Best Of

Re: Near boiler piping/replacement boiler

Thanks for all of your help Ed. It's not cold enough in CT to see if the room temperatures are good, but I expect them to be good.

I figured there will be instances when the boiler run times will still be short, but downfiring to the .85 nozzle has made a big improvement on getting longer run times.

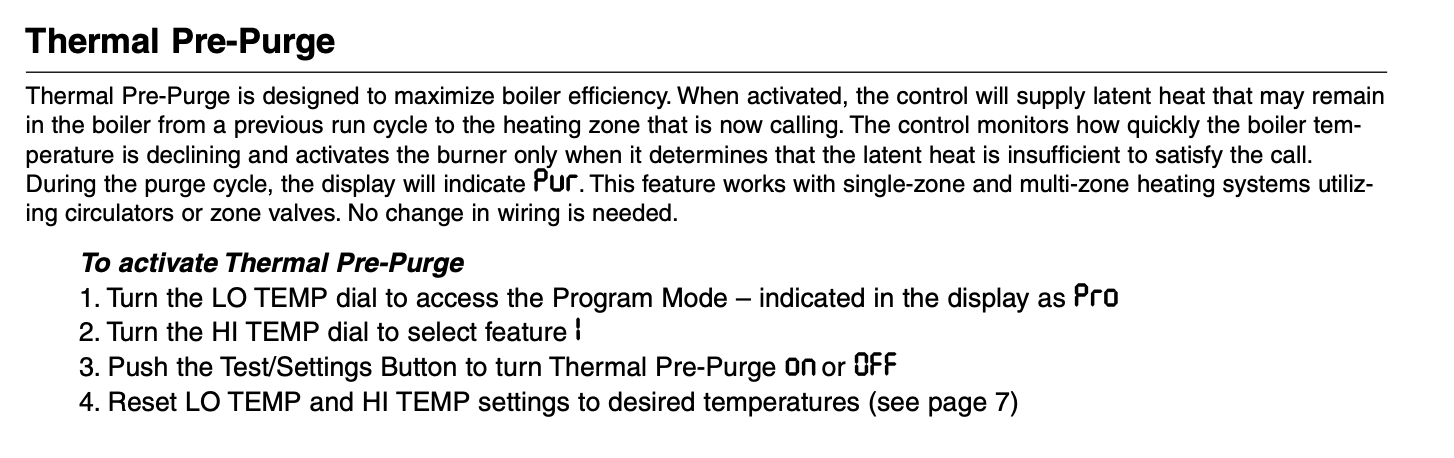

I configured the Hydrostat 3250 to enable the thermal pre-purge so the latent heat in the boiler can be circulated thereby eliminating unnecessary burner firings:

I also disabled the economy feature, and set the differential to 30 to maximize the burner runtime.

I'll do a few more tests once the heating season begins and the boiler is operating under normal heating conditions.

Everyone here has been a tremendous asset with all of your help and suggestions, and I greatly appreciate all of your wisdom and assistance.

Re: combustion set up on burnham V82

Don't take this the wrong way but in my experience, you have screwed this burner up beyond all expectations.

It is my experience that this burner ONLY runs well with Delavan nozzles with the one that the BOILER manufacturer recommends in the burner application you are dealing with. If one gets them to run with a different nozzle, it is usually some variation of the suggested nozzle. And the experience of the technician doing the work which was gathered from years of experience and the developed skills.

I NEVER "F" with the "Z" dimension. I have never needed to.

With a .50 GPH nozzle, if you have dirty strainer/filters and you change the nozzle, the nozzle strainer will IMMEDIATELY plug up. I doubt seriously you have a Webster pump. All pumps come through with Suntecs. You should use two spin-on filters. You also need to have an experienced pro that really knows what they are doing. You have really messed this thing up. As far as cleaning it, I doubt that you have been able to clean this to the level that I clean them. Did you use a soot saw? you probably need to.

Is a V82 a V series, model 8 with two sections? If so, these really small boilers are very difficult to keep running properly with such small nozzles.

