Best Of

Re: Cheap, Easy, And Invisible DIY Solar Thermal?

Go full passive. It's called well thought windows and and insulation and building mass.

If you're not keen on the passive solar houses which Bill Shurcliff and Norman Suanders and I were doing now some 60 years ago in New England, which still are working well — but have no sizzle, no pipes, no collectors, no pumps, no fancy valve systems (which was and remains a problem — people can't believe they work since they look verry ordinary) go visit Acoma Pueblo ("Sky City") in New Mexico. These folks had it figure out 1500 years ago.

But I'm tired of preaching passive solar, so…

Re: Radiant flow not pushing fast enough

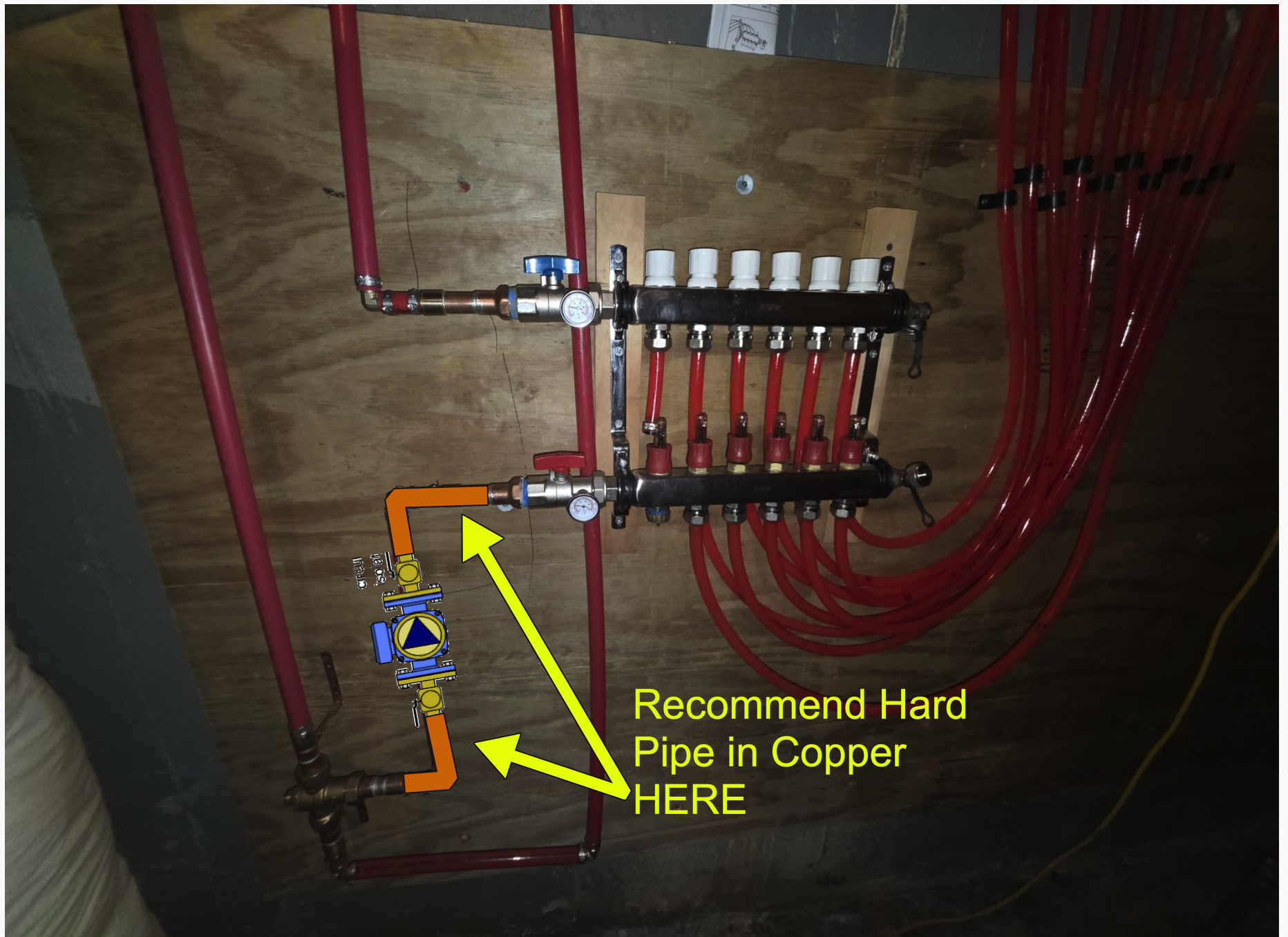

Where is the circulator for the Radiant floor zone located? It should be here (see Photo)

You may not need the circulator on the boiler side of the mixing valve as indicated by @hot_rod

