TT Excellence DHW Tank Replacement

I have a customer with a 12 year old Excellence boiler that has a leaking tank. He is not ready to replace the boiler and wants just the tank replaced. Has anyone ever done this job before?

The boiler is in a confined closet and there is no space on the right side. I'm hoping I can remove all the connections and lift the tank off a hanger.

Two btu per sq ft for degree difference for a slab

Comments

-

Is there supposed to be pics?

0 -

Sorry, no. But most of you know what an Excellence boiler looks like inside.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

@Alan (California Radiant) Forbes

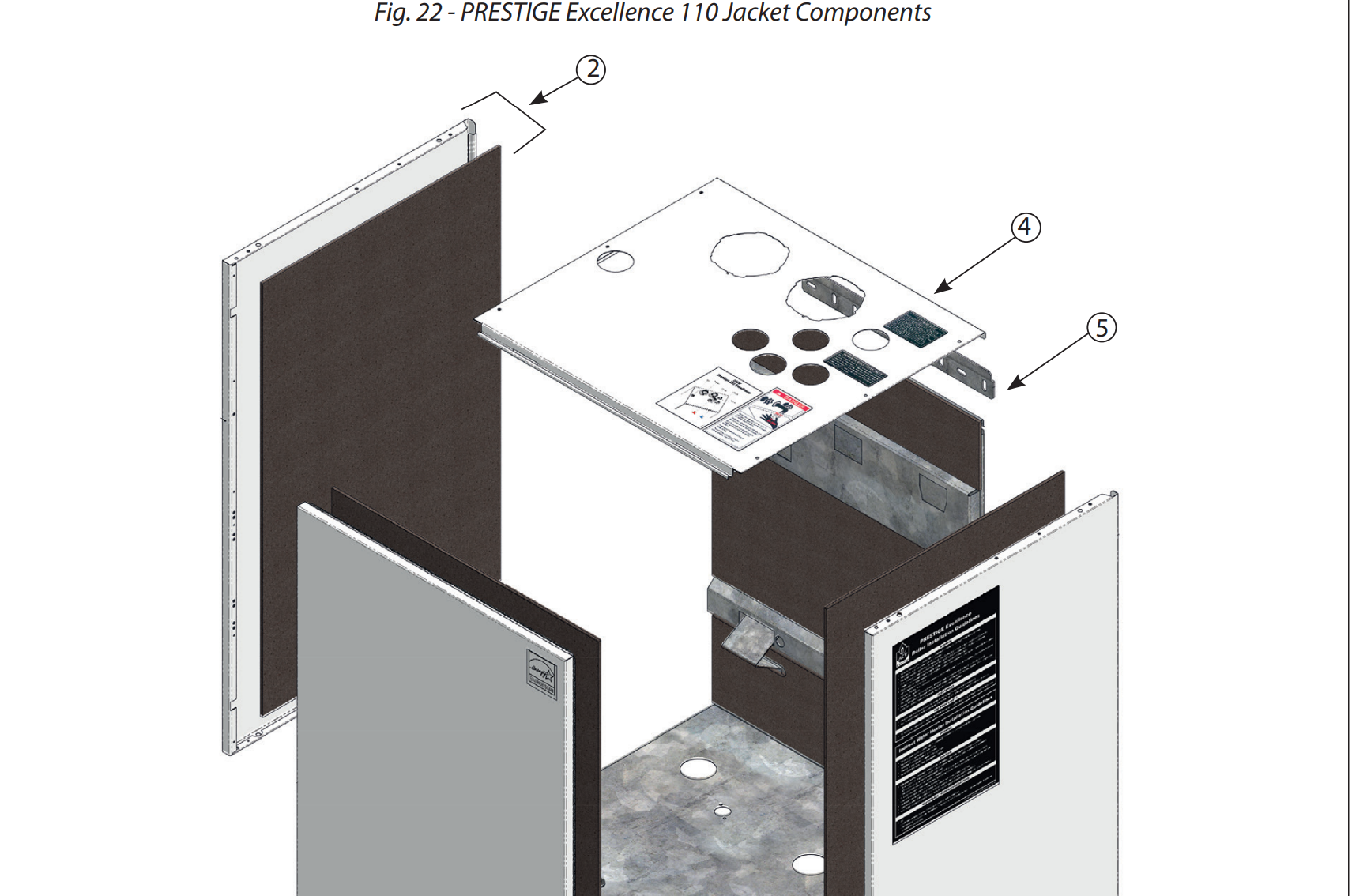

Is this the unit you are referring to? Looks like quite the undertaking.

https://s3.amazonaws.com/s3.supplyhouse.com/product_files/Triangle%20Tube-PEA110-Replacement%20Parts%20List.pdf

This might be a tech support conversation at Viessmann. 1-888-484-8643….in California.

By the time you get the tank out and replaced, the cost of an entire new unit might be very similar.

0 -

I don't. There's not many TT boilers by me. So I looked. If there's room to add couplings to the intake and exhaust, it might be easier to remove the whole boiler. Replace the tank and reinstall.

