Best Of

Re: Utica Combi Boiler (MAC-150)-Error 133- Causing big bang noise after few trial of combustion

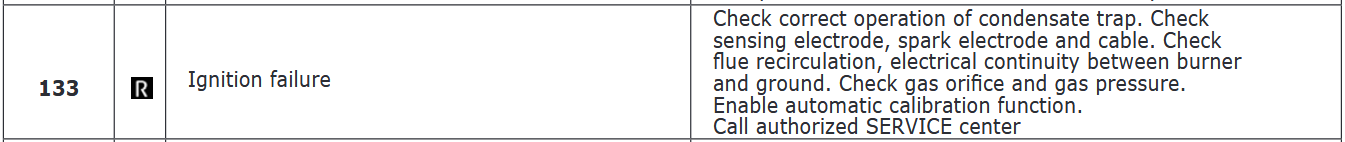

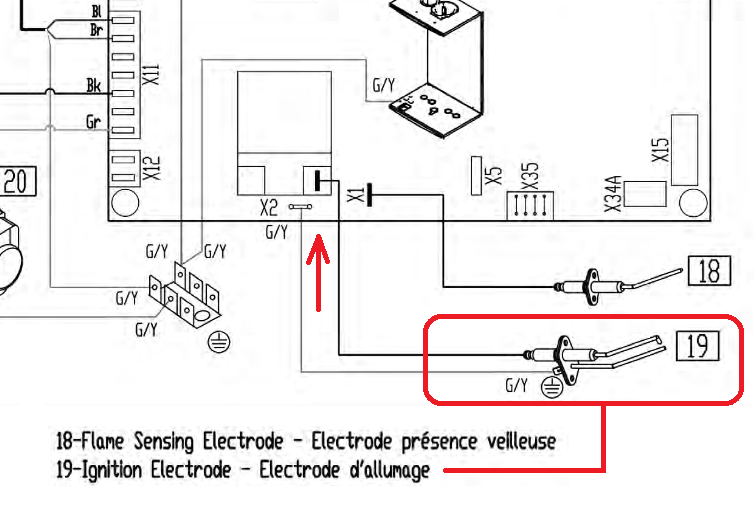

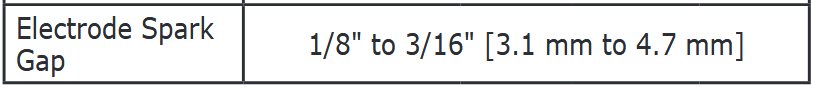

Was everything on the list for that error verified ? If the spark is poor OR not where it needs to be it won't work correctly.

https://uticaboilers.com/wp-content/uploads/2022/02/MAC-Boiler-Manual-REV-A-WEB.pdf

Re: Utica Combi Boiler (MAC-150)-Error 133- Causing big bang noise after few trial of combustion

hello all . Thank you for all suggestions. It turned out that Igniter was not working properly. Replaced Igniter and Flame Sensor solve the problem.

