Best Of

Re: The Master Steam Trap Mistake: Why It’s Costly, Dangerous, and Outdated, this weeks video

I loved the video Ray Ray..mad Dog

Re: NJ Boiler replacement decision points...

So I used 55° incoming water temperature, raised to 110, which is about as hot as you could run to a faucet. You could go online and determine the city water temperature high and low probably.

Wintertime water in Phoenix runs around 80°, in Milwaukee down to 35- 37° in above ground water towers.

The only way to get 90% plus is if the boiler is running a low temperature 130 or lower so it condenses. What temperature do you run the Munchkin?

Since the boiler kicks up to 180° for hot water production, 85-87% efficience in that mode.

With a combi the boiler heats water instantly, so no need to calculate gallon like an indirect.

At a 3 gpm flow it could run now until the end of time and produce 110° hot water. It works much like a tankless water heater.

hot_rod

hot_rod

Re: Ignition transformer insulation (Navien)

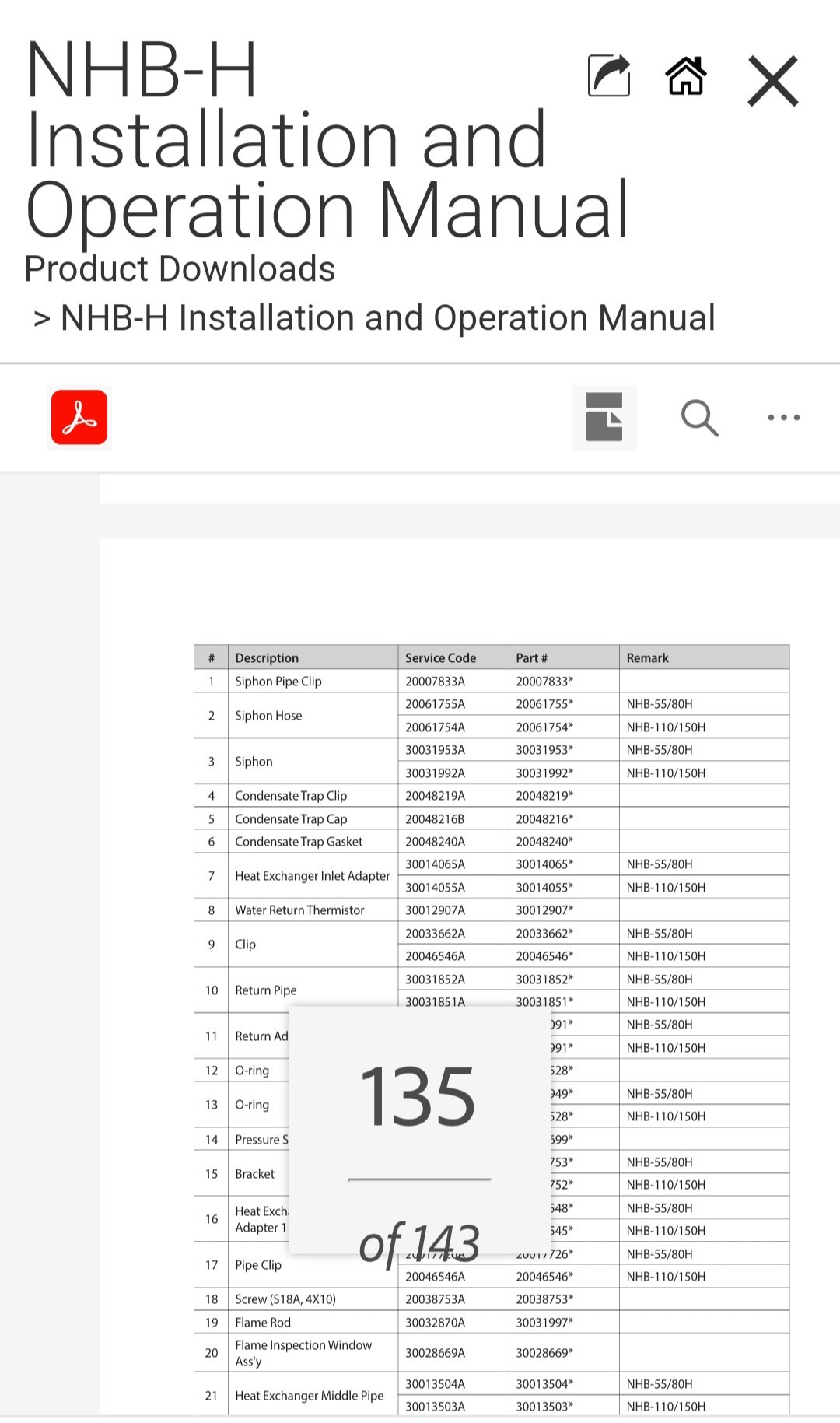

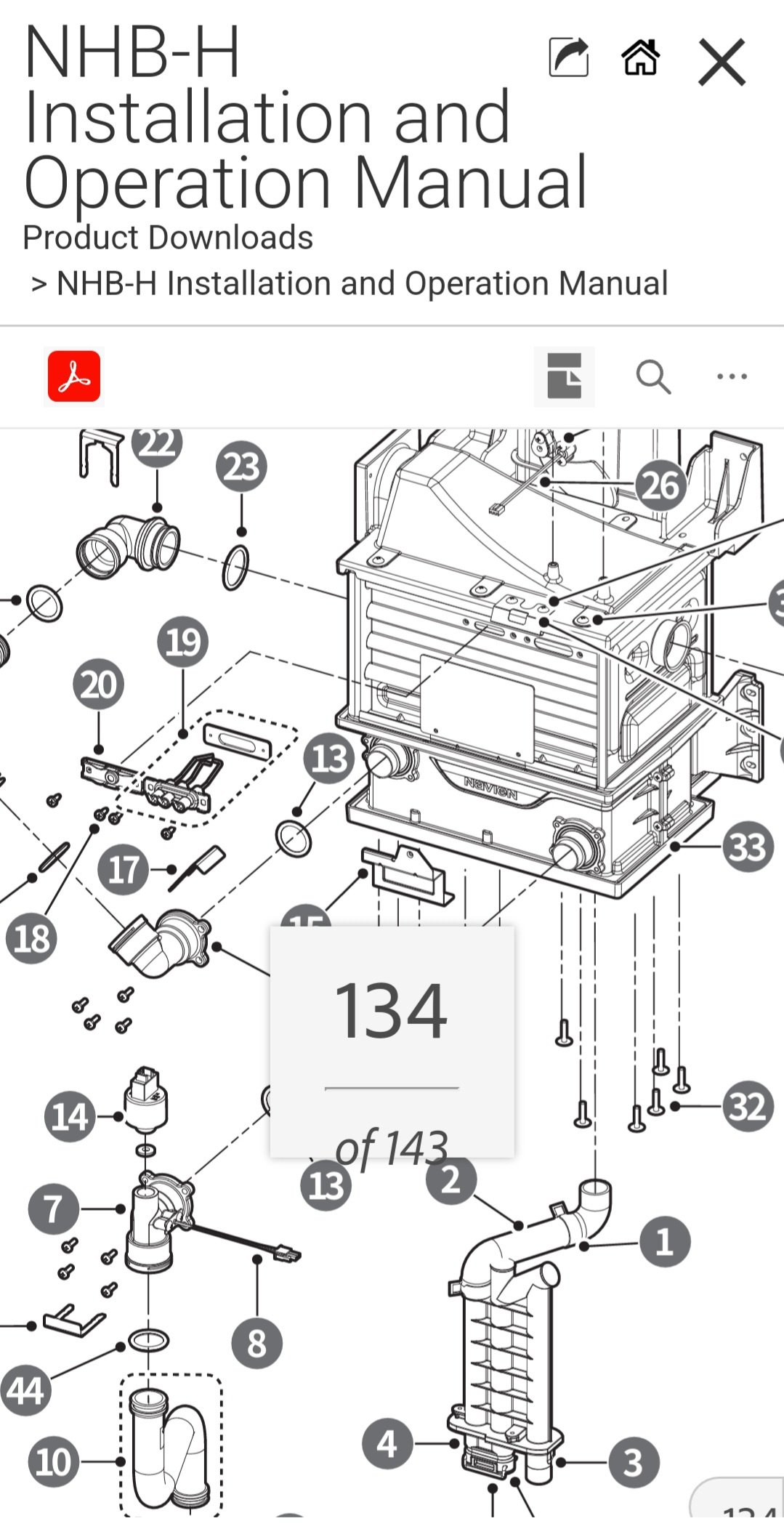

Item 19, Flame Rod, shows it comes with the gasket. They should supply 10 with every Flame Rod because they fall apart if you breathe on them.

HVACNUT

HVACNUT

Re: new concrete slab with radiant heat that will be polished for finished flooring

Just to emphasize a couple of @hot_rod 's excellent summary. He's right. Fibers won't be a problem if you power trowel. You won't notice them. And use enough. Also, his comment on don't add water. Just don't. As he says, if for some reason you need it to flow better, specify adding plasticizer — and let the ready mix company do it.

Last tidbit. Keep the concrete moist or at least damp for at least 72 hours. That is really truly critical, and a lot of the problem surface cracking one sees is from not doing this. Perhaps I can explain why. Cement is the binder in concrete — it's what sticks to the aggregate and holds it all together. Cement does NOT dry. It cures by reacting with water to form a crystalline solid. This takes time — and enough water. If there isn't adequate water, not all the cement can react and the cement won't cure. This is particularly true at the surface of, for instance, a slab. Too much water is almost as bad. Concrete mixes are very carefully designed!

Re: Ignition transformer insulation (Navien)

I have never seen anything like that on the inside of an ignition cable connection. Is that really an original equipment part (or substance)? I would not use that stuff in making a connection to the ignition system. The innards of that wire and connector boot should make a metal to metal connection without any fibrous fungus inside it. That is just my opinion.

Re: Anticipator setting for my steam boiler

For steam heat with cast iron radiators you want a relatively long cycle. It needs to be long enough so that steam reaches all rooms before the burner shuts down. You may have to experiment a bit, but a higher amp draw setting giving less anticipation is probably what you need.

bburd

bburd

Re: Tomorrow is Install Day!

remember to take care of the install people.

plenty of water

A cold one after they’re done is always appreciated

pecmsg

pecmsg

Re: ECM pumps interfering with each other

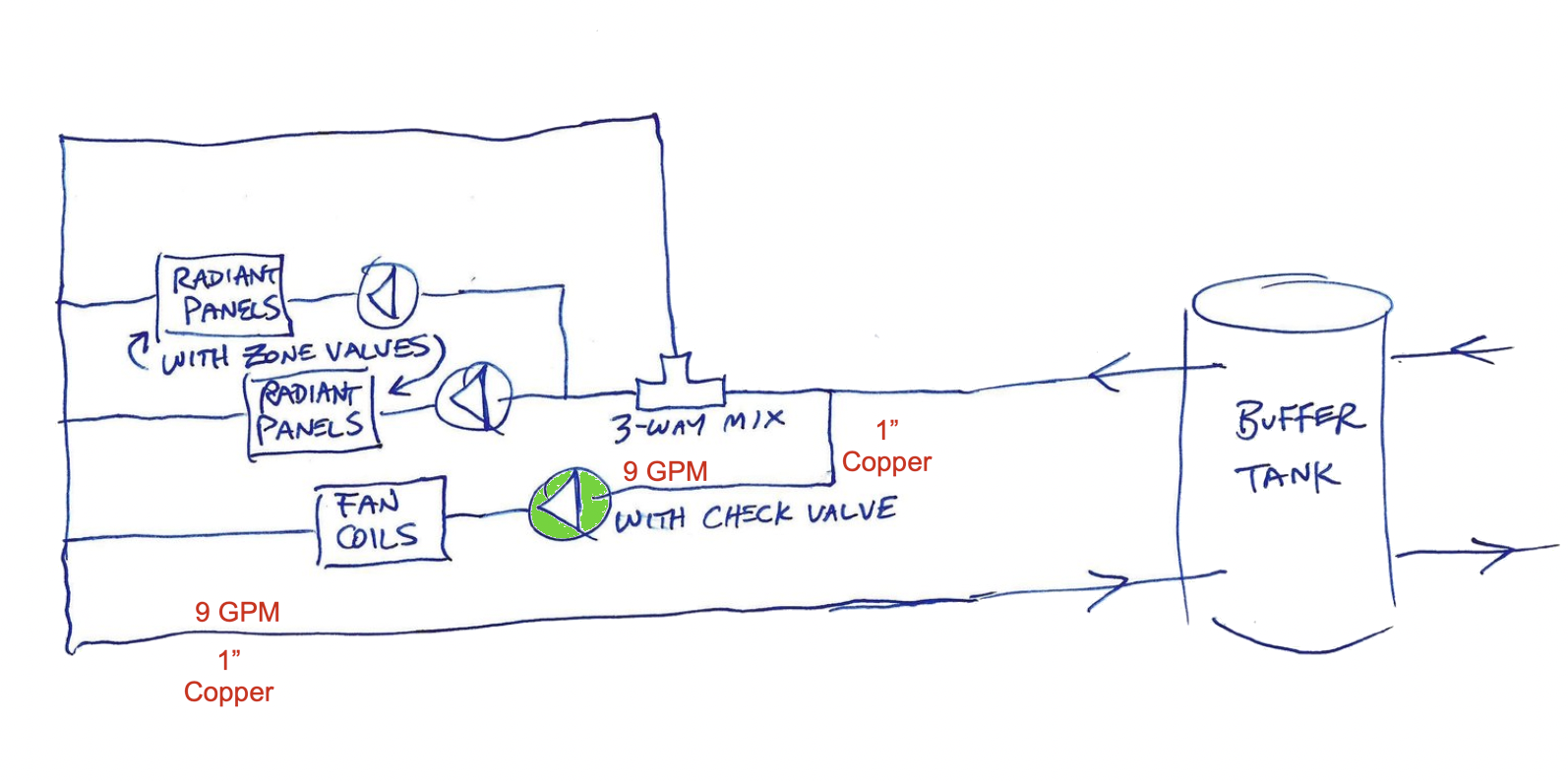

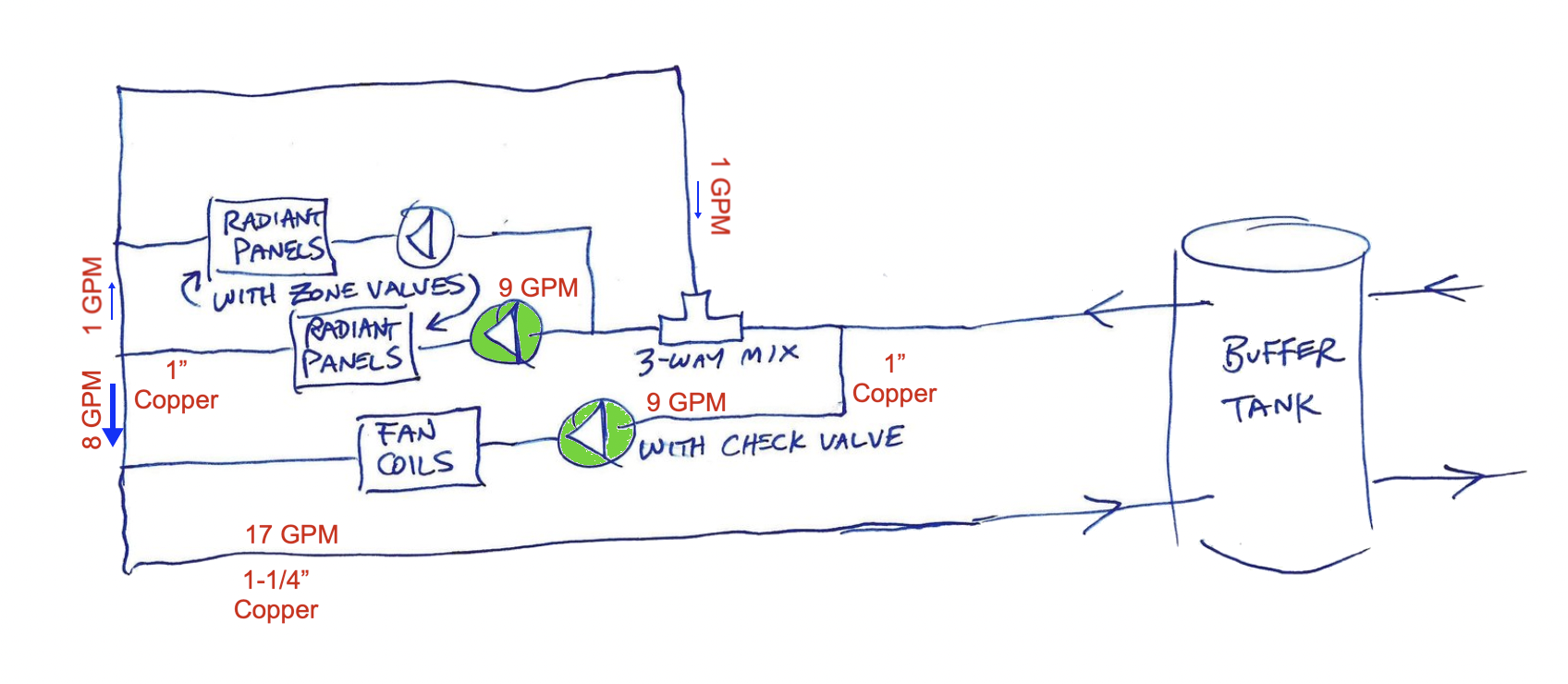

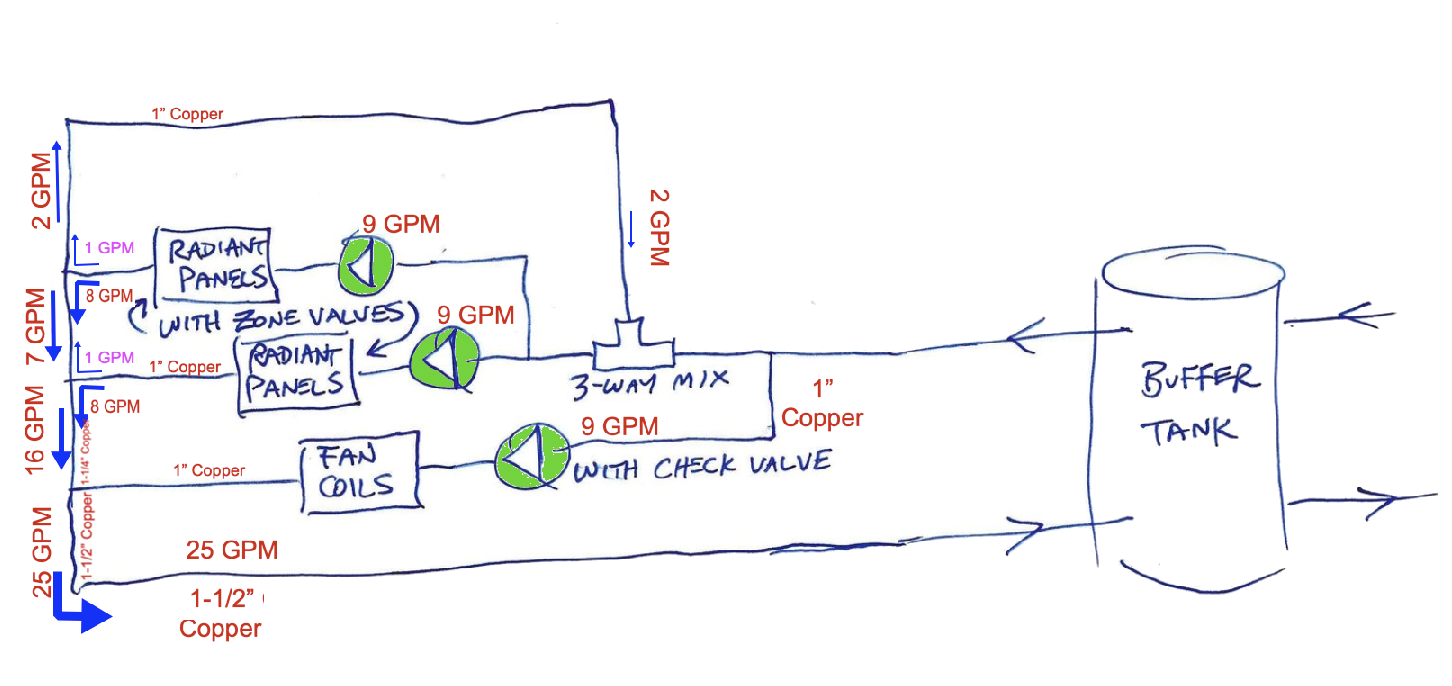

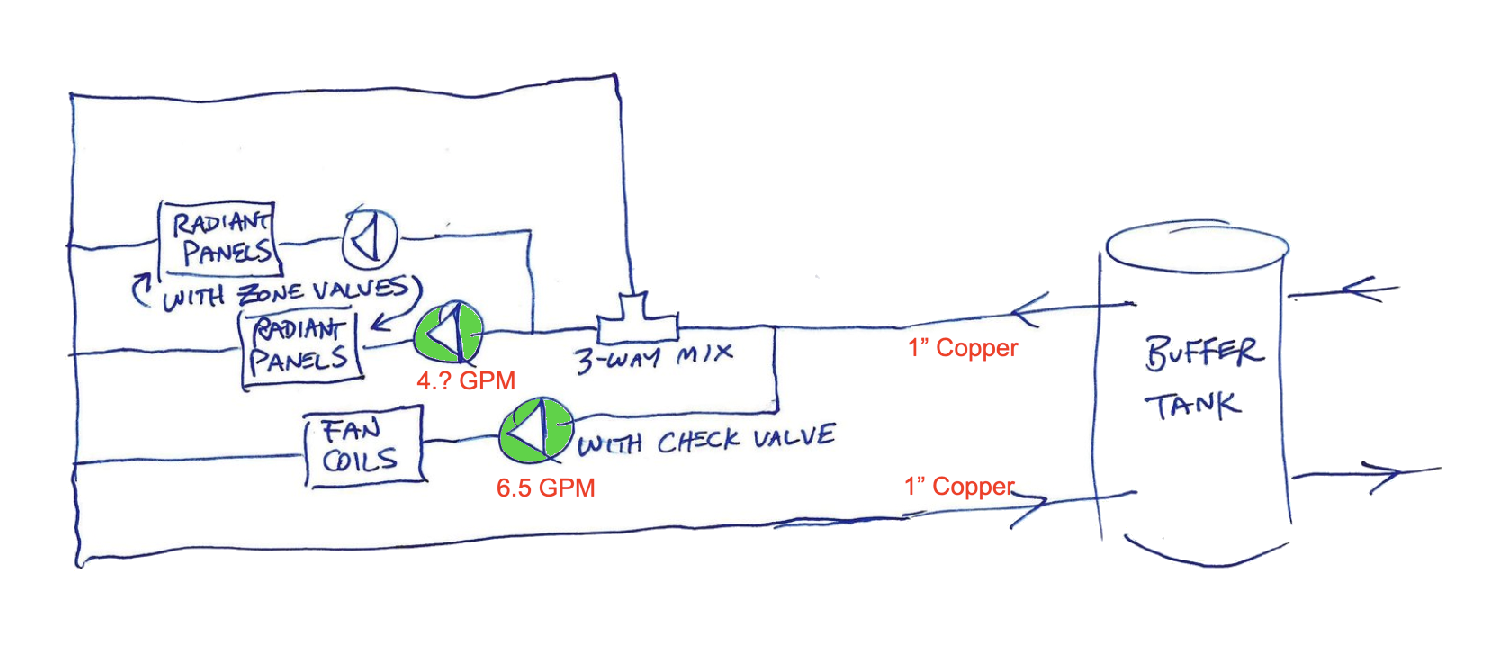

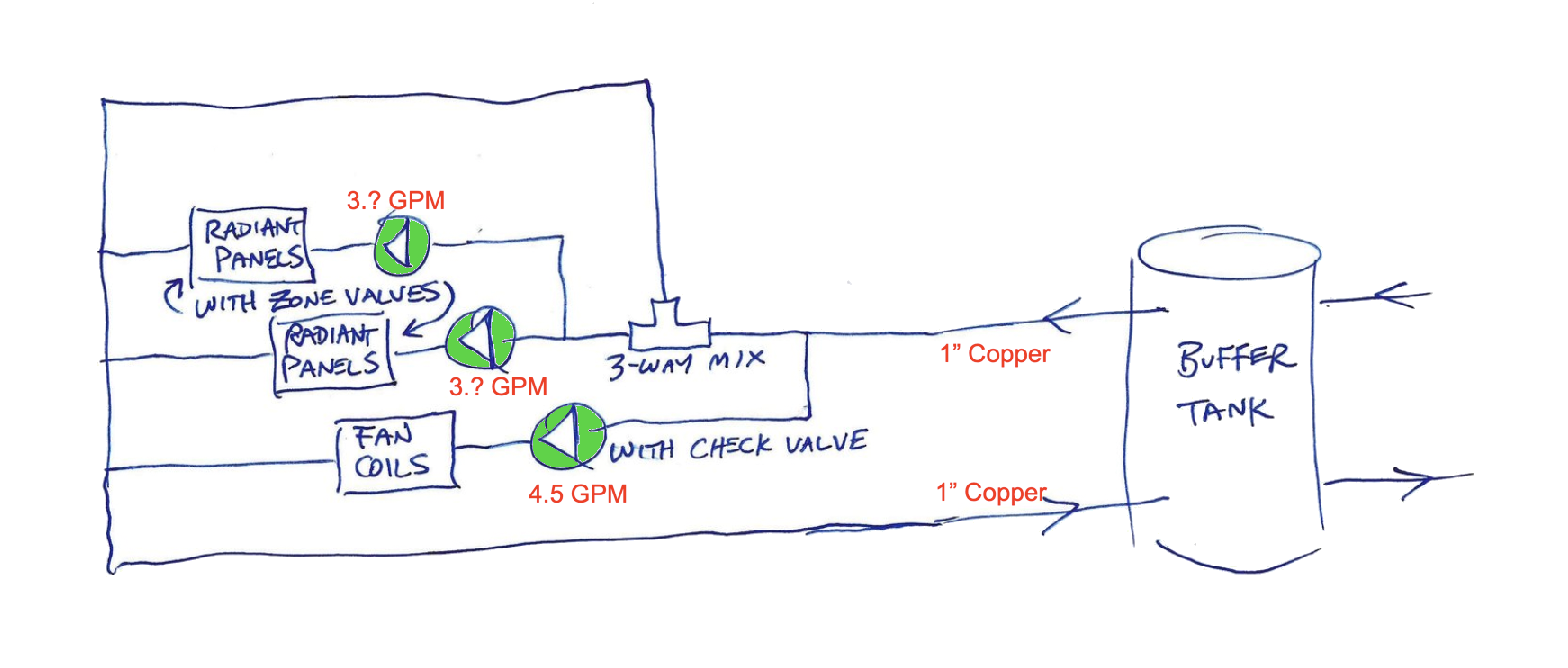

To put in picture form, you can get 9 GPM from all three pumps if you have the correct piping sizes.

With only one pump operating at 9 GPM you can use 1" copper and get all the flow you need. That is because 9 GPM can move freely and relatively noise free thru 1" copper. But 9 GPM is about the maximum you can fit in a 1" Copper pipe. more than that and the system will get noisy. (8 GPM is the recommended max flow for 1" Copper)

The problem happens when you try to move 18 GPM thru 1" copper. There is not enough room. So your original design needs to have 1-1/4" copper in order to accommodate the flow from 2 pumps. Even if some of the return water from the radiant loop goes back to the mixing valve there is still the chance that the return to the boiler will

overwhelm the 1" return to the boiler or buffer tank.

When you add a third pump, now you need to increase to 1-1/2" copper to accommodate 27 GPM in the shared piping.

With 1" Copper shared piping, when more than one circulator pump is operating the pumps need to operate against a greater pressure drop or Pump Head as more water needs to move thru. the same space. So the pump curve will move from 9 GPM each, down to something lower, like 6.5 GPM as the other pump fights more friction from the mixing valve, radiant floor tubing, manifolds and the like. So pumps of equal capacity will move different GPM based on the friction loss of the zone it is operating.

With all three pumps operating on smaller common piping, you will get even lower GPM from each pump. Designing piping systems you need to take into account the sahred piping and the flow rate under the worst case. All pumps operating at full capacity at the same time. If you don't take that into consideration, then you will end up with performance issues, short cycling, noise and many other. problems.

These diagrams should make things clear as mud for you

Re: Warm Start Boiler Summer Leak

I would guess not. Since this is a WTGO boiler it was equipped with a tankless coil, that would mean to offer DHW priority the circulator would stop pumping cold radiator water when the aquastat reached the low limit circulator cut out temperature. The boiler would always maintain 140° or more if the low limit was set at 160° with a 20° diff. No need for boiler protection in this case.

Now that the cold start boiler is an option, they may need to think about boiler protection with a bypass of some sort, or some reverse strap on aquastat that keeps the circulator from operating when the supply temperature is below say 150°. the circulator would cycle several times as a result, but it did that when it was operating for DHW anyway. So no big deal.