Best Of

Re: Near boiler piping/replacement boiler

Hi all, I just wanted to give you some updates:

I had some repiping done - supply header is now 1 1/4" and return is 1". Left the circs on the return. Added a Caleffi 573 feed valve. Set low limit to off, so boiler is now a cold start. High limit is set to 180, economy off and differential to 30. Thermal pre-purge is enabled on the hydrostat 3250.

I changed the headbar to 1.00/85 and put in a .85 nozzle at 145 psi pump pressure.

Here are some numbers:

Boiler sat overnight with no calls and dropped to 105 degrees and 10psi water pressure.

I turned on two of the three heating zones to call the boiler on.

This is with the thermostat reading 72 degree house temperature, so it's not really testing at ideal conditions.

3 minutes runtime - stack temp=340, boiler temp=122

4 minutes runtime - stack temp=350, boiler temp=137

5 minutes runtime - stack temp=358, boiler temp=149

6 minutes runtime - stack temp=359, boiler temp=147

7 minutes runtime - stack temp=356, boiler temp=135 - return pipe just getting warm, water feed at 15 psi

8 minutes runtime - stack temp=357, boiler temp=134

9 minutes runtime - stack temp=362, boiler temp=144 - return pipe warm

10 minutes runtime - stack temp=368, boiler temp=155 - baseboard temp=126

11 minutes runtime - stack temp=374, boiler temp=161 17psi water feed, return pipe hot

12 minutes runtime - stack temp=375, boiler temp=165

13 minutes runtime - stack temp=378, boiler temp=171 - baseboard temp=145

14 minutes runtime - stack temp=379, boiler temp=175

15 minutes runtime - stack temp=383, boiler temp=180 - baseboard temp=157

I've never had the boiler run this long, but it might have to do with starting at such a low temperature.

The indirect called about 30 minutes later when the boiler was still at 180 high limit - here are the numbers for that:

145 degrees - boiler fires

2 minutes runtime - boiler temp=149

3 minutes runtime - boiler temp=157

4 minutes runtime - stack temp=350, boiler temp=166

5 minutes runtime - stack temp=360, boiler temp=171

6 minutes runtime - stack temp=372, boiler temp=177

6 minutes 30 seconds - boiler hits 180 high limit again with indirect still calling

I have to do a combustion analysis to see where my numbers are with the .85 nozzle.

Do my stack temperatures look good enough to prevent condensation, or should I increase to a .90 or 1.00 nozzle?

I couldn't measure the return pipe temperature exactly to see if I got 140 degrees after 5 minute. My infrared camera was not picking up the return pipe temperature that well.

Thanks!

Re: Sun Room- Add Sixth Baseboard Hotwater Zone or a Mini Split

I'd run the baseboard into the sun room — but on its own zone, as sun room heat demands are so different from other rooms.

As to freezing — unless that room is isolated from the rest of the house (doesn't sound like it) it's not much more likely to freeze than the rest of the house!

Re: Refurbished radiator making bird noises. Not vent?

Is this the only radiator making noise?

Make sure that the shutoff valve is fully open.

Where any other changes made to the system?

Is this the same radiator that was there before (meaning did you buy a new radiator or did you refurbish one that was there previously)?

Try running the heat without any air vents on, just for kicks.

Re: Oversized overtall chimney?

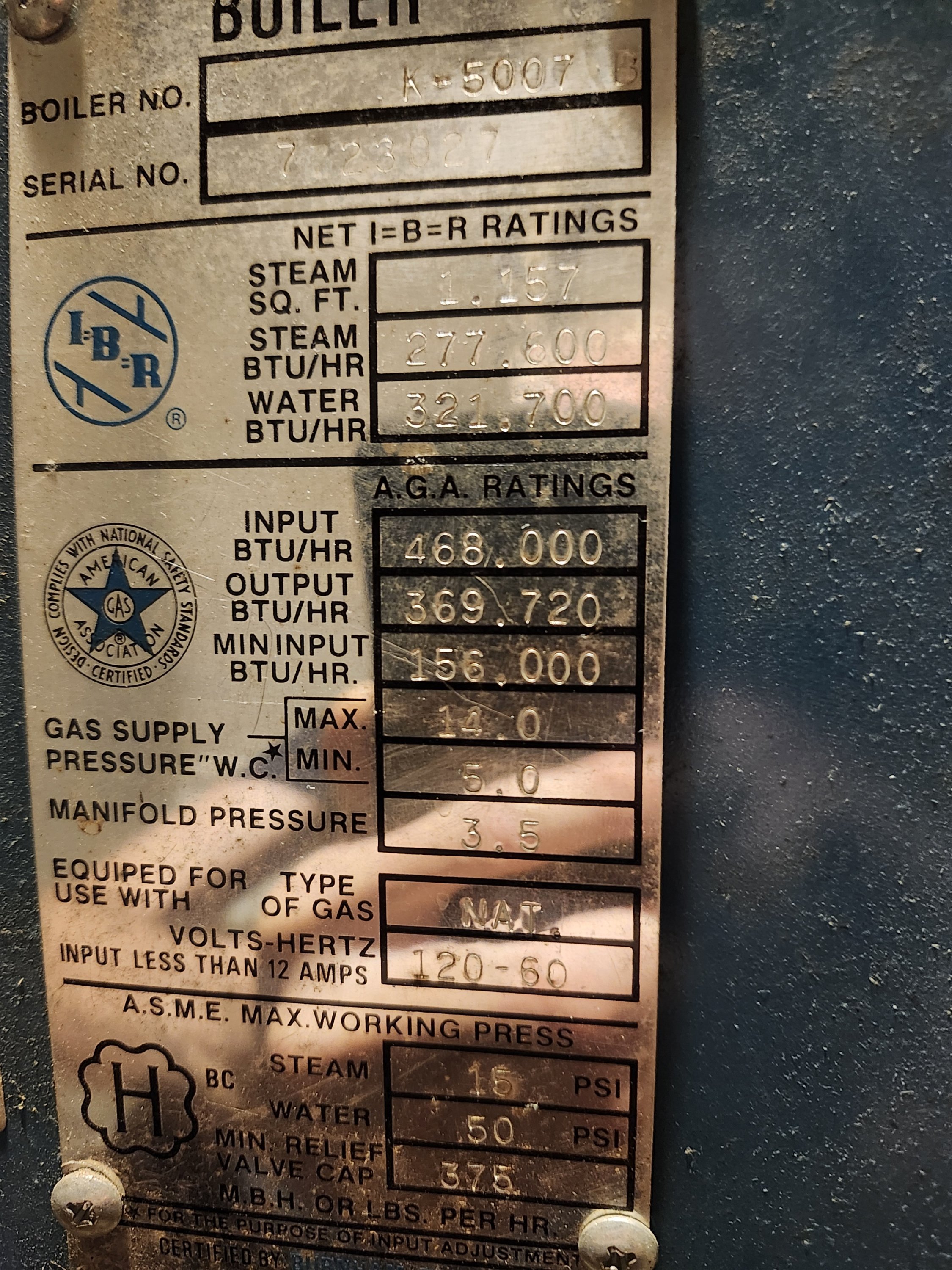

Nameplate on the K-5007 says it can go from 468 down to 156 kbtu or 33%. I didn't initially believe it either but it lights off smoothly, makes steam quietly, and doesn't drive my 1950s remuddled distribution system to conniptions like it did at full firing rate. Been at this setting since 2013, through numerous polar vortices. I love my steam heat; I just hate the crazy draft it pulls.

Re: Help with Goodman GSXC16 Error code 04

Update. My son is working full time as a welder, so he does the family trade as a side gig. Since everyone is asking for the fall tune up of their oil burners and other service calls as needed, he has been busy after work and on weekends. He has just finished looking at just about every possibility all of you have been so helpful contributing, but it has taken some time to get there.

Finally contacted Goodman Tech support on Tuesday, and they asked him to get a megger and test the compressor windings. (locked rotor and stuff like that may have caused winding insulation deterioration). Since I sold the business and no longer have a megger, he needed to borrow one from the guy I sold mine to. That test indicated that the compressor is just fine with over 1000 megs. (anything less than 700, Goodman would have condemned the compressor). So, Goodman told him to get a new circuit board under warranty. And just so happens that the counterman from the supply house where he purchased the equipment stopped by for a beer and to see how Ed Jr. was making out, and he heard the Goodman tech support guy tell him that. Case number and all!

So on Monday, there will be an order for a replacement board placed if they don't have any in stock.

Future updates to follow. Thanks for all the help everyone. Since this is newer technology on this compressor, I will keep you all updated on the progress. As of now the 04 code is a daily occurrence.

May be related to this issue:

The lights have been dimming on occasion when two appliances are operated at the same time, like the washing machine and the garbage disposal. and the Comcast Cable repairman has also needed to come look ar some of the reasons for poor performance of the cable and internet. His findings have indicated that some of the components having to do with the cable were showing signs of partial failure. although there was no actual "fried cable" He said top call the electric company and tell them the the cable guy (Not Larry) said he had to replace a fried cable and that will get them out to do some testing for electrical problems.

The electric company did diagnose a problem that was effecting Ed's home and several customers further down the main. There was a work crew that spend most of the night, in to the wee hours of the morning working on the underground electrical service lines. they were gone bu the morning when he went to work. That evenoing when he came home he did some testing of appliances by operating several appliances at the same time that were known to cause the dimming lights. The problem with the "Dirty Electric" was gone. no lights dimming anymore. Perhaps the electrical problem was playing havoc with the software chips and diodes in the circuit board of the Goodman Equipment. ????

Re: Need some advice for a vintage Peerless radiator valve hookup

You have to remove the spud and replace it with the spud that comes with the new valve. If your plumber doesn't know how to do that without breaking the radiator, find a better plumber.

Why you must flush hydronic piping before installing a boiler, this weeks video

This weeks video talks about the importance of flushing a hydronic system before replacing a boiler. By not doing so, you could actually void the warranty.

Re: Combi Boiler water heater side... need a T&P

Just a relief valve…. nothing more.

I have never seen a temp and pressure relief valve on the isolation valve set ups.

Re: Oversized overtall chimney?

No other criteria other than the house is still standing, and no dead people for a safe "successful" operating system?

I wonder what the combustion numbers are from downfiring an atmospheric boiler by 53%. Good thing there's excellent draft to get that CO outside where it belongs.

HVACNUT

HVACNUT

Re: Pricing on refurbished cast iron radiators

Hat's off to Canada!

Um…better keep that hat on.