Best Of

Re: Radiant flow not pushing fast enough

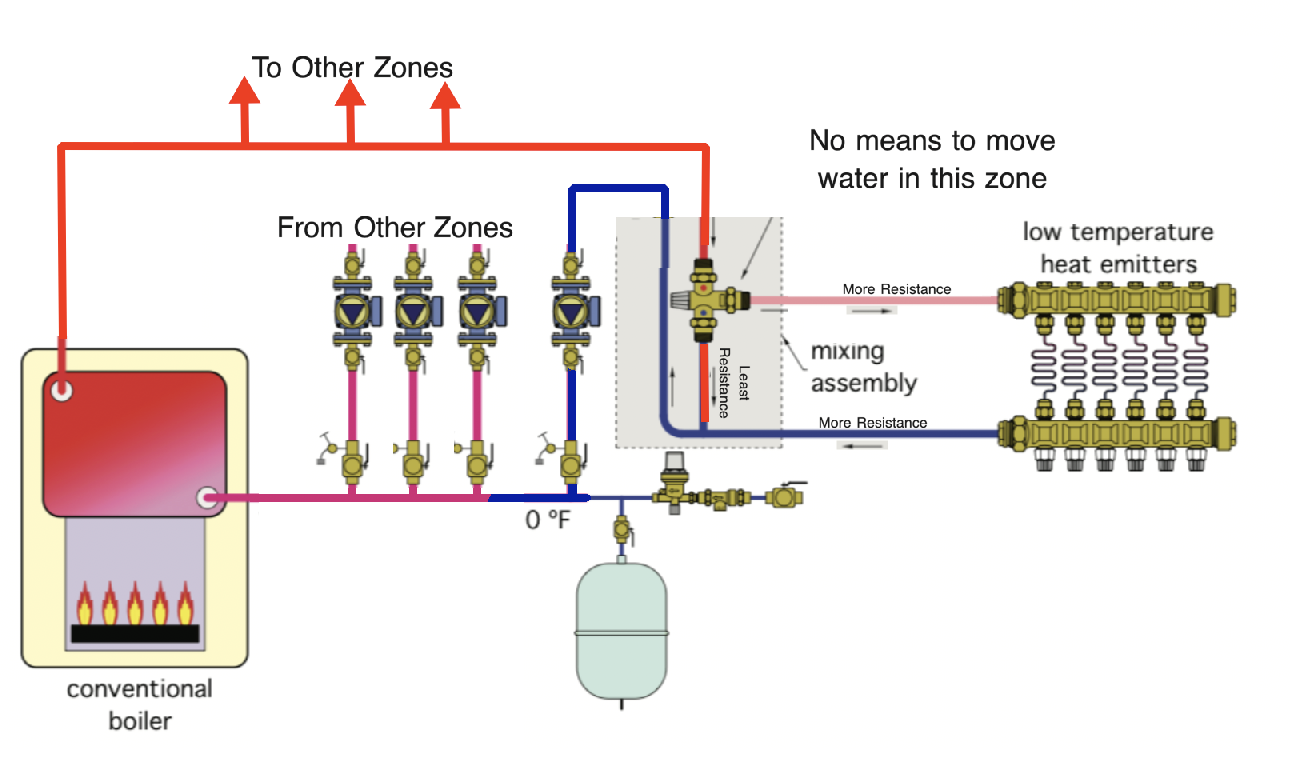

I see that circulator in your photo. This diagram is how your system might me piped:

You can see there is not a lot of pressure drop across the mixing valve when the MAIN pump is operating because is pulling equally on the cold inlet of the mixing valve and the return from the radiant floor loops. There is nothing to move the water into the cold side of the mixing valve, so all you get is what might pass thru the mix valve top the radiant loop and the rest of the flow may even go in the opposite direction on the mixing valve cold inlet port.

