Best Of

After all these

years, I finally installed my first Navien. A NFB-301C. I thought it was nice.

Re: Heat Pump Cooling Not Working

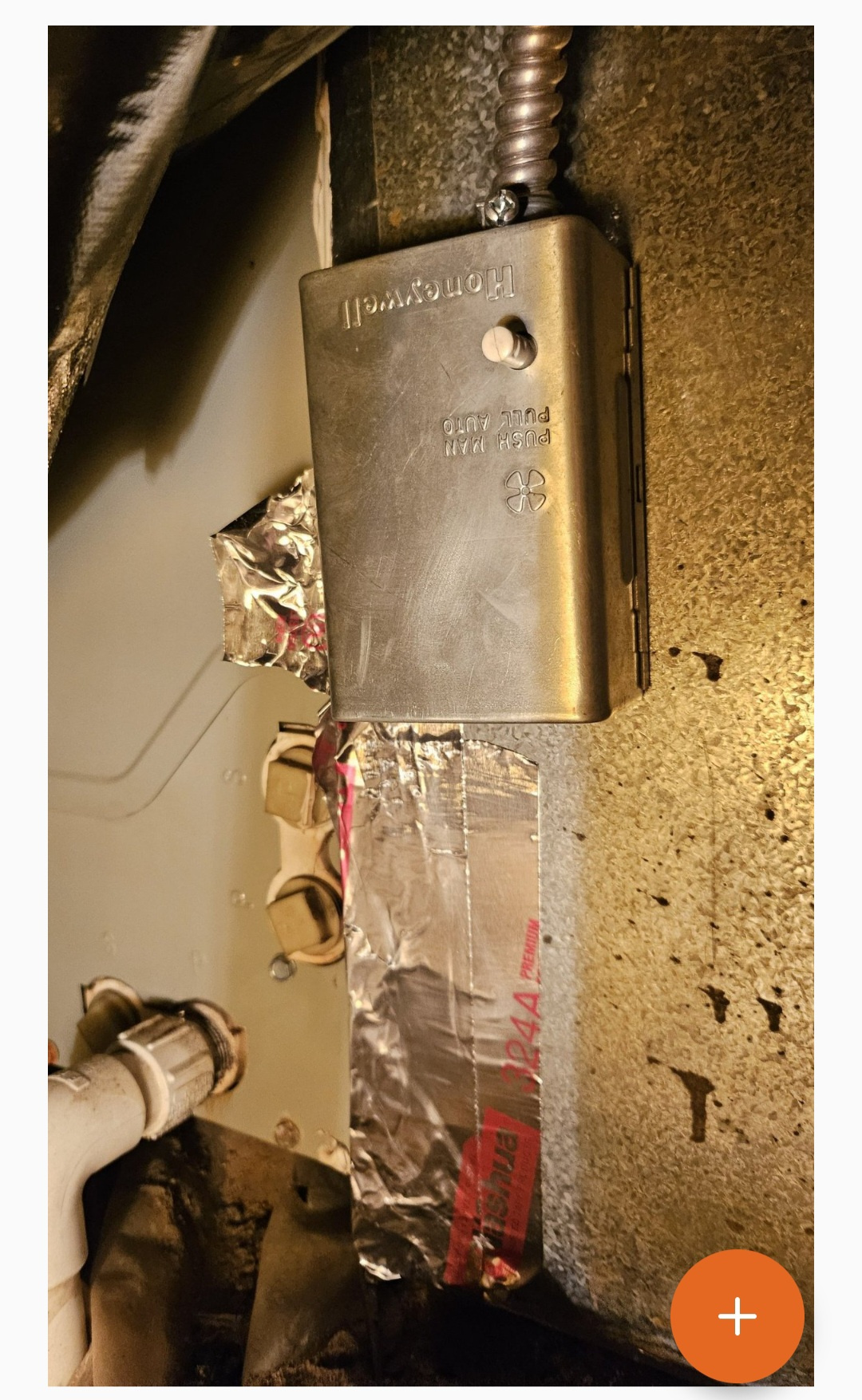

@heatingrabbit, this is a Fan/Limit control.

Its part of the heating portion of the system, not the AC. There's some type of horizontal furnace there. I assume thats why there's 2 thermostats.

