Best Of

Re: A/C Capacitor Voltage

The life of an electrolytic cap is a function of voltage and temp. It will work a bit above its rated voltage for quite a while but won't get its rated life. You can get more life by using a cap with a significantly higher voltage rating than the working voltage.

Re: A/C Capacitor Voltage

When it comes to Capacitors for HVAC repair I stopped stocking 20 different dual and 15 different single caps in favor of the Turbo 200. Three of those per truck and one of the larger Turbo caps greatly reduced truck inventory costs and space. I can also offer a 3 year warranty on them because Turbo offers a 5 year warranty. I just need to cover the labor portion. That Turbos are all rated at 440 and you can build the exact uf you need. I know that they are more expensive that the ones made of chinesuim but the warranty suggests that they will last longer. A better deal for the customer that is paying retail for repairs.

Re: A/C Capacitor Voltage

The voltage rating refers to what voltage the capacitor is rated to withstand, not to what voltage that will be measured at its terminals. If the actual measured voltage is in excess of its RATED voltage, then a higher rated capacitor should be used.

It never hurts to go up in rated voltage. In fact, it’s a good practice.

Ironman

Ironman

Re: A/C Capacitor Voltage

If you need a 370 V capacitor you can use a 440 v capacitor. If you need a 440 V capacitor you can not use a 370 V capacitor. So if you don't know if you need a 370 or 440 then you should use the 440. If you can find the original specification in the equipment docs, and it specifies a 370, the you are good to go.

Re: tiny droplet leak from the oil tank firomatic shut off valve.

I know it was asked a few times but How old is the tank? This can be a simple repair for an experienced oil technician. It can also turn to crap pretty quick.

Before I thought about this job I would let an experienced set of eyes take a look at the whole tank. Better safe than sorry.