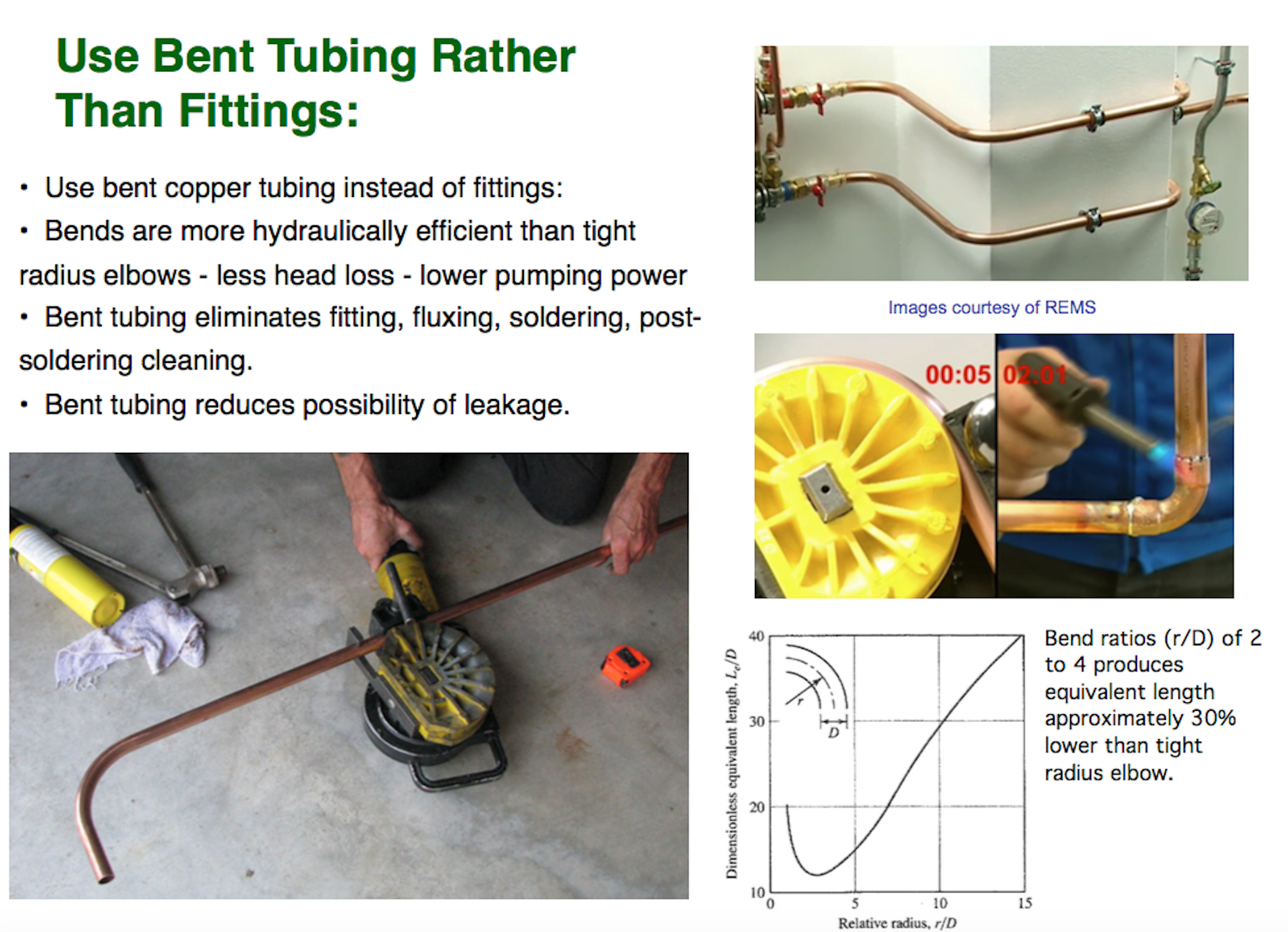

Re: What happened to Rems Tools(USA)

