Best Of

Re: How drain boiler for repair?

@EdTheHeaterMan I just glanced at your posts, and will now read them more closely. But I just happened upon where you say the leak is not admitting air, because of the pressure. Of course! Now I see! (The fact that that never even occurred to me shows that, unlike my hydronic system, my head is both leaking something and admitting air.) I will probably leave that adaptor alone. I think I can stand to lose a drop of water every month or so.

For all the advice you have given me now and in the past, if I owned a brewery I would give it to you.

I'll now read those posts more closely.

Re: DIY Boiler Installation -- Peerless 63-03

[Boiler slip-and-slide cont'd Sat Aug 31st]

The first step in this endeavour was to lower the boiler onto its back, which was accomplished with a lot of leverage and a long 2x8 on the back side. The boiler was lowered onto an old dolly I built years ago with 2" wheels, which made maneuvering pretty easy. My kitchen floor is thick slate tile, and I was careful to place rosin paper and thin fiber board under the load. Nothing broke or cracked.

I used two twelve-foot long 2x10s, with pieces of 2x4 between them, to build the slide. The boards were braced at the foot of the stairs to the opposite wall to keep them from sliding.

There was enough stair left on either side to be able to walk up and down to aid the load. Straps were looped through the feet of the boiler and provided a place to loop a rope through, with one end stationary. This provided 2:1 leverage and quite a bit of friction to make the job manageable. In the end, the kid did all the lowering, with me guiding the boiler down the stairs. That turned out to be the easiest part of the job.

One important point: I had to shorten the strap loops, since at the point of tilting, the ropes were about to disappear under the boiler, which could have complicated things. See pictures for details.

With the boiler on its back, I put 3" hard rubber casters on its feet. This turned out to be a great idea -- once we had righted the unit, it was easy to push it around like a shopping cart, and it allows fine-tuning the position to match up to the main.

First, some pictures. Here's the view from the half bath opposite the basement door. It's not everyday you sit on the throne trying to control a 350-lb load…

The moment of truth — just before 'tippage.'

Note that the straps around the boiler have been shortened.

..and we're on our way. No pictures were taken "during" the slide process… we had our hands full. As it turned out, the boiler hardly needed any force to keep it from sliding — it was nearly neutral and sometimes had to be nudged to move another inch. The transition off the dolly was the most critical and nerve-wracking time. Overall, I would do it again like this, and probably just build a ramp for the trip from the driveway to the kitchen.

Success!

Now it was easy to get the boiler into position. You can juuust see the edge of the main in the top left corner of the picture.

And of course I couldn't resist a quick test fit. With both risers open, I have to "plug" them somehow anyway, so I'll extend the factory piping with a second riser.

I took today off for some rest and some cooking. Tomorrow will be a long day.

Thanks again to everyone who helped me get this far, and fingers crossed this will be a smooth finish. My goal is to have a hot radiator somewhere in the house by the end of next weekend.

-Matt

Re: What size pex tubing do you recommend?

And I'm not arguing that a piece of concrete will melt snow or ice regardless of the size of, or spacing of, tubing in it.

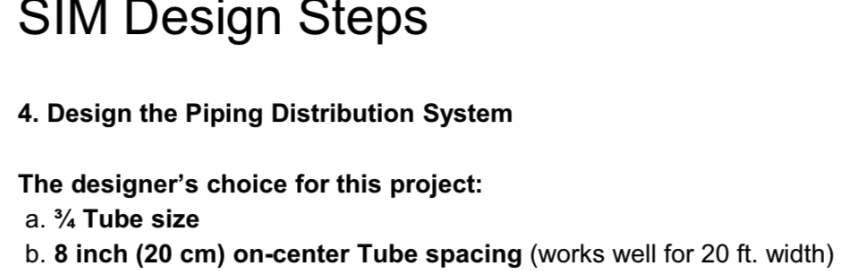

I agree with that and have for years promoted tight 6" spacing, 10- 15 ∆ in residential heating, specifically for comfort, quick ramp, and lowest SWT. I don't see these 6" tube spacing numbers numbers being critical for SIM design.

