Best Of

Re: Lochinvar WBN080 lockout

I believe the dual sensor is (1/2) sensor is a thermistor (S1 on the diagram), so variable high resistance that changes with temperature, usually NTC (Negative Temperature coefficient), temp goes up the resistance goes down. The other (1/2) sensor is a (needs to be) thermal snap switch type (Auto Reset Hi-Limit, Orange / Gray wires) which when closed at room and normal boiler operating temperatures has a very low resistance, like less than 1 Ohm to support the load current of the Gas valve. At least that is what the wiring diagrams are telling me. You should have the original documentation, are they significantly different than my postings ?

You may have the wrong sensor. Or your new sensor is defective. If you prefer chase out the 24 VAC that powers the Gas Valve and see where it stops.

Additionally the flame proving time should be long enough for a digital meter to settle if normal voltage is actually present. So an analog meter or and indicating load (such as lamp(s) that I like) should not be needed in this case.

If you replace the Gas Valve you probably need to do a combustion analysis. A combustion analysis may not be a bad idea for a tuneup when you get it running.

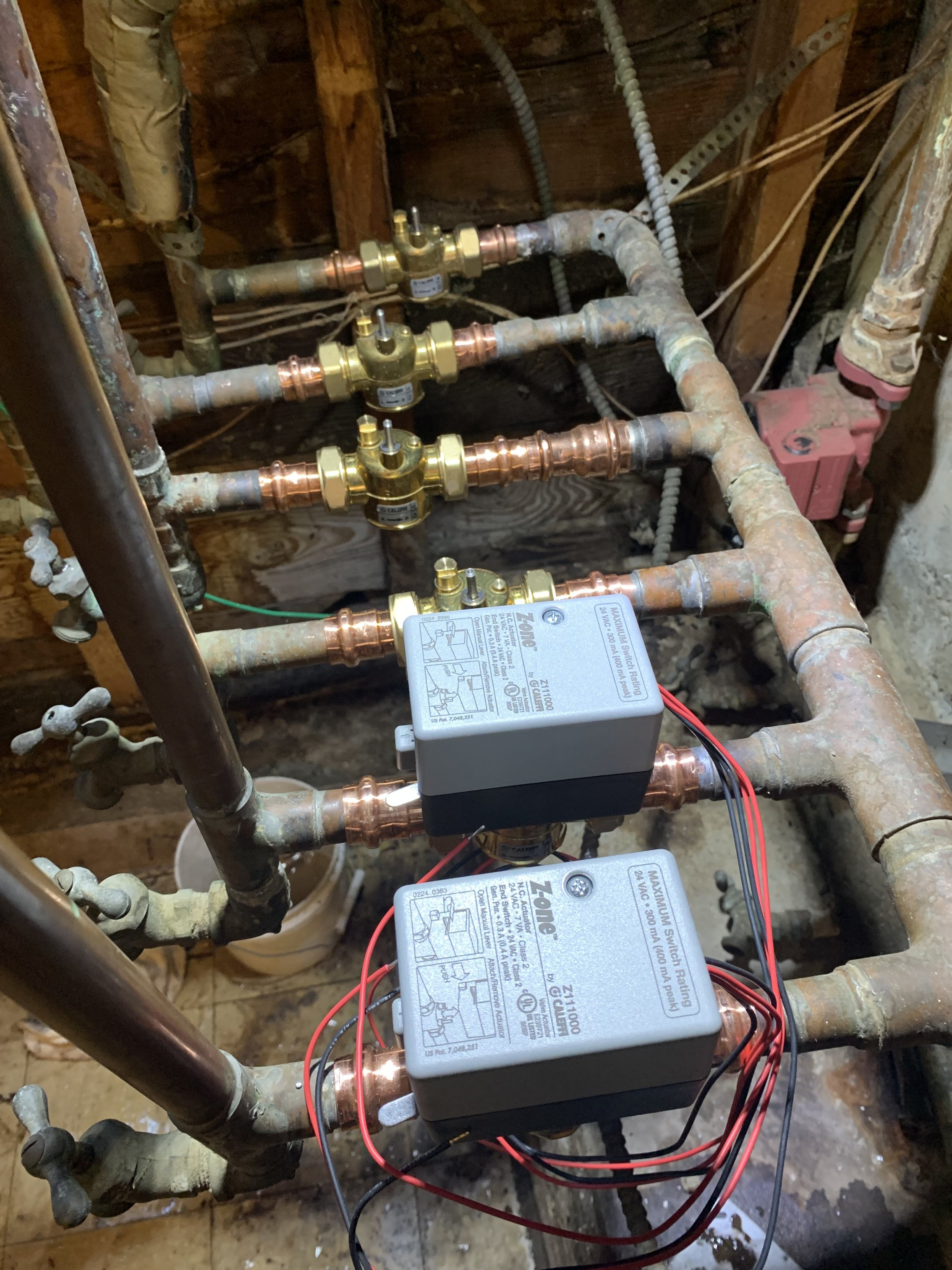

Caleffi Zone Valves

I like the new o-ring seals vs. fiber washers.

Re: What's a good humidity meter?

it is a very old school hygromteter, i think it was in my elementary school science books that were published in like 1970 and i think one of the middle school science rooms had one. i'm guessing they've been around since the 20's or 30's. that tube in the middle fills with water and keeps the wick wet.

Re: Sad day at work - wall mount toilet tank hole

I don't think there is an issue with a toilet tank in the wall as Any water line in the wall can eventually cause you problems to rip out wall going how many floors down... I have seen damage 4 floors down from a screw in pipe behind the kitchen started leaking 3 years after house was built

Here in Brooklyn every inch counts and it counts a lot🤑

9326yssh

9326yssh

Re: Firetube vs Watertube Boilers Explained: Which One Is Better for Steam Heating?

I am a boiler operator. Fire‑tube boilers are more suitable for low‑pressure (<1.8 MPa) applications in the 2–30 t/h range, while water‑tube boilers are typically used for high‑pressure, high‑temperature industrial processes. Neither type is inherently “better”—you select the boiler that best fits your specific process requirements.