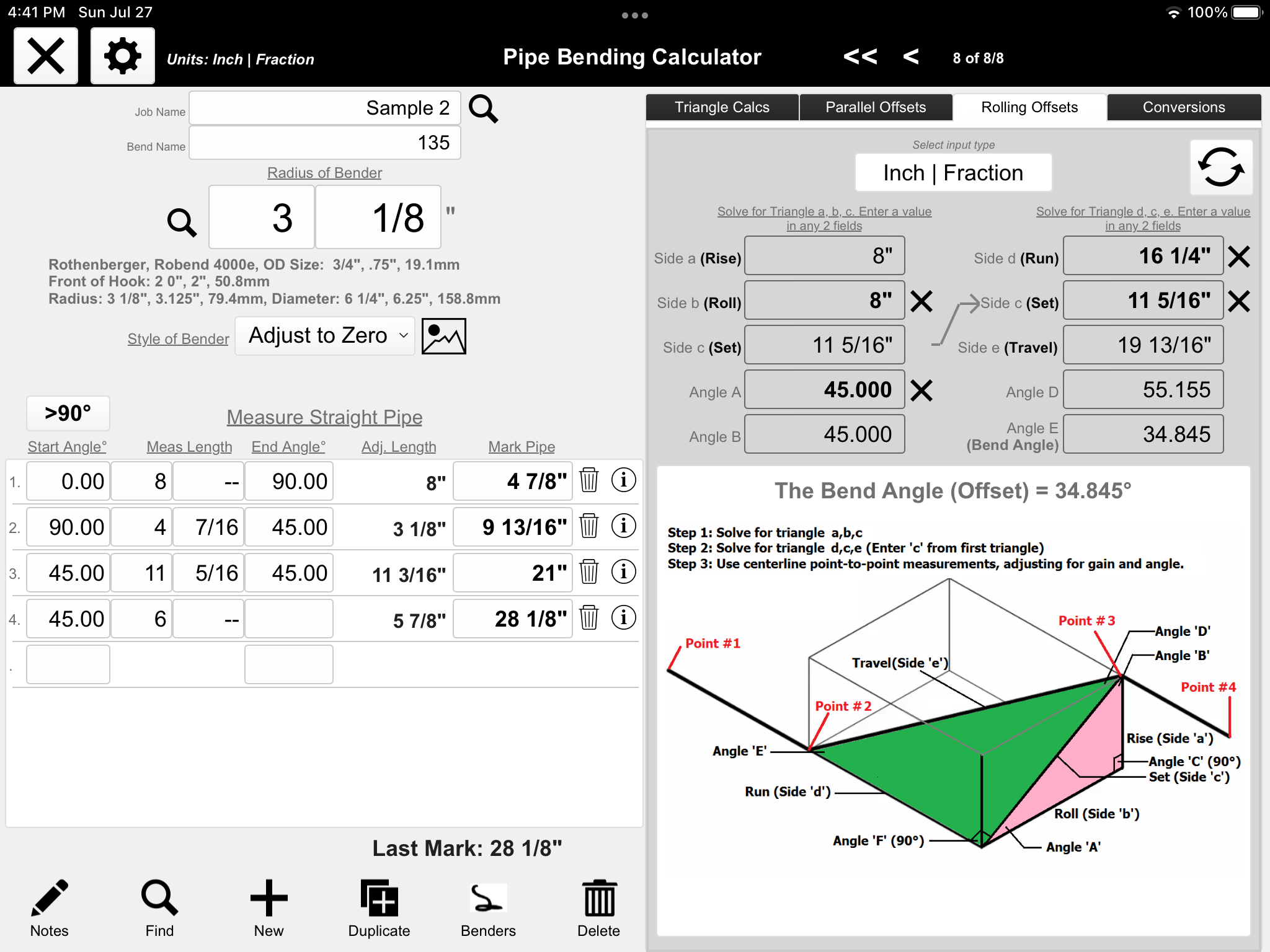

I use the Rothenberger Robend 4000. My buddy, who used to be on here, made a really cool calculator to easily do the math.

He also showed me how to buy it overseas for about 1/2 the price as you can from Rothenberger USA. The only downside was it took about 3 weeks to come in.

Re: What happened to Rems Tools(USA)

Ever watch a good electrician bent EMT condiut. Once you get the math down it goes pretty quickly. There are some bending software programs also.

I doubt it is as fast as press fittings, but faster than sweat copper.

Yes the outer radius thins and the inner "bunches up", I suppose:)

I know those return bends on the end on HW and refrigeration coils are very thin copper. They run some pretty high pressures.

Bending is addressed in the CDA manuals and I believe is accepted in all the plumbing and mechanical codes.

I have bent some type M, but it tends to pucker up on the inner radius, L works best with plenty of lube.

I have found that old copper tends to split on the bend, for some reason. Like it hardens on the shelf??

