Best Of

Re: Need help with new install of radiant with Buderus cast iron boiler

my guess would be 3- 300’ loops

4-300’loops, so tube is 12” oc approximately

Tube length is usually printed on the tube

The shop looks well insulated. Not much glass. A load calc and design would answer some questions, I suspect you are covered

As for mix valve, the tekmar requires 3 pieces, valve, actuator and control, probably 1200 or so based on supplyhouse prices

The tekmar 360 control has more functions and would control the boilers operation. It is programmable with the digital display readout. Sometimes called a PLC, programmable logic control. So you would need to learn how to program and drive it.

Looks like the Taco uses dip switches for choices,

Like buying anything, how many features do you need or want?

https://s3.amazonaws.com/s3.supplyhouse.com/product_files/Tekmar-360-install.pdf

What control is on the boiler? It may have some of the functions you need?

Another option, put in the tekmar without the actuator or control. Manually adjust the valve at design condition. If the boiler has a control with ODR, no need to have two ODR functions

A control could be added later if you want more control

That boiler is fairly radiant friendly as it is

hot_rod

hot_rod

Re: Objects found in heating systems

Thanks so much for these great stories. You keep America warm. Lives well lived. I am learning from all of you! Thanks.

Re: Need help with new install of radiant with Buderus cast iron boiler

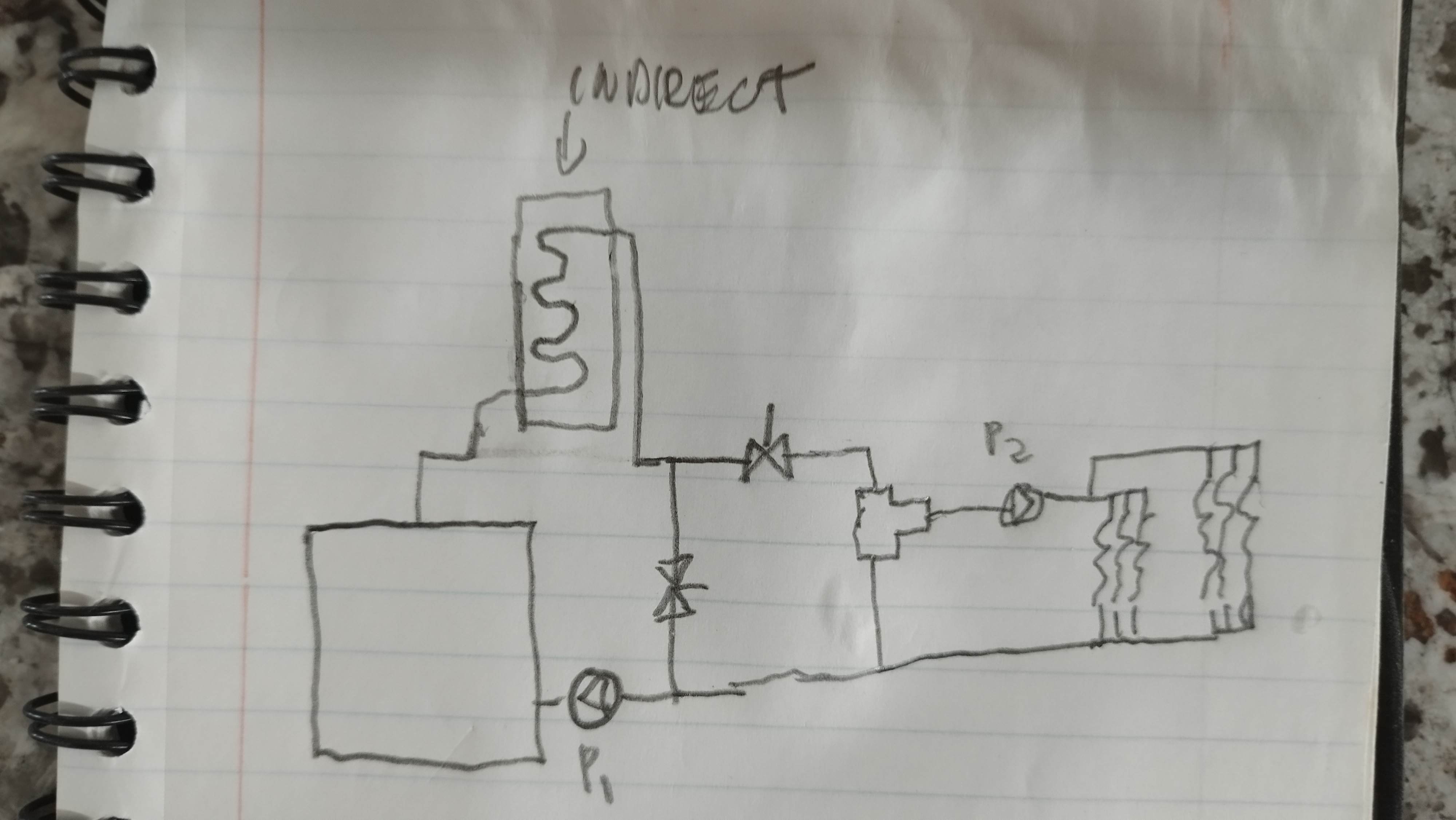

How about this as a cost optimized setup.

Fixed bypass and hold off on P1 for boiler temperature protection. Thermostatic mix valve for floor heat. No zoning to limit short cycling.

