Best Of

Re: Thermostatic Radiator Valves with Indoor Temperature Sensors

You need to fix the system problems before you think about TRVs. TRVs are good to help a room that chronically overheats or has a varying load, but you need to get the system basically balanced and fix issues that are causing some emitters to not hear before TRVs will help anything. If the pressure is well controlled and the system is balanced, TRVs closing shouldn't affect how fast or ho much of the remaining emitters heat appreciably.

If you try to solve system problems with TRVs it won't go well.

Re: What happened to Rems Tools(USA)

The RE#MS tee puller is a lot less $$ compared to a T-Drill. This is a T-Drill notch tool, however. Notching a piece of solar absorber tube .

By code it needs to have two dimples on the stub. One gets silver soldered over, the other is for inspection to assure of the depth. This older tool only does one dimple.

i have seen an even simplier tee puller that goes into a cordless drill I think Flynnstone posted it somewhere.

hot_rod

hot_rod

Re: Which is the C (common) terminal on a Honeywell Aquastat L8148E?

B2 is neutral on the line volt side. There's a reason Honeywell puts a cardboard divider between the line and low volt terminals.The L8148 comes in three versions. The L8148A controls line-voltage burner circuits; the L8148E,J control low-voltage burner circuits; the L8148J controls millivoltage burner circuits. All models control

W/Z is Common on the low volt side.

You will sometimes see diagrams using W for switching through the thermostats or completing the circuit on zone valves, but not on thermostats that require 24v power.

line-voltage circulator circuits. L8148A,E,J have provisions for adding low-limit controllers; L8148E,J can power valves in multizone systems.

And this is where the confusion might arise. B2 is common on the line voltage models. However B2 on the low voltage model may not necessarily be common on the E and is not part of the low voltage circuit in the J model. It is isolated for millivoltage use of B1 and B2 thru the limit.

In order to keep it simple for the layman (original poster) I believe it is irresponsible for professionals to have this debate on his discussion. If we can't agree with a consensus, how is the non professional supposed to be helped by HeatingHelp.com?

If I were to be incorrect, I would admit it so as not to have the person asking for help, do something that will damage the control or thermostat they are trying to connect to the heating boiler.

Just an opinion.

Oh, By the way, I looked up an old record in my business files, it seams that I did exactly that wiring diagram for one of my mechanics in order to install a Nest thermostat. At the time I was a NEST PRO and getting referrals from NEST to professionally install their products. This added a few years to the warranty and gave me new customer leads for servicing their heating equipment.