Others here may disagree with me but where I work, there once was a guy that decided that a 70 degree nozzle in a red container was the universal oil burner nozzle. Every burner he serviced, he put in a 70 degree nozzle. Even on Carlins that only ran well with Hago, 60 degree semi solid nozzles. On these he put 70 degree delavan blue containers that were solid spray. He serviced a huge amount of accounts. All the guys he trained and employed all do the same thing.

I've changed a lot of nozzles to the correct ones to solve these problems.

The burner manufacturers spend a lot of money and time testing their burners in different boilers for maximum performance and efficiency. I have never gone wrong going by their specs.

It takes years to develop the experience to do what we do. If I do a lot of soldering, for a week or more at a time, it becomes "natural". All my skills are there. If I don't do it for a long period of time, I need time to get my "edge" back. Same as working on oil and gas boilers. You can't do something once a year and be proficient.

When I first go ice sailing for the year, I don't have the edge I will have after a weekend or two of sailing. Like keeping the boat moving in light air. I develop a "feel" for the wind and ice. Same with using a combustion tester and adjusting a burner. I've been doing it for a long time and I am still learning things every day.

Get a pro.

Re: Cost to clean a heat exchanger?

The tech put his probe in the wrong place, which means he has no clue how to use a combustion analyzer. What was the flue temperature?

If the boiler is sooted you will find soot on the floor below the drafthood and in the drafthood.

Just because it is producing CO doesn't mean it has soot. I have measured many pieces of equipment with CO over 1000 ppm and there was no soot,

What part of Ohio

Re: Cost to clean a heat exchanger?

They don't make a more simple boiler. That's an open draft hood, so I hope the tech got the probe up over the top of the block. With those numbers, it seems the techs sampling was diluted. Atmospheric oxygen at sea level is about 21%, so getting 16.58% during a combustion test means the tech didn't stick the probe where it needs to be stuck.

@Evan0307 , did you see for yourself the dirty flue passages in the boiler? Dollars to donuts its clean as a whistle.

HVACNUT

HVACNUT

Re: Warren Webster 02H thermostatic radiator traps

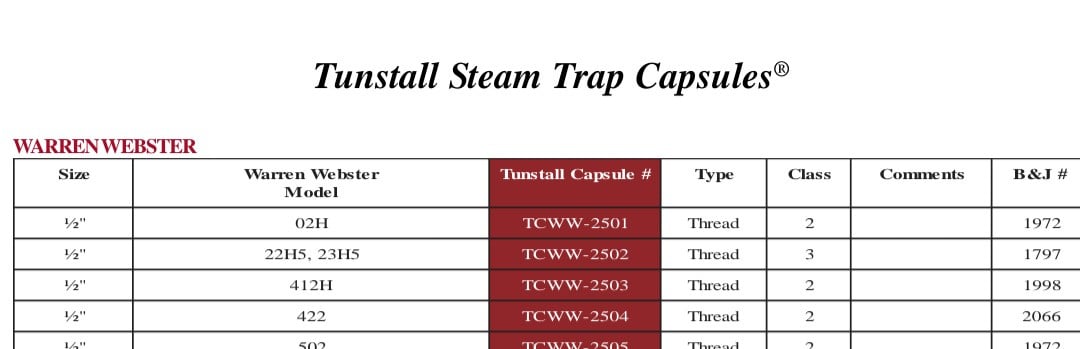

I was able to find the correct capsule right from Tunstalls website.

Re: Oil furnace rumble and smoke

This really isn't something you want to try on your own. You need an experienced technician with the proper test equipment. This may not be an easy fix. Even if it is the burner needs to be properly calibrated or your issues will just get bigger and more expensive.

