Best Of

Re: original circulator sized too small?

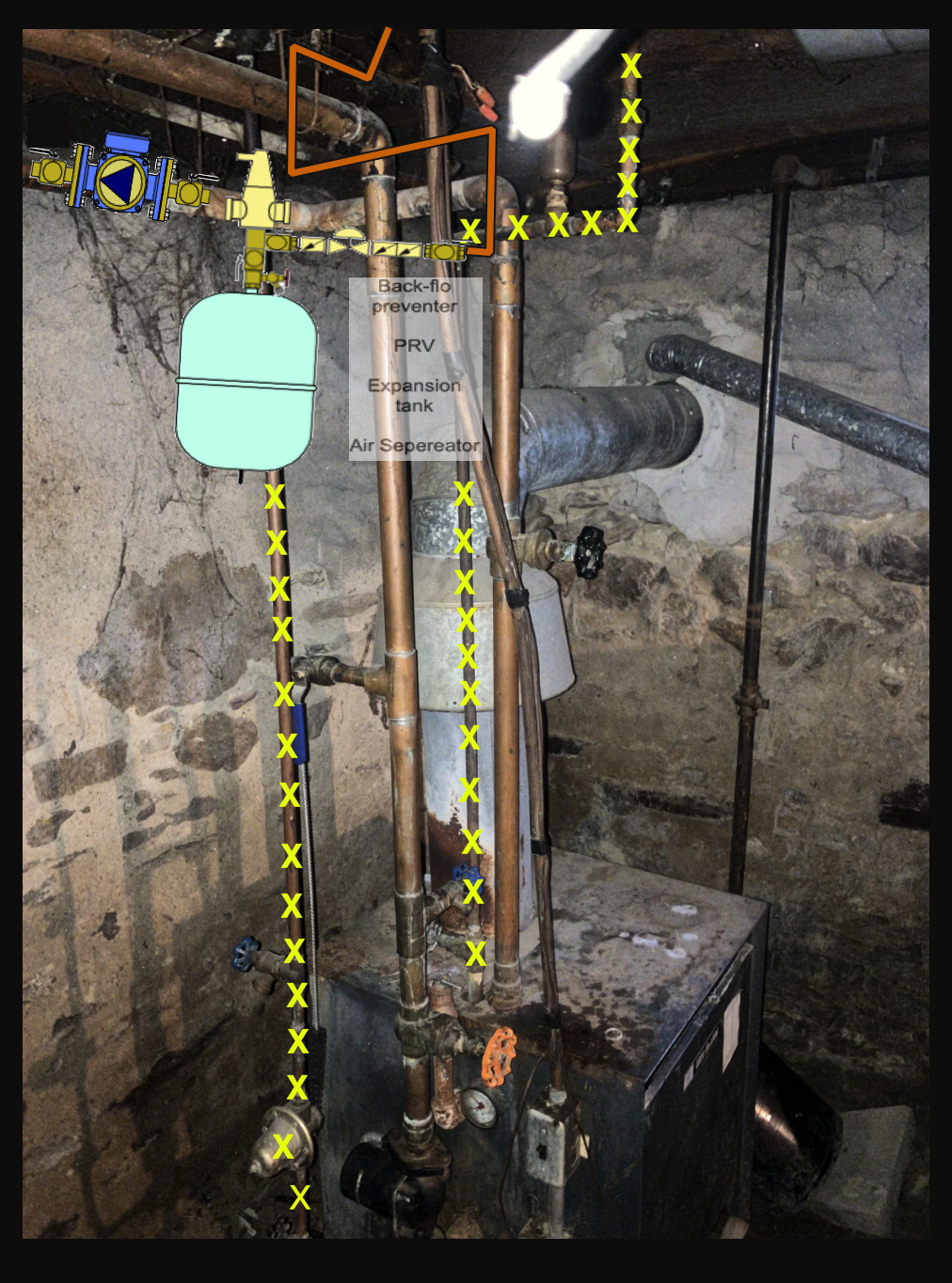

I would surely go with the Caleffi Discal or SpiroVent to make all those micro bubbles crash into the element inside the vent that causes them to make larger (more buoyant) so the can easily float to the top of the air vent chamber. Then the vent will open to let out that air. Noe your current boiler feed and expansion tank piping needs to be redesigned, you may as well just get new Extrol 60 for your system and make it look like this.

The new feed line will enter at the same location as the expansion tank so not to have the pressure of the tank and the auto feed working against each other. (see new copper feed). You can just place a set of circulator flanges connected to a 5-1/2" long x 1-1/4" pipe nipple to replace the existing circulator. No repiping needed. Just a set of flanges and a a couple of full face flange gaskets.

Re: Steam device to be identified

@jeje59350 , read the article I linked to above. I'll bet it explains much about that system.

Re: Steam device to be identified

@jeje59350 , welcome to HeatingHelp. It looks like I'm going to have to visit Paris at some point.

A "boiler return trap" is basically a pressure-powered pump that comes into play if the steam pressure gets too high for condensate (water) to return to the boiler by gravity. These were pretty common in the States, and were used mostly on Vapor systems, which were 2-pipe steam systems that ran with a maximum pressure of 8 ounces (roughly 40 millibars) or so.

Where does that pipe go that comes down from the bottom of the device? Does it connect to the return line? Are there any check (one-way) valves in the piping under the device?

