Best Of

Re: On the hunt for the Blueray oil burner

Well he stopped ticking in 1995 after all those BlueRay recalls closed the company. I wonder if there is a connection?

Re: Water hammer - novice question

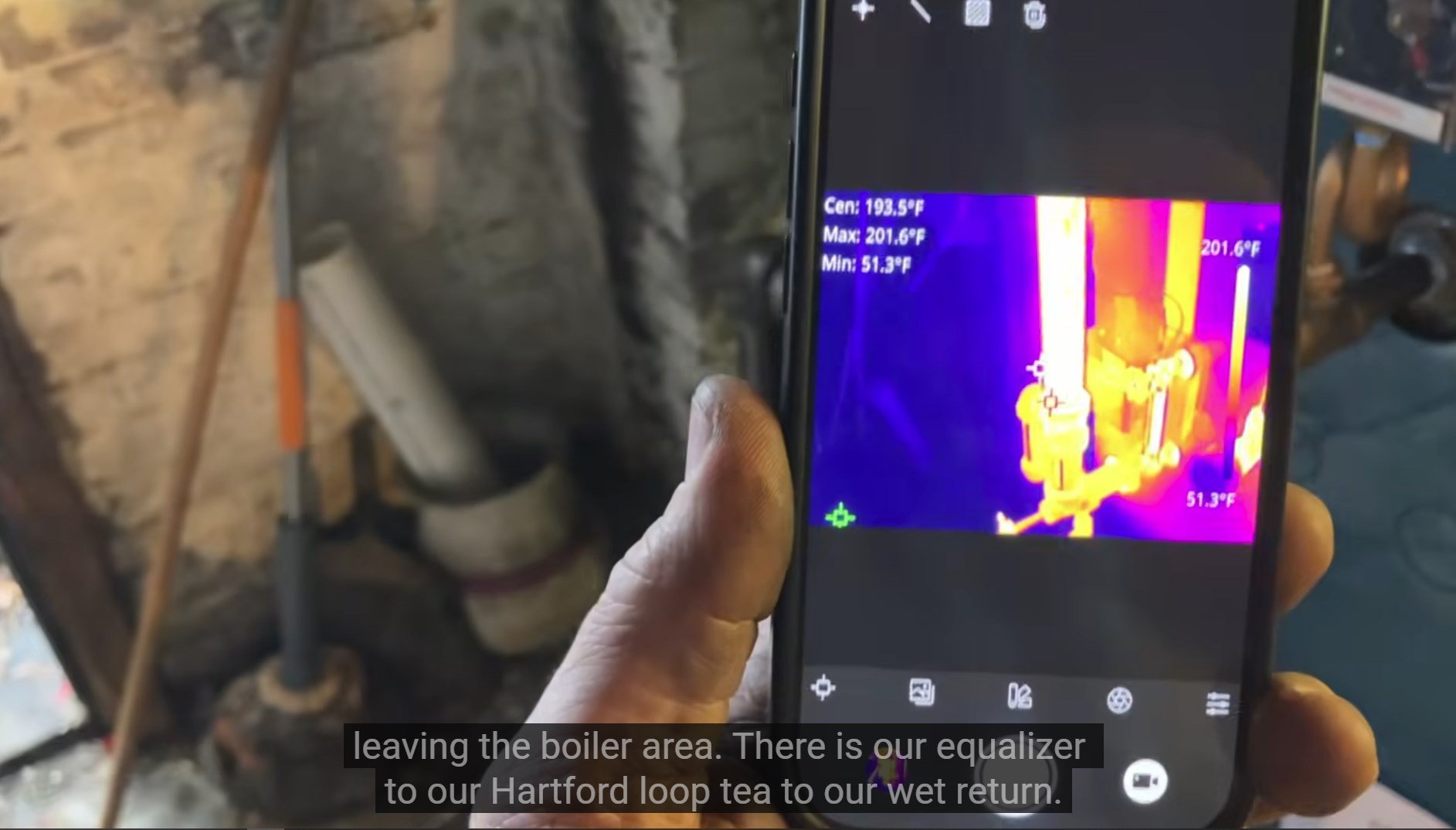

Does a thermal imaging camera lie or is this equalizer darn near steam hot down to the Hartford Loop? courtesy Mikey Pipes

Re: What was the craziest things you’ve found above ceilings?