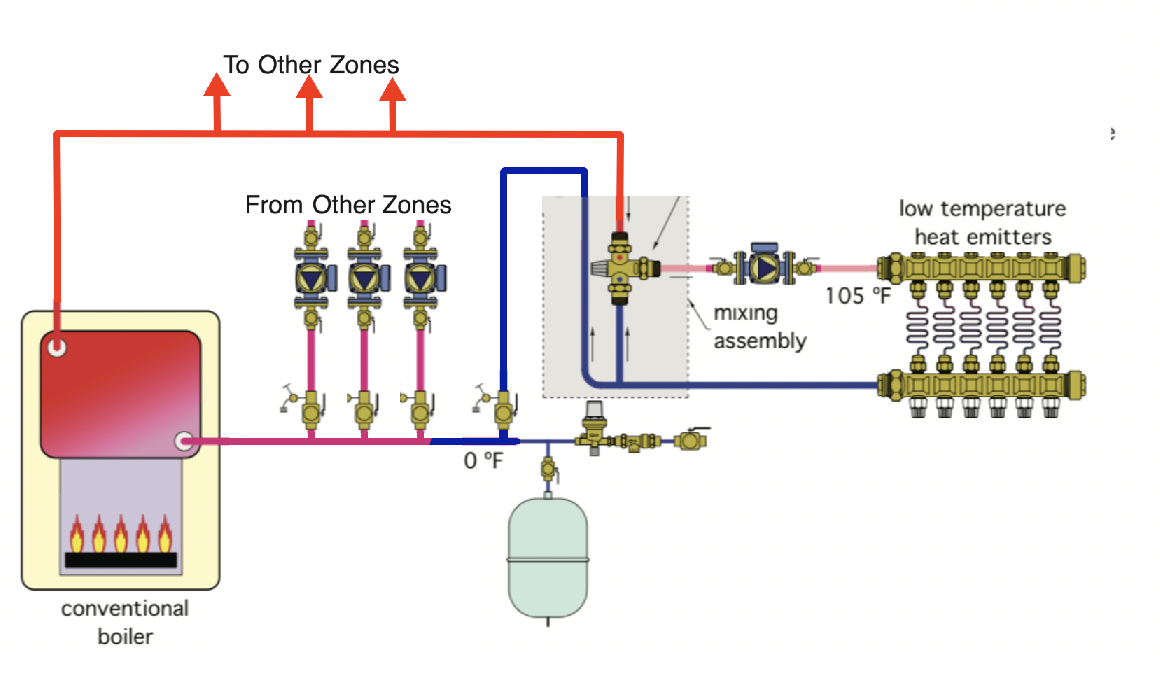

This next illustration indicates the circulator in the proper location.

The pump will pull water from both the hot and the cold ports to get the proper water temperature and move it thru the radiant floor tubes. I have also learned that you do not need the circulator pump where you actually have it located. That is because the mixing valve will pull the water from the boiler as needed to maintain the "MIX" temperature you set it for. If it needs more or less hot water that valve will compensate automatically.

Re: My three worst jobs sites. What are yours?

This post makes me smile. Vacuum pumps are used in rendering plants, so yes, been in lots of those. Edible oil and shortening plants are slippery too. Really had to be careful climbing the stairs.

Sewage treatment plants too. They're not that bad, really.

Poultry processing plants use vacuum pumps for evisceration. Really nice when we'd get one in for repair that had been baking in a hot enclosed semi trailer for a day or 2.

Re: My three worst jobs sites. What are yours?

Went into a crawlspace to fix a floor furnace. After I got in there and was laying in some wet muddy crawlspace floor, someone flushed the toilet and I found out quickly that the sewage piping was broken, got out fast and went home to shower and change clothes. Never went back to that house.

Re: Gas Floor Furnace quit working

Hi @mattmia2 , I'm very careful with referrals. I'm of the "go slowly and do it well, and just once" bent. Too many are of the "go fast and mess up" approach. I don't want my name attached to that. And, although I don't mind crawlspaces, just guessing I'm in the minority. 🤠

Yours, Larry

Re: 1930's Hydronic System help understanding

The Low Water Cut Of Switch should be installed in one of the tapping's in the side of the new boiler and it should be wired as the first electric control to protect the boiler in the event of a water loss as it will immediately cut the power to the boiler if the LWCOS senses no water.

About the steel compression tank; it would be better and more effective keeping this tank for air management as it has a much greater capacity to create and maintain the point of no pressure change. The steel compression tank creates a huge air cushion to provide the Point Of No Pressure Change and quickly removes air bubbles and microbubbles as long as an In Line Air Separator and Airtrol valve is installed correctly.

Once the boiler, steel compression tank and system is filled with water the water feed valve is shut off completely and the boiler started the remaining air in the system will migrate to the steel compression tank dissolve from the water and will remain in the air blanket above the water in the steel compression tank to maintain the Point Of No Pressure change and keep the circulator flooded.

Re: Gas Floor Furnace quit working

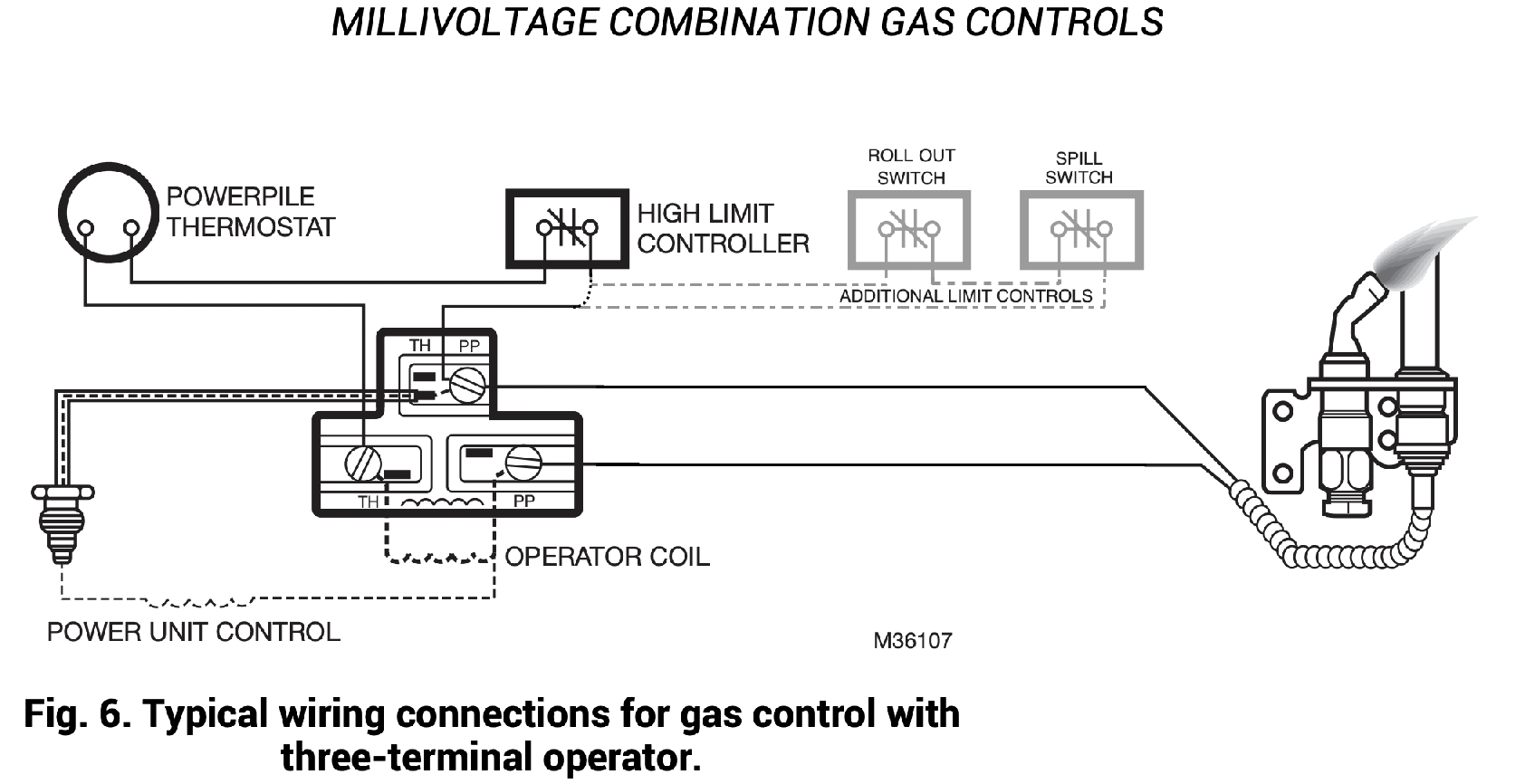

Chances are that your gas valve is powered by 750 millivolts. That power is generated by the pilot flame burning on the pilot power generator. There are several items that connect the electrical parts to make the millivolts open the gas valve.

- First there is the power generator sometimes called a power pile.

- Next there is a Gas Valve that uses that power

- Then there is the thermostat that opens and closes the electric current based on the room temperature

- Then there may be a Limit switch or even more limit switches placed in different locations around the furnace in order to keep the furnace from overheating.

Some of these limit switches may have a manual reset. If you have a manual reset limit, that may be the reason you have no heat. Follow the wires to see if there are any limit switches. See if those switches have a tiny button between the wire connectors and press it. If you feel a slight click when you push it then it was tripped. If you do not feel a slight click then it was not tripped.

Another reason for no heat is the power generator thermopile may be defective.

Here is a wiring diagram that might be close to what you have in your floor furnace.