The indirect is always on the heat loop, when the boiler runs, indirect is always heated. When only indirect needs to run, only P1 is turned. Will need a valve before P2 that can be closed in the summer to stop flow through the floor heat.

The indirect does double duty as a buffer to reduce cycling.

Kaos

Kaos

Re: Loop PEX *under* joist instead of through? Reasons it won’t work?

Appreciate all comments and challenges. The perspectives are very informative.

Always part of plan but not mentioned detailed: Presence of ~4in of mineral wool (brand FlumRoc) with R value ~16 with snug fit between joists (see photo). That is to help send the heat „up“ into the subfloor and not down to ceiling.

So, from top ("0" layer) to bottom ("-5" layer):

0) Floor finish: 0.6 in wood parquet, but ceramic tiles in wet areas. (est. R value of wood: ~0.6)

-1) Subfloor: 1.1 inches Gypsum fiber board (28mm Knauf GIFAfloor, R value: ~0.4)

-2) Heat transfer plates: 1/2“ Alu c-clamp plates (Uponor)

-3) Pipe: 16mm, O2-barrier (Rehau RauTherm NEO-X5, 0.63 inches OD)

-4) Insulation: 4 in Mineral wool batts (10cm FlumRoc with R value of ~16 h•ft2•F/BTU)

-5) Sheetrock: 5/8“ sheet rock for 21“ span between joists (R value: ~0.6)

(Note: You may notice I didn't use screws to fasten plates to the gypsum fiber board. The screws simply twist off when driving them in. Pre-drilling would take forever. Opted for concrete nails instead. Hilti BX-3 battery-powered nail gun with 2/3 in (17mm) nails on a magazine. Incredibly easy and fast. Incredibly strong fastening. Would recommend that system if fastening to thick gypsum fiber board. Battery-powered roofing nail gun (DeWalt) might be option if OSB subfloor?…)

