Best Of

Re: new concrete slab with radiant heat that will be polished for finished flooring

Just to emphasize a couple of @hot_rod 's excellent summary. He's right. Fibers won't be a problem if you power trowel. You won't notice them. And use enough. Also, his comment on don't add water. Just don't. As he says, if for some reason you need it to flow better, specify adding plasticizer — and let the ready mix company do it.

Last tidbit. Keep the concrete moist or at least damp for at least 72 hours. That is really truly critical, and a lot of the problem surface cracking one sees is from not doing this. Perhaps I can explain why. Cement is the binder in concrete — it's what sticks to the aggregate and holds it all together. Cement does NOT dry. It cures by reacting with water to form a crystalline solid. This takes time — and enough water. If there isn't adequate water, not all the cement can react and the cement won't cure. This is particularly true at the surface of, for instance, a slab. Too much water is almost as bad. Concrete mixes are very carefully designed!

Re: Ignition transformer insulation (Navien)

I have never seen anything like that on the inside of an ignition cable connection. Is that really an original equipment part (or substance)? I would not use that stuff in making a connection to the ignition system. The innards of that wire and connector boot should make a metal to metal connection without any fibrous fungus inside it. That is just my opinion.

Re: Anticipator setting for my steam boiler

For steam heat with cast iron radiators you want a relatively long cycle. It needs to be long enough so that steam reaches all rooms before the burner shuts down. You may have to experiment a bit, but a higher amp draw setting giving less anticipation is probably what you need.

bburd

bburd

Re: Tomorrow is Install Day!

remember to take care of the install people.