If you are not comfrotable playing with the safety controls on a gas appliance then i would suggest you call a professional for service. but pushing a reset button on a limit control is usually a DIY first step. If the limit trips again, then you need to find the cause. The safety switches are there to let you know something is wrong and needs further attention. Don't bypass them.

Re: Gas Floor Furnace quit working

Hi @borecrazy , What region or city in CA are you in? I keep trying to be retired, so am not looking for work, but am near Monterey and have experience with floor furnaces.

Yours, Larry

Re: Cast iron boiler replacement with Navien High Efficiency Condensing Boiler NFB 200H

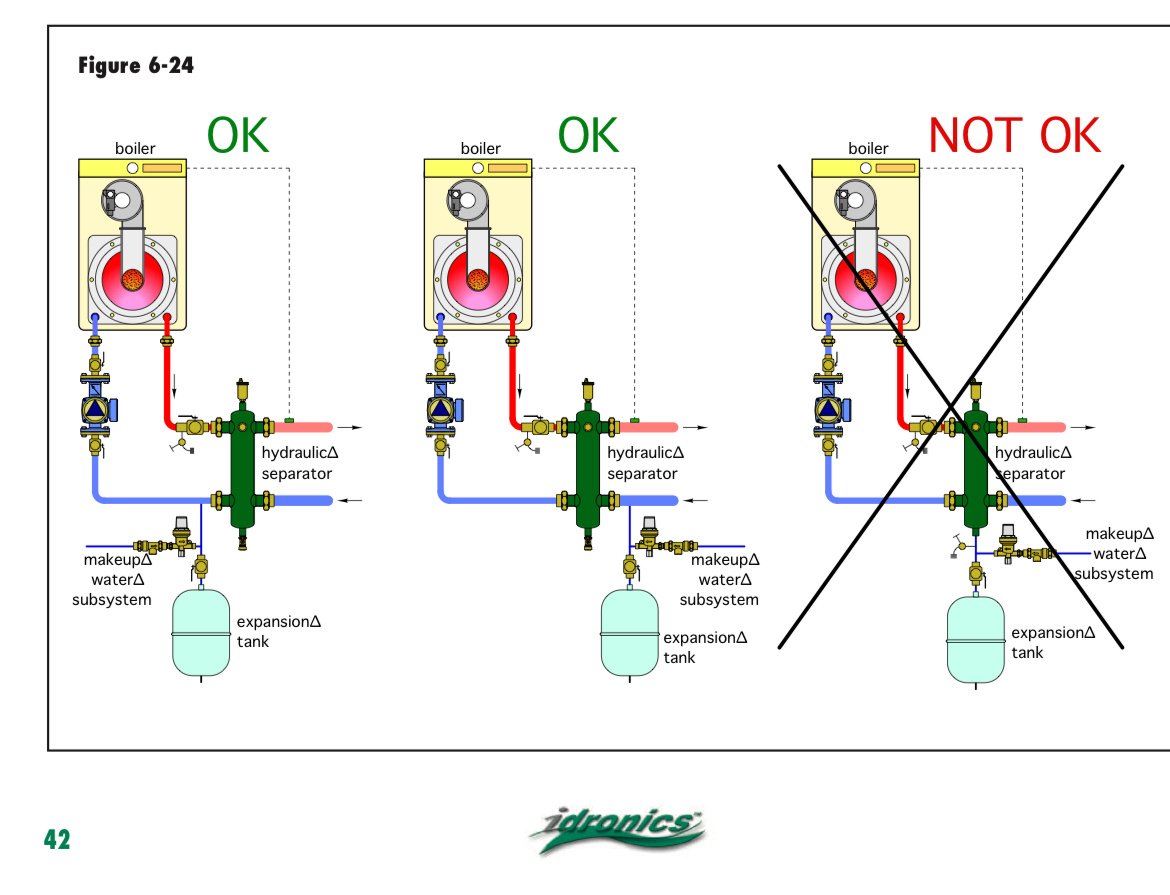

the expansion tank and fill could connect at any of the 4 connections

Most often at one of the bottom, return connections

But not right off the bottom as it collects debris from the dirt separator inside

pump and zone valves on red line, the upper right

hot_rod

hot_rod

Re: my boiler has dissolved...

Start here:

And get a Burnham MegaSteam this time. It will last a whole lot longer and has the best warranty in the business.

Re: Fixing the gurgling at the end of my Steam Mains

yeah….it looks better from there! Too many other pipes and wires run that way and it wouldn’t have run with the right pitch.

thanks for all your help on this one. Ill post pics of the other side in a couple days when it hopefully all comes together again smoothly