Re: Radiant flow not pushing fast enough

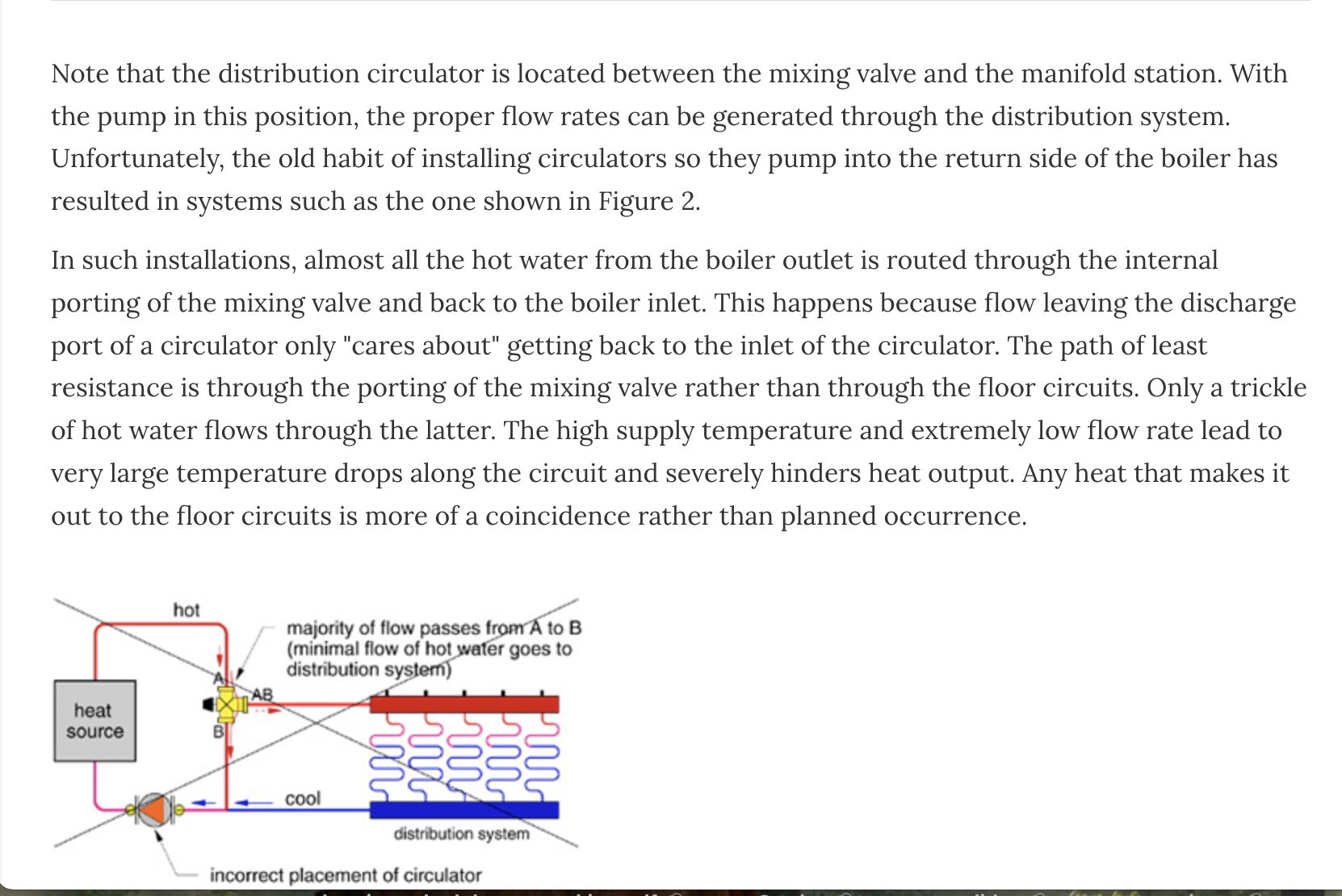

I suppose it depends on the design of the valve, not all valves shut off the hot port 100%. ASSE listed scald protection valves can shut off the hot 100%.

You should pipe up a few demos and report back :)