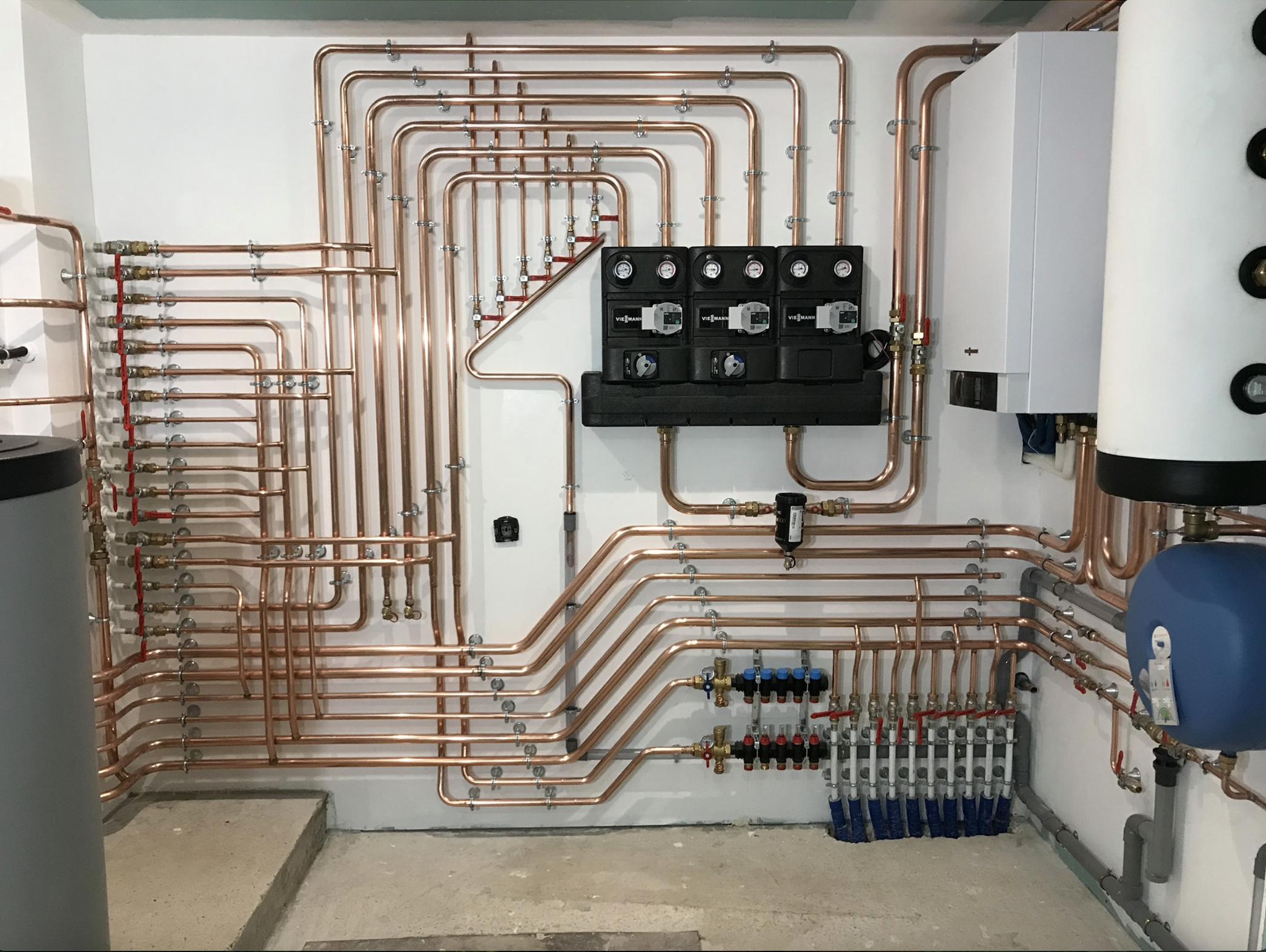

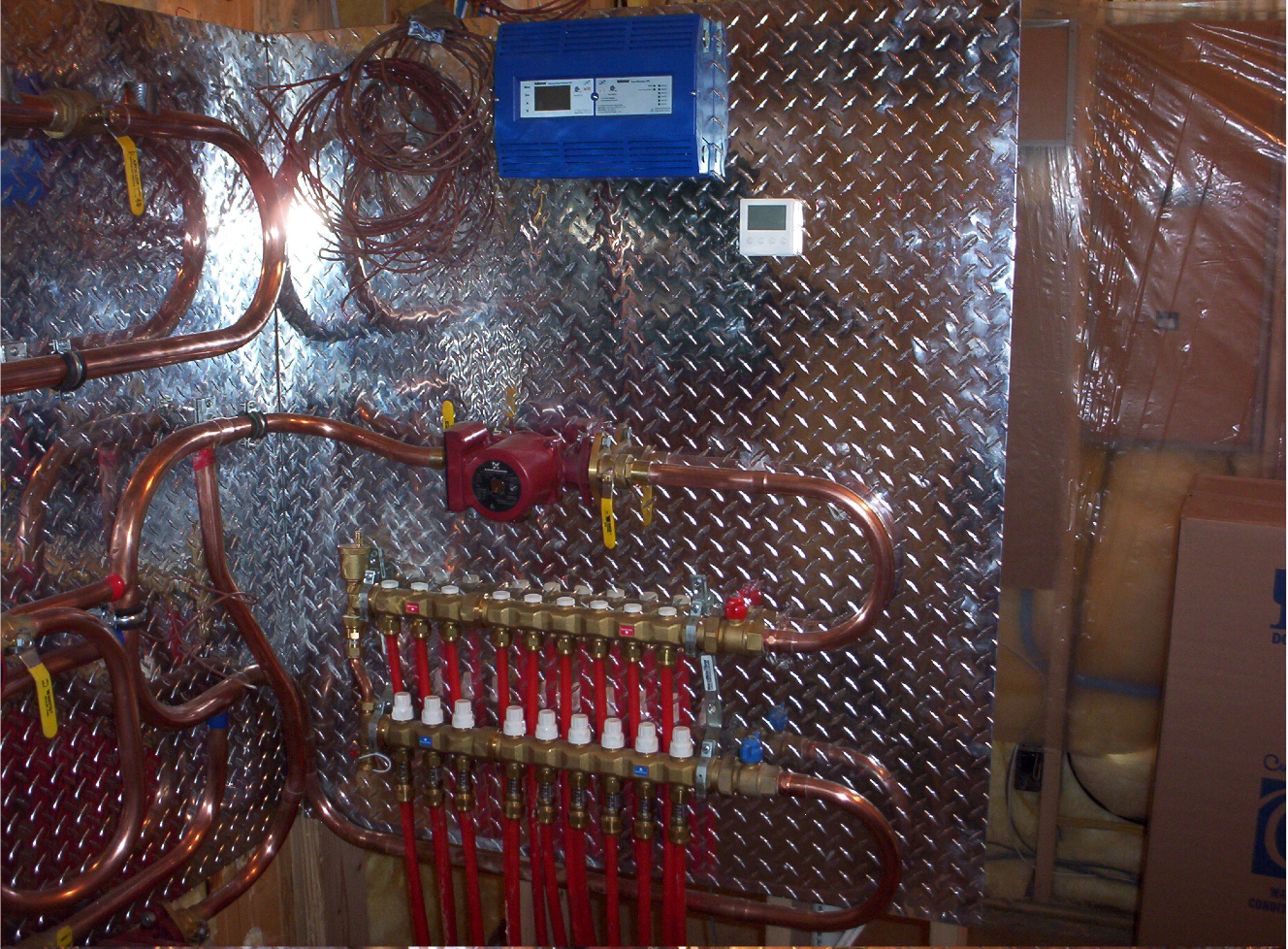

There is a rep/ wholesaler in Illinois that made hundred of copper tube radiant ceiling grids. They had a home made copper bending tool. They kept the layout drawings of all the jobs, dating back to the 1950's, till recently so they could furnish repair loops!

hot_rod

hot_rod

Re: What happened to Rems Tools(USA)

Teal Industries in Minnesota is the importer and repair point for REMS. I've sent my tools there for repairs. Are they still open? REMSusa.com

There is a handful of guys that post on IG that do a lot of bending, Mike Flynn flynnstone1 and jeffdemhvac have done demos at some trade shows, AHR and others.