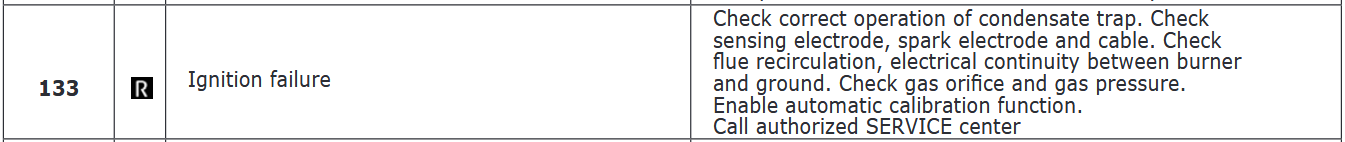

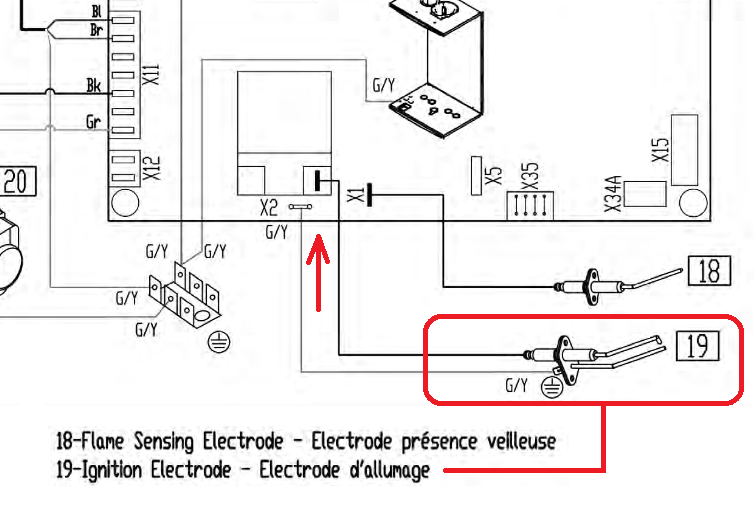

Re: Utica Combi Boiler (MAC-150)-Error 133- Causing big bang noise after few trial of combustion

Was everything on the list for that error verified ? If the spark is poor OR not where it needs to be it won't work correctly.

https://uticaboilers.com/wp-content/uploads/2022/02/MAC-Boiler-Manual-REV-A-WEB.pdf

Re: Utica Combi Boiler (MAC-150)-Error 133- Causing big bang noise after few trial of combustion

hello all . Thank you for all suggestions. It turned out that Igniter was not working properly. Replaced Igniter and Flame Sensor solve the problem.

Re: What happened to Rems Tools(USA)