plenty of water

A cold one after they’re done is always appreciated

pecmsg

pecmsg

Re: ECM pumps interfering with each other

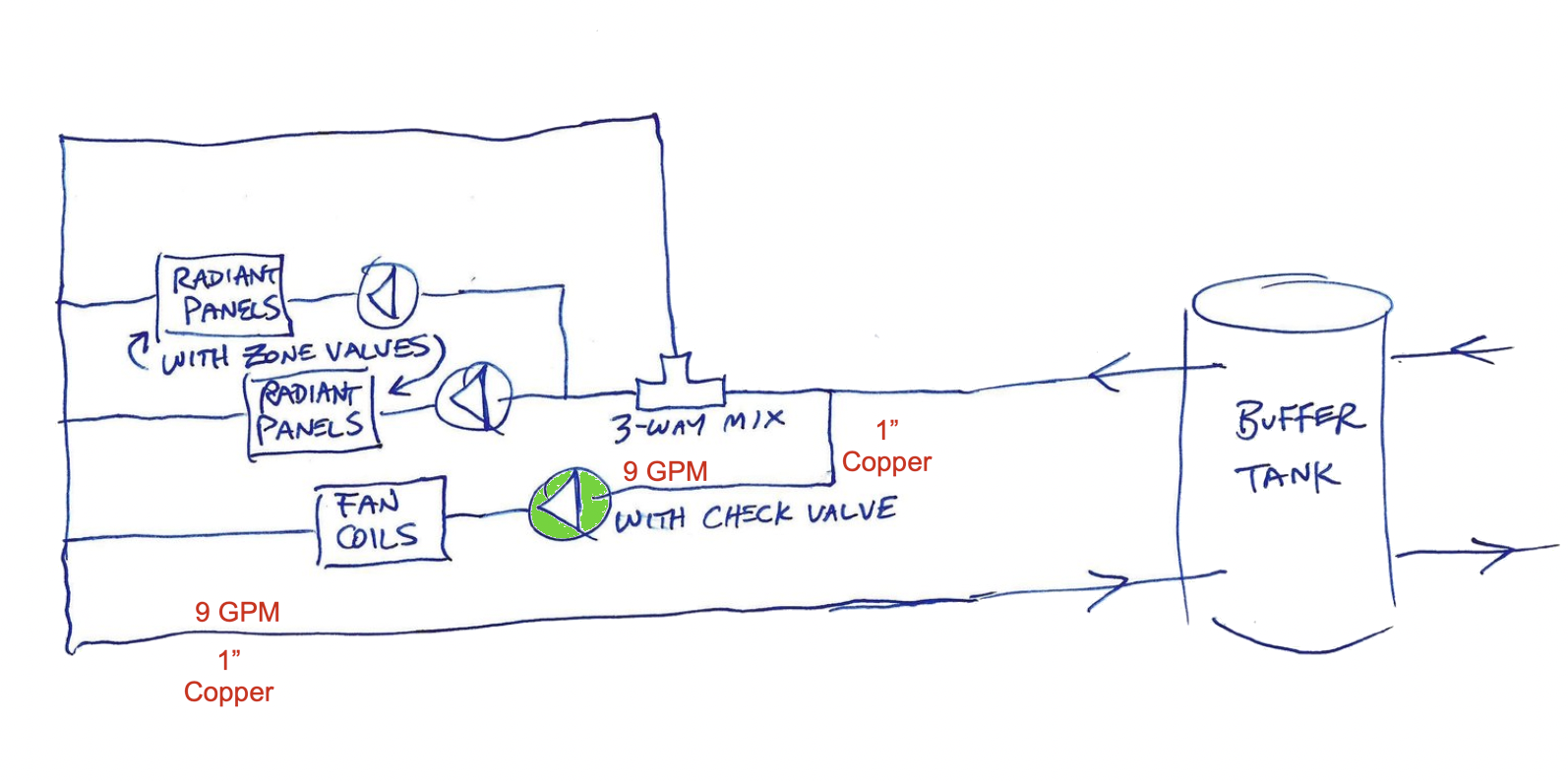

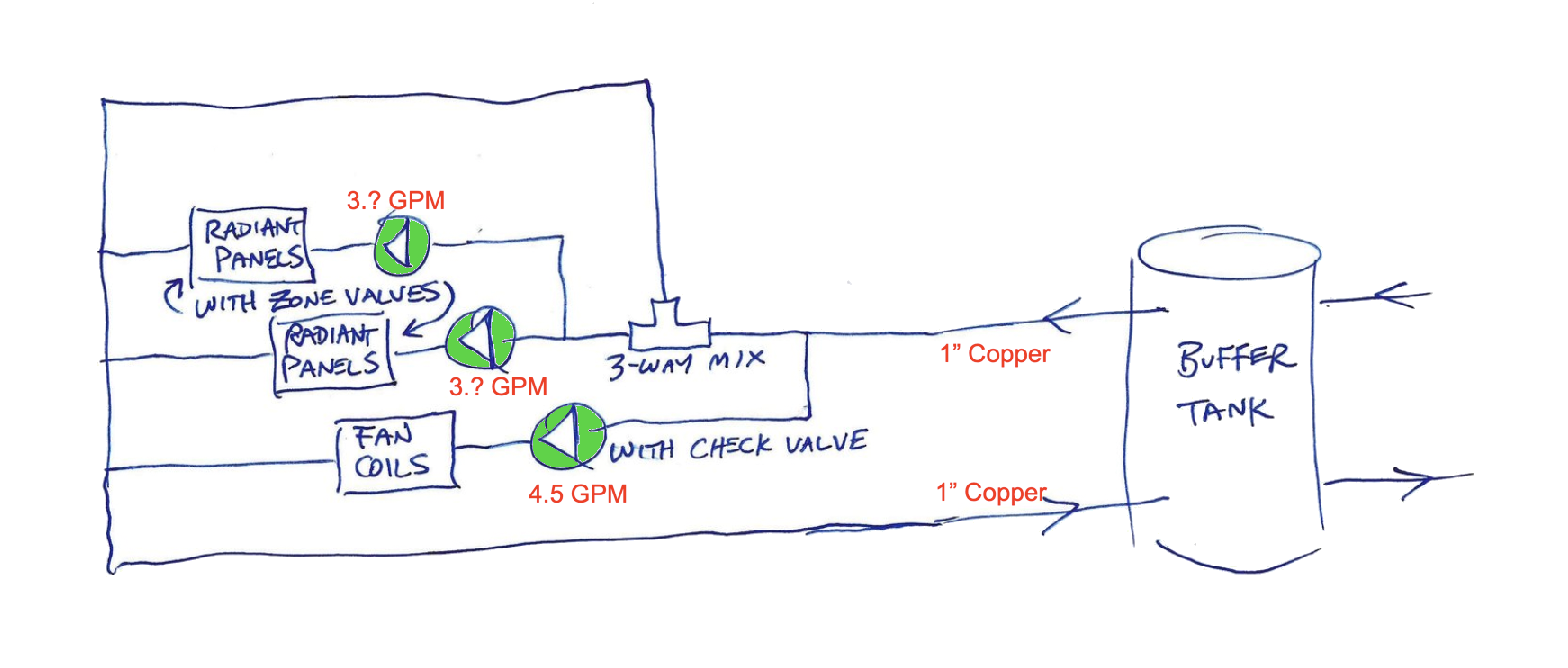

To put in picture form, you can get 9 GPM from all three pumps if you have the correct piping sizes.

With only one pump operating at 9 GPM you can use 1" copper and get all the flow you need. That is because 9 GPM can move freely and relatively noise free thru 1" copper. But 9 GPM is about the maximum you can fit in a 1" Copper pipe. more than that and the system will get noisy. (8 GPM is the recommended max flow for 1" Copper)

