Best Of

Re: Dry Fire Failure? Water Feeder Options?

For those not familiar, the Dunkirk D247 is the same as the Utica J series, currently in version F and called JF.

Most jurisdictions require CSD-1 controls on boilers this big, which involves two low-water cutoffs. But the D247/JF does not appear to have the proper tappings so the installer can use probe-type low-water cutoffs for both the primary and secondary controls, with the probes extending into the boiler section. These boilers have only one probe tapping- which is better than the Weil-McLain LGB, which has none- but the secondary has to be a float type, with moving parts and their inherent unreliability.

In a commercial application, generally someone has the responsibility to blow down the LWCOs. But on residential, many times the blowdowns don't get done. This can lead to dry-firing.

@Fishin_Rod , where are you located? And can you post a pic of a couple radiators (with covers removed)?

Re: Why Is It So Hard To Hire A Contractor?

I had this thought the other day, I think it is a lot more people in project management roles and higher up management that either should know better or aer intentionally scamming trades that don't budget enough time or money or both for the work they need done in their project then expect the trades to fix it by either sacrificing their personal life or being paid fairly for their work. This makes people who are considering trades that would be good at it see this happening early on and run the other way to do something else where they get threated better. Until the industry fixes the way it treats trades they will not be recruiting new people which just makes the problem worse.

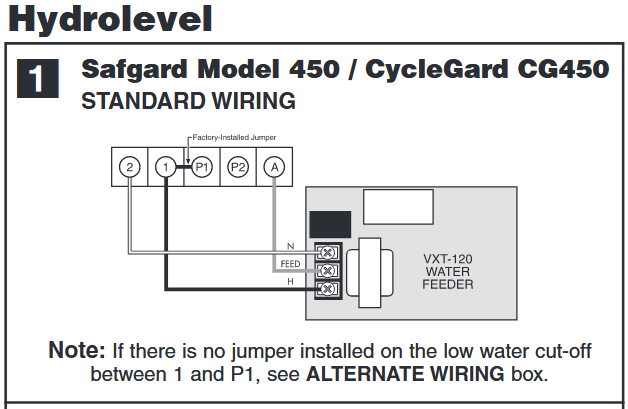

Re: comms between LWCO and water feed?

If all the high tech electrical / electronic gadgets are OK the VXT valve or manual bypass valve may be leaking.

Re: KBR 42 3 Bosch Greenstar

@GGross do you think poor water quality could cause a leak in two years time? I’m not exactly sure how to test for a leak in the heat exchanger without taking it completely out…

I will say that the boiler has been firing up consistently for over a week now- we haven’t had it shut down. I can’t figure out what it was.

I have an ejector put in the lower level that the drains feed into. At one time there was an issue with the float and the drains overflowed with the ejector pit full. This would have prevented condensate from draining. My suspicion is that I started having issues around this time… the Condenstate trap was full of sludge when I cleaned it. Perhaps it just took awhile for everything to get cleaned out and running normally again, with a few instances of that error code even after it was cleaned. It appears to be back to normal now.

I appreciate everyone’s responses and help.

Re: comms between LWCO and water feed?

I believe when 120 VAC is applied to the 'Feed ' terminal that activates the feeder. Yes why Hydrolevel used that nomenclature is beyond me, I would have been happy if P1, P2 and A was NO, NC, and Common since I believe it is a relay inside. If you disconnect the wire between the A and the Feed what voltage was on the Feed terminal before and after in reference the the Neutral ? What state is the LWCO in ?

Parts cannon mentality, just change both units, it will probably fix the problem and it makes them more money.

There are manuals for both of those units.

https://hydrolevel.com/wp-content/uploads/2022/03/CG450-CGT450-Instructions-012422.pdf

https://fwwebbimage.fwwebb.com/ProductInfo/VXT-120-Instructions-web.pdf

Re: comms between LWCO and water feed?

HVAC manufacturers don't provide information like that, as every installation is slightly different. If one manufacturer made the whole thing, yeah — then they probably would. But in this case, the Cyclegard manual for your LWCO gives the connections at the LWCO (two possibilities) while the VXT-120 manual gives the connections to the Cyclegard. Nice of them.

Re: comms between LWCO and water feed?

Hydrolevel's documentation is kind of awful. Most aren't like that.

Re: Loop PEX *under* joist instead of through? Reasons it won’t work?

Thank you @hot_rod and @Alan (California Radiant) Forbes !😎👍

I completed some of project with the „under-joist“ method…

Really like it because:

- Don’t need to prepare by pre-looping (?) the needed length into each joist cavity. Can simply lay the tube coming directly off the roll.

2. My joists are 5 inches wide of solid pine so a lot to drill through.

The photo shows an example.

Unfortunately the yellowish vapor barrier obscures the tubing routing. But from left to right:

Feed line comes under the left joist

Tube placed into track 2, water flow towards the viewer

Tube placed into track 4, water flow away from viewer

Tube placed into track 1, water flow towards viewer

Tube place into track 3, water flow away from viewer

And so on…

The „non sequential“ order of placing tube was to broaden the loops in the tube to make installation easier, eliminate kinking in loops, makes exit and entrance of joist cavity more gradual.

Used Rehau RauTherm Neo X5 16mm (1/2“) for tubing and Uponor Joist Trak for heat transfer.

Project is in Switzerland

Re: Steam boilers that are piped wrong

Paul, can you explain what you said like I was a 5 year old…..

Snowmelt

Snowmelt