Best Of

Re: Cyclegard green light blinking and clicking rapidly - boiler wont fire

Agree with @ethicalpaul, but I would rule out the free stuff first. The time delay in the circuitry would eliminate the rapid clicking of the Cyclegard LWCO, But with anything electronic, you never know what that machine is thinking.

Open the Door Hal. Open the Door Hal.

You're traveling through another dimension where you believe you are sitting in your basement watching your Cyclegard, but really you are caught in a time and space wilderness with unknown electronic devices far beyond the ordinary items you are familiar with

Your are in the…

Re: Expansion tank waterlogged

90 psi and a failed expansion tank could lead to a pressure relief valve valve going off or dripping.

Where do you read 90 psi? Plumbing code states 80 psi maximum

hot_rod

hot_rod

Re: Axeman-Anderson oil fired boiler vs. Burnham oil fired

The oil flow has nothing to do with the flame sensing circuit. So good oil flow from the pump will not be part of diagnosing the flame failure problem as long as there is a steady flame in the combustion chamber.

Think of the flame sensing circuit as a basic circuit that uses the Cadmium Sulfide Cell (Cad Cell) as the on-off switch. When the light from the flame is exposed to the cadmium sulfide, the resistance to electricity changes and allows the electric current to flow. You can measure this change in resistance with an ohm meter. This change in electrical resistance opens the circuit to the safety switch. With the safety switch activation circuit turned off, the control will not fail on manual reset. The burner continues to operate.

If the cadmium sulfide does not get enough light, then the safety circuit will stay turned on and the safety switch will trip open and stop the burner from operating. So with information you can clearly understand that the more light the Cad Cell Eye can “see” The less chance there is of a flame failure lockout.

This Cad Cell is not an on off switch but changes in increments based on the amount of light the Eye can “see”. On the older 3 wire protecto-relays the point at which the control must get the signal is 1700 ohms or less. On those analogue controls the safetiming is determined by the amount of time a small resistance heater takes to bend a piece of bi-metal to cause a set of contacts to open. If there is full power for 45 seconds the contacts will trip open and must be manually reset. If however the electric current only gets sent for a split second several times a minute the safety heater will not get as hot as fast. If the call for heat is over before the safety heater gets hot enough to trip the contacts open, then that heater can cool off and start over with the next call for heat. If the call for heat is longer, then all those split seconds electrical connections add up to heat up the safety heater, then it could trip after operating for 30 minutes or so. I have experienced just that scenario on more than one occasion when the burner operates properly while you are there, but fails as some other time late at night when no one is looking at it. I was taught to look at the ohm reading when I came across that problem.

Here is how I was taught to measure OHMs for the flame signal on a Cad Cell Eye.

Check Oil Primary Relay

NOTE: You will need an insulated jumper wire with both ends stripped.

- Disconnect cad cell leads from F-F or F1-F2 terminals.

- Reset the safety switch and set the thermostat to call for heat.

- Burner should start. Within the safety switch timing, use insulated wire to jumper F-F or F1-F2 terminals.

- Burner should continue to run.

- With the Cad Cell wires not connected to the control. Measure the Ohm’s resistance between the two yellow wires.

- The measurement should be below 1700 Ohms resistance for the flame signal to be detected by the control

- If the measurement is above 1700 Ohms, clean the cad cell with a soft cloth and perform the test again.

- If the measurement is above 1700 Ohms then try to reposition the cad cell to get more light exposure from the flame

- If the measurement is above 1700 replace the cad cell eye

- If the measurement is above 1700 replace the complete cad cell wiring harness

- If the measurement is below 1200, and the control is still shutting down by the safety switch, then the control is defective.

- After the safety switch timing, remove the jumper. Burner should shut down in the safety switch timing. If the operation is not as described, replace the oil primary control.

On the left is how to connect the meter.

On the righe is how to adjust the eye for a better flame signal

Re: Have you cleaned the piping system for a converted gravity hot water space heating system?

When you pipe P/S, does that Hydrolevel hold off the boiler or system pump? Or both?

hot_rod

hot_rod

Re: History of Oil Tank Installation Permitting

Many of the smaller towns in western mass didn't keep underground tank records until the 70s or 80s. The bigger cities are better, Springfield for example has tank records that go back to the 1920s.

What town do you live in and how old is your house? It was not at all uncommon for underground tanks to get installed at residential houses without any records. Also, some towns have lost their records to floods, fires, and carelessness.

Attached are some photos of how tank records are kept in the City of Springfield. Black means installations, red means removals.

Re: What would cause such rapid destruction of valves?

I would not have a fill valve on a system with glycol. Use a fill tank. Or a separate expansion tank as a fill.

Air vents will spit some air and fluid from time to time, that is not unusual.

The glycol should be checked every few years Ph mainly. A test meter or test strips is all you need.

When the ph drops into the low 7 or below it is time to flush and replace the glycol.

Tough call on whether you really need or want it? Do you drain down the plumbing system in winter?

