Best Of

Re: New Propane Boiler Options

There are 3 separate BTU numbers on each boiler. Prior to 1968 there were only 2 but when the government got involved with the department of energy they needed to have an equal footing to measure furnaces and boilers for those yellow Energy Guide stickers on each heating appliance to make it easy to compare the different systems. But I digress

Back to the three different BTU numbers.

- Gross Input aka Input aka GPH on oil fired equipment = How much energy goes in

- Output or DOE output is how much energy gets put into the home (maybe). Or better described as what is left over after what is lost out the vent pipe.

- NET output aka I=B=R NET and now known as DOE NET. This is the number that you are supposed to use when you know the actual heat loss of the building. It is actually a 15% lower number that takes into piping and pickup consideration on a water boiler. (it is 30% on steam boilers)

So when you know that you need 46,000 BTU per hour on a design day (that is what we consider the average coldest day of the year for an area) Then you use the NET number which is much smaller that the Input that the boiler usually is sized by.

Re: Who owns who?

did you press the little button with the less than/greater than on it and paste the url in to there?

https://www.sec.gov/Archives/edgar/data/93556/000009355622000015/ex21-subsidiariesofstanley.htm

Re: What's your favorite multi-tool? I mean that folding one you keep with you at all times at work.

wish I could see a picture or at least have a list of what's hanging on out there

Me too getting those odd looks here and there and people getting amazed of the amount of tools easily walking out of my pockets, The old fashioned wide suspenders is adding nice color to everything

But The satisfaction I have when getting a service call done with only tools hanging on me is worth all the money

I think the customers love it, you done already? Didn't have to bring in tools? Oh Wow! I just smile looking down at my pockets HERE IT IS

9326yssh

9326yssh

Re: Who owns who?

I still like Milwaukee for some things…….maybe because they used to be great. I would call them good now but not great. I also have a lot of Ryobi stuff which is cheap and most scoff at it but I find it holds up pretty well.

As with any tools I have worked with people who could destroy any tool made. I use tools hard but I don't beat the crap out of them and whatever I bought it usually lasted pretty good.

If I had a lot of concrete drilling, wood drilling or sawing I would still prefer a corded tool. Walking around with a bunch of batteries and a charge doesn't appeal to me. I had a small inverter in my truck large enough to charge batteries on the way to a job.

The dog days of summer....

So hot even Tillman needs a cold boiler room floor to stay cool. Too hot even in the shade.....The Williamson boiler to the left serves as a pool heater & I am adding a zone for keeping Koi Pond ice free in winter

Re: How Do I Connect This Wire?

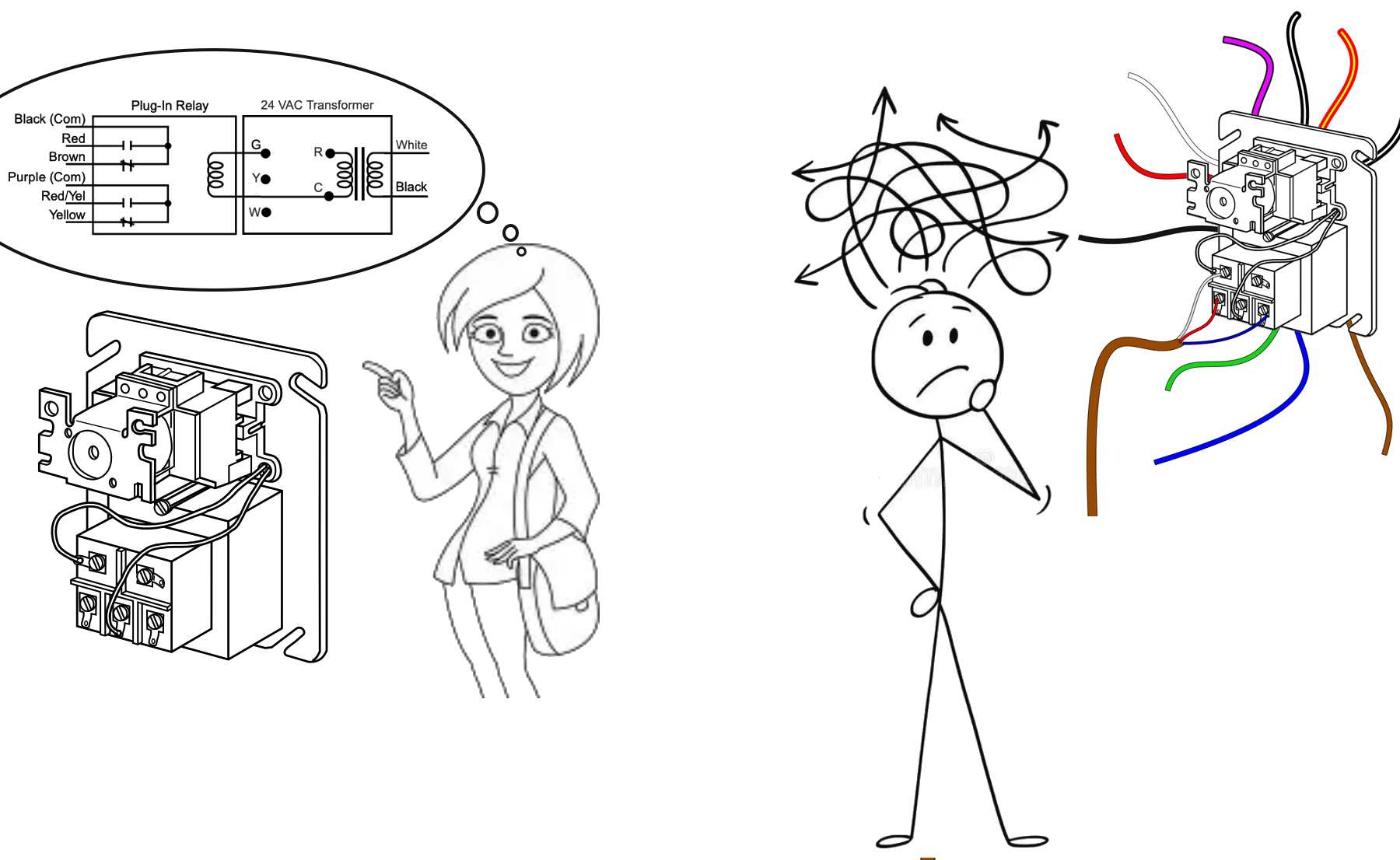

@Steamhead & @EBEBRATT-Ed… You can purchase a "Fan Center" from a boiler manufacturer for over $100.00 and find that it is identical to any of the lower priced items. The "rub" is that the wire colors are different. Since many plumbers (and even some electricians) are not that good at control wiring, changing the colors of the wires make it difficult for some to adapt the identical low cost part with the expensive "Factory Authorized" part.

Regardless of the political climate. The boiler manufacturers will always have an excessive markup for the generic parts they sell. That is why they have slight changes in them. Just so you won't try to buy the lower cost generic parts. That is the reason I like Crown by Velocity Boiler Works over Weil McLain. Crown will tend to use standard parts for their boilers rather than modified "OEM" parts.

When the Tariff's kick in, you can see the OEM fan centers go from 100 to 200 while the generic will still cost less than 50.

Re: What's your favorite multi-tool? I mean that folding one you keep with you at all times at work.

@SlamDunk LOL I saw one of those somewhere.