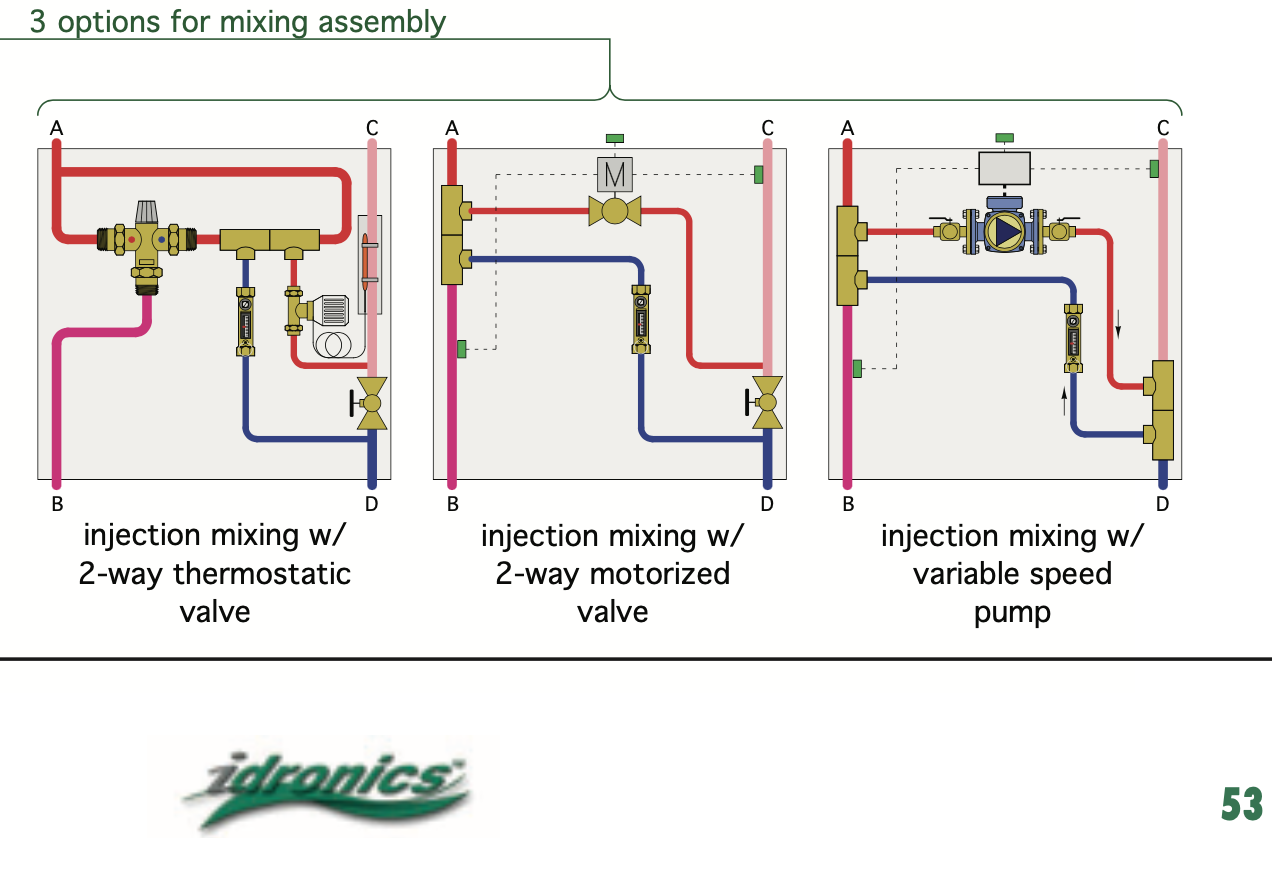

Over the years we have tried various mixing ideas, show below are yet more injection mixing ideas using valves and a VS pump. And a pic of 3 valve based mix options.

All have pros and cons.

Trying to KISS yet check all the boxes for what you want or need for your system. If it is a temporary system (boiler), I hate to throw too much technology at it.

I have seen CI boilers connected directly to radiant with a couple ball valves for temperature control, last years before failing. That is an option if this is a throw away boiler?