There should be a transformer in the furnace. Probably 40 va, and enough for both. With the AC transformer in the condenser, it tells me someone's hands have been touching things they shouldn't be touching. Transformers haven't been in condensers since they used belt drive motors. So Ohm out the wires, take notes, pictures, label the wires, and add a 3 amp fuse to the new transformer.

HVACNUT

HVACNUT

Re: Heat Pump Cooling Not Working

With what you are finding with the current state of dysfunction, your speculation that the 2019 model thermostat was connected wrong makes sense. I would disconnect the blue wires at each end of the thermostat cable and also that short piece of blue wire that goes between to the original transformer and the blue wire in the thermostat cable.

It seems all you need is the R on the transformer to the R on the thermostat, during an AC call the thermostat closes RC to Y (note jumper between R and RC), Y goes to the coil of the contractor and the other Blue wire connects the other side of the contractor's coil to the C of the transformer.

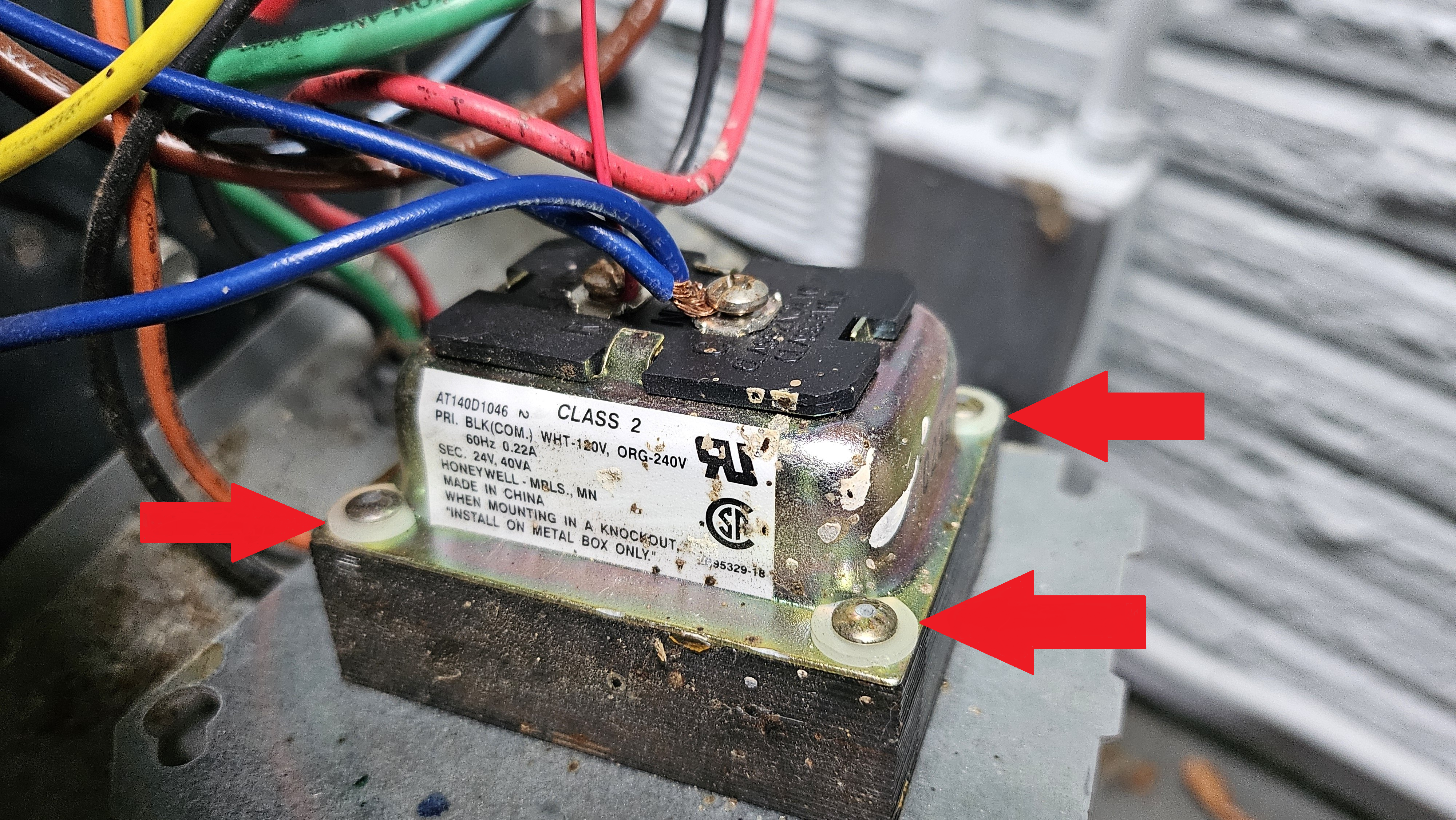

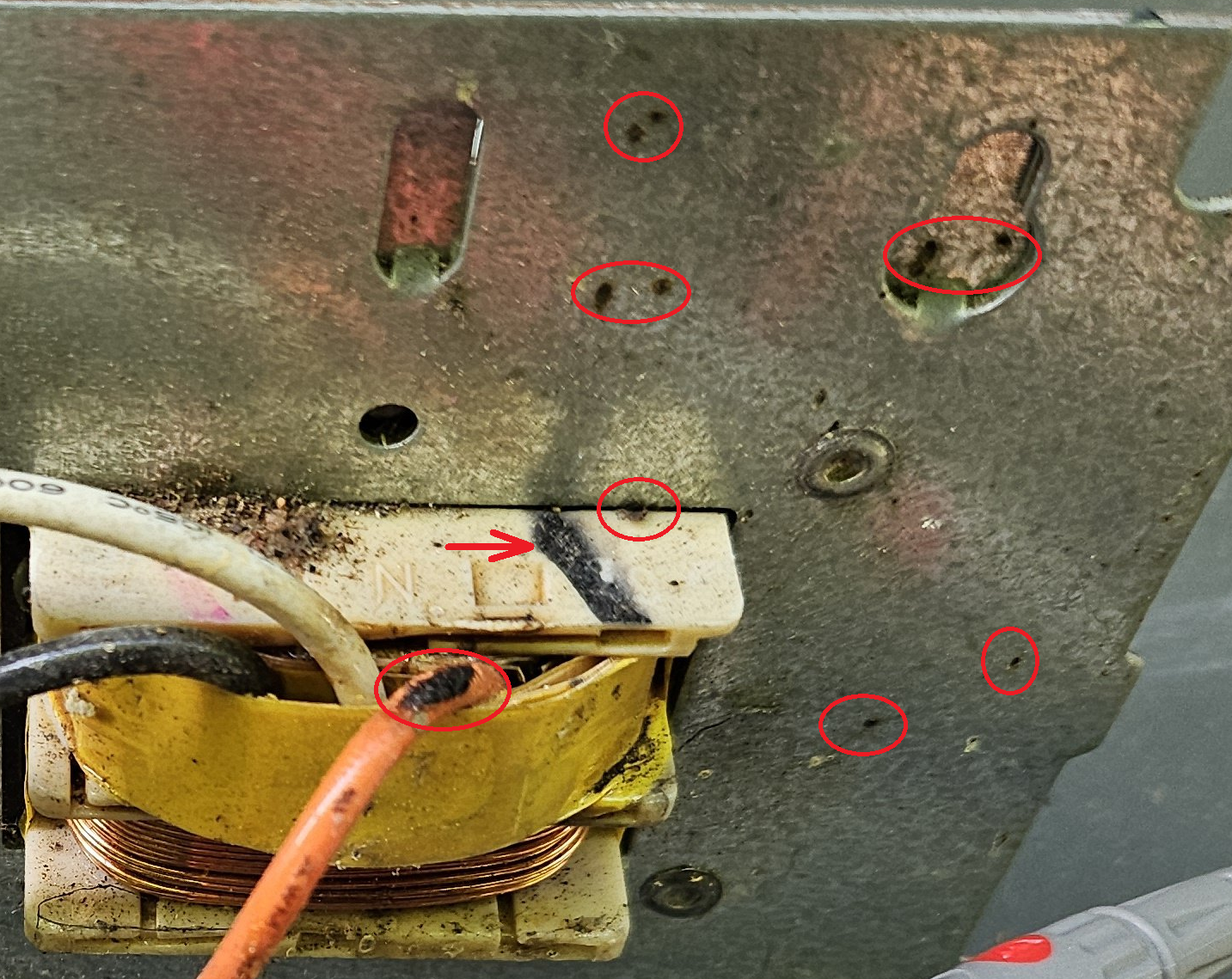

Not sure what the difference is with the original AT140D1046 and the Amazon AT140A1042 except the original comes with the junction box mounting plate which is secured with insulated rivets at one end, and the Amazon seems to be just the transformer with insulated rivets. If you do a transformer transplant using the original cover plate the insulated washers must stay intact.