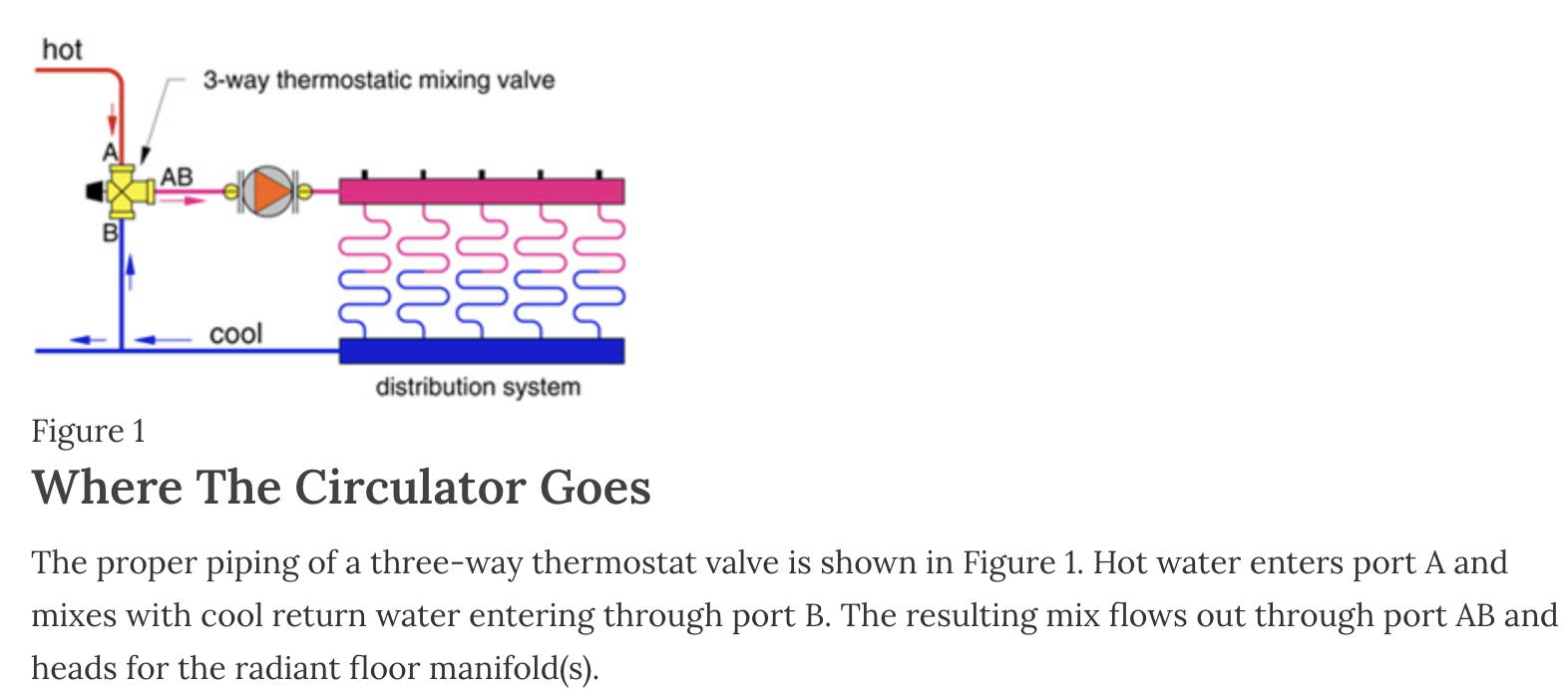

Regardless, this is how most if not all three way thermostatic manufacturers require a 3 way thermostatic to be piped, for hydronic mixing use. Piped this way it will work, piped in any other configuration you may not always get the results you expect.

hot_rod

hot_rod

Re: kenmore side by side refrigerator/Freezer

is the evaporator frozen up or just frost in the ductwork?

pecmsg

pecmsg

Re: Heating the Henry Ford Museum

As a native Michigander I really appreciated this "blast-from-the-past". But, one question: shouldn't all of those prices have been redacted—as per website policy? (I kid).

Re: Heating the Henry Ford Museum

It’s a wonderful museum. I couldn’t stop smiling at those radiators. By chance, I was visiting on the day that Rosa Parks died. I sat for a while in her seat on the bus. That also made me smile.

Heating the Henry Ford Museum

The Henry Ford Museum in Dearborn, MI has an interesting hot-water heating system. Take a look at the radiators below. They are from the Shaw-Perkins Manufacturing Company of Pittsburgh, PA. Click the button above to download the original manufacturer's documentation for these radiators. Thank you to KC_Jones for sharing these photos with us.

Re: Fixing the gurgling at the end of my Steam Mains

After you get all the crud out that is possible and assuming that both returns drop into a wet return pipe before rising up into the Hartford Loop return, you could:

Add a valve to isolate the wet return from the boiler and add a full size drain valve to the lowest point on the wet return.

Then run the boiler in the "no return" mode. This is shutting the valve to prevent any return going into the boiler. Open the new drain valve to waste the return water down a drain. You will have to monitor the water level in the boiler as you do this.

The wet return at the boiler also performs as a "P" trap and is where any crud from the return lines will collect. Your "no return" mode will flush the returns.

If you go to the "Silent Steam" U-tubes by Gordo S. you will see that they often do that with a new boiler install.

After some operation, just draining the wet returns with the drain valve will remove more debris before it gets into the boiler.

Also remove the handle from the valve that isolates the returns from the boiler when finished with the no return operation.

Re: Couple of recent boiler installation

Thanks @Steamhead much appreciated.

The steamers and one of the EKs boilers recommendations came heatinghelp.

EzzyT

EzzyT