But keeping it safe also is a concern with the boiler within the boiler within the living enevelop.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I don’t want to throw more info at you than is necessary, but one very important question that I don’t think was asked: is that O2 barrier pex tubing that was used in the floor. It will state it in the labeling on the tube every 3 feet if it is.

If it’s not, then you’ll have to add a heat exchanger between the floor and the boiler as oxygenated water will destroy even the best cast iron boiler.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Would it be specially marked for oxygen barrier, or is all PEX-B O2 barrier? Because I don't see any specific marks for O2 barrier.

0 -

-

Ok next question.

I'd like to run a glycol mix, are there any cheaper options than the $120 5 gal buckets of cryo-tek?

Its not too uncommon to see 20 below zero in February around here.

We're at the end of the power grid and have frequent power outages, I do have a generator setup but am still nervous should something happen when we're away.

0 -

Call local supply houses and check their prices if they will sell to the general public. online retailers have to have a higher markup on glycol because of shipping and handling concerns.

0 -

I have ordered all the components to build the manual 4 way to keep things as simplistic as possible for now. Maybe I'll keep an eye on eBay to see if a cheap actuator and control pop up...

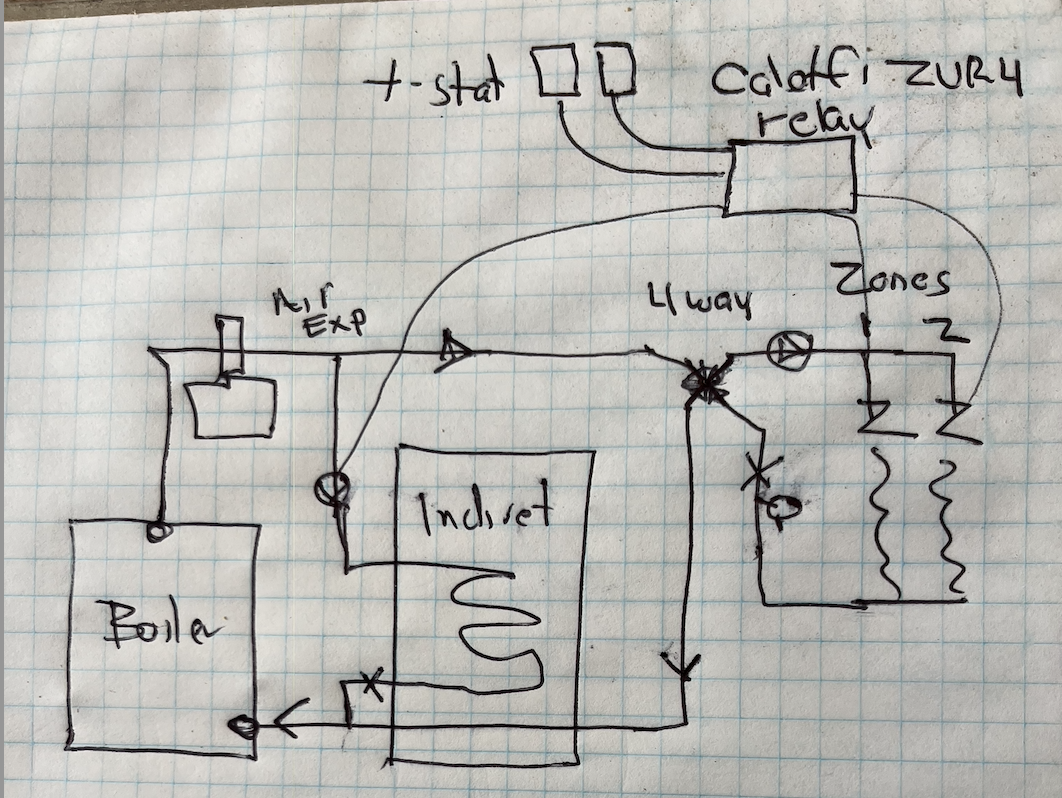

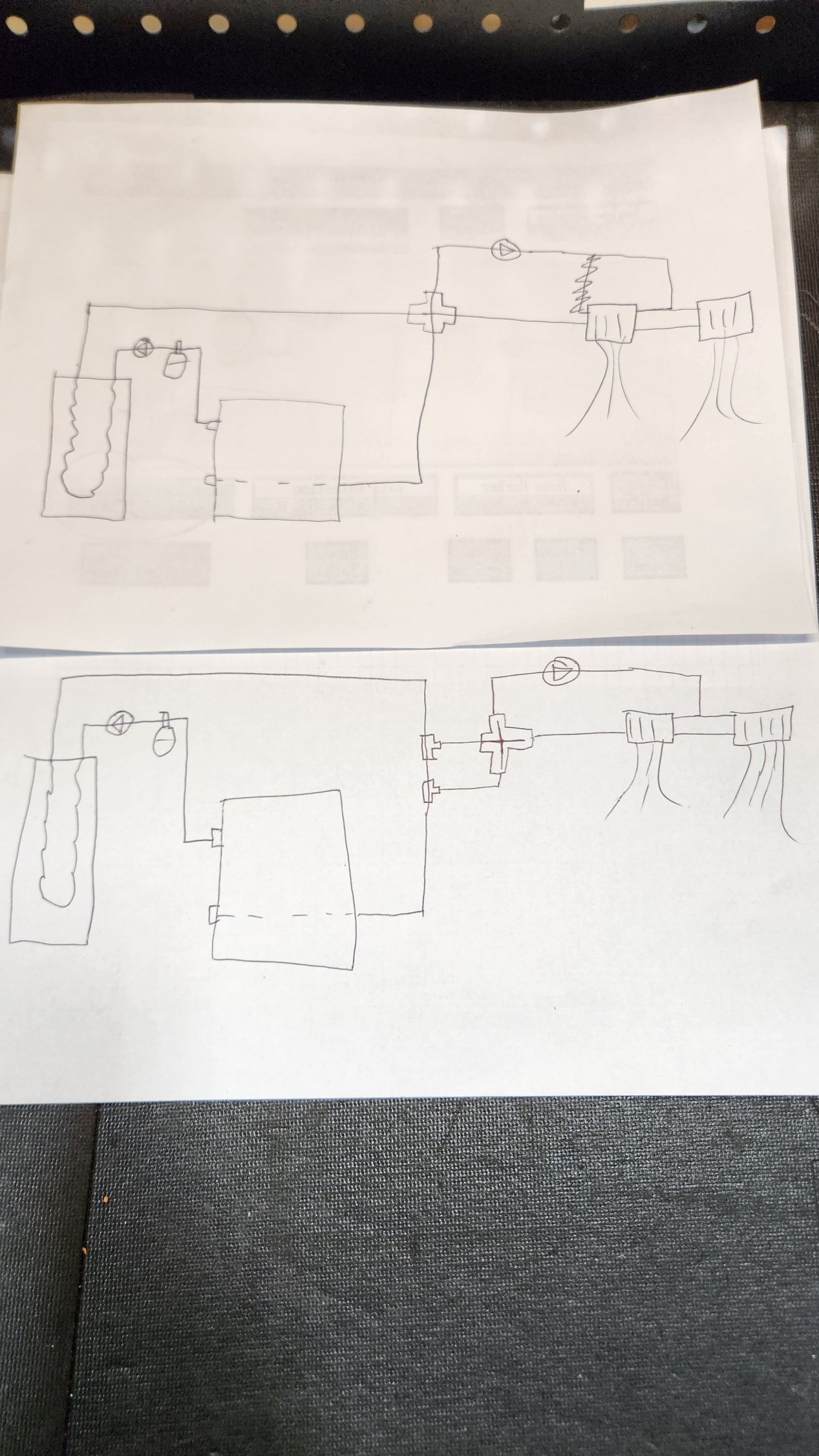

I do want to keep the indirect in the boiler loop as dual purpose/buffer, so that the indirect auqastat is what is calling the boiler on, and the thermostat will just cycle the pump in the system as one zone.

I figure I will need a primary/secondary setup with closely spaces tees to separate the loops so that heat doesn't bleed through when only the indirect is calling for heat. Is that correct?

Here are my sketches, the top was without the closely spaces tees. The bottom is what I'm planning on.