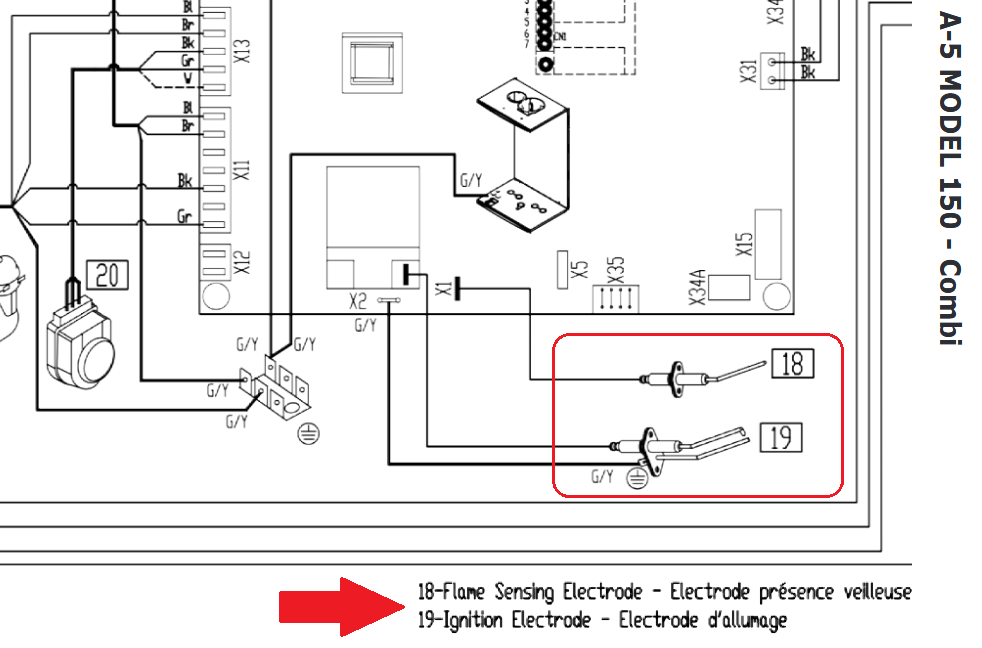

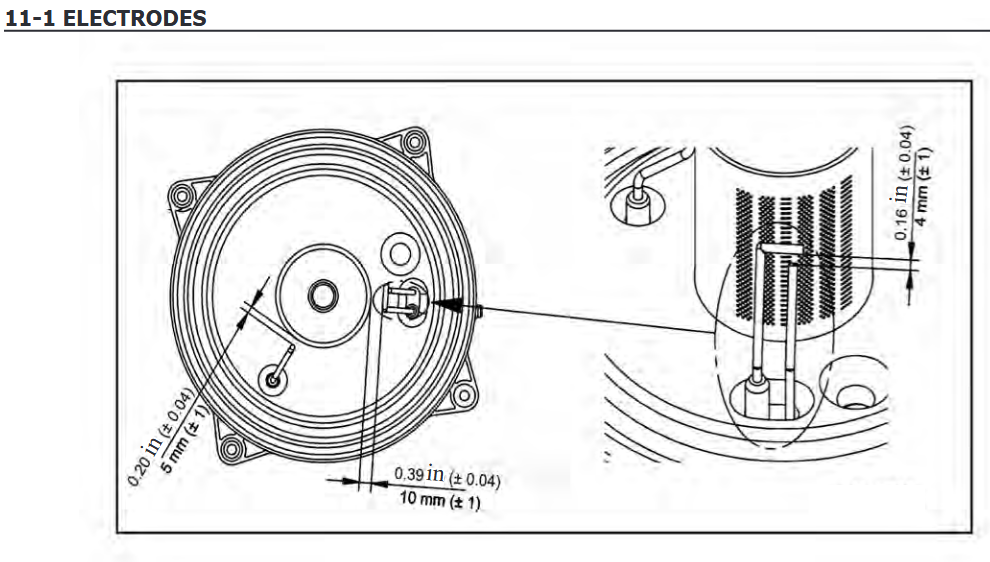

Re: Strange situation of Utica MACF 150

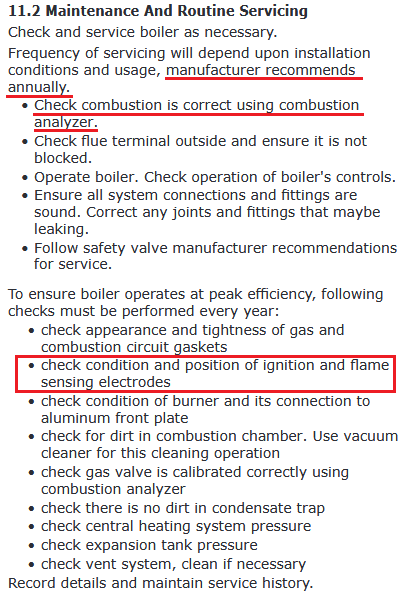

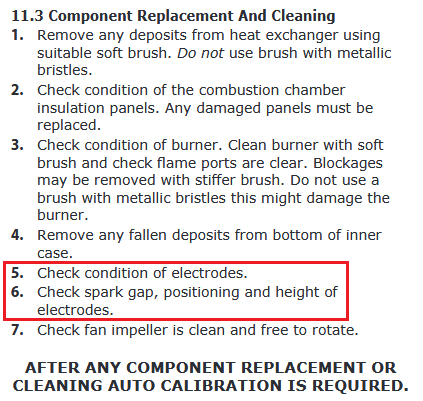

Regardless of who put what where I would restore it to the manufacture's intended electrode placement. Looks to me like there is an intentional bend with both electrodes to get the electrodes near where the flame is expected to be. Since the electrode gaps are almost the same, 4mm & 5mm I could see it working if the wires were swapped. However it appears the Ignition Electrode has its own dedicated ground wire. The ignition spark should jump across the ignition electrodes gap. If the flame sensor is used for the ignition spark it would arc to the burner which may cause damage.

If either or both electrodes are dilapidated they should be replaced.

https://uticaboilers.com/wp-content/uploads/2022/09/MACF-MAHF-75-205-FLOOR-CONDENSING-BOILER-MANUALS-MGC-1225-REV-A.pdf

Re: Air Vent Requirement

On a one pipe steam system, vets on the main or the risers will determine how fast steam reaches a given radiator. The vent on the radiator will determine how long after steam gets there before the radiator is filled. Two different functions — but on most one pipe systems the runouts and risers do not have vents, and the radiator vent handles both functions, and that is perfectly fine if the radiator heats adequately along with the rest of the system. If a specific radiator gets steam much more slowly than desired, then a vent on the runout or riser can help

Re: What size pex tubing do you recommend?

For an ice melt system you would want 3/4" pex, 9" on center.

What size boiler do you have to run this?

Call; it 600 sq ft times 125- 150 BTU/ sq ft = 75- 90,000 btu/hr per bay

hot_rod

hot_rod

Re: any suggestions on pumps?

well you don't add the 2 head loss together assuming they are piped normally, if they are piped in series so one has to flow through the other first then your "furthest" zone via piping would just have a higher pressure drop (head)

So your first example with a 20 degree delta T you would size your pump for

(2 + 3.5) GPM @ 7' head (highest pressure drop)

5.5 GPM @ 7' Head

add a little fudge factor to that

6GPM @ 10' head = Alpha 15-58 even if you were to add the head this would fall within the curve so not sure where the issue is there

or for example 2 with a little fudge factor

10 GPM @ 25' head = Alpha 26-99

I would go with the 15-58 personally, especially if you are pumping each zone. If the 10 degree delta is very important then you would need a 26-99. feels a bit like overkill though.

Re: how to connect this steam radiator?

With any kind of luck, that means that the more or less horizontal runout under the floor isn't horizontal — that it's sloped back to the main, as it should be. That would be very nice…

And no, that is WAY too much out of line for a union to work. In fact, any alignment error is too much for a union.

However, there are ways… and the best is create a swing joint with two elbows at 90 degrees to each other (or one 90 and one 45) and a straight, rather than angle valve. With two elbows — I'd use street elbows — one can correct any amount of alignment error.