I would flush that system, run a hydronic cleaner, then refill with a 30- 35% premix glycol.

hot_rod

hot_rod

Re: What is Boiler Draft, this weeks video

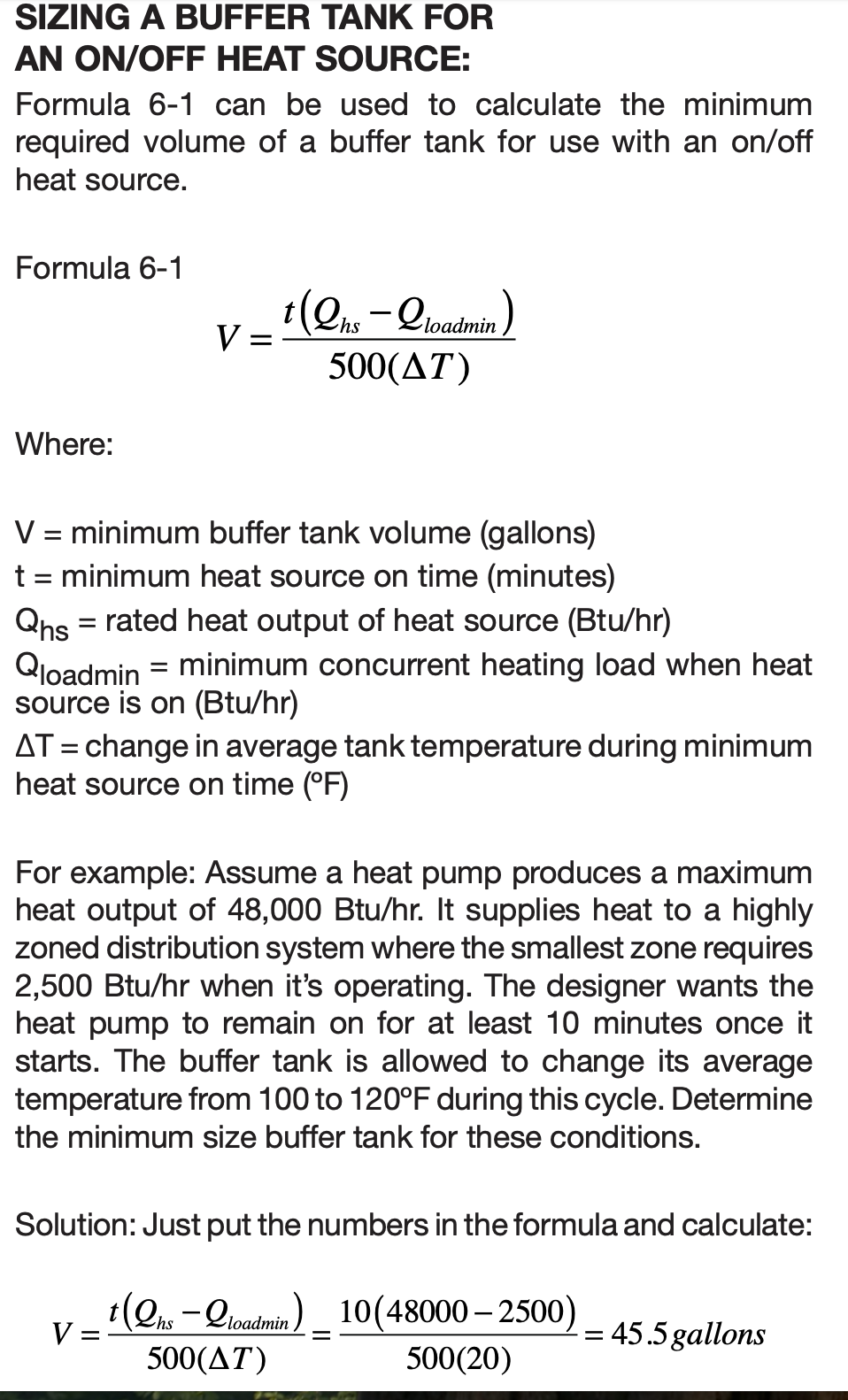

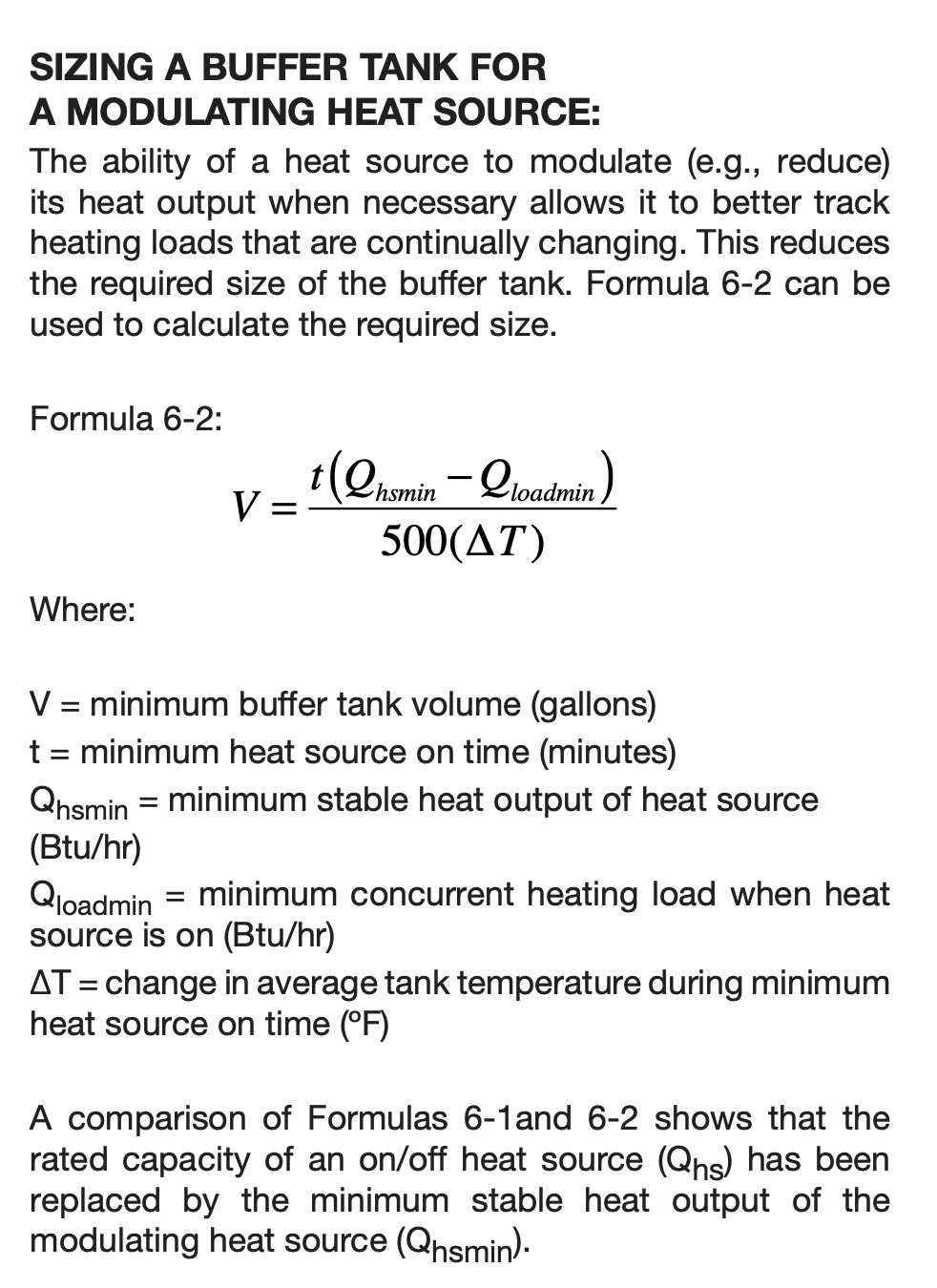

Here are a couple formulas to play with. The fixed output/on-off boiler or energy source vs the modulation.

hot_rod

hot_rod

Re: Have you cleaned the piping system for a converted gravity hot water space heating system?

that would be tough to calculate system volume on!

fill it up with a water meter connected to the fill valve might be the only way to get a close number?

But I don’t know of any cleaners that would dissolve rust and scale to flush it out

you would need some very high gpm flow to get 5 fps flow velocity in a 6” pipe. That is what it takes to get solids moving along

This company purges large systems like that, I met them at a IGSHP show years ago.

Their purge pumps start at 5 hp and go up to hundreds of hp!

hot_rod

hot_rod

Re: What is Boiler Draft, this weeks video

some systems get designed with buffer tanks to maximize efficiency and reduce cycling. Solid fueled boilers, large chillers are examples.

More and more we see heating and cooling equipment that can modulate, which helps reduce the buffer capacity required. Pellet and cordwood boilers now have some modulating capacity, so the buffer tank sizing has gotten smaller

There are always trade-offs. Large pressurized, insulated tanks are $$. Heat loss is a concern, space requirements also.

A buffer is an option for oversized boilers also, is the cost going to off set the poor efficiency, or extend the boilers life those are some of the decisions.

Micro and multi zoned systems with non modulating boilers are often a good match for a buffer tank.

Gravity systems with cast radiators had the buffer built into the distribution system. The boilers mass and large water content also are part of the buffer

The perfect hydronic boiler could modulate from no load to 100% load, think of a variable speed drill motor , now that would be ideal

hot_rod

hot_rod

Re: heating oil tank manufacturer's warranty voided by transfer of oil from the old tank?

Transfer the oil to the temporary tank and connect to the existing oil line to get the burner(s) running.

Install new oil tank with new oil line, filter, OSV, etc. to the burner. Plug the end of the oil line at the burner, and close valves.

Fill the new tank while someone is inside at the tank to observe there are no leaks during delivery.

When the temporary tank runs dry, call the service provider and they'll come to connect to the new tank. Replace the nozzle and strainer. Prime and start. Combustion test. Done.

HVACNUT

HVACNUT