Best Of

Re: buying a hydronics business

- You are purchasing an income stream. If the cost of that income stream is more than the actual income you are expecting, then it is not worth the price. (maybe over a few years to recover the investment) This would include the phone number, customer list and service agreement payments that you need to honor for the remaining months until you can collect the renewals yourself.

- You are purchasing durable tools and equipment including: trucks, tools, job-site trailers, pipe threaders, copy machines, file cabinets, and all sorts of things needed to operate the business. All these items have been depreciated on the books and depending on the age of the equipment, may have no real value accounting wise. So 10 cents to 50 cents on the dollar for most of those items is fair, and rolling stock has a blue book value. You are paying the wholesale number, not the retail number. The seller is like trading in the vehicles and you are the car dealer. You don't pay retail for that stuff. What could the seller get it he was trading that stuff into a car dealer?

- You are purchasing inventory. If there is new equipment like boilers, heat exchangers and water heaters, and they are less than 2 years old, then you can sell them as new and can afford to pay 50 cents on the dollar. Small parts like relays, circuit boards, controls and thermostats, then those are 10 to 20 cents on the dollar. Many of those parts that are over 2 years old are something that you may sit on for 10 years and never be able to sell to a customer. You want to get those inventory parts down in value to something you really don't want. Many items can be purchased as needed with internet suppliers shipping the next day. So having a large parts inventory over and above what you may want as truck stock is really an expense you want to keep as low as possible. My inventory when I sold my company was in the books at the price I paid for those items and not deprecated. You need to discount that number based on what you can expect to sell within the next 2 years.

- Real Estate or location rental is to be negotiated based on the size of the business and your existing location. Is this going to provide you with an affordable answer to growing your business that you may have been running out of your garage. So that must be considered.

With all that to consider, you need to look at the books and tax returns for the last three years to determine if you can get value from what you pay for the business.

Re: buying a hydronics business

at 21 & 23 I don’t see enough experience to run a business and hire employees much less spend money you don’t have.

do you have a business plan that the bank will want to see?

Know the cost of Workman’s comp, liability insurance, vehicles, tools on and on.

pecmsg

pecmsg

Re: buying a hydronics business

I would pass and just build up the business yourselves through quality work and word of mouth. A good business coach would be a better investment.

Generally the business you look to buy is fairly worthless for 'good will' and only the equipment has value.

Unless they can prove to you an income stream, and/or large service contracts providing repeat business, you’re over paying for leads.

Re: Why don't we pump away from expansion tank on dhw recirc systems?

Probably the simplest reason is that as many have implied there is very little if any chance of the pump cavitating, never mind pulling air. It would be a very rare domestic water setup which had a static pressure less than around 20 psig; 30 psig would be more normal. With that much static pressure you would need 60 feet of head loss or more between the expansion tank and the pump inlet to get in trouble. Not going to happen…

Re: Why don't we pump away from expansion tank on dhw recirc systems?

I suspect the chances of a pump pulling air in are mighty slim when the system is somewhere between 40-90 PSIG. The inlet of the pump is never going below atmosphere.

And even if it does, no one cares with domestic hot water.

That's my thoughts, but, I have very little knowledge on hot water systems.

ChrisJ

ChrisJ

Re: Soldering close to soldered fitting

Cut it all out and sweat it. It will take less time than worrying about the press fittings. You have plenty of copper coming out of the valve on the run of the tee. Remove the PP tee and coupling and sweat it.

No need to spend $25 on heat block for what a few fittings cost.

Re: buying a hydronics business

What does this "business" include? Does he have a lengthy clientele list or service contracts that come with it? Trucks? Inventory? Property? Tools? Without a name/reputation and clientele, a business is generally worth about 80% of real property value (tools, vehicles, inventory, equipment, etc). I run an upper 6 figure hydronics business but if I sold out tomorrow, it'd be worth $50k at most and that's only because of the aforementioned real property. The name isn't worth a dime if somebody else is at the helm, and there are no service contracts or guaranteed income to sell.

Re: compressor

Resistance of the windings is different than megging the windings.

Winding resistance is taken with a multimeter (or ohmmeter) set to resistance/ohms/Ω (if not autoranging then generally the lowest range). Should be less than 40 Ω between the run terminal ("R") and common ("C"). It will be different between start ("S") and common, but I can never remember if it's a little higher or a little lower. The measurement between R & S is ≈ the sum of the measurement between R & C and S & C.