Also, you might be interested in this article:

Re: Debate me Bro-3/8 inch pex 150 foot lenths AOK for high delta T radiant

fair question. dont have the tools on my cell but IIRC the pressure loss in 150' of 3/8 is still more than 300' of 1/2. so i was anticipating that i wouldnt amp up the circulator and the flow rate would be lower than target but i would be counting on high delta T to get the btus out and i have always 0referred that strategy even with 1/2 inch.

i can see from post below you share my affection dor 3/8. and they aint going broke selling it dor essentially the same price as 1/2.

and , to be fair, it is the pressure delivery at flow numbers on the plumbing side that warn folks off but i shower with 3/8 pex and im happy. i have to admit i chickened out running it on hot side to showers in 4 story building although i wanted to to cut the time to get hot to the shower head. if i would have had easier access to the chase i would have tried it .

so my occams razor take on the 'industry' is not even that they tell folks to do qhat is profitable to them but that they have given up on thinking about the best ways to so things and go the easy way for them. that includes the industry letting us down with regards to speaking out against bad regulation instead of just going along .

brian

Re: Oil Water Heater for Disabled Couple on Long Island

In the land of nearly reasonable electric rates….(thinking LI not so)…..an electric WH would seem good for an elderly couple.

Re: My three worst jobs sites. What are yours?

Aw c'mn guys. Sewage treatment plants aren't bad. I've worked several in my day, and first place you get used to the smell. Second place, personal hygiene is number one. Never washed my hands as often again. Third place, if the operator is any good at all, the place is really pretty clean… and we were really big on confined space protocols.

Oh just one more thing. Don't go for a swim…

Re: Debate me Bro-3/8 inch pex 150 foot lenths AOK for high delta T radiant

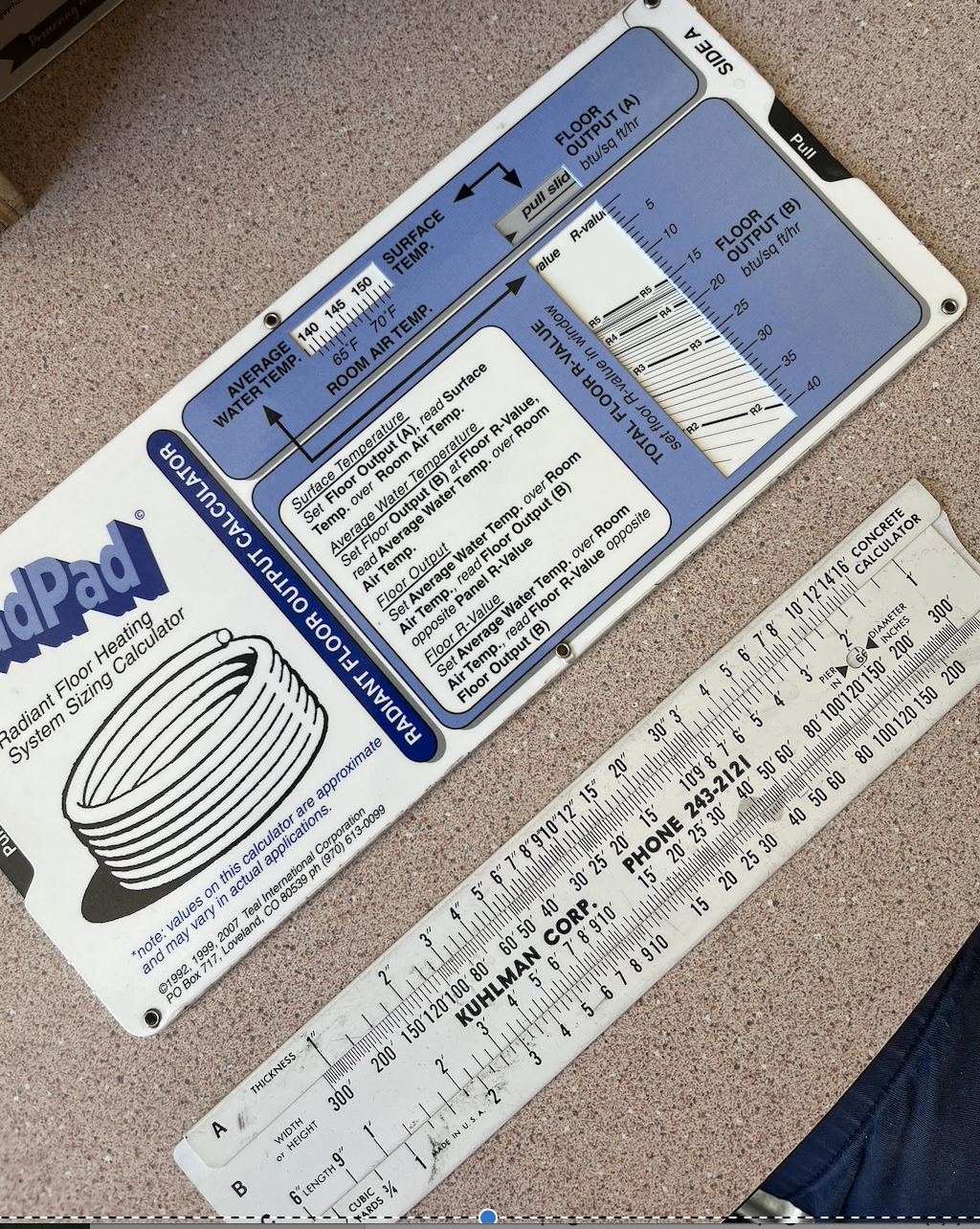

Two slide rules that I still use. I find them as fast as opening a software or app.

The Rad Pad developed by Larry Drake. 1992!!

A concrete calculator.

I do have an extra RadPad somewhere if @archibald tuttle wants it

hot_rod

hot_rod

Re: Ruud Monel Water Heater

where is it leaking? unless it is a connection it is done. those have a gas valve that is questionable at best and i believe have the inlet and outlet tubes routed in such a way that you can't put a modern t& p valve on them.