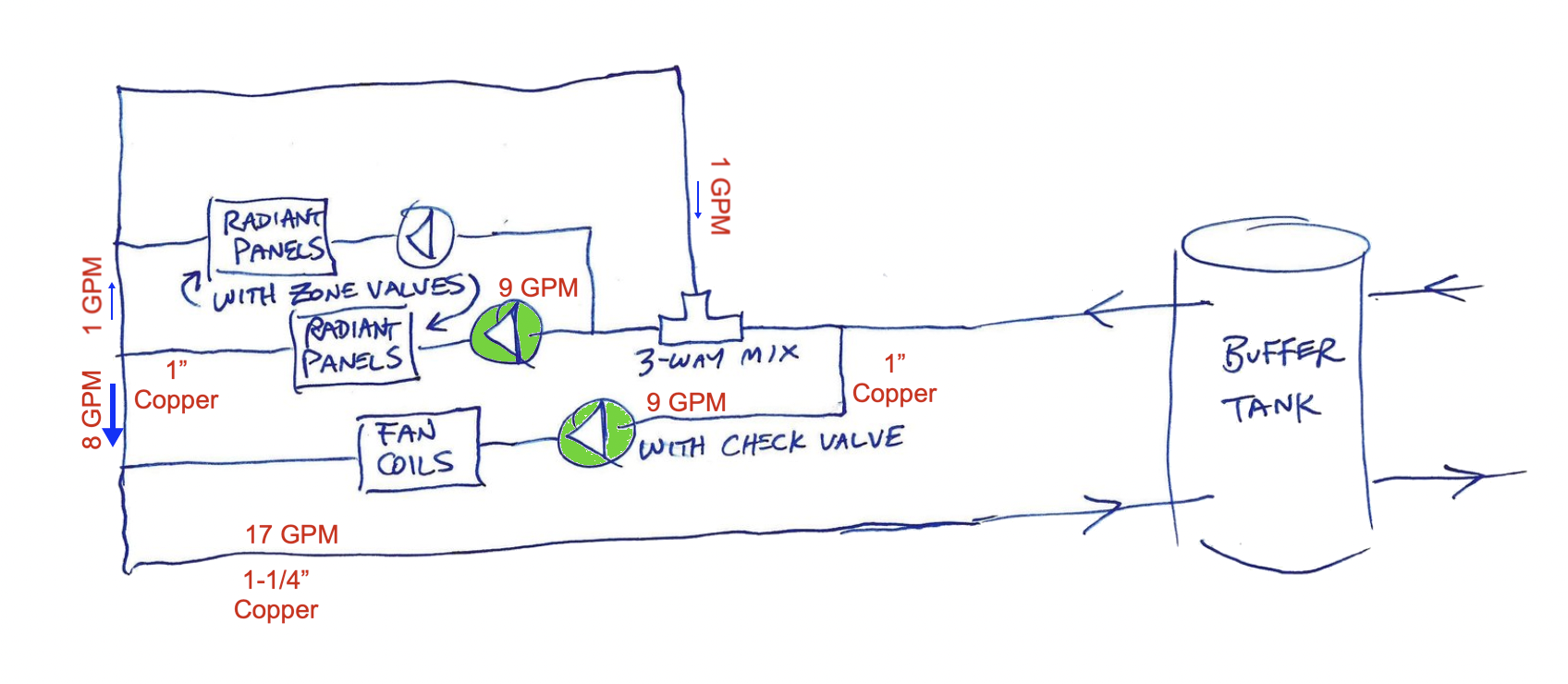

The problem happens when you try to move 18 GPM thru 1" copper. There is not enough room. So your original design needs to have 1-1/4" copper in order to accommodate the flow from 2 pumps. Even if some of the return water from the radiant loop goes back to the mixing valve there is still the chance that the return to the boiler will

overwhelm the 1" return to the boiler or buffer tank.