If you have any questions, you can read the blog I wrote on my personal website:

Re: Is my heat exchanger hosed?

A couple of tests. Start the furnace with the blower off and the stat set to auto. Watch the flame closely and see if it changes when the fan starts. If it does the hx is toast.

The other way is to cover the flue outlet outside with plastic wrap or plastic bag secured with a rubber band. Have someone start and stop the fan while you watch the plastic bag for movement

Re: Caleffi Zone Valves

i hate those fiber gaskets, i especially hated them when i had to cut one out of sheet gasket because i had to break the union and couldn't get the old one to seal and I didn't have a spare.

Re: Sad day at work - wall mount toilet tank hole

i think that is going to happen sooner or later where you have to rip the wall open to fix something if you bury a toiler rank in a wall.

Re: Replacing 30 year old Vesta oil boiler….

The boiler you are thinking of is a very good boiler. Normally I would say that the first thing one should do is determine the actual heat loss of the house and also the type and amount of radiation to properly size a boiler, and I'm a little concerned that that may be a bigger boiler than you need. But otherwise the general plan you seem to have in mind should work well for you.

That said, particularly with the newer boilers, it is essential that the contractor really knows what he or she is doing. They are not just a matter of dropping it off the truck and attaching a couple of fittings. To get the kind of efficiency and satisfaction of which they are capable, some time and expertise is required — so pick your contractor well (if you tell us where you are, we may know someone…).

I'd avoid a contractor who says you don't need a permit like the plague. I know of very few jurisdictions where you don't, and being willing to suggest slipping by without one does not encourage me…

As to the tank and lines — if the lines don't leak, they're fine, though replacing them is cheap. Your oil company should be able to test the tank for integrity for a nominal price — you really can't tell just by looking (or even tapping!).

The chimney? If you have a wood stove, you also have a chimney sweep I hope. Have him or her look at the chimney and advise you.