My point is larger tube give you more BTU capacity, longer loop length, less pump power requirement. I doubt many are barefooted in carwash bays in the winter??

All I suggest is the OP read some of the attached info I present.

I suspect the screenshots I offered throughout this post were generated in SIM software from Uponor, PPI, Rehau, others.

There is no specific way SIM HAS to be done. But there are industry guidelines based on hundreds of systems that perform to expectations.

The tube size recommendations, the 25-30 delta, tube spacing, loop length, SWT, flow rate, etc, etc all come from the manufacturers design example. These are not numbers I'm pulling from thin air.

When you have a load calc done by one of the reps or manufacturers, and sign off on the assumption doc., they guarantee the system will perform as designed.

If someone designs for a 25- 30 and only attains a 50∆, they missed something. A 50∆ in a 200' loop seems awful high?

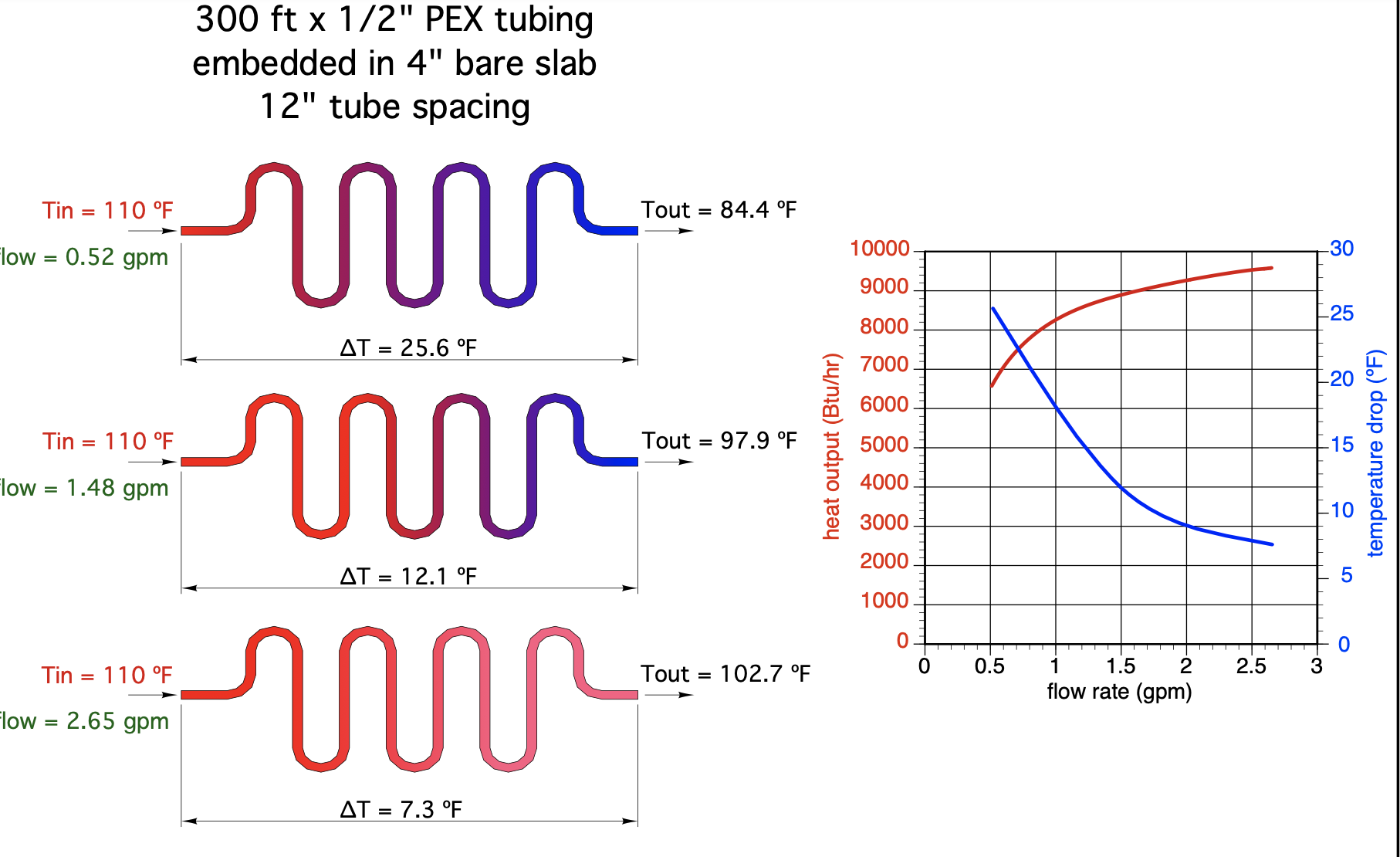

While running tighter delta increases the slab btu output a 20∆ probably isn't juice worth the squeeze for melting snow, considering the pumping power required to get there. An example attached of 3 different ∆Ts and their output change. Same SWT in all cases. I'm seeing a specific pattern from the 3 or so examples I have shown which is 5/8 or 3/4 tube size, 25- 30 delta.

( a heat transfer demo example, not intended for a SIM design) Tighter ∆ obtained by higher flow rate= higher BTU output in the loop and section of slab it is in. You would see the same variance if you plotted a 20, 30 and 50∆ for a SIM example. Which is why I suspect the industry looks at 25- 30 ∆ in SIM designs, reasonable output, reasonable pump requirement. Which is mentioned in all the manufacturers guidelines.

Pinning down the BTU required for the OP specific job is best accomplished by the industry guidelines, in my opinion.

I did check around some carwash forms and found even wilder suggestions of 100,000 btu/hr/ bay!?

Although in the OP case the 125 btu/ hr I suggested comes out to 75,000 BTU/hr. per bay. A bit shy of what the owner/ operators on those forums suggest.

