Best Of

Re: Why don't we pump away from expansion tank on dhw recirc systems?

Probably the simplest reason is that as many have implied there is very little if any chance of the pump cavitating, never mind pulling air. It would be a very rare domestic water setup which had a static pressure less than around 20 psig; 30 psig would be more normal. With that much static pressure you would need 60 feet of head loss or more between the expansion tank and the pump inlet to get in trouble. Not going to happen…

Re: Why don't we pump away from expansion tank on dhw recirc systems?

I suspect the chances of a pump pulling air in are mighty slim when the system is somewhere between 40-90 PSIG. The inlet of the pump is never going below atmosphere.

And even if it does, no one cares with domestic hot water.

That's my thoughts, but, I have very little knowledge on hot water systems.

ChrisJ

ChrisJ

Re: Soldering close to soldered fitting

Cut it all out and sweat it. It will take less time than worrying about the press fittings. You have plenty of copper coming out of the valve on the run of the tee. Remove the PP tee and coupling and sweat it.

No need to spend $25 on heat block for what a few fittings cost.

Re: buying a hydronics business

What does this "business" include? Does he have a lengthy clientele list or service contracts that come with it? Trucks? Inventory? Property? Tools? Without a name/reputation and clientele, a business is generally worth about 80% of real property value (tools, vehicles, inventory, equipment, etc). I run an upper 6 figure hydronics business but if I sold out tomorrow, it'd be worth $50k at most and that's only because of the aforementioned real property. The name isn't worth a dime if somebody else is at the helm, and there are no service contracts or guaranteed income to sell.

Re: compressor

Resistance of the windings is different than megging the windings.

Winding resistance is taken with a multimeter (or ohmmeter) set to resistance/ohms/Ω (if not autoranging then generally the lowest range). Should be less than 40 Ω between the run terminal ("R") and common ("C"). It will be different between start ("S") and common, but I can never remember if it's a little higher or a little lower. The measurement between R & S is ≈ the sum of the measurement between R & C and S & C.

'Megging' a compressor is measuring the resistance of the insulation of the motor. It's taken with a megohmmeter between any one compressor terminal (doesn't matter which) and ground. With a cold compressor, it may be as low as 20 MΩ but may creep up as you measure. A regular multimeter isn't a good choice for this measurement. While it can tell you if the windings are good and shorted, it can't tell you if there's a weak spot that's getting ready to blow through.

Re: Soldering close to soldered fitting

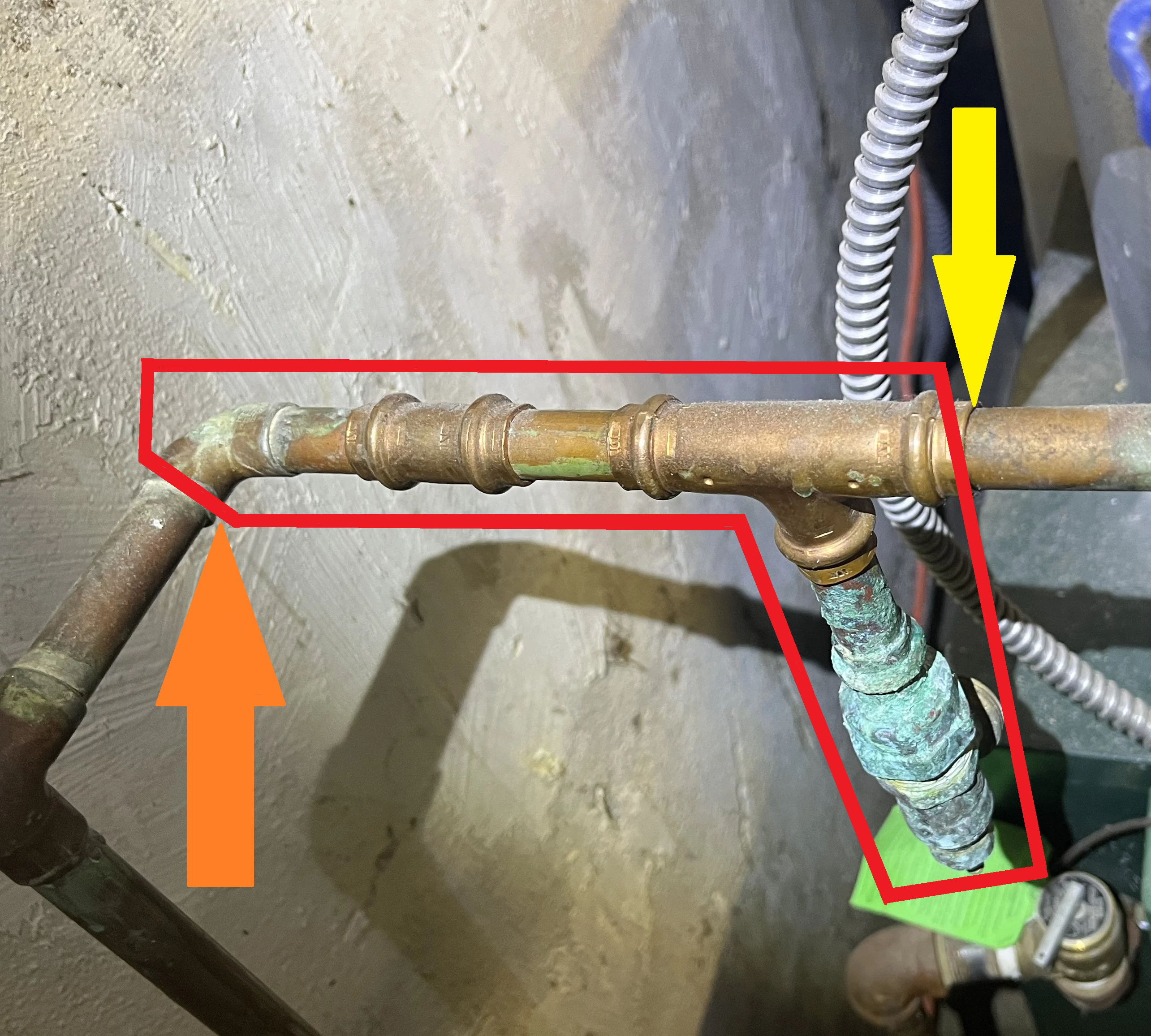

If it were me, I'd remove the mess encircled in Red by cutting at the Yellow arrow and un-solder at the Orange arrow and rebuild as needed.

Re: Any plumbers good at small bathroom layout?

lack of counter space would be a non-starter with my wife. A shower instead of a tub would be another option.

How creative do you want to get??

hot_rod

hot_rod

Re: compressor

Amp draw on the compressor R, S, & C when the contactor draws in? Resistance between R & C and between S & C?

Re: Baseboard Heaters - Slant Fin - Maintenance

True but baseboards will get dirty faster if they don't clean the apartment. its not like they need cleaning every year. Probably every 5 years.