How does this layout look, is there anything I can do better or any important details I'm missing? I ordered a dirt separator as well, I assume that should be down low?

0 -

Cryo-tek AG is 100% glycol, as opposed to 50% for the regular. It's currently $168 for 5 gallons at Supplyhouse.com:

https://www.supplyhouse.com/Hercules-35285-Cryo-tekTM-AG-Anti-Freeze-Glycol-5-Gallon

Cheaper, but still stiff.

0 -

-

I made a deal with someone on FB marketplace to buy 4 unopened buckets of cryo-tek 100 for 300 bucks.

I plan to start building the system this weekend, just have to buy the copper pipe. Is there any reason to go with type L over M or is it not worth the extra expense? I will be sweating everything.

0 -

If you're looking to keep the cost down, M Copper is perfect. Using L on heating is overkill in most cases. Mad Dog

1 -

Ok I hate to keep bouncing back and forth but I am learning SO much and thanks to all for that!

I'm comparing costs and am now coming back to the variable speed injection. Turns out the cost of a 4 way Tekmar valve and 4 unions is about the same cost at a Tekmar 356 injection mixing controller.

So basically cost difference between a completely modulated VSIM system with ODR, vs a totally manual "dumb" system with no ODR, is just the injection pump.

Are there any other pumps aside from the $330 Grundfos 10-16 that are low flow enough to work? It appears the only low flow pumps are for DHW recirculation which I assume are higher $ because they are potable.

I have a lead on a used Taco 006-B4 hot water circulator pump I could get cheap. I looked up the curve but am having difficulty interpreting what it means.