0 -

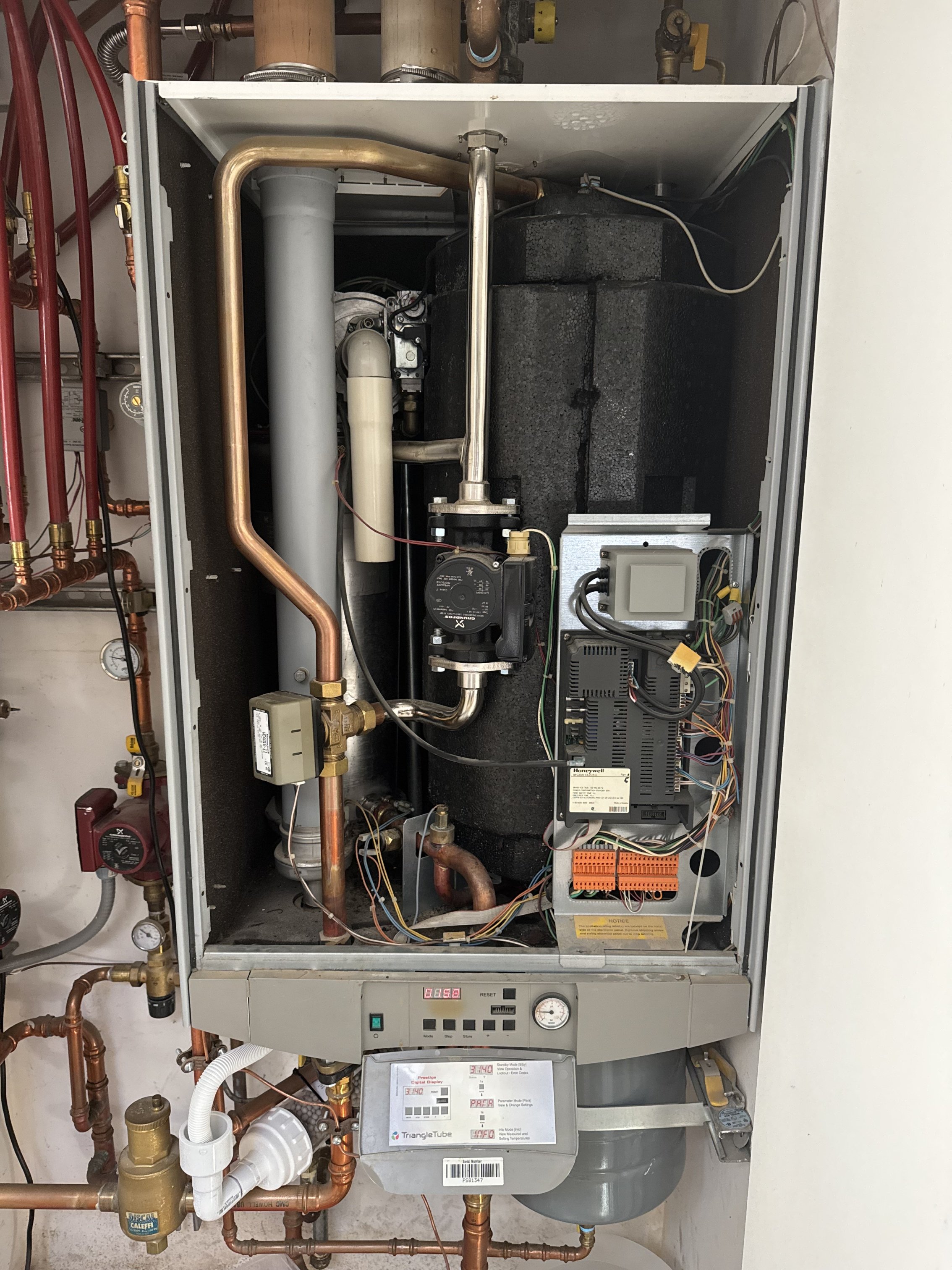

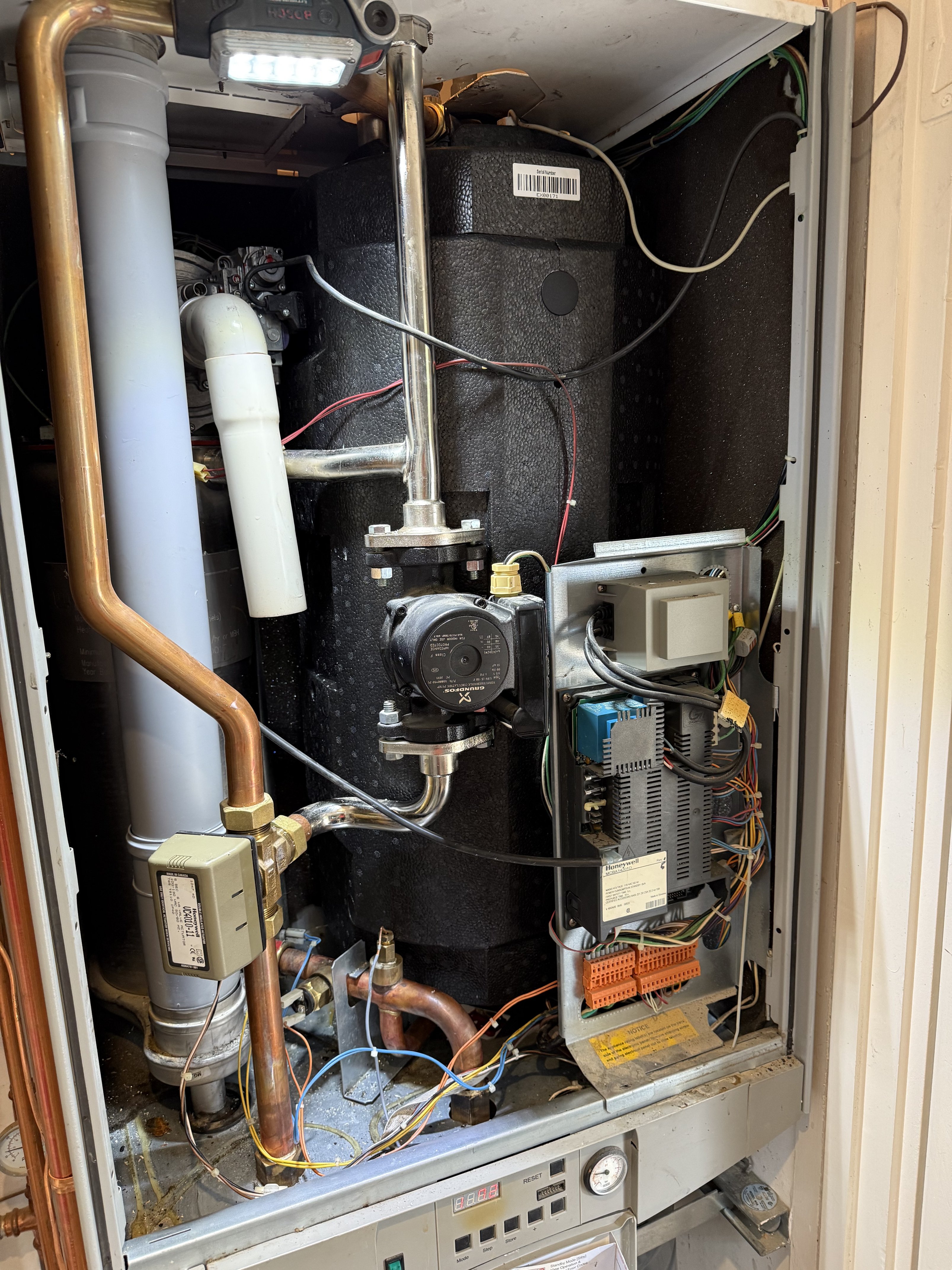

This is the best picture I could find. You can see the insulated tank behind the circuit board and pump.

I considered changing the tank in vitro, but there are too many difficult connections; above and below the boiler.

The guys I spoke to at TT tech. support had never replaced a tank, but they we able to send me instructions which helps.

After draining DHW and heating water, disconnecting the sensors and piping, you have to lift the tank off the high and low hangers in the back. This is the hard part as the right side of the enclosure is up against a wall which may make removing the lid of the enclosure difficult as the screws for the lid may come in from the side.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