Re: Need help with new install of radiant with Buderus cast iron boiler

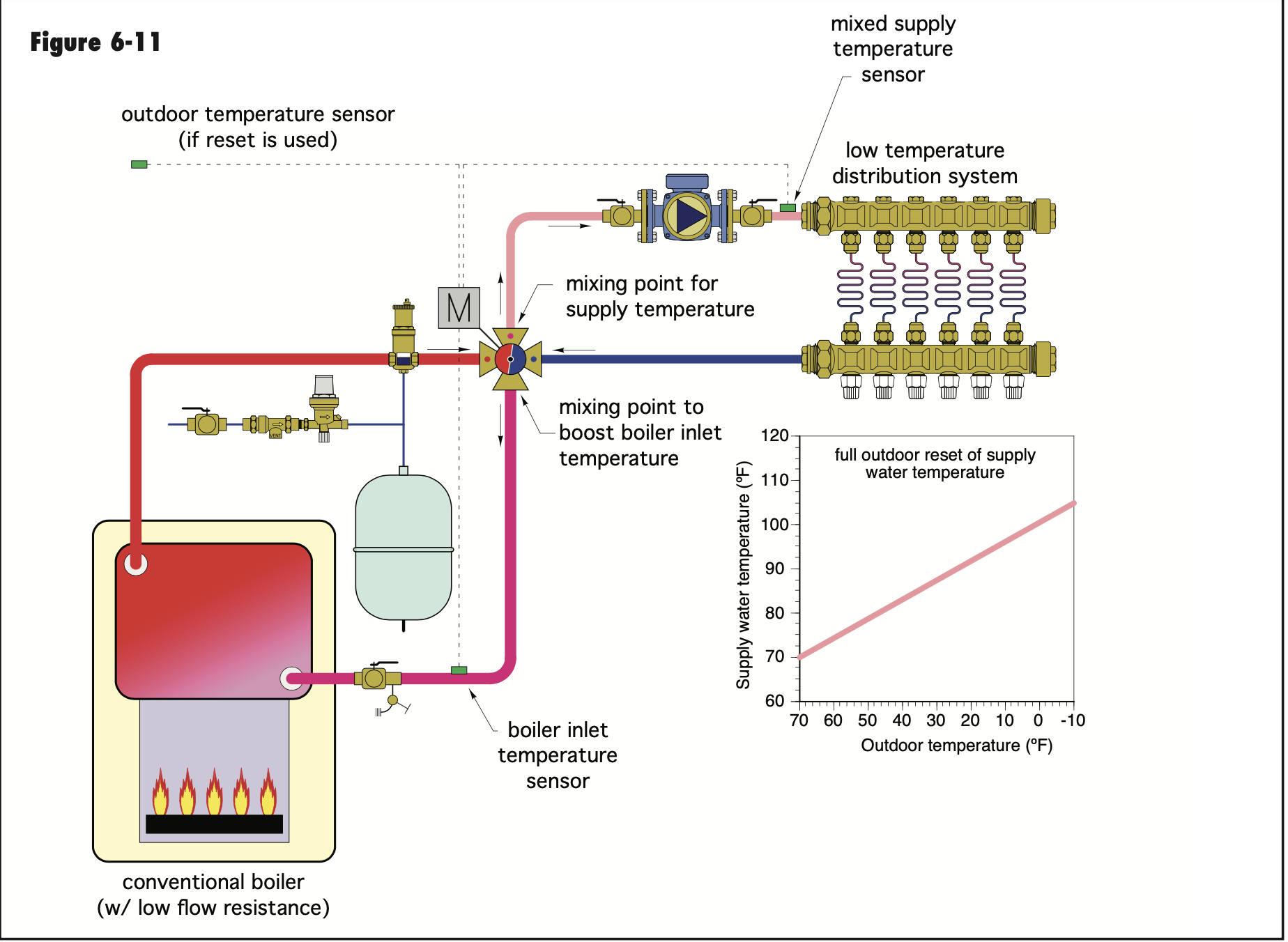

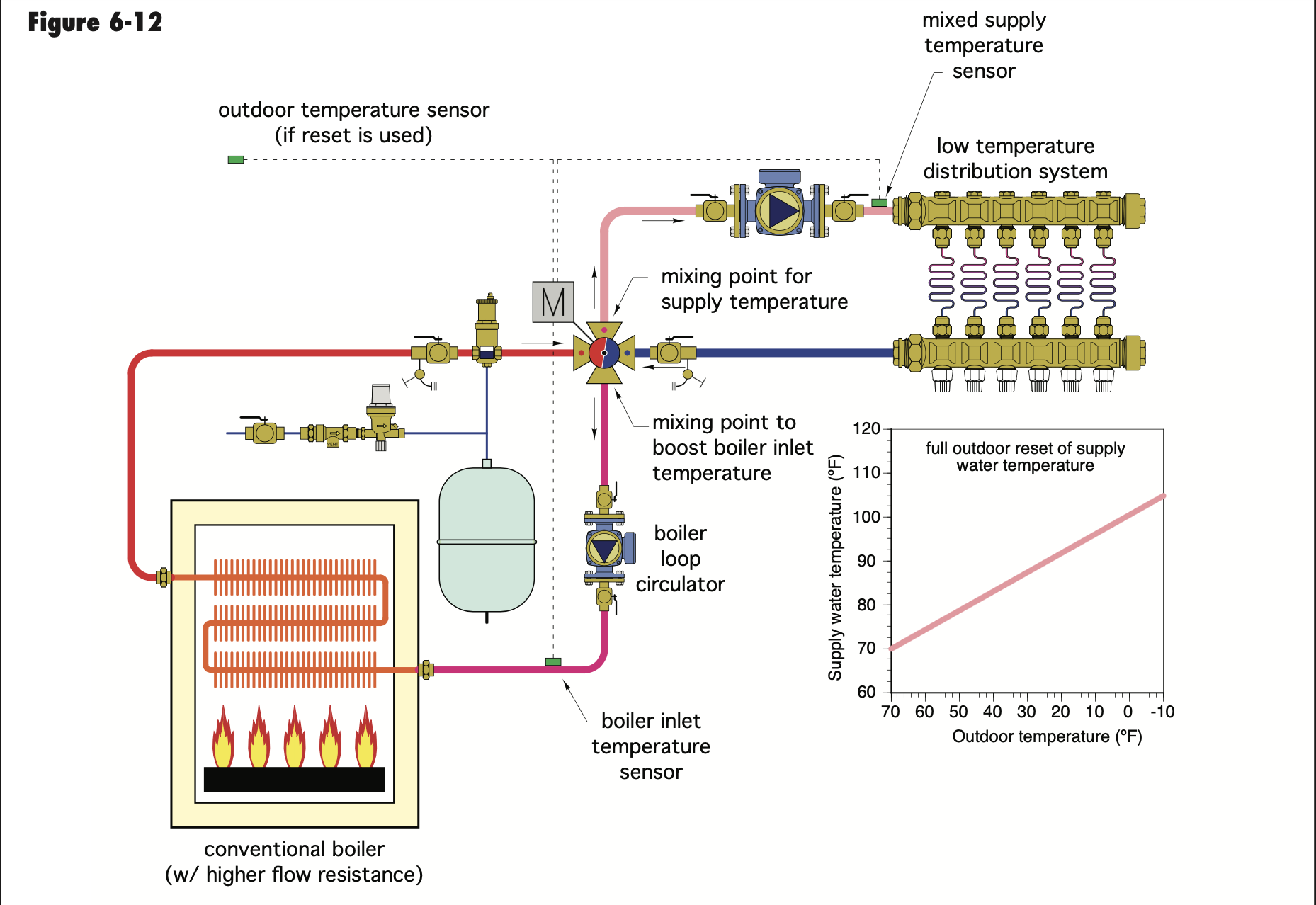

Back in the day, before mod cons, CI boilers were commonly piped with 4 way motorized mix valves.

This valve both protects the boiler from low return, and provides the mix down temperature. Many of the Euro boilers offered this assembly. Tekmar, HBX are a few that still offer the valve, actuator, and controller.

\If return drops below acceptable temperature the valve modulates to protect it as priority.

Possibly a single circ will; work, depending on the loop requirements, gpm and head.

If not a two pump system was used with either a high pressure drop boiler, or high pressure drop radiant.

Buderus used to promote that "flexible cast iron" as being able to accept low return without damage? But flue gas condensation needs to be considered.

Price it with the components to use that boiler, or a combi.

Many here rave about simplicity and long life, inexpensive maintenance and parts of CI boilers.

The 4 way also provides outdoor reset.