0 -

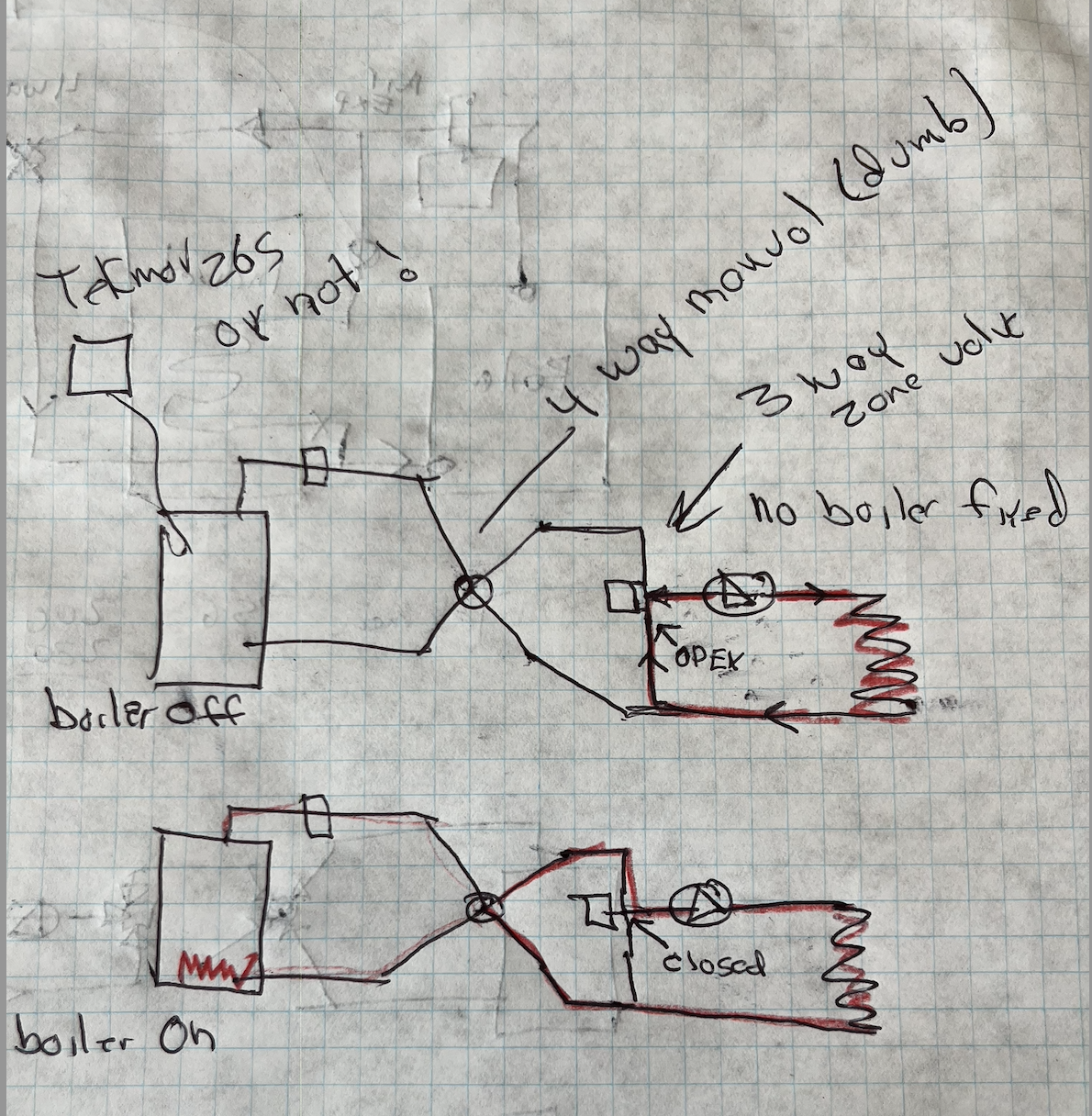

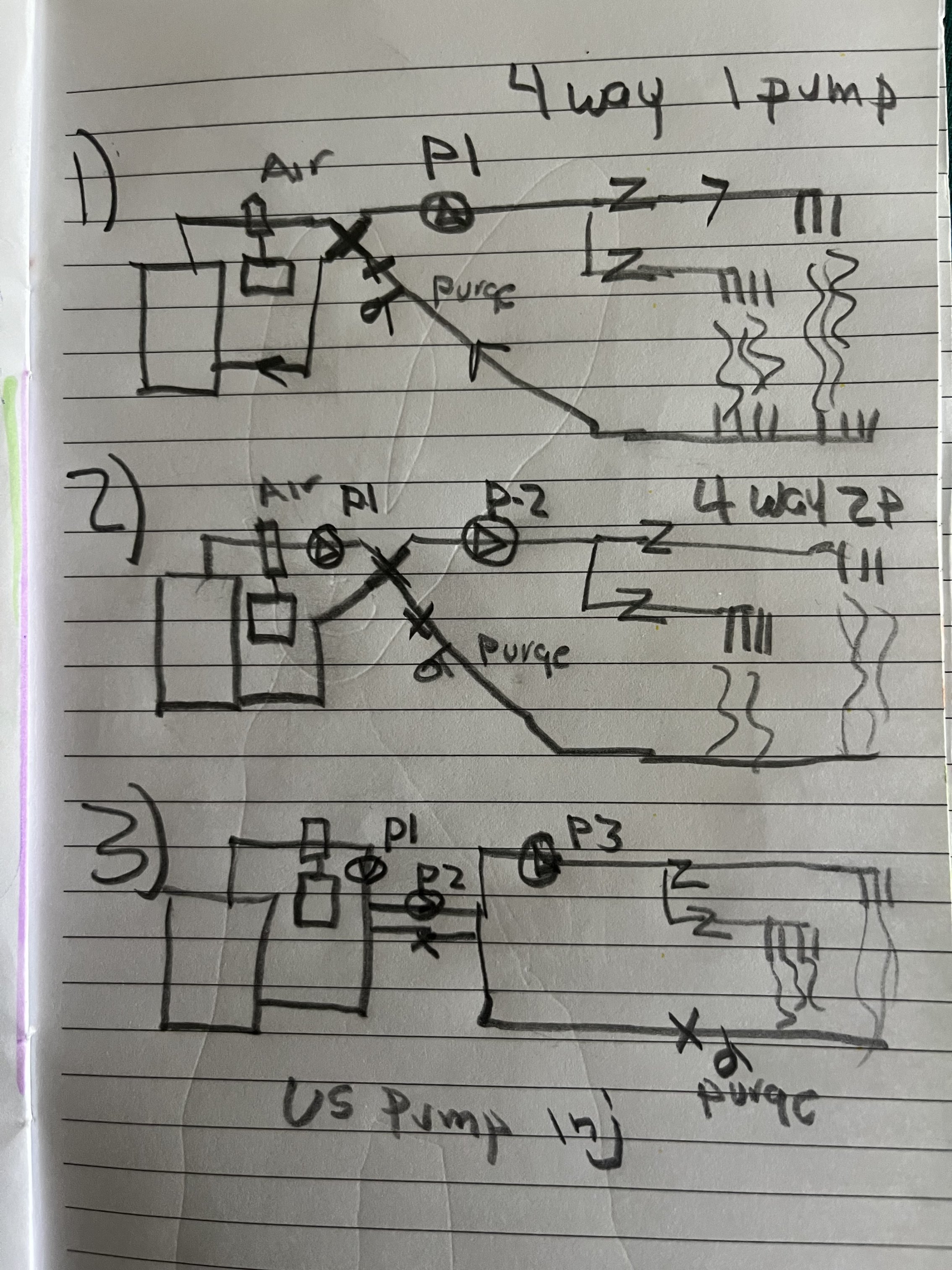

Here are 3 options on one page to better show the difference.

Option 1, my choice, a 4 way valve with only 1 pump

Option 2 a 4 way valve in a primary secondary circuit, requires 2 pumps, one for the boiler one for the radiant loops. Basically the Taco i-valve drawing

Option 3 variable speed pump injection. This will require 3 pumps. A boiler loop (primary loop) p1.

The injection pump, p2 yes an 006 would work, and a balance valve in that cross over piping.

Then the radiant loops pump p3You want isolation flanges at every pump also for future service

Not shown is the indirect, it would need a pump also as a parallel loop

so add the cost of the 3 options with all the required parts

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@ajping3830 You are finding the challenge with anything hydronic. The big stuff is reasonable price but all the little bits can add up very quickly.

I think my earlier suggestion with the fixed bypass and thermostatic mix is probably the cheapest BOM, Hot_rod's single pump is probably similar cost.

I would not bother with anything copper. Use a bit of black pipe around the boiler to support any pumps, the rest with O2 barrier PEX or PERT. Sticks of 1" PEX are your friend for a clean install.

0 -

Thanks for all the help guys. I think I've learned enough that I'm entirely capable of building any of these systems successfully, at this point it's just up to me to pick a direction and go. I'm struggling to decide between keeping it as simple/cheap as possible or spending a little more for a more efficient system.