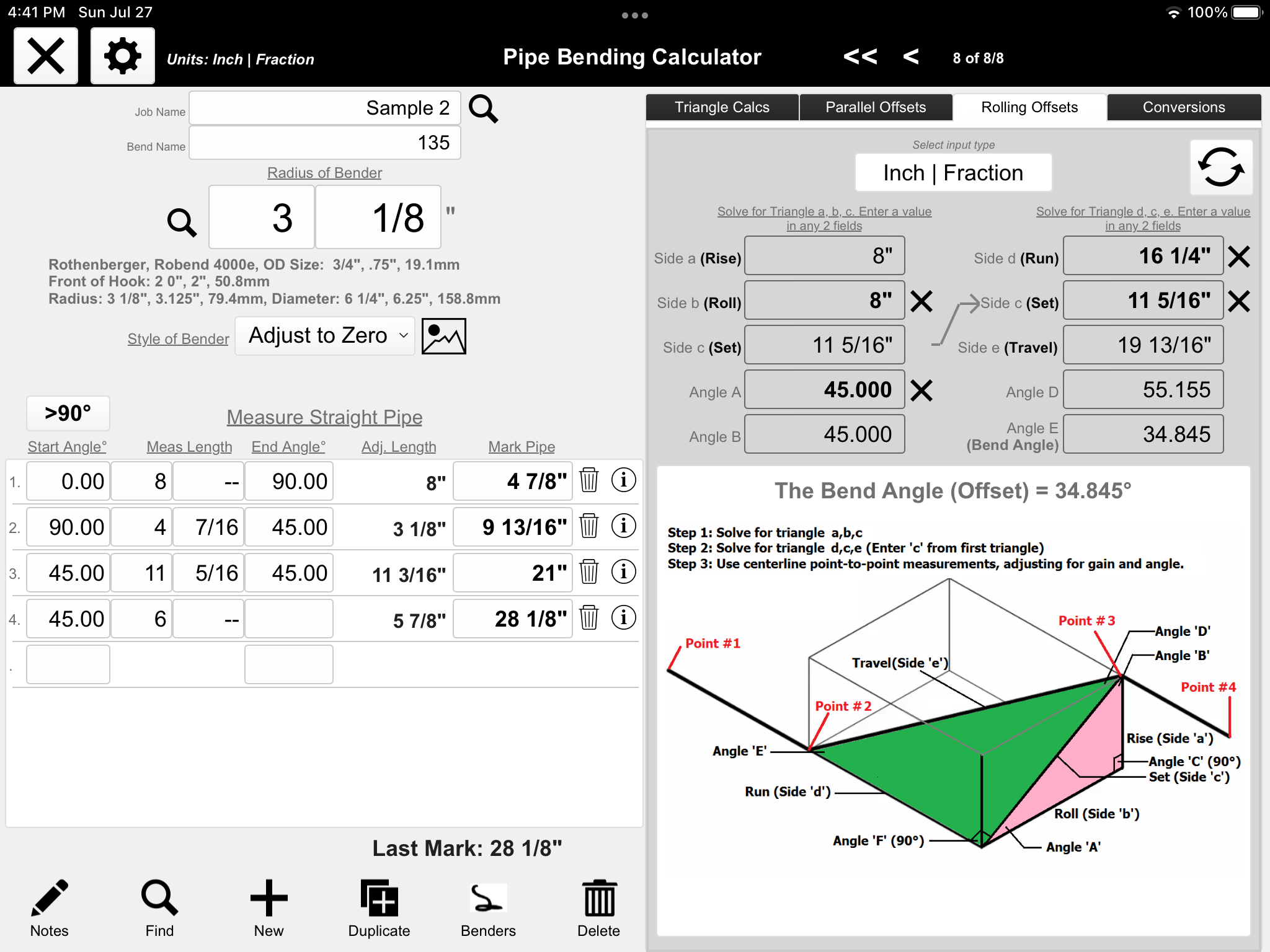

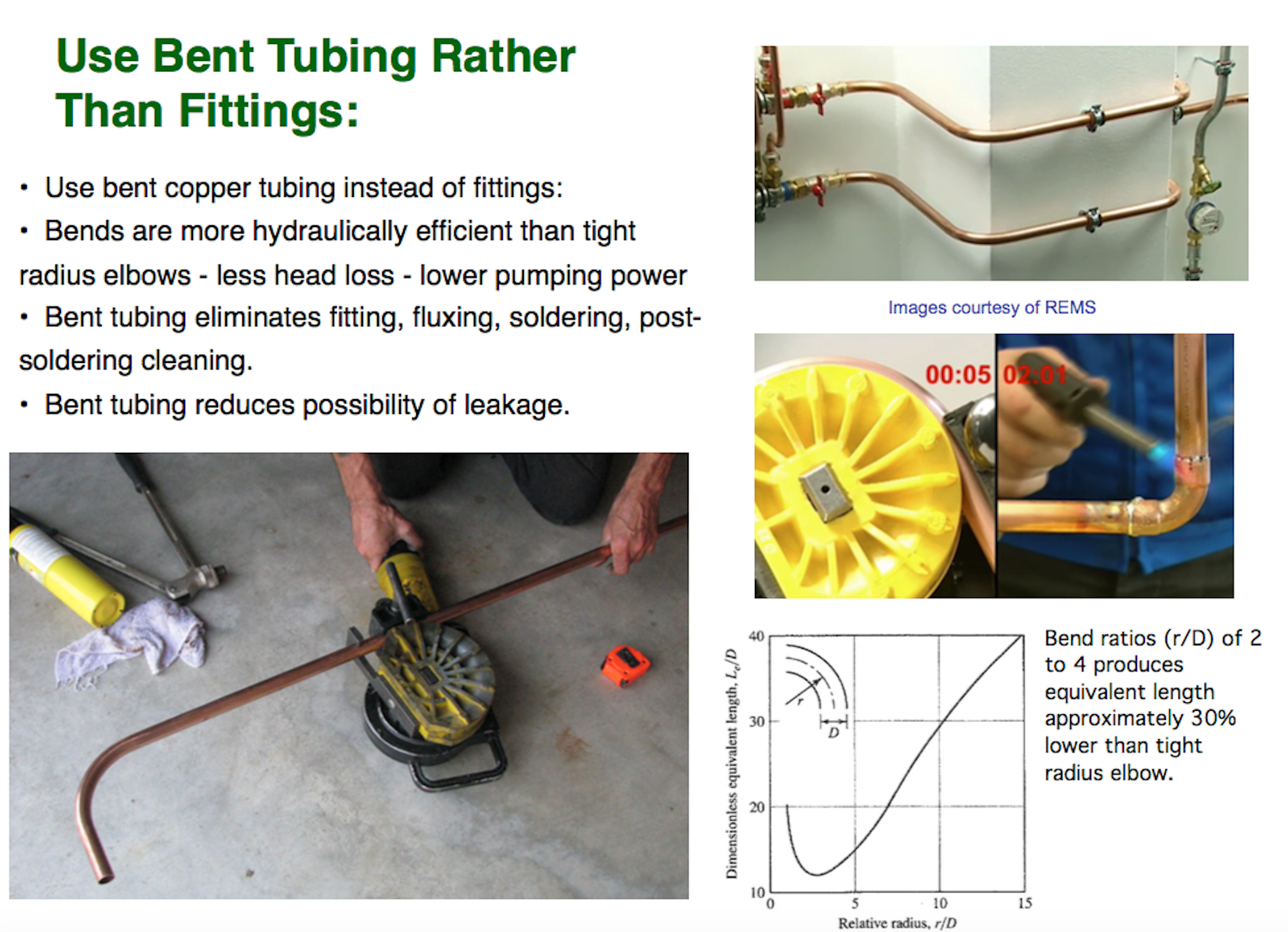

I use the Rothenberger Robend 4000. My buddy, who used to be on here, made a really cool calculator to easily do the math.

He also showed me how to buy it overseas for about 1/2 the price as you can from Rothenberger USA. The only downside was it took about 3 weeks to come in.

Re: What happened to Rems Tools(USA)

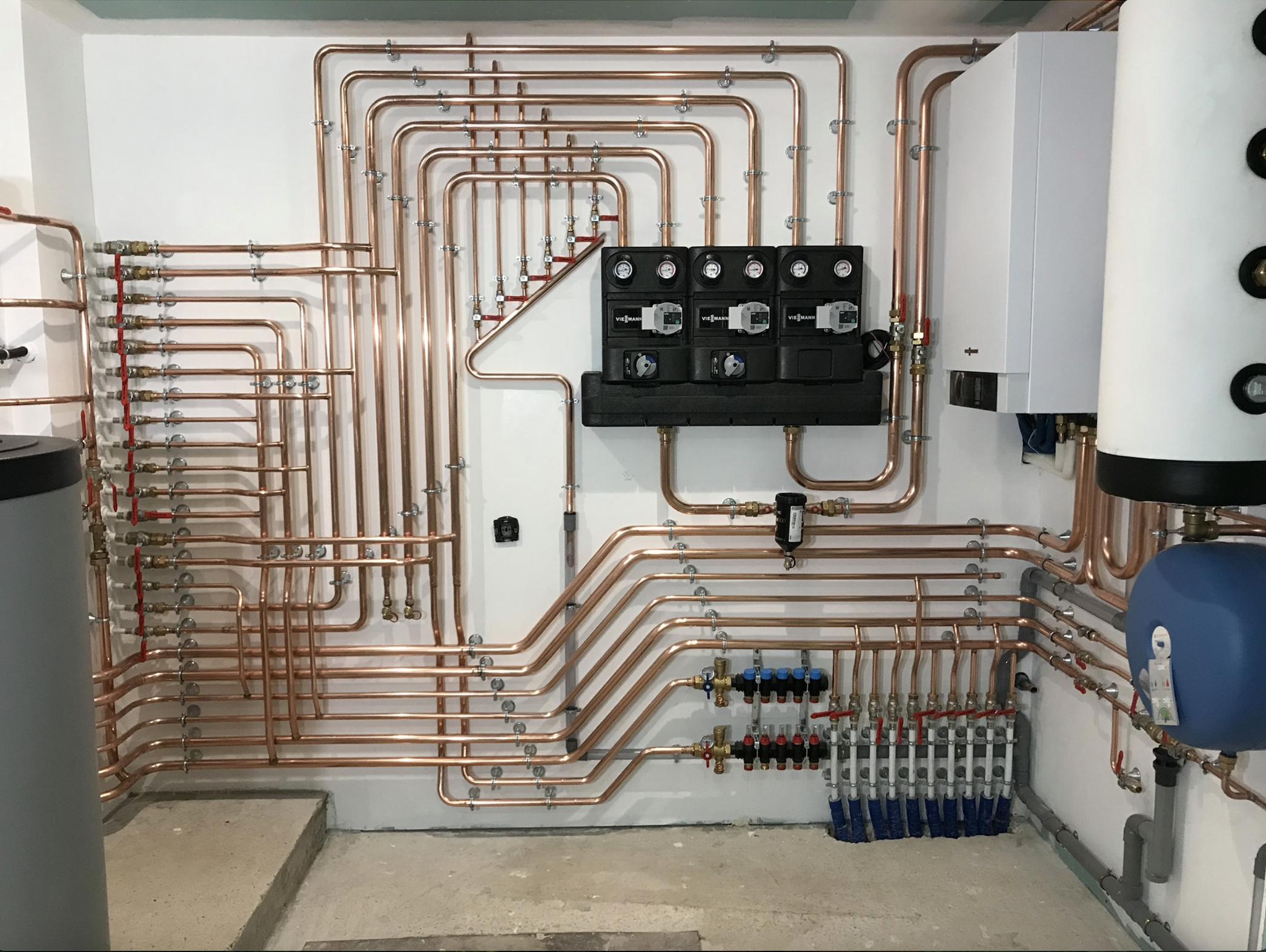

Ever watch a good electrician bent EMT condiut. Once you get the math down it goes pretty quickly. There are some bending software programs also.

I doubt it is as fast as press fittings, but faster than sweat copper.

Yes the outer radius thins and the inner "bunches up", I suppose:)

I know those return bends on the end on HW and refrigeration coils are very thin copper. They run some pretty high pressures.

Bending is addressed in the CDA manuals and I believe is accepted in all the plumbing and mechanical codes.

I have bent some type M, but it tends to pucker up on the inner radius, L works best with plenty of lube.

I have found that old copper tends to split on the bend, for some reason. Like it hardens on the shelf??