Granted these attached designs are snowmelt, the concept of melting snow or warming a slab to melt ice, and turn to liquid, or keep the floor ice free, maybe even dry after evaporation, within the same temperature ∆ would be similar in my mind. At days end we are trying to keep the slab surface around 38°F at a specific OAT.

Digging deeper at all the manufacturers sites may turn up a 3 walled carwash specific design. My money suggests they would be 100 btu/ft or higher designs.

Don't shoot the messenger, I'm just parroting readily available, industry accepted numbers and suggestions.

I suppose 1/4 copper tube loops 25' long at 2" OC could be made to work also😉

hot_rod

hot_rod

Re: Universal replacement boards for modern furnaces

The Universal Honeywell EFT covers all of Honeywells EFT's including the one for Smart Valve. It does not however replace the ST9162 series which is for the Two Stage Honeywell Smart Valve.

So the Honeywell S9200U-1000 is the Universal Integrated Furnace Control replacement. It replaces United Technologies, Rheem/Robertshaw, Nordyne, Texas Instrument, York, Lennox, White-Rodgers, Goodman and ICM.

The Universal Electronic Fan Timer is the ST9120U - 1003 it replaces 25 Honeywell Controls, central wiring for most of the components on the furnace, controls heat and cooling and constant fan applications, runs the induced draft blower and the circulating fan, monitors limits and other controls, has a field replaceable fuse and dip switch settings to control fan on and off times.

Now I do not have to e-mail you Honeywell. I will however e-mail you info about White Rodgers.

Re: OT: Underground Wiring Options

That wouldn't cut it here. They would want it opened a second time.

pecmsg

pecmsg

Re: OT: Underground Wiring Options

Depending on your local ordinances a permit may be required for the work you are presently doing. Also some inspectors get weird about the use of an underground conduit if the trench was back filled without it ever being inspected. I guess take good picture of the quality and depth.

Re: OT: Underground Wiring Options

Here is depends a whole lot on who you are, if they think you know what you're doing and don't feel like you are trying to hide something from them they will let you tell them about something rather than having to see it if it got concealed.

Re: OT: Underground Wiring Options

my strategy was to ptu it in the trench and take pictures and deal with a permit when i wanted to hook it up.