Re: TT Excellence DHW Tank Replacement

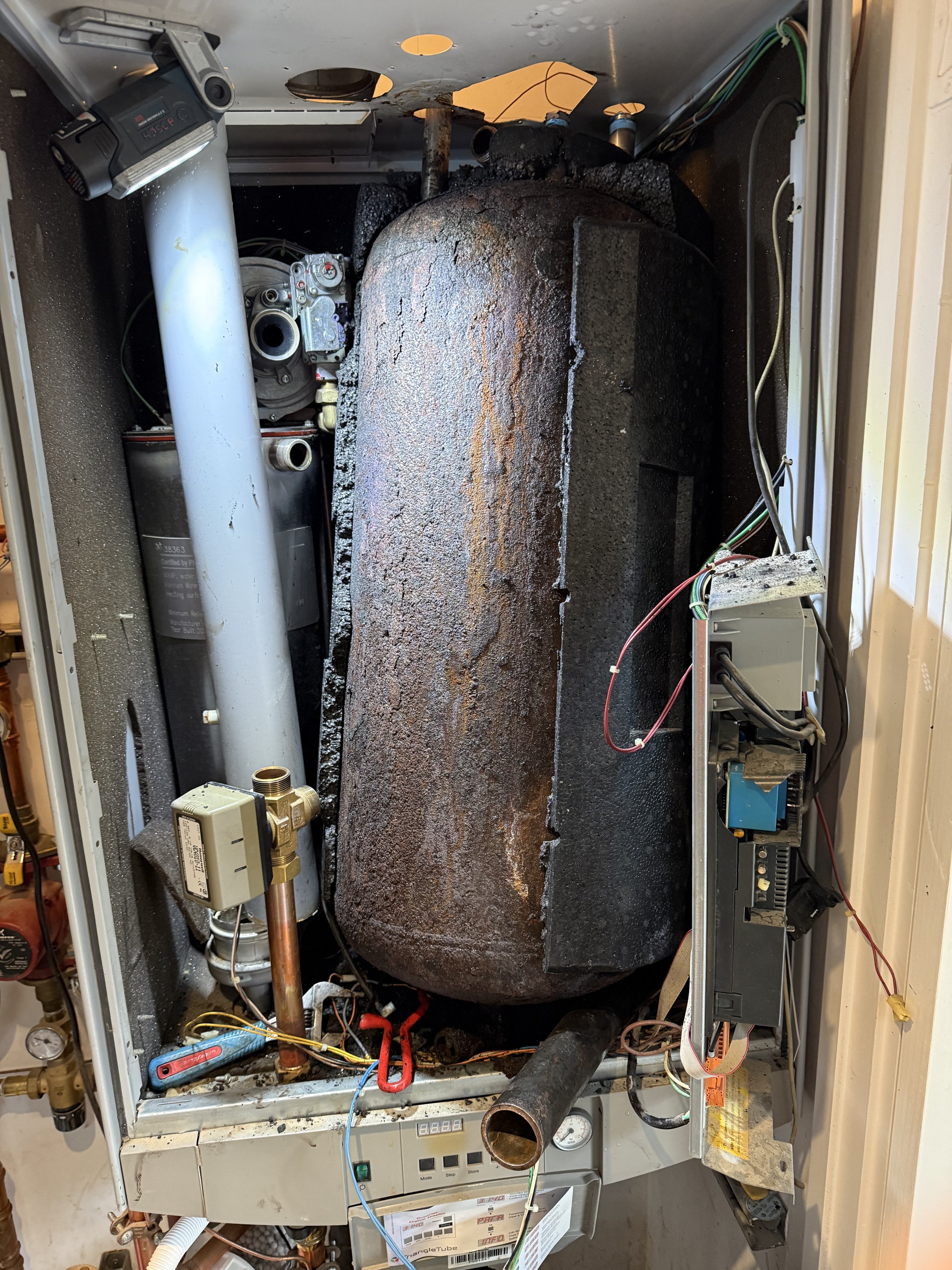

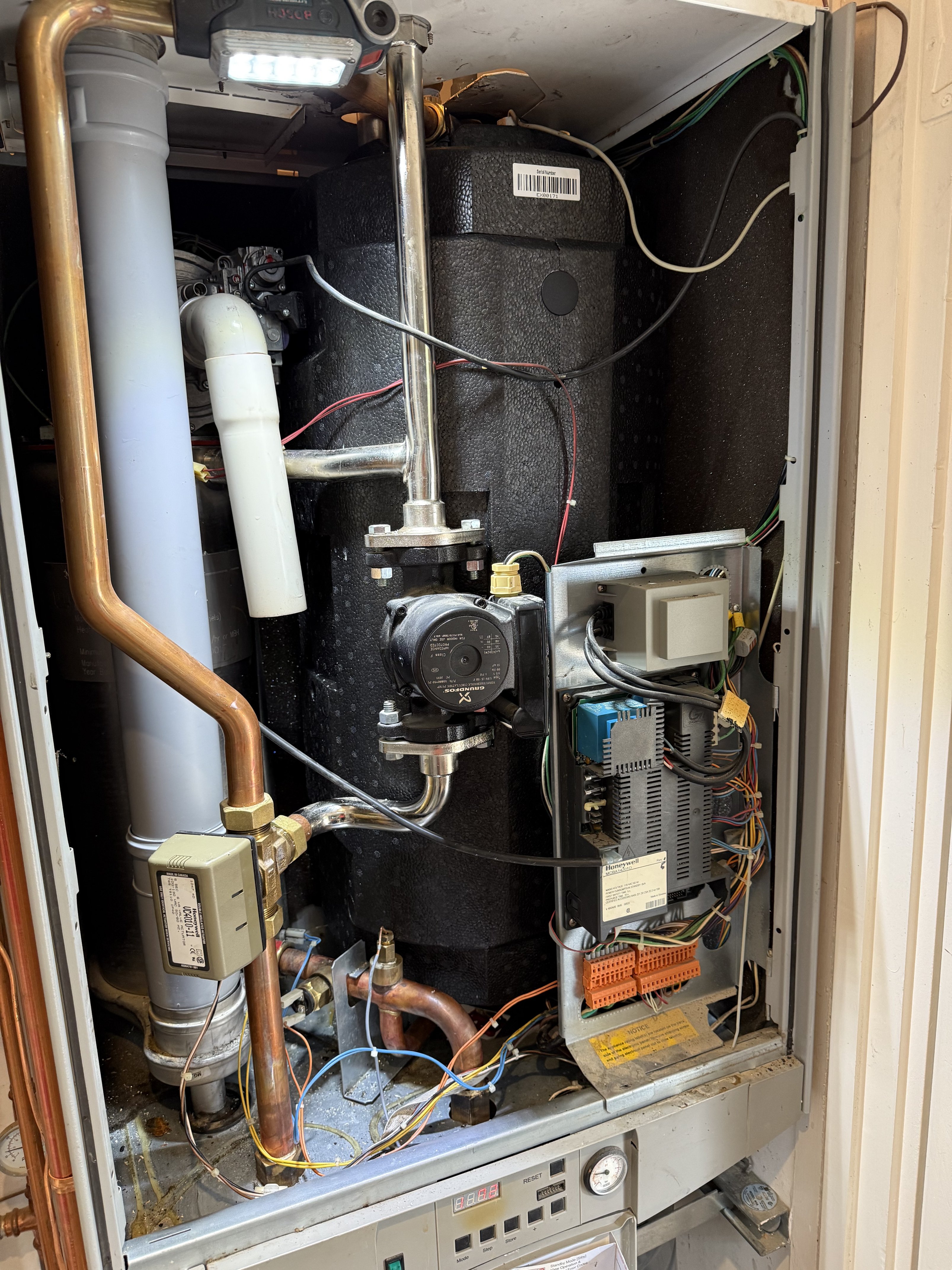

I won’t be doing this again anytime soon. It was not fun.

Re: F&T oddity

Collum of water 28" tall is 1 psi. So, if you had to lift the condensate 1 foot you would need the steam pressure to be .42psi" higher than the return pressure (if any).

In reality you need a little more to open the check valve and overcome any trap resistance which is minor.

Re: Small baseboard zones

I have never found any info on why 20 is used, @DanHolohan might know.

Most agree it is to make the math simple as you indicated.

Much of the rest of the world heats with panel rads, they tend to use 25- 40 ∆ in their design. Wider ∆ allows small 11 mm tube, for example, to be used for S&R piping

hot_rod

hot_rod