Realistically, as long as the system is reliable it could be in place for a few/several years so any $$ put towards efficiency gains may pay for themselves. As much as I'd like to think we'll be upgrading to a modcon soon, as much as we have left to do yet on the build it could be a while until we could afford that.

Would there be a significant difference in efficiency with say a VSIM system with ODR vs a entirely mechanical/manual system?

Also @Kaos why didn't you mention the PEX sooner! I don't know why I never thought of that 🤦♂️

I've already ordered almost all of the fittings but no pipe yet, maybe I can return some fittings and do sort of a hybrid copper/black pipe/pex system with any of the longer runs being PEX.

0 -

Do you have a way to cut and thread black steel pipe? If not you need to buy all pre-threaded nipples. You may may find the copper comes out cheaper and you can cut to exact dimensions easily. Although the HD and Lowes stores will cut and thread black steel pipe at no charge if you take a list of sizes. My local HD will do up to 1"

For the flow rates you are working with 4 gpm or so, 1" pex could do some of the piping. You need the crimp tools, of course.

With that high mass slab, you really want a system controlled with ODR. It will prevent over-shooting, the flywheel effect and keep operating costs at a minimum.

I would like to see how low you could actually run the boiler. If you could run down to 150, that would save some fuel also. I'm not sure how the DHW indirect would perform at low boiler operating conditions. Recovery time would slow, compared to a boiler running 180F.

If you start with the manual 4 way you can up grade later.

Neither the 4 way or VS injection will be needed if and when you go to a mod con.

