Best Of

Re: Tamper free switches

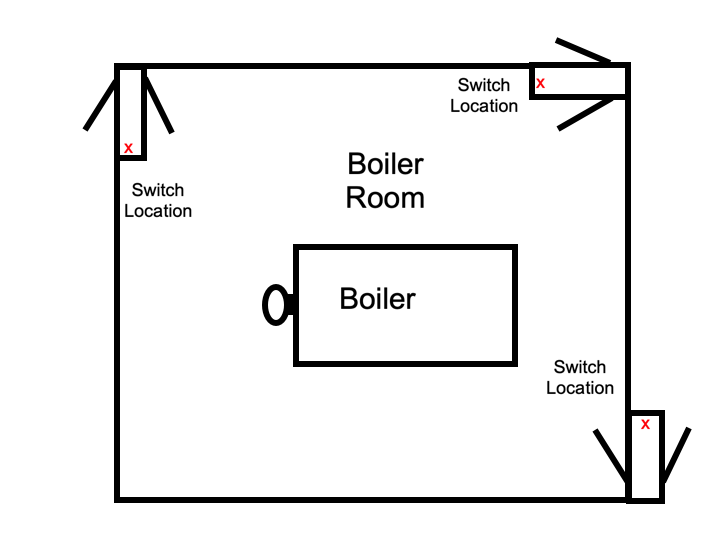

How much room is there inside the boiler room? Is there enough room to place a one foot vestibule just inside the boiler room, or just outside the boiler room in order to make the switch pass inspection outside of the boiler room door but still out of public area?

Re: Venting into a chimney

Absolutely not...that is a 95% Condensing boiler (very low flue temperature). You can ONLY use the old chimney as a pipe chase, as the other guys stated. I'm using the exact same Viessman model on a project right now, but using PP (polypropylene) venting directly outside through basement wall. Mad Dog

Re: Venting into a chimney

To be clear on your query, I can not find any specifications on a Viessmann model BK200E anywhere in the old or new equipment catalogs i have access to. I do know that many of the Viessman gas and LP boilers are condensing boilers and do not fall into the Category I venting design that allows for chimney venting.

here are the venting categories:

Category I is characterized by negative pressure and non-condensing appliances. These systems rely on gravity to vent flue gases, and if there is a leak, air from the space will flow into the flue pipe rather than flue gas leaking out. Category I venting systems can use single wall, double wall, B-vent flue pipe, or even a chimney.

Category II is also under negative pressure but may produce excessive condensate. These appliances are typically condensing and have a combustion efficiency greater than 83 percent under ANSI test conditions. However, Category II products are no longer manufactured.

Category III operates with positive pressure and non-condensing appliances. If there is a leak in the venting system, flue gas will flow from the flue pipe into the space, which poses a safety hazard. Therefore, Category III vent pipes must meet additional safety requirements, such as being gas-tight with gas tight venting systems.

Category IV is positive pressure and condensing, typically used for high-efficiency appliances with an annual fuel utilization efficiency (AFUE) of 90 percent or higher. These systems require sealed joints and are often made of materials like PVC or CPVC.

I believe the Viessman boiler you have would fit into Category IV, but I can not be absolutely sure since the model number you posted is either incorrect or is from a time before internet records are available. Absent more information my vote would be the vent according to the manufacturers venting instructions.

EDIT: it appears that Viessmann does make a steam boiler for commercial use. I do not have information on older models, so it is possible that if @heron98105's old Weil McLain is a commercial boiler in the 20 HP range and above,

Then there may be a Viessmann steamer to replace it. I don't have access to older model numbers but the newer boilers may be one of these:

And this Viessmann may be able to be vented into a chimney after you follow @Jamie Hall's suggestion about inspection. The consensus is still "Follow the manufacturer's venting instructions."

Re: Venting into a chimney

I couldn't find that model number so I could reference the listed instructions. However, if this is a condensing boiler, which I believe it is, then the venting must be listed to UL 1738 for positive vent pressure. That would probably mean a polypropylene plastic liner. Masonry chimneys are not approved for positive vent pressure. Most stainless liners are Not listed to 1738 for positive pressure or condensing.

Re: Venting into a chimney

but you could use the unused chimney as a chase to run the correct flue.

Re: Venting into a chimney

Consensus doesn’t matter. The fact is that you cannot vent a condensing boiler into a masonry or metal chimney.

The manufacturer’s installation instructions give detailed info on how the appliance must be vented and it’s mandatory that they be followed.

Ironman

Ironman

Re: New Refrigerants

There's nothing wrong with R764……

I would think adding 410A to a system tagged for R454B would be a violation, no? Even if it does work, now the next guy doesn't know what's in it.

How does adding two blended refrigerants together work out in the end?

ChrisJ

ChrisJ

Re: Automatic air bleed, but how?

Put a mini ball valve on it to make cleaning and change outs easy. I’ve only used Caleffi ones for the last 5 years. Better built/made and able to clean repair. The one you have pictured, to me, is a throw away item.

Re: EK System 2000 hot water suddenly too hot?

Good morning, All. Not much left to cover here as everyone seems to have hit the nail on the head. I've attached a sheet that may help with trouble shooting. I would confirm with a clamp on thermometer, if you can, those temperatures. Based on the IF unit your using and the patina of the pipe the readings can vary. You'll also want to check out the boiler side and look for a 35 ° drop there under the same conditions of a tank re-heating. If your temperatures are outside the 70° rise and 35 ° drop, confirm your smart pump 006 is operational. Confirm the check valve is holding. At this time i would replace the plate exchanger.

It appears that the thermostat is turning on and off, but really that's all it's supposed to do. It doesn't control the temperature per say just confirms when the tank is totally hot. I didn't see a mixing valve in the pictures, but installation of one will give you more consistent hot water outlet temperatures.

If you need a service provider in your area you can call our Territory manager Brian Kiernan 570-872-6997 or the factory 908-735-2066.

Re: EK System 2000 hot water suddenly too hot?

It is a good investment to have a listed thermostatic mixing valve on the tank. At least 4 States require a mixing valve on any DHW source.

An ASSE 1070 or dual listed 1017/1070 would limit the DHW to120 and fail cold.

hot_rod

hot_rod