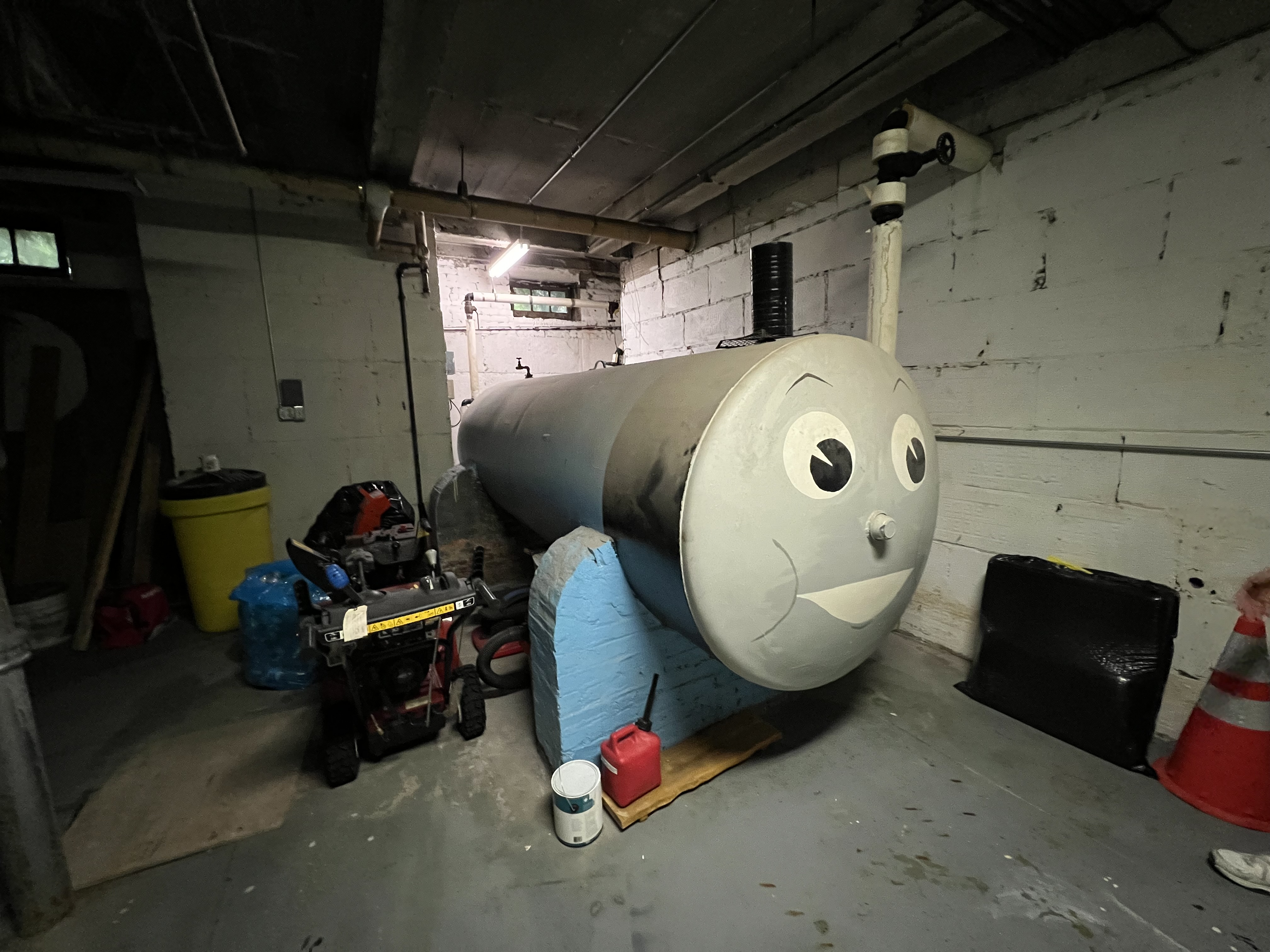

Well of course, 😂

Unfortunately "Thomas the Abandoned in Place Vintage Domestic Booster Expansion Tank Engine" is no longer there. The building chopped him up a couple years ago to make room for some new equipment

Re: some people will do anything to keep from fixing the problem

There you go again! Criticizing my work. Gad!

Re: RADIANT FLOOR HEAT QUESTIONS

No matter how low I turn the volume on my laptop, I still think that DAN IS SHOUTING AT ME!

Re: What was the craziest things you’ve found above ceilings?

It's amazing the things that people can manage to flush down a gym toilet that then gets clogged in the sewage pumps. Of course there's the usual wipes, tampon sleeves, needles and such, but we've also pulled entire pairs of shorts and padlocks out of the the pumps.

Old NYC buildings have the best random finds and it's not always vintage junk, although the vintage junk is always fun too.

Re: What was the craziest things you’ve found above ceilings?

Ok. Finding someone sleeping in the ceiling. I was running a job in a hospital, had a lot of work in a hung ceiling in a lab area. Come up the ladder, and there's this guy sound asleep right next to the opening in the ceiling, didn't even have brains enough to crawl in. So I went across the hall and asked one of the nurses for some ice. She gave me a few cubes. Went back climbed up the ladder, held the ice in my hand and dripped ice water right between his eyes. He woke up screaming, dreaming he was having a lobotomy. I damn near fell off the ladder laughing.

Re: What was the craziest things you’ve found above ceilings?

"1978 hustler" sounds like an amc model.