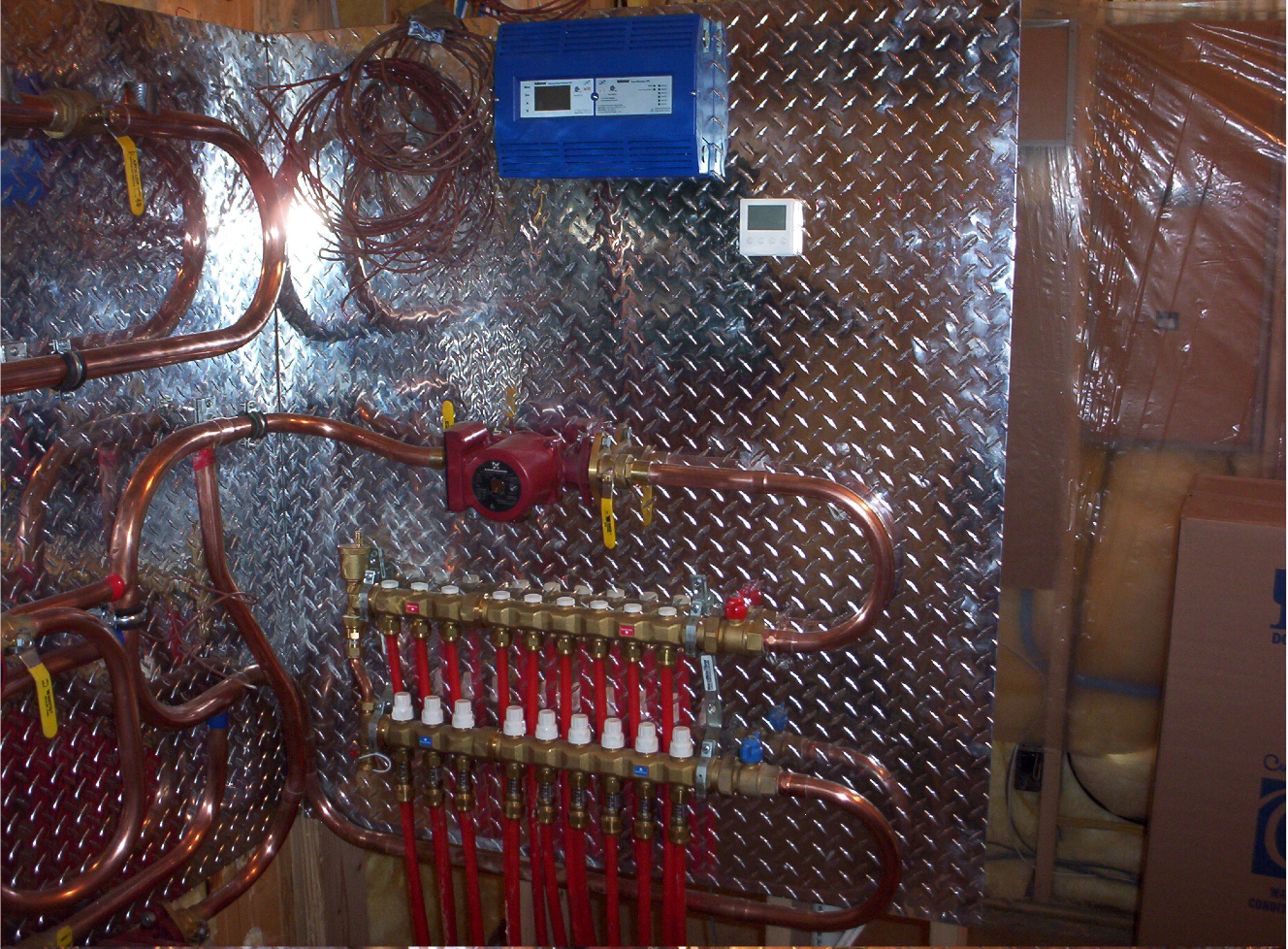

There is a rep/ wholesaler in Illinois that made hundred of copper tube radiant ceiling grids. They had a home made copper bending tool. They kept the layout drawings of all the jobs, dating back to the 1950's, till recently so they could furnish repair loops!

hot_rod

hot_rod

Re: What happened to Rems Tools(USA)