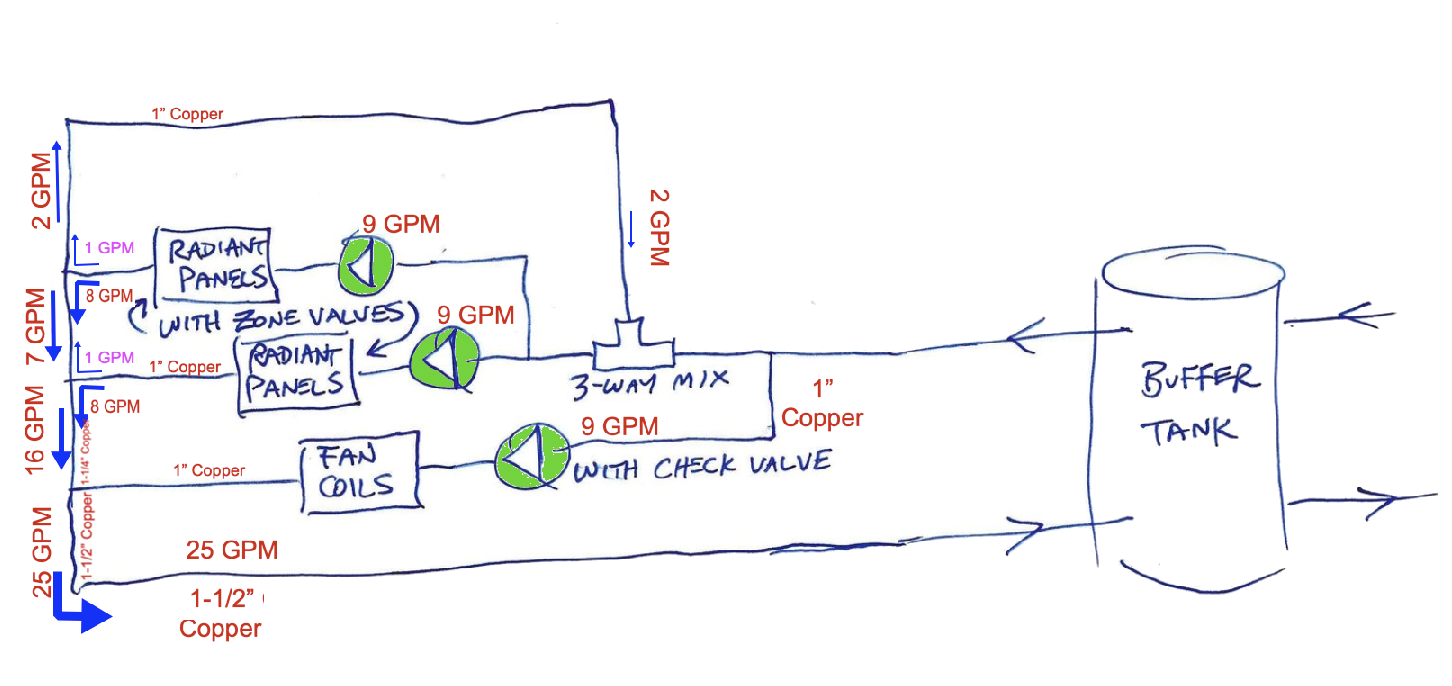

When you add a third pump, now you need to increase to 1-1/2" copper to accommodate 27 GPM in the shared piping.

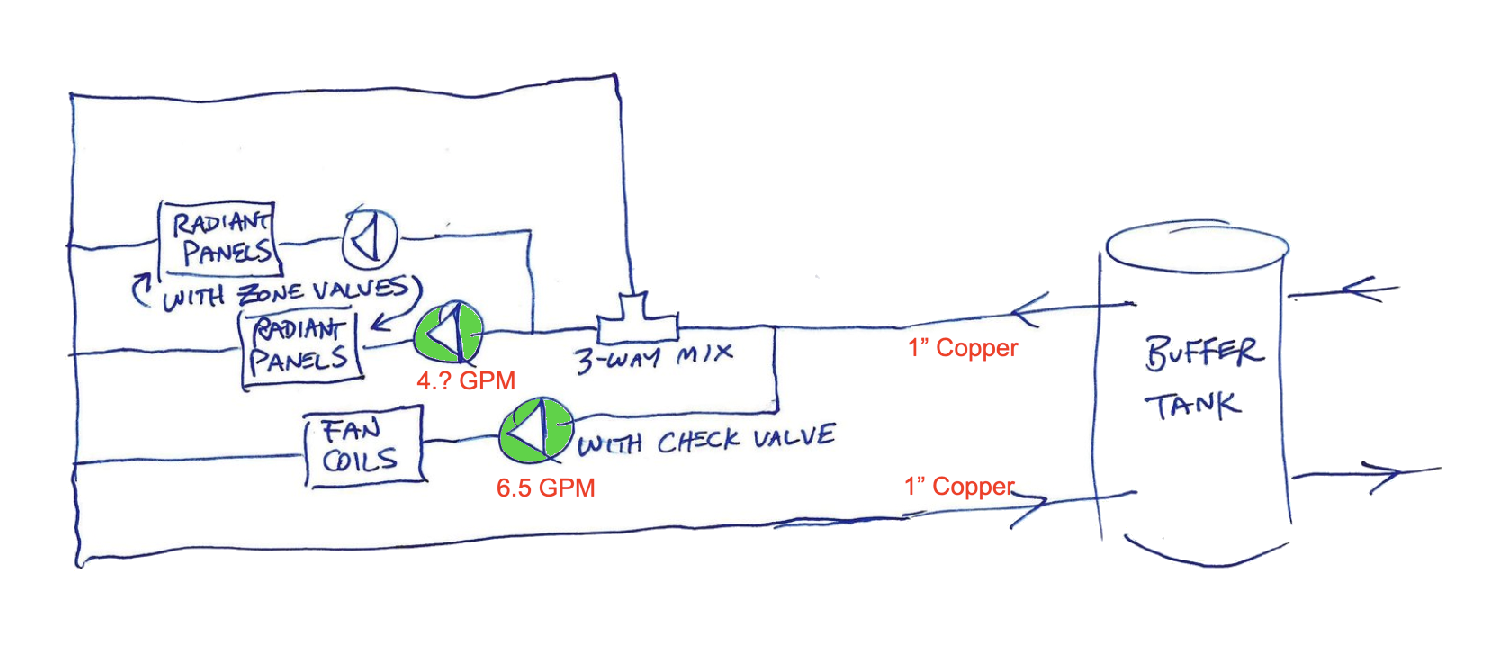

With 1" Copper shared piping, when more than one circulator pump is operating the pumps need to operate against a greater pressure drop or Pump Head as more water needs to move thru. the same space. So the pump curve will move from 9 GPM each, down to something lower, like 6.5 GPM as the other pump fights more friction from the mixing valve, radiant floor tubing, manifolds and the like. So pumps of equal capacity will move different GPM based on the friction loss of the zone it is operating.

With all three pumps operating on smaller common piping, you will get even lower GPM from each pump. Designing piping systems you need to take into account the sahred piping and the flow rate under the worst case. All pumps operating at full capacity at the same time. If you don't take that into consideration, then you will end up with performance issues, short cycling, noise and many other. problems.

These diagrams should make things clear as mud for you

Re: Warm Start Boiler Summer Leak

I would guess not. Since this is a WTGO boiler it was equipped with a tankless coil, that would mean to offer DHW priority the circulator would stop pumping cold radiator water when the aquastat reached the low limit circulator cut out temperature. The boiler would always maintain 140° or more if the low limit was set at 160° with a 20° diff. No need for boiler protection in this case.

Now that the cold start boiler is an option, they may need to think about boiler protection with a bypass of some sort, or some reverse strap on aquastat that keeps the circulator from operating when the supply temperature is below say 150°. the circulator would cycle several times as a result, but it did that when it was operating for DHW anyway. So no big deal.

Re: EK System 2000 hot water suddenly too hot?

Probably a short in the thermostat wire. Also, hot water needs to be set per @Robertw ’s instruction.

Roger

Roger

Re: tiny droplet leak from the oil tank firomatic shut off valve.

I don't see any oil stain on the concrete floor just below the valve or the oil filter. This looks pretty normal to me. that coating of shiny fuel glaze on the pipes, fittings, and oil filter seem to be normal from my experience. If there were dripping fuel, that would be a different story. I would expect to see a darker stain on the concrete floor all around that tank leg like this:

But if you have a constant drip… drip… drip and the only place on the concrete that is showing the oil stain is that small spot, then the black rim must be a sump pump pit that is cemented into the basement floor. If all the dripping oil is ending up in the pit and pumped away to the pump's discharge termination, wherever that is, then you have a real problem.

If that is the case, you need to solve this sooner than later.

Good practice for replacing oil tanks

- Do not put any oil from the old tank into the new tank.

- If you are going to use a contractor that is including putting your old iol back in the new tank, then get another contractor.

- With 1/2 tank of oil, you will need three 55 gallon drums to remove all the old oil in order to remove the old tank

- If you can install the replacement tank in a different location, then you can avoid pumping old oil from the old tank. leave the old tank in place with that drip pan for collecting the dripping oil while you burn off the oil.

- With all the old oil removed from the tank and the new tank in place (or the new tank in a different place) you can have new fuel delivered from a delivery truck while the tank installer is on location. It is always good practice to have two people for the first delivery in case there is a problem with the install, the person on the inside can alert the delivery driver to stop the delivery so the problem can be fixed before it becomes a bigger problem.

- Have the 55 gallon drums remain on site with a temporary fuel supply from the drums to the oil burner until you run out of old oil.

- If that is not an option and you can not install the new tank so the old tank can be the temporary storage, then donate your oil to a local church or pay to have it disposed of. While your fuel oil is on your property it is either a usable fuel or a hazardous waste, you get to decide.

- DO NO PUT ANY FUEL FROM THE OLD FUEL TANK INTO YOUR NEW TANK, no matter how good of a filter your contractor says he has.

Finally I have told this story before: read the EDIT: Case History here

Did you happen to read that I don't recommend old oil be placed into a new tank?

Re: HTP Boiler humidity dislike + Error Code 11

btw those "additions" are the aluminum from the fins in the stainless hx.

Re: HTP Boiler humidity dislike + Error Code 11

If you stuck your finger into where the condensate trap connects and found goo then you need a cleaning on the fire side of the heat exchanger, not the water side. Clean the fire side of the heat exchanger first, nothing here indicates an issue in the water side