Caleffi Idronics #7 talks about numerous mixing options for projects like yours. Hard to beat a 4 way.

hot_rod

hot_rod

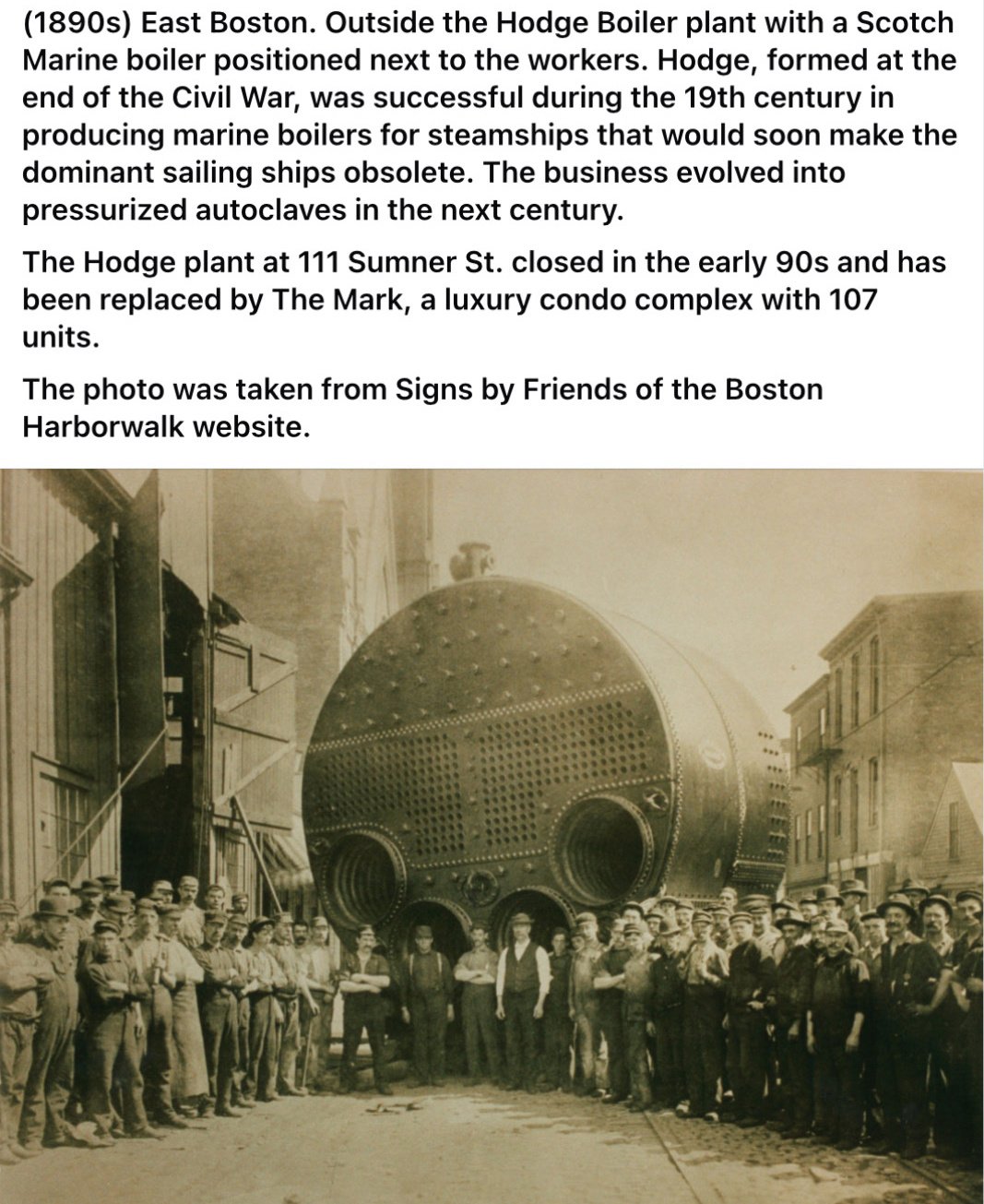

Hodge Boiler Plant Photo (1890s)

Thanks to our friend Steve for sharing this piece of history with us!

Re: Interchanging Warm Morning Heater Parts

That would be difficult to do. Maybe you would be better off replacing the entire unit

Re: Hodge Boiler Plant Photo (1890s)

Impressive!

Can you imagine the noise created from doing up all those rivets?

Re: Hodge Boiler Plant Photo (1890s)

@mattmia2 I did not know that. I always assumed the steel bridges they built in the 1800's and early 1900's used the "hot rivet method" that I saw in the cartoons as a kid some fifty years ago. I think it was Bugs Bunny or perhaps it was Wile E Coyote?