-

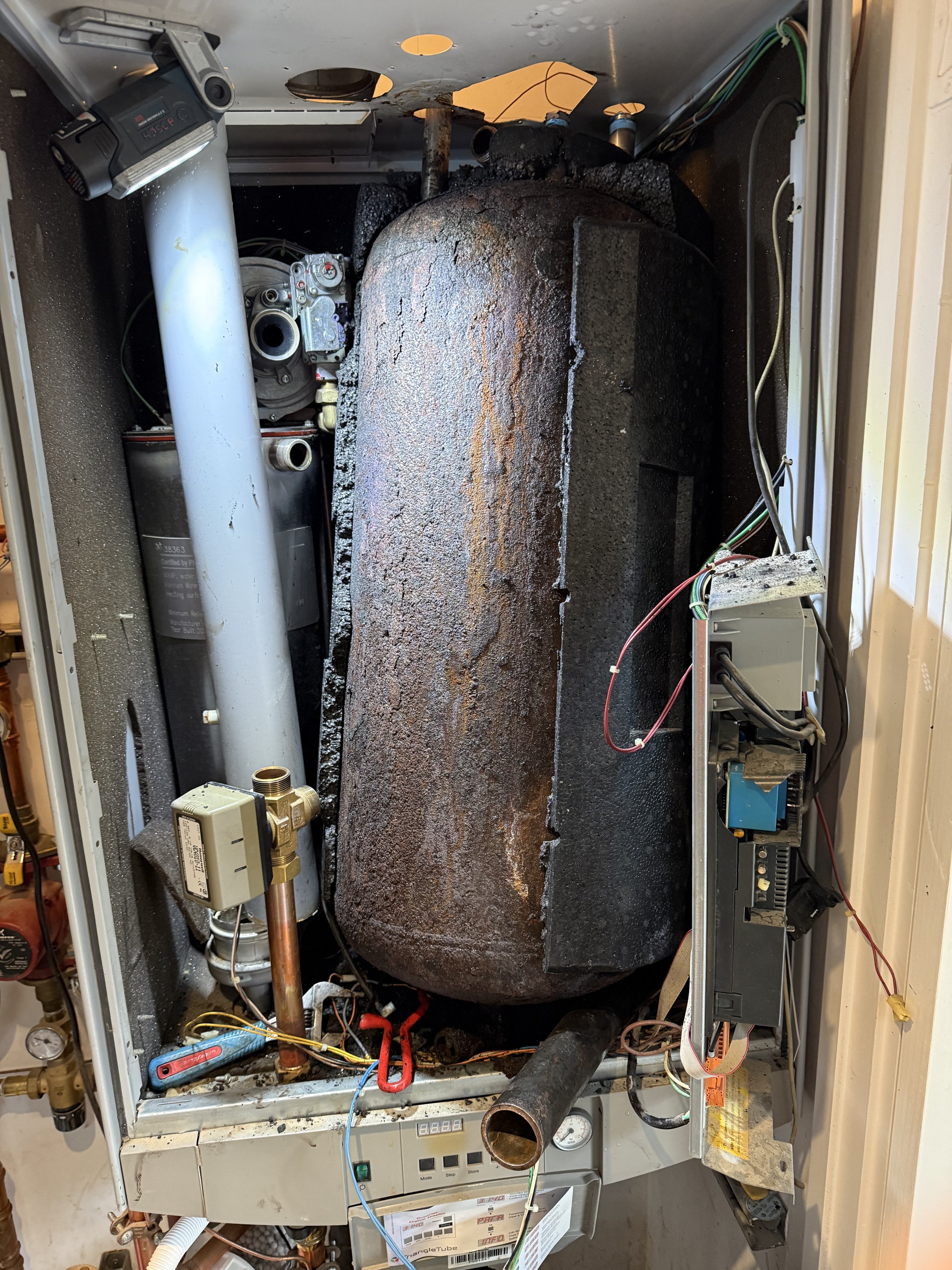

I’ve replaced one of these tanks before — total pain. The manual says that after draining the tank and disconnecting the unions, it should lift right off the hanger inside the cabinet. In reality, I didn’t have enough clearance, so I had to cut the exhaust and intake and remove the top of the cabinet just to get it out. Also, be ready to siphon or pump water from the DHW side, since many installers skip adding the required drain fitting on the cold inlet.

1 -

Here is a picture of the one I'm working on:

You can see that there's no room to lift up the tank without hitting the top of the enclosure. I'm thinking I have to cut the enclosure in half widthwise, just where that chrome pipe goes through to the relief valve and then bend and remove the lid to give me room to lift the tank.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

It looks like the top panel screws down through the top in to the side panels but it also sort of looks like that forms a lot of the structure that lets it hang from the wall bracket

0 -

It also looks like the vent connections to the boiler itself are essentially ferncos so you can take them apart.

0 -

Alan, the unit i worked on was a newer style pt series i believe that is a ps series? The enclosure on that ps unit might be slightly different? Either way i was able to get it out after removing the flue and intake. I don’t fully remember but i might have not had to fully remove the top but removed enough of the fasteners to flex the lid up high enough so the tank would clear. Definitely looks like the chromed supply piping needs to come out of the way. I remember the tank replacement came with all new gaskets/washers if i remember correctly? Either way it’s going to take sone finesse to get that tank replaced. Good luck.

1 -

-

Unbelievable Alan! Good man.

0 -

Not sure I could have talked myself into that one. It's really nice when the mfgs plan so well for replacement of components LOL.

Good job. I am sure most would have said "replace the boiler". The worst thing about those jobs is the thought process.

Once you look at it it gets in your head thinking about it

1 -

The hardest part was making the boiler water connections. The old tank nipples had thick walls at the nipple ends which were a nice shelf for the fiber washers to sit secure, but the new connection points didn't have that thickened end and the washers would slip into the pipe as you tightened the nut.

A properly sized brass friction ring would have kept the washer in place, but we eventually hit on some thick Viessmann washers that worked well. I know now why I never throw unused washers away.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab3 -

Would it have been faster/ simpler to replace w. a decent combi boiler?

0 -

”Once you look at it it gets in your head thinking about it”

Over and over and over!

0 -

I totally agree, but the owner didn't want to spend the money as he wants to save up for a solar installation.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements