Best Of

Re: Radiant flow not pushing fast enough

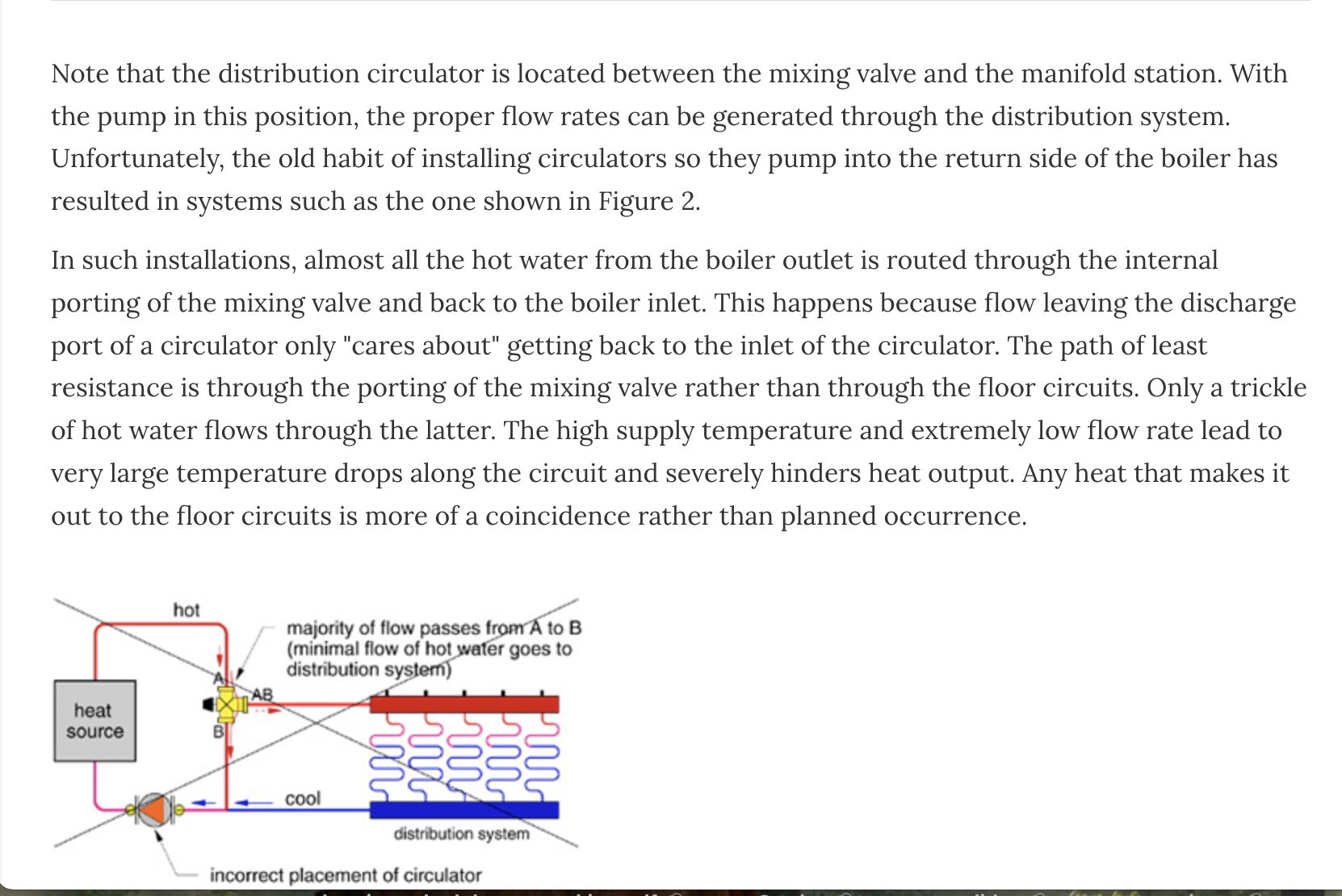

Since the circulator is pumping in to the hot port of the thermostatic valve, isn't the thermostatic valve going to close that port off and fully open the cold port when the outlet of the valve gets to the setpoint. Won't the valve get to the setpoint very quickly when they boiler is up to temp because it will be pushing water that is hotter than the mixing valve setpoint in to it? There will be essentially no flow in to the cold port because the circulator will pull the water that goes in to the loop back to the boiler through the return when the valve is open on the hot side and once it closes the hot side completely there will be no flow at all. I think the combination of hot boiler water and deadheading the circulator is making it hot. That will eventually damage it but it may still be ok now.

The valve does modulate between hot and cold but if the setpoint is like 120 f and there is 160 degree water being pumped in to it, it will go full to cold.

Re: Indirect water heater drywell overflowing?

unless you stick a rolled up piece of paper towel or something in the well to soak up the water it may take a very long time to dry out.

Re: Indirect water heater drywell overflowing?

This is the tank that I'm referring to. This is the one that Weil McLain stopped selling while I was still working in the trade. Weil McLain Plus indirect brochure This was the tank within a tank that had the leaking well issue.

Weil McLain's current indirect tank offering Weil McLain Aqua Plus Indirect Water Heater. I believe this one uses a coil that is serviced from the top. I never installed one of these myself.

Re: Drip leg or the end of main steam line

Looks like the supply rises up and goes through the wall and the drip comes down into the return.

Re: Radiant flow not pushing fast enough

This is the case regardless of the pump on supply or return piping at the boiler.

hot_rod

hot_rod

Re: Radiant flow not pushing fast enough

pump away from the mix port on the valve

the return from the manifold also needs to go back to the boiler

if you have a cast iron boiler you may need return temperature protection also

hot_rod

hot_rod

Re: Oversized overtall chimney?

Again, forget about the equipment until you fix the thermal envelope of the structure. If you do, it will take far less boiler to do the job. If you just throw more equipment at the problem the utility will thank you for wasting so much energy and paying for it. You don't have to rebuild the house but close the barn doors then think about the boiler. BTW, the standard is to have a blower door test done with infrared thermography, which will generate numbers on just how leaky the house is as a baseline. Once you tighten it up, you can re-test, calculate the improvement, which can then be used to calculate the savings and if further improvement would pay for itself. You can install a TurboBlaster 2000 with the flux capacitor and inverter raterfrazzer but if the building is a sieve you're wasting money.

Re: 1930's Hydronic System help understanding

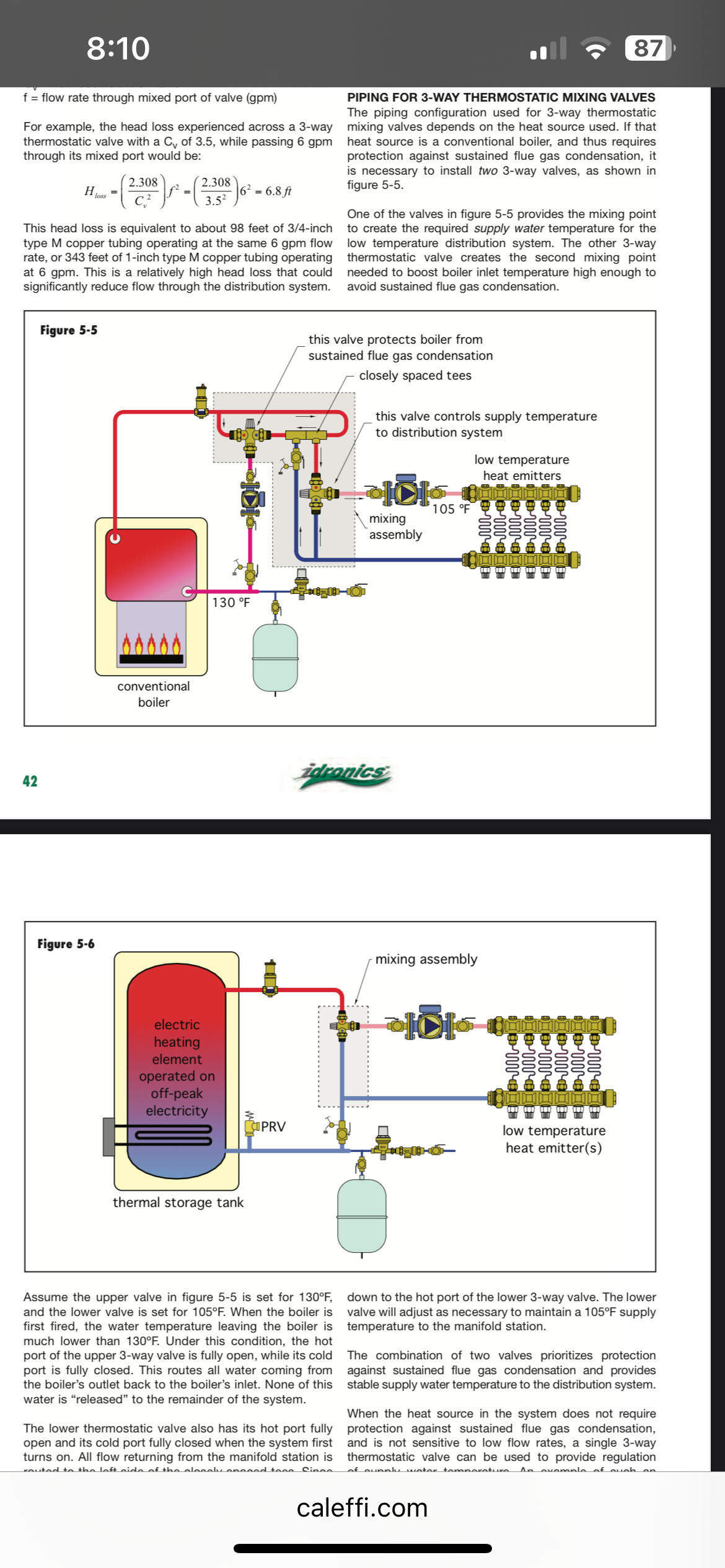

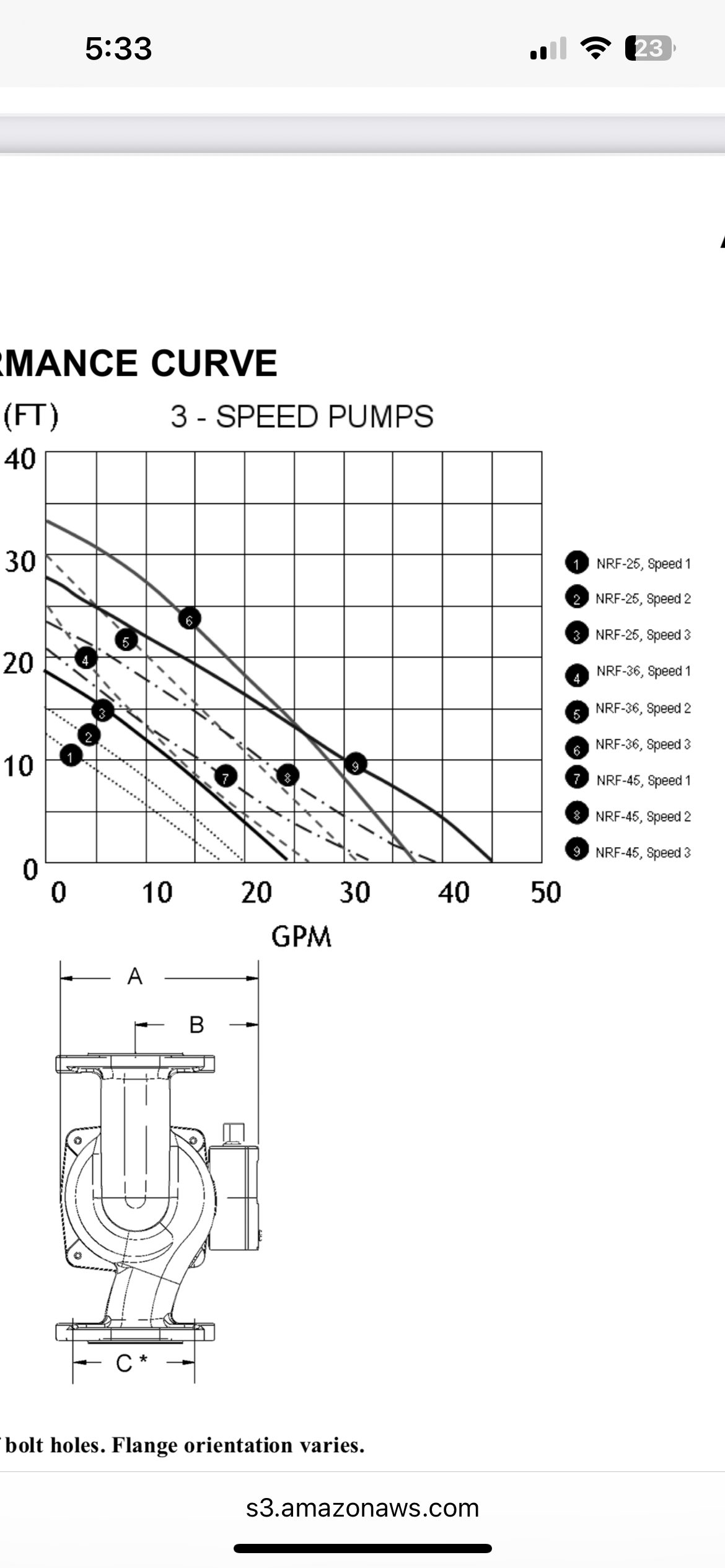

Some of the B&G NRF series are close to that specA 3 speed NRF 25 maybe

There used to be a LR series that was high flow low head. These are one piece wet rotor type circulators

hot_rod

hot_rod

Re: My Aquastat only has a high limit any reason why or should I put a low limit controller on.

this is desirable if you do not need to maintain boiler temp for your Domestic hot water such as in your case with your separate water heater.

By allowing your boiler to cool off more in between cycles you achieve longer run times during a call for heat which is more efficient than maintaining your boiler temp at say 140°F

Longer run times are better then short run times... (think highway driving vs city driving)

If the tech changed your aqua stat from a cold start to a non cold start then I would call them and ask them to install the correct control.

you will no doubt use some extra fuel by maintaining the boiler temp full time.