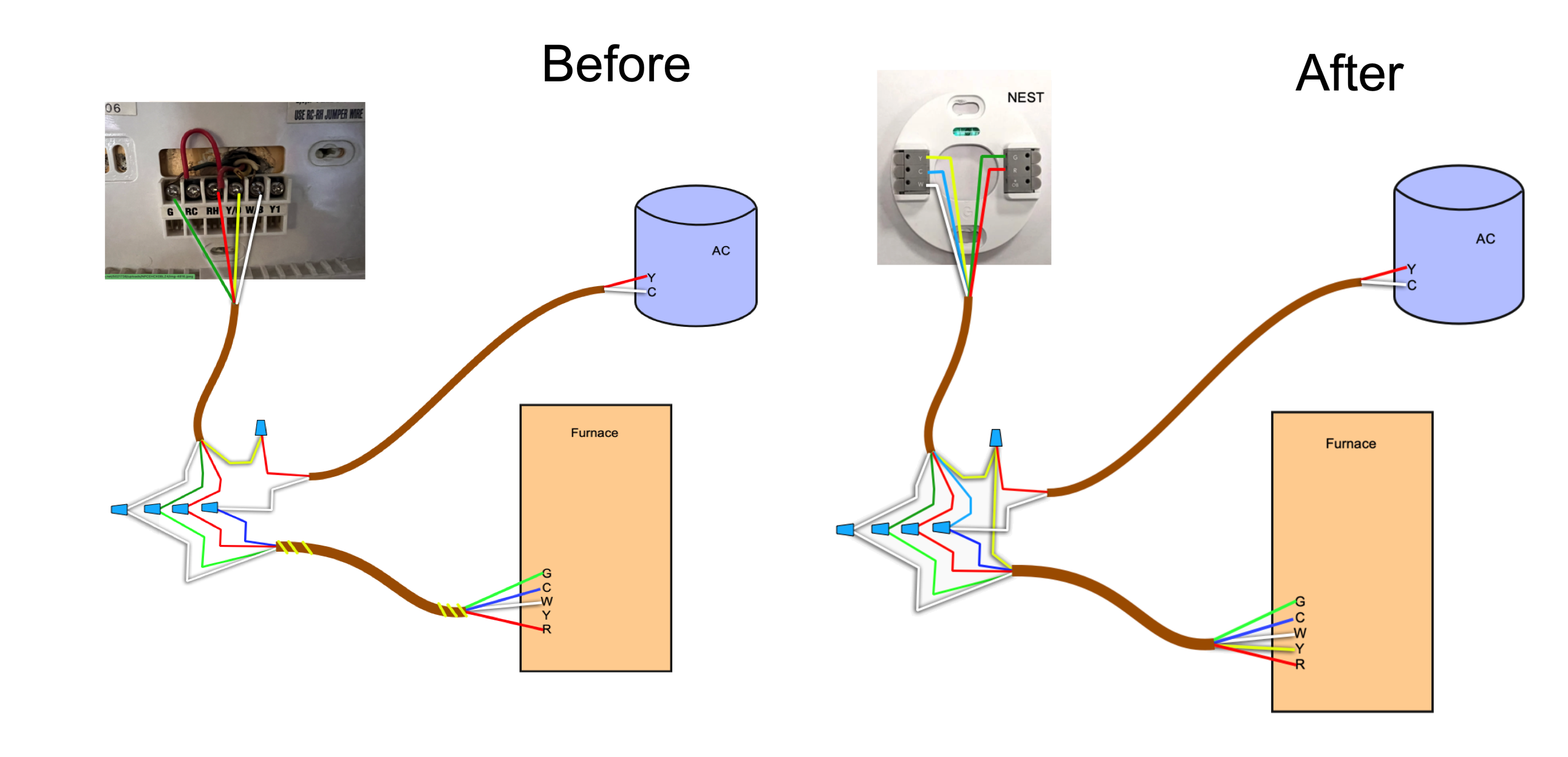

Re: Adding C-wire to my system

Sometimes it is difficult for some folks to follow wiring diagrams so I thought I would post the before and after diagram. Of course, I don't have a crystal ball so the BEFORE is a guess at how the wires are connected, So @domolek will need to verify the "Before" diagram.

I have seen the “Before” wiring several times in my short 45 years of doing this stuff. As long as there is an extra unused wire in the line from the thermostat to the junction area, then it should be easy to do the "After" diagram. I don't know what color the extra wire might be on the line from the thermostat to the junction area, so I selected light blue to indicate that wire. But you can use whatever color the extra wire is, because electric is colorblind.

Hope this makes this idea as clear as can be