Best Of

Re: What would an “Expansion Tank Relay” been used for historically?

I think — and I could well be wrong! — that the switch is mounted on what looks like it might be a wooden arm which is hooked under something on the left side. The bellows pushes up on that arm, and the spring pulls down. But… without actually standing there fiddling with it, I could be all wrong!

Re: What would an “Expansion Tank Relay” been used for historically?

That spring with the screw at the bottom adjusts the setpoint. I think the arm is some sort of phenoilc or phenolic soaked paper or cloth but i can't quite tell if the pivot is on the left or right or at some 3rd point we can't see. If you lift where the bellows contact it, it should tip. Where the pivot is will dictate if it is close on rise or open on rise. I am still surprised that there isn't a manufacturer's label inside somewhere. Even though it is in a 4 square box, it is clearly was made in a factory.

The lever might be ceramic or brass too, hard to tell in that picture.

Re: Need help with new install of radiant with Buderus cast iron boiler

That valve is yet another way to protect a boiler from getting cold return water. It blends some output from the boiler with the return.

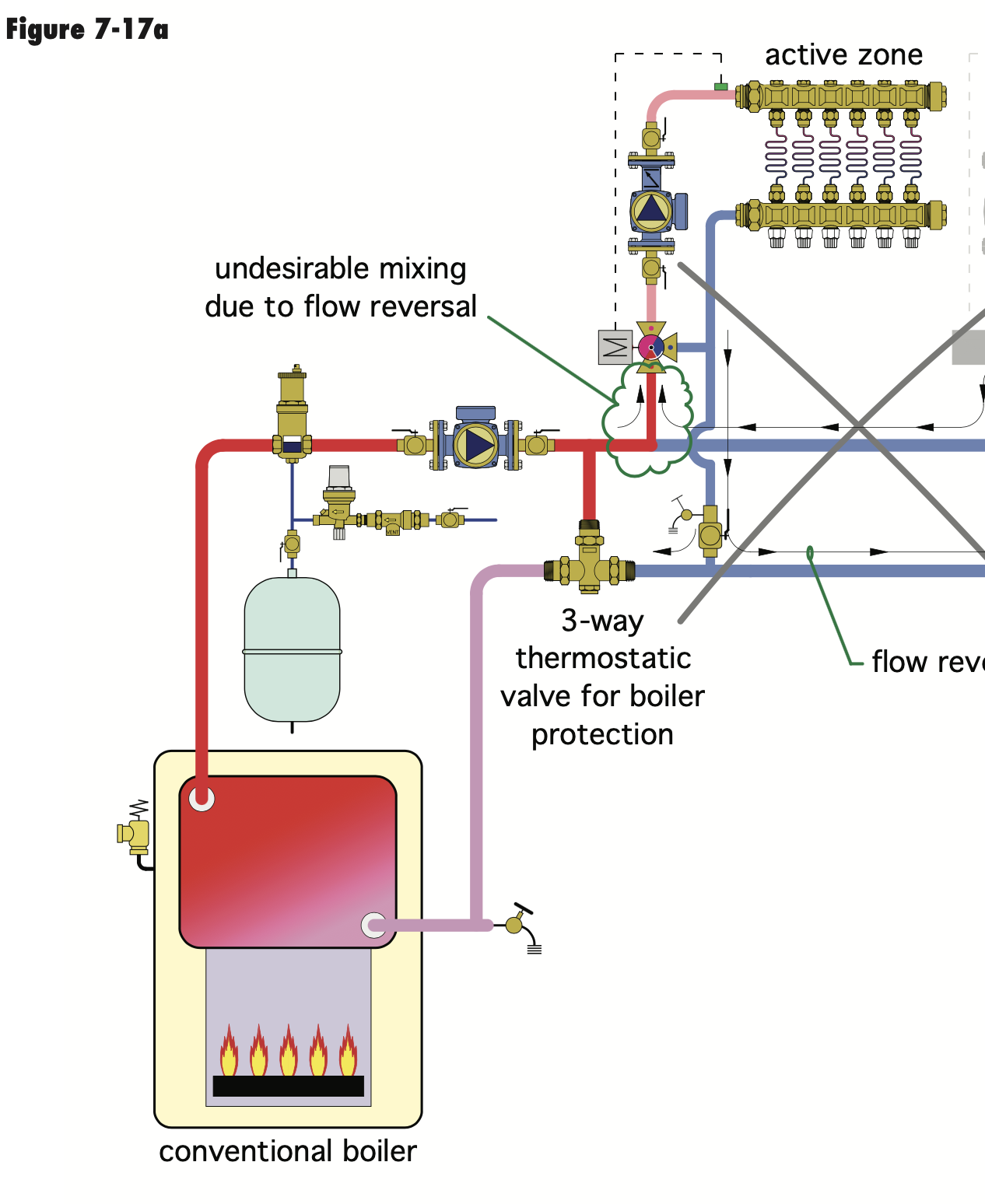

In this pic it shows a non electric valve being used to protect the boiler, the 280, and a 3 way motorized valve to mix down the radiant.

There are probably a dozen ways to pipe a system like yours as far as temperature mix down, boiler protection, buffering the over-sized boiler, etc.

Some use electronic controls, like the tekmar options. So use thermostatic valves shown here.

Some use motorized valves. Some use a combination of the above.

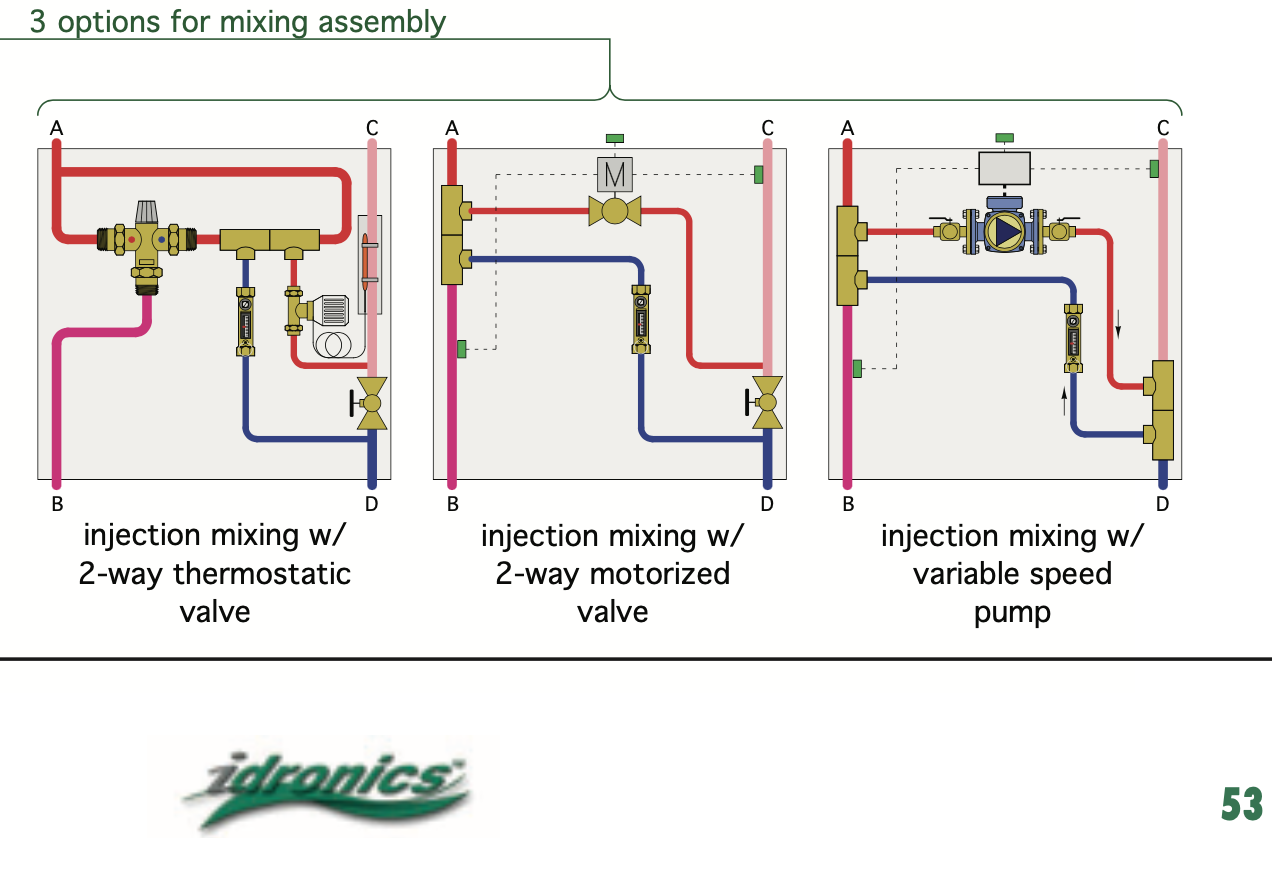

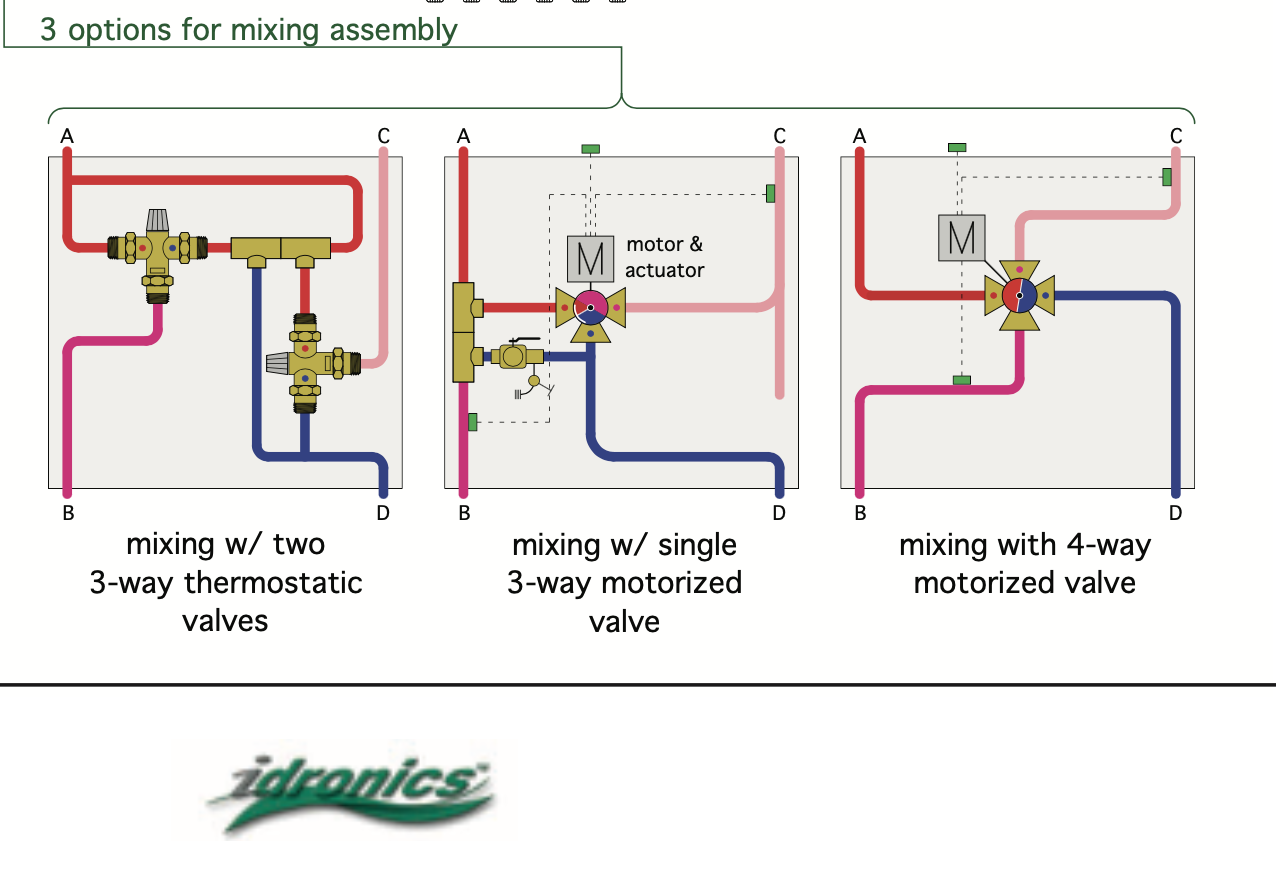

Over the years we have tried various mixing ideas, show below are yet more injection mixing ideas using valves and a VS pump. And a pic of 3 valve based mix options.

All have pros and cons.

Trying to KISS yet check all the boxes for what you want or need for your system. If it is a temporary system (boiler), I hate to throw too much technology at it.

I have seen CI boilers connected directly to radiant with a couple ball valves for temperature control, last years before failing. That is an option if this is a throw away boiler?

But keeping it safe also is a concern with the boiler within the boiler within the living enevelop.

hot_rod

hot_rod

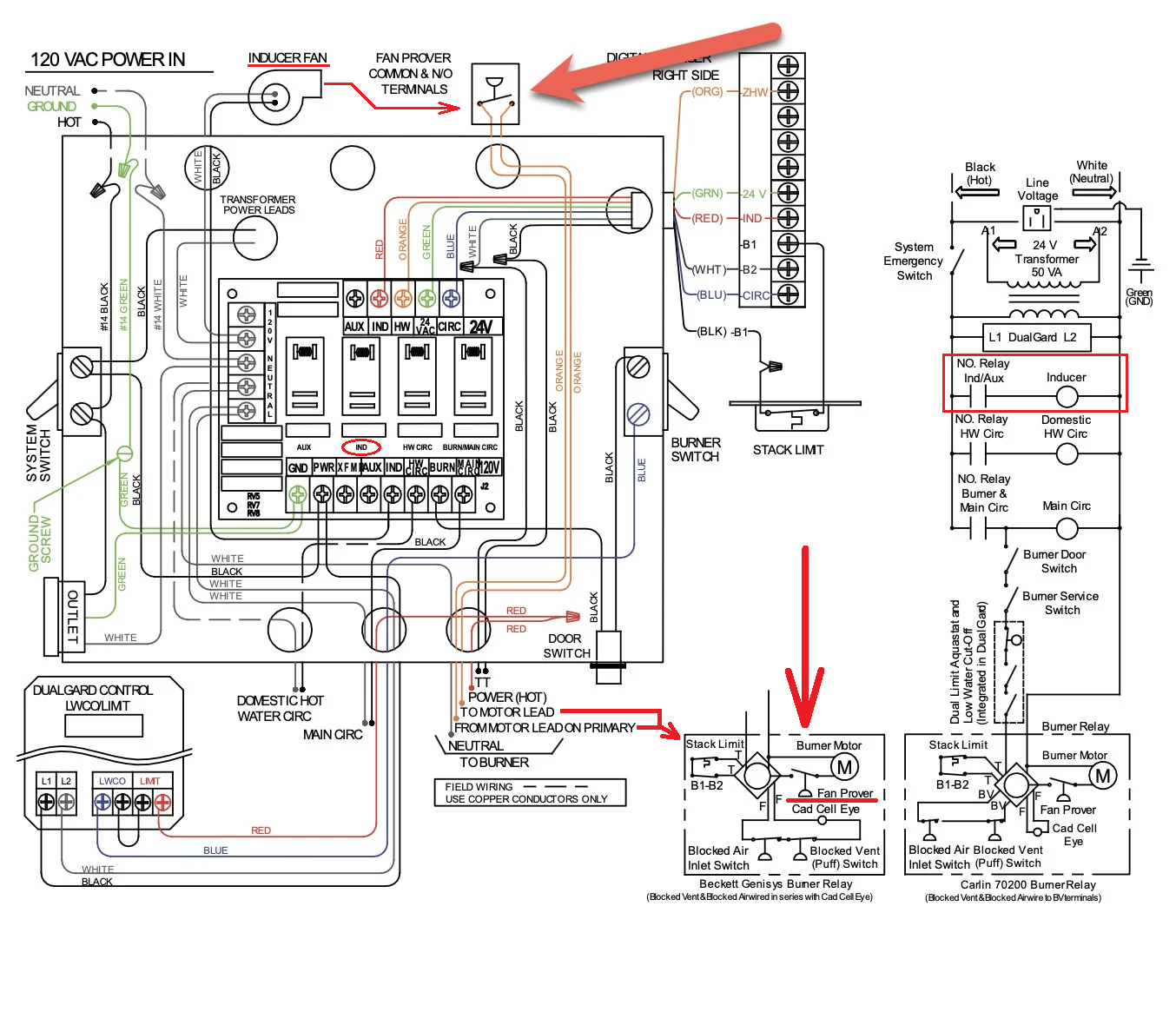

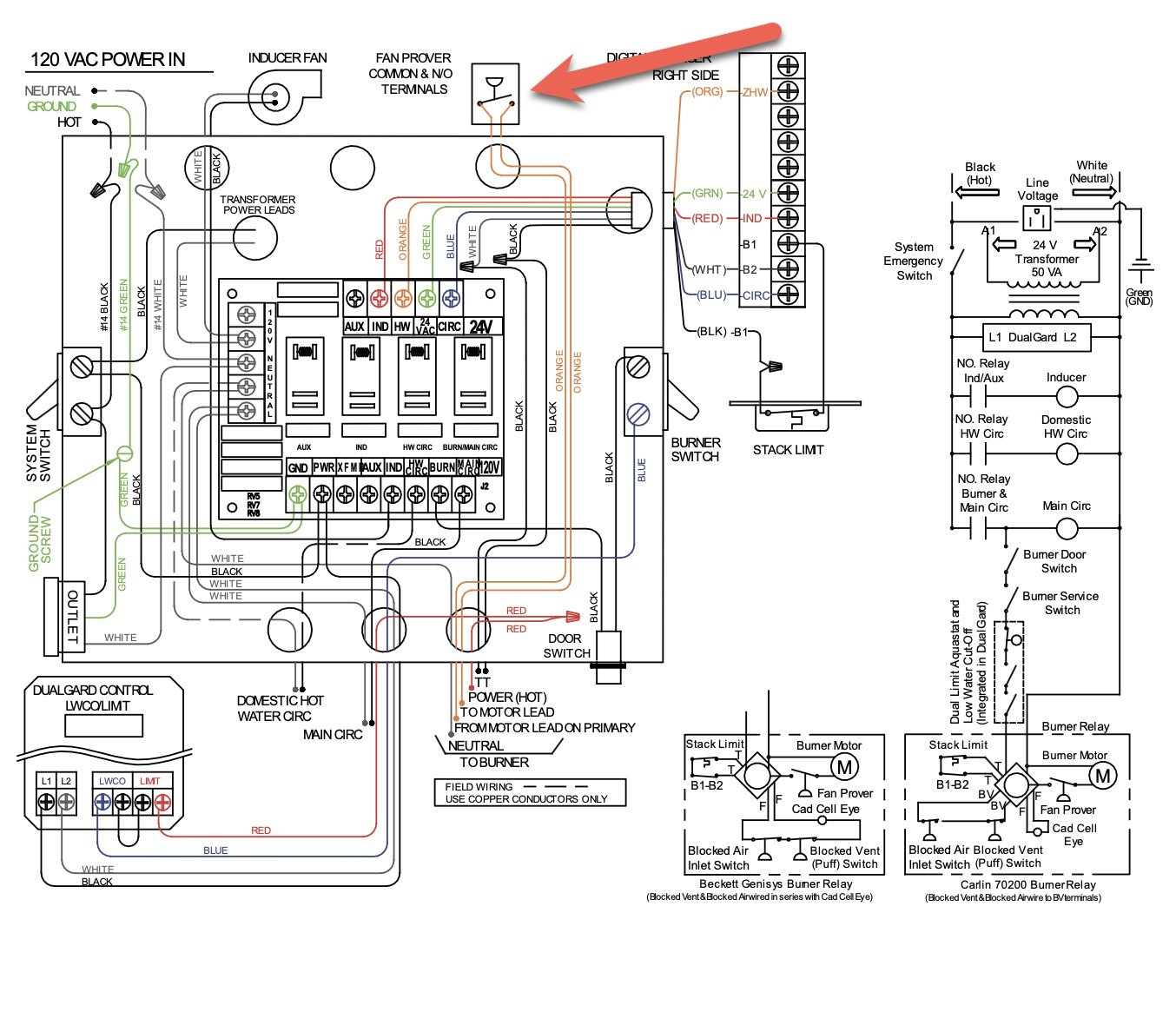

Re: Energy Kinetics System 2000 hard lock out

Glad you were able to fix it before the long cold Alaska Winter.

Very Happy to have helped. Feel free to reach out if there is anything else we can help you with.

Re: Energy Kinetics System 2000 hard lock out

Good find !!!

(" Sometimes the burner motor starts during the Valve On Delay,...sometimes it does not. "). I would imagine that restriction made the fan proving just at the point of being intermittent.

Maybe that should be on the list of maintenance items to inspect.

Sad the " repair technician " could not find it.

How did you find it, Multi-meter, logic, visual inspection, all of the above, none of the above, other ?

Re: Energy Kinetics System 2000 hard lock out

"It is getting harder and harder to find a "qualified" oil tech. The "old" guy who cleaned out the burner chamber said they all retired. I live in Alaska so there's only so much talent here…"

Umm, I hope that wasn't me. I do however still do phone repairs for a few of my customers. 😀

I'm still a little confused as to what is happening. You say the burner motor will wait until it lights, which makes no sense. It can't light without the burner motor running. So, does the burner motor run, but then doesn't fire the burner, and then goes in to lockout, or does it run for a bit then shutoff on its own without a lockout? If it is the second case, sometimes it is just a bad timing thing, as the zone is just shutting down just after the burner starts to fire. Also, you never mentioned checking or changing the cad cell, which is what signals the burner to lockout if there is a problem.

If it runs but doesn't light, then the the best thing to do is have a pressure gauge to make sure the nozzle is getting fuel pressure. That test would tell you where to go next.

My wag is going to be fuel pump coupling slipping, or cad cell.

Rick