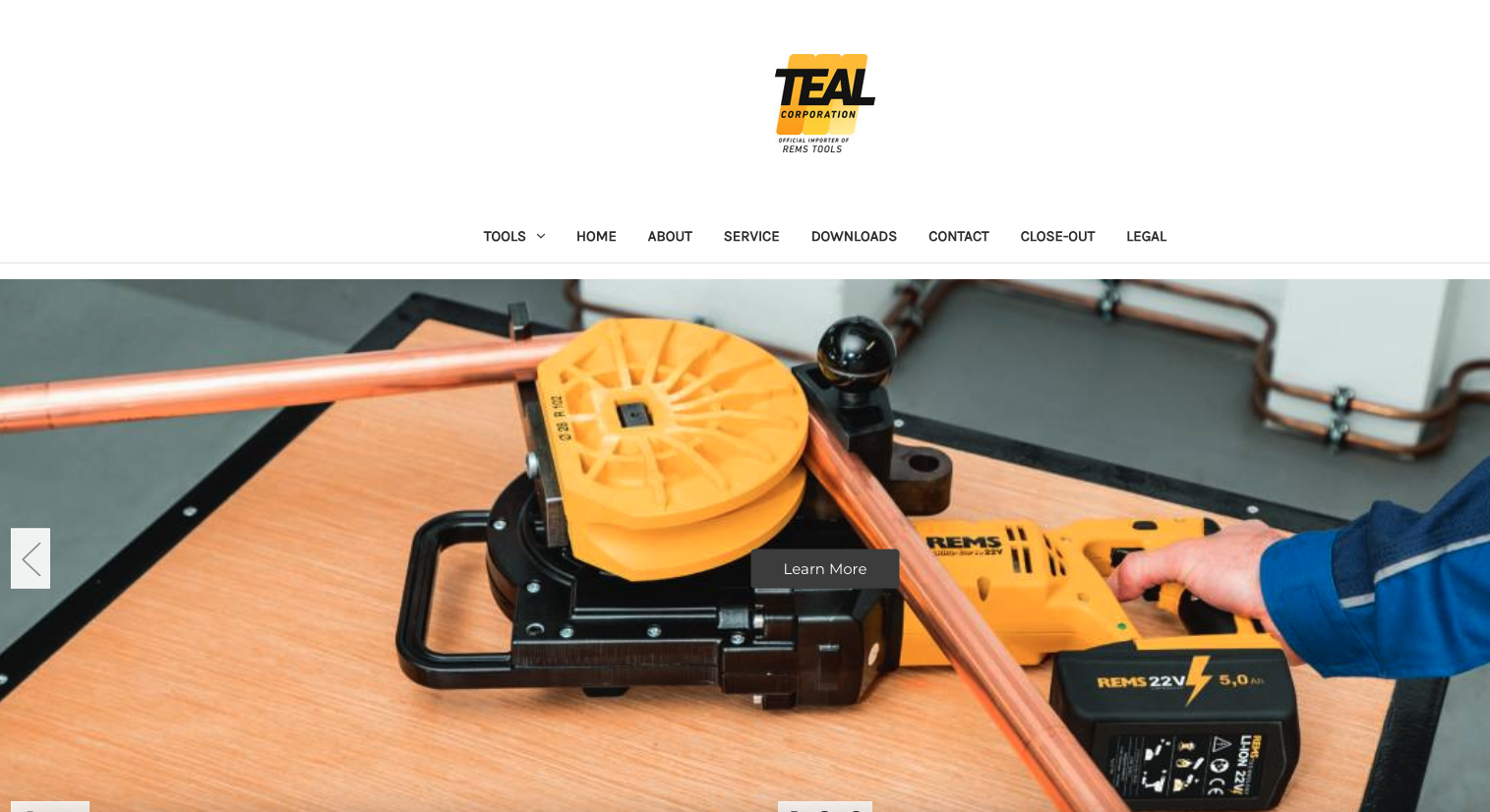

Teal Industries in Minnesota is the importer and repair point for REMS. I've sent my tools there for repairs. Are they still open? REMSusa.com

There is a handful of guys that post on IG that do a lot of bending, Mike Flynn flynnstone1 and jeffdemhvac have done demos at some trade shows, AHR and others.

I used to do a lot of bending on my jobs, mostly hobby stuff now. You can also bend steel pipe and PVC pipe with it, cold!

I think Rothenberger has a bender also.

hot_rod

hot_rod

Compression fitting going from lead to anything modern (e.g. steel/brass)

I'm going to have to replace both my sillcocks which are over 60 years old and are leaking from the stems when I open them. I could probbaly try to scrape the paint off the compression nuts and tighten them, but this is my opportunity to replace them with frost free ones.

One of them is connected to copper pipe but the other one is connected to a lead pipe (black appearance, non-magnetic, when I scrape it it reveals a gray surface below)

The copper one I will replace with a propress ball valve and a frost free sillcock which I will attach with propress compression fittings.

What can I do with the lead one? Are there compression fittings that let me go from lead to copper/brass etc? The lead pipe has a 0.63" OD.

Thank you!

Re: Trane Air Handler Fan Constantly Running

I think those are just double terminals for the coil so that it can be used as a junction point too.

That one terminal looks burned, probably from the failing contacts. I'd replace the terminal on the wire that connects to that terminal too.