'Megging' a compressor is measuring the resistance of the insulation of the motor. It's taken with a megohmmeter between any one compressor terminal (doesn't matter which) and ground. With a cold compressor, it may be as low as 20 MΩ but may creep up as you measure. A regular multimeter isn't a good choice for this measurement. While it can tell you if the windings are good and shorted, it can't tell you if there's a weak spot that's getting ready to blow through.

Re: Soldering close to soldered fitting

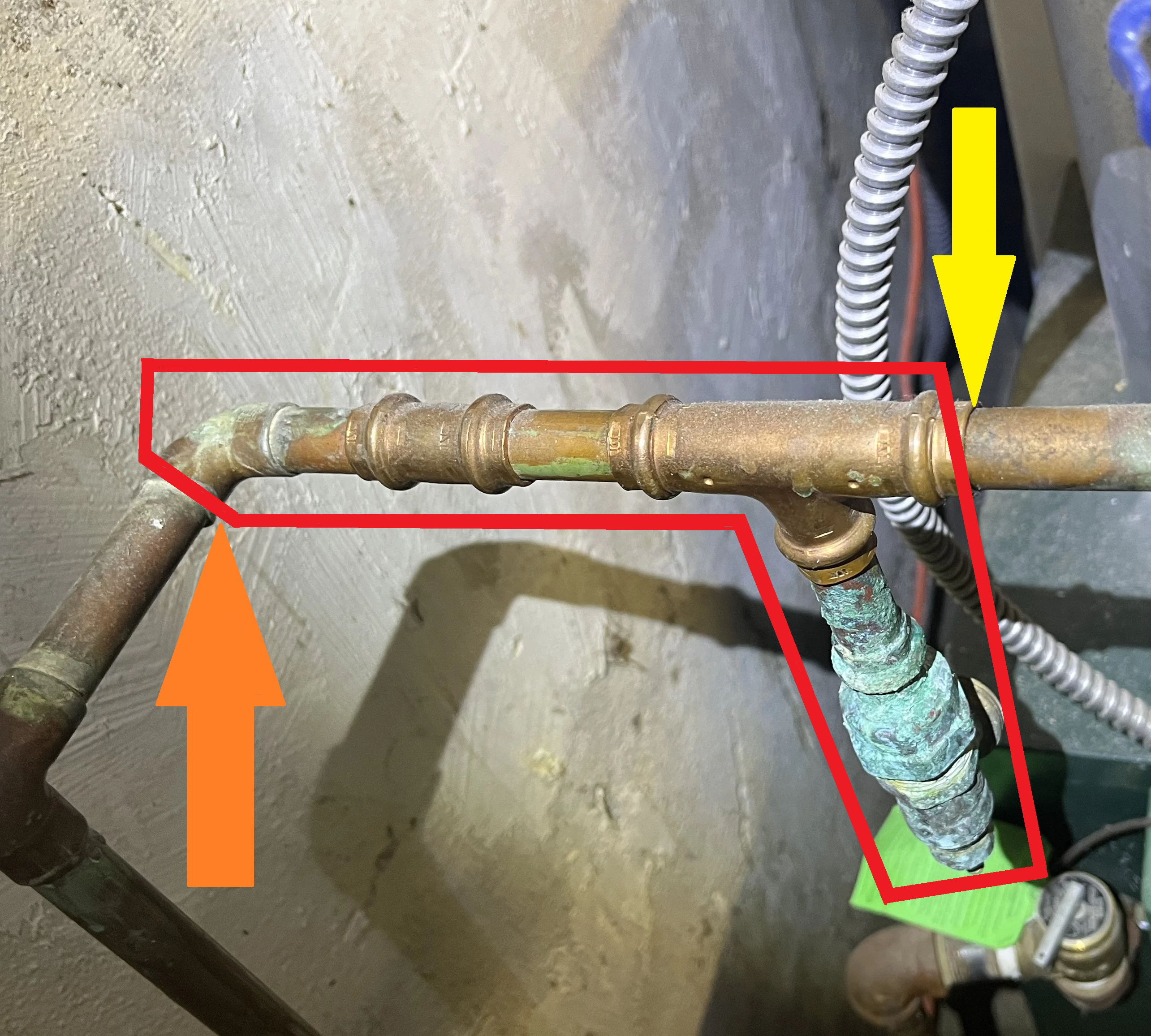

If it were me, I'd remove the mess encircled in Red by cutting at the Yellow arrow and un-solder at the Orange arrow and rebuild as needed.