Best Of

Re: Its hot in here 84deg but I am a lot hotter

They just want to make sure you're serious about wanting the warranty replacement, that's all. I mean, if you give up after just a few li'l emails, you really didn't want it that much after all, right? 😉

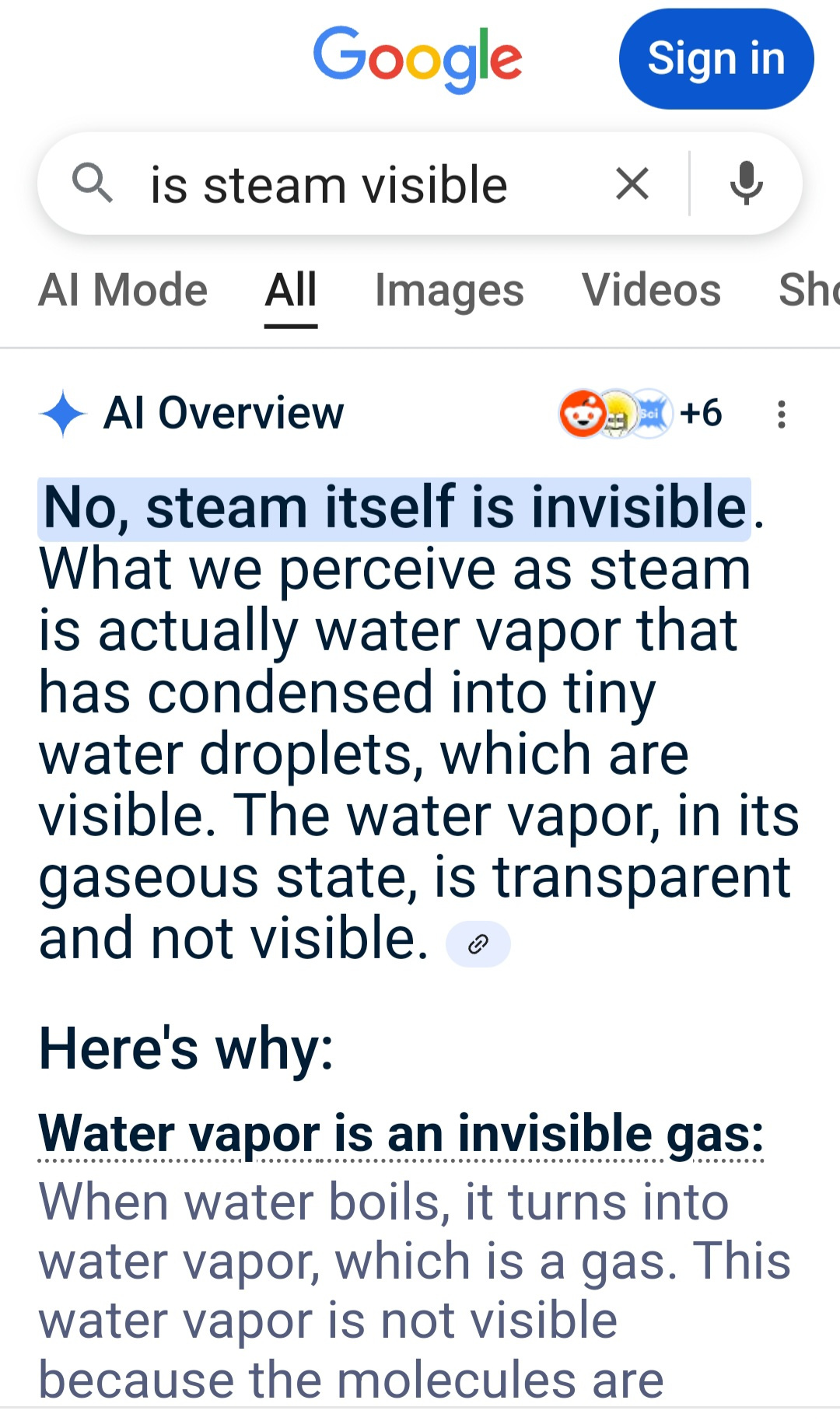

Re: Electric Steam Boiler

I would ask the client to restate his complaint. Then ask why is it so important to see the steam. Is he not getting the same results other than visually? Then ask if he trusts Google's AI thing.

His money back for the boiler (if you can return it), and he'll pay the labor for removal, right?

HVACNUT

HVACNUT

Re: Gorton air eliminator, condensation/sweating in summer

Sure the system hasn't gotten over-filled?

Happy Father's Day!

Happy Father's Day to all! We hope you have a relaxing and joyful day with your families.

Hug your kids. ❤️

Re: Snowmelt PEX loop max length

As with anything have a proper heatloss. done.

Uponor's C-dam manual has all that included. Shorter lengths are better.

The contractor should have all that done.

Re: Snowmelt PEX loop max length

There are a lot of things to consider.

Snowmelt most often operates between 15-35 deg. This is the temp range in which snow falls.

What % age of snow times and clearance do you want melting to occur. Class 1-2-or 3

There is very little difference in heat delivery between tube size 1/2" to 5/8" or 5/8" to 3'4" foot for foot. Heat delivered (BTUs) is dependent on Supply Water Temp and flow. Pex size has more to do with pumping power and tube length. Are you using Pex A-B-C? Use Pex A with an O2 barrier. I use 3/4" tube for increased flow and low pumping power.

You are going to use Anti-freeze, what % age? Anti-freeze increases the need for more pumping power at a given flow.

How is it to be installed? Sand Bed, Concrete, Asphalt, etc. Pavers going to be the finish?

How is the Pex laid out? Serpentine, Counter-flow. I always use a Counter-flow pattern. What about Pex spacing? Too long a loop length—too long and you could run out heat energy before hot water reached the end of the loop. 250' , I would think is the max.

What are you going to use (insulation) to prevent back and side heat loss?

Is it going to be an automatic of manual sys?

Re: Its on every plumbing exam.......

OK I get it now, the the caulk refers to the lead, I was thinking literal caulk in a tube 🤣

Re: Copper boiler piping in a pool room

Resolved:

The backwash had nothing to do with it. Controls were a mess. I tidied it up and put a boiler kill switch in the pool room. Straitened out the pool temp controller, brought that boiler loop down from 180 to 150. Limit to 200. And pool temp at 80.

Replumbed in copper and tested all the stats and safeties. Running good.

Thanks all