There seems to be some oddities about that original transformer, char marks and maybe an arc flash event in the near vicinity. The secondary winding does not look overheated. If the thermostat shorted the secondary like you speculate the primary may have quickly become an open circuit like you are finding.

With a new transformer you could add a 3 Amp fuse on one side of the secondary winding to protect the transformer in case other issues still exist.

Curious, does that meter have any other Ohmmeter ranges besides 200K and 20M ? That meter may have very poor resolution when looking at resistances under 10 Ohms. You would have to check the user manual.

Re: Store in Staten Island that sells/services Heat Timers

I'm the guy. Still in business for 2025 and onward. I am at heattimersforsale.com. I now ship from Fl and can overnight a panel or send via regular post. If you have a pile of them, or just one, I'd be grateful for your business. Haven't raised prices since 2017, don't plan on raising them any time soon. Thank you for taking the time to read this. Paul aka Willy B

Re: What is causing this?

Add a couple pictures from couple foot back so we can see the configuration and any isolation valves in the area. If you use the picture icon to attach the photos, it will save us from having to open each JPEG.

PC7060

PC7060

Direct Piping

This photo is from an Eichler home in the Bay Area. You can see one manifold under the boiler and there's at least one other manifold in a closet inside the house.

The installer is using the boiler pump as the system pump when the manufacturer's instructions say to pipe the system with two pumps and a primary-secondary piping layout; either with a low-loss header or closely spaced tees.

I'll be going to the job next week to find out how the system has been working, but my guess is that it works fine. Some Eichler's have 3/8" tubing and you have to use a bigger pump to overcome the pressure drop, but the one manifold look to have at least ½" loops.

But, however tempting, common practice is to uncouple boiler and system.

The company that installed this boiler sold out to a larger plumbing company. When the owner called to have it serviced, they said they don't have anyone trained to do that work.

Re: Replacing cast iron radiator with smaller one

@amaiale, Can you post a floor plan for your new kitchen cabinets in including the radiator location. In an earlier live I worked for a lumber company that sold kitchen cabinets and was involved in designing kitchen cabinet layouts. With this experience I was able to save one of my heating system customers the cost of replacing a washer and dryer set with a stackable appliance or apartment combo unit in the utility room. The existing boiler was in that room and when they wanted to replace the Oil Heat with Gas Heat, I was able to redesign the small room by moving the heater location from one side of the room to the other side. This left room on the opposite wall for a washer, a dryer, and narrow laundry tub. Something the wife always wanted was a laundry tub, but it would not fit with the oil burner on that wall.

If I could look at the floor plan of the new Kitchen cabinets, I might see something that the cabinet design folks do not see, regarding how the radiator can be incorporated into the design.

Re: COP & sizing question

@Jamie Hall : "The Mitsubishi @DCContrarian mentioned is a good cold climate heat pump , and should only cost about twice as much to run as a modern oil or gas boiler or furnace."

Your bias is showing.

As fate would have it, I just finished an analysis of that particular heat pump vs oil for someone in Massachusetts, the difference was $5.09 a year, in favor of oil. You can read it here:

If you add the cost of annual cleaning of an oil burner the heat pump is cheaper.

I think the point is that people are sold heat pumps with the claim they'll save lots of money. In New England that's generally not true.

Re: Any new feelings about Stay Brite 8 soldering vs brazing?

Brazing flows into the fitting just like solder no difference. With brazing you can get away with no flux because the chemicals in the brazing rod take care of that. True that you can "puddle" some braze material on the outside and some people do that (I do) but its not really necessary

With brazing you don't really need to clean the pipe and fittings unless they are really oxidized although it doesn't hurt and I usually clean them for best results.

get some scrap tubing and fittings and try it and then un solder it you will see how it flows. best to practice before do a real job