I used to do a lot of bending on my jobs, mostly hobby stuff now. You can also bend steel pipe and PVC pipe with it, cold!

I think Rothenberger has a bender also.

hot_rod

hot_rod

Compression fitting going from lead to anything modern (e.g. steel/brass)

I'm going to have to replace both my sillcocks which are over 60 years old and are leaking from the stems when I open them. I could probbaly try to scrape the paint off the compression nuts and tighten them, but this is my opportunity to replace them with frost free ones.

One of them is connected to copper pipe but the other one is connected to a lead pipe (black appearance, non-magnetic, when I scrape it it reveals a gray surface below)

The copper one I will replace with a propress ball valve and a frost free sillcock which I will attach with propress compression fittings.

What can I do with the lead one? Are there compression fittings that let me go from lead to copper/brass etc? The lead pipe has a 0.63" OD.

Thank you!

Re: Trane Air Handler Fan Constantly Running

I think those are just double terminals for the coil so that it can be used as a junction point too.

That one terminal looks burned, probably from the failing contacts. I'd replace the terminal on the wire that connects to that terminal too.

NYC Boiler Room - Smoke Alarm that will cut off boiler

https://www.kidde.com/home-safety/en/us/products/fire-safety/safety-accessories/auxiliary-devices/sm120x/

I found this accessory, but it seems it only send a signal to an external device and not necessarily kill the power .

Thanks!

I assume this is no bueno

The meter isn't professional by any means, but this doesn't seem right. Before I make a call, just want to gut check with pros that this is an unacceptable level of CO in a Navien tankless heater exhaust. I've read that some can be present but this seems high.

Circulator aquastat for thermal post purge?

I'm continuing to try to make incremental small improvements on our two Weil Mclain WGO-5 hot water boiler systems. The next thing I'm looking at is installing some sort of post purge to get the residual heat out of the boilers after each heating cycle. The boilers are cold start and typically run for 30 minutes or so before the Tstat is satisfied. Then they sit idle for several hours until the next call, during which some (most?) of the residual heat trickles away up the chimney.

These are 700+ pound cast iron boilers with 10+ gallons of water inside, so there is a lot of residual heat left inside after a burn, and I'd like to recover some of that with post purge. Recently I read a post from someone who was questioning how the Energy Kinetics boilers can advertise such high cycle efficiency, and Roger from Energy Kinetics explained that their high cycle efficiency was due to (1) low mass of the heat exchanger, (2) small water volume inside the HX, and (3) post purge. I can't reduce the mass of our heat exchangers or the water volume, but I can (hopefully) install a post purge.

Because the boilers are so massive, I would like to get at least 20 minutes of post purge capacity. I have seen some electronic controls that could be wired to give me up to 10 minutes of post purge, but I don't think that's going to be enough for maximum heat extraction, and I don't want to go through the trouble of buying and wiring something up only to find the max purge period is too short.

So I'm wondering if I could hard-wire the circulator directly to this Honeywell aquastat that has an external temperature sensor, which I could mount on the supply pipe coming out of the top of the boiler.

I would set the "make" temperature for, say, 100 degrees. Then when the boiler starts cold, the circulator won't start until the water temp in the supply pipe right above the boiler reaches 100 degrees. The circulator will then start, but because there's so much cold water in the system, as soon as the circulator starts, it will flood the boiler with cold water, which will lower the supply temp, causing the circulator to shut off. This process will repeat until all the water in the system has heated sufficiently to allow the circulator to run continuously.

Then after the Tstat satisfies and the boiler shuts down, the circulator will continue running until the supply water temp drops below 100 degrees. At that point, a significant amount of residual thermal energy will have been (hopefully) extracted from the boiler and sent to the radiators.

One possible objection to this setup is that, if the circulator aquastat fails, the boiler will run without water circulation until its own aquastat shuts it down on high limit. I wouldn't want this to happen routinely, but in theory that's the safety mechanism against boiler overheating.

Has anyone seen post purge done this way, and am I missing any obvious alternatives?