At this point I am more concerned about a very small heat load (1 zone running) on that size boiler. It could cycle on/off every few minutes. That is not a good operating condition for fuel use and boiler life. You may drive that boiler down to a 70% cycle efficiency if it bangs on and off all season.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If you want to keep it as a simple as possible "forever" an overhead gravity system eliminates the need for circulators and the open to air expansion tank can have its overflow pipe piped to a laundry sink or floor drain.

There is a great deal of information here on the forum about gravity hot water systems that you can read about or you could purchase Mr. Holohans book CLASSIC HYDRONICS from the Heating Help Forum Bookstore and learn how the gravity hot water system works with no circulators.

The open to air expansion tank can be a vertical tank simply placed on the upper floor in the loft out of the way and the drain line could be pex to a laundry sink or floor drain.

The open to air expansion tank would have a sight glass in it to show the water level in the tank or you could occasionally add water to the manually through the boiler to maintain the needed water level for it to heat and rise into the tank and drop back down through your heating loops.

I helped a friend in New Mexico repair and replace his neighbors rusted out open to air expansion tank with a new galvanized expansion tank mounted in its original saddle mount configuration and his neighbor is very happy as she has plenty of heat in her hot water radiators now.

You run the boiler at 170 degrees and the water will rise naturally to the tank and then drop back down to your heating loops without a circulator.

0 -

Honest question: how would you provide thermostatic control on a system like this?

0 -

The boiler high limit is all that is needed to regulate the system temperature.

Each radiator has shut off valve that can be closed slightly or fully closed if desired slowing the flow of hot water entering the radiator from the top in an overhead gravity hot water system.

The hot water simply rises with the temperature of the water in the hot water riser which reaches the open to air expansion tank in the upper floor and then drops by gravity to the radiators below and from the radiators to the boiler sump.

There is no need to complicate his heating system further when everything is wide open and he can place an expansion tank in the loft and pipe/pex the overflow line to a laundry sink or floor drain. The water feed line is tied into the hot water riser to refill the system as needed watching the overflow line from the tank to shut the water feed line off assuring the open to air expansion tank is filled to the correct level.

0 -

How do you make it so that it produces more heat when it's 10F out than when it's 50F out?

0 -

The boiler continues to fire heating the water to 160-170+ degrees in the system until the thermostat in the home is satisfied. Simple controls, simple operation, the homes heat loss affects how well the heat created by the overhead gravity heating system is sent through the radiators and in floor heat as it will be moving continuously by simple convection.

Gravity hot water heating systems create slow and even heat for all weather conditions heating the entire living space as one room so to speak as the hot water is constantly moving and radiating heat and returning to the boiler sump at a cooler temperature but not so cold that it could shock the boiler.

The twin risers to the loft where the open to air expansion tank is could be one inch copper or pex to allow the hot water to move quicky to the highest point and then descend quickly to the floor heat and radiators if used.

0 -

"the homes heat loss affects how well the heat created by the overhead gravity heating system is sent through the radiators and in floor heat as it will be moving continuously by simple convection."

I have heard this claim made many times, usually for floor heat, that somehow systems will be self-regulating because the heat delivered will increase as the heating load increases. This can only be true if the temperature difference between the water and the interior of the house increases. In order for that to happen either the water temperature has to change or the interior temperature of the house has to change.

If you're relying on the interior temperature to change to regulate the output, you don't really have thermostatic control!

I agree that a simple on/off thermostat that controls the boiler could work, assuming that the time lag between the boiler firing and heat being delivered can be kept to a reasonable amount of time.

Now, with a concrete floor, the assumption is that the time lag isn't going to be reasonable, it's actually likely to be somewhere between several and many hours. To control the amount of heat the boiler delivers to the floor you have to either modulate the temperature or the flow rate of the water, and you can't base that modulation on the indoor temperature, you have to base that on the heating load, which typically is done by measuring the outdoor temperature.

Another approach is to have the floor output a relatively modest amount of heat, and use either radiators or force air to give real-time adjustment to the total heat output to match changes in the interior temperature.

0 -

-

You should add steel and cast iron tube radiators of all sizes to the graph Bob.

They put livestock watering tanks in the attics of homes in England and New Zealand to store hot water for the thermal mass heating in gravity hot water systems.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements