Best Of

Re: What was the craziest things you’ve found above ceilings?

@Metalguy thats incredible DIYers watch a 30 minute show on HGTV and think they are experts

Re: Air Vent Maintenance

Either will work — but It's much easier just to turn off the boiler while you are working on the vents, and then turn it back on when you are done.

No need to drain anything or anything else — just flip the switch.

Re: Efficient and dependable cast iron boiler recommendation

If your set on cast iron, go with a 3 pass boiler. Not sure if WM still makes the Ultra Oil. They used to come with the Beckett NX but they don't make the NX anymore. Dunkirk isn't popular by me. Biasi, Trio, Viessmann, Buderus is what I see.

HVACNUT

HVACNUT

Re: PMJ plc system

As requested I put a temp sensor on the boiler and charted it. It is a separate chart but I also made a 6 hour one for system pressure to show the same time frame. The sensor is on the header and not actually in the water which explains why it doesn't quite make it to 212. So add 2-3 degrees. See attached.

As I already knew the boiler doesn't cool that much. It was 15-20 degrees out overnight when this was charted from 11pm to 5am. The tstat was satisfied 3 times and I put the approx total boiler off time for each. You can see during the regular 18 minute off times the header doesn't even make it down to 200 which at the low pressure is barely under the boiling point. I knew this already given that on new fires after being off that long boiling starts immediately and steam gets to the most remote radiator in 3.5 minutes. After the 42 minute off time the time to delivery on remote steam was 7.5 minutes. I included the cycle chart for the same time period for reference.

Summing up I think it is pretty clear looking at this that concerns about losing efficiency from being off too long doing two cycles per hour instead of one long one are not justified. I will argue that the total time to steam from fire is actually shorter with two burns. So as @109A_5 speculated, the system basically never really stops steaming, especially as demand increases. The heat is surely a lot more even this way.

PMJ

PMJ

Re: How Do I Connect This Wire?

A chapter the ins and outs of thermostats. Including using power robbing thermostats, or not using them.

2 years ago I did a cleaning on a steam boiler. And the elderly woman told me that her thermostat was too high it was an older Honeywell round. And she wanted to move it down but it was already falling apart so I told her I would replace it with a new one that was not that expensive so I did. I positioned it at eye level and she loved it the heat came on and everything was fine. The next morning I get a desperate call that "my house is freezing". I get there and there's no call for heat from the thermostat. So I learned about power robbing thermostats. I replaced it with a Honeywell mechanical which is no longer round but square and isn't as easy to read as the round. (She did not want anything with batteries)

Re: Utica PEG 112 missing burner parts

Looks like you are ok. I don't think changing the orifices will help

Re: Thermostat replacement

Awesome, I didn't expect all the analysis.

Here's my summary at a 5th grade level (LOL). Too much current flow through the anticipator heats it up too much. It shuts off the boiler and takes a long time to cool down and reset so the boiler can run again.

PS: In my working days I was a charts and graphs kind of guy, along with 38 years of working in the nuclear navy business in NY and CT. Learned a lot there and tremendously proud of it. That being said when I bought my rental in 1989, I had a lot to learn about residential steam heat…thanks to all the folks at HH giving me great guidance (Jamie, ChrisJ, Ethicalpaul, and others) and validation of some of the things I did along the way.

Every chance I get, I mention HH to people I deal with in the heating business.

Re: Efficient and dependable cast iron boiler recommendation

I wouldn't scratch Burnham off this list. Their problematic gas boiler was the Independence steam unit, and you don't have steam. I like the Burnham Series 2, ES2 and Series 3 hot-water units- the basic cast-iron block in these units has been in production for decades and seems to last a long time.

Re: First time designing and installing radiant - feedback

That is a nice compact piping package.

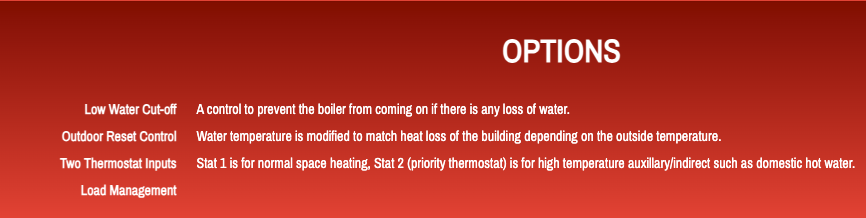

A few thoughts. You can get an optional reset control so the boiler would modulate its temperature based on outdoor temperature . This saves $$ on operating cost and the slab will stay a nice consistent temperature, never over or undershooting. Maybe you have ODR in that boiler control? It is worth the time and $$ to set up.

With the boiler above the piping, glycol with no make up, you want a low water cutout. Maybe the boiler has a pressure switch to protect it and the pump if the fluid drops? If not they have an optional one.

Here are the options listed at Lion Boilwers site.

hot_rod

hot_rod

Re: Utica PEG 112 missing burner parts

The CO reading is more important .Its a Old boiler you want to leave it safe… It may need an adjustment or cleaning..

The old standard was 100ppm , the new 50ppm .

Big Ed_4

Big Ed_4