Best Of

Re: Gas boiler heating house without call for heat

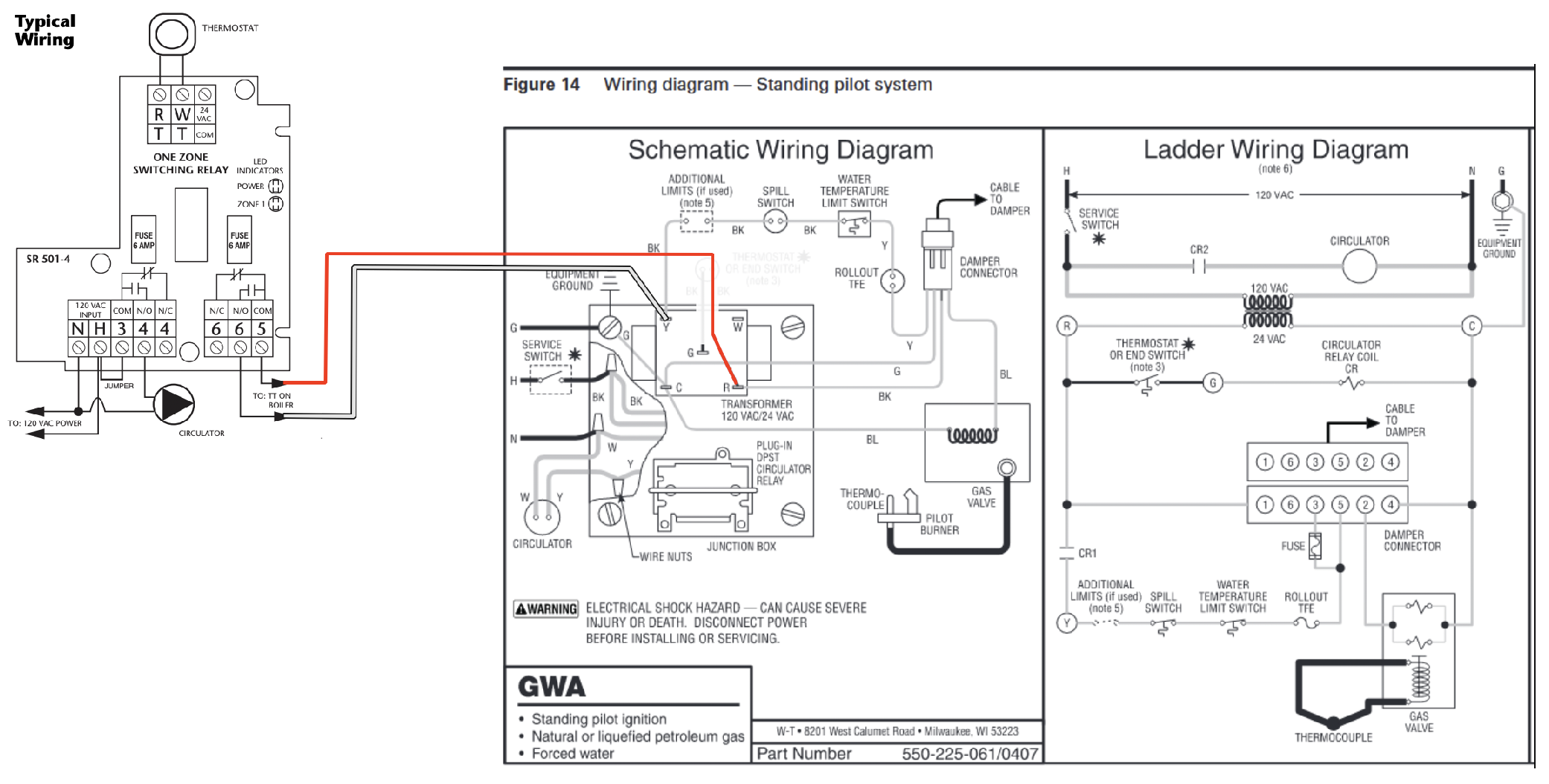

Either way should work, although having relays in series is just more stuff to fail. However it keeps the boiler wiring consistent with the OEM drawings.

Re: Gas boiler heating house without call for heat

With all the detective work you guys have done on my behalf, I kinda feel like I've let you down ordering a replacement part 😂

Re: Gas boiler heating house without call for heat

You need to know your meter…. on my digital meter 000.0 ohms means no resistance. Closed circuit. For an open circuit my meter would read OL which was translated from the infinity symbol (∞) on the old analogue meters in the original instruction manuals. But that was back in the day when old farts were converting from analogue Simpson multi meters to Digital stuff and they thought we needed to be told that ∞ = OL.

Re: Gas boiler heating house without call for heat

I ordered a replacement from Supply House. Will arrive tomorrow

Re: Gas boiler heating house without call for heat

relay is bad. once one contact welds it can hold the other contact closed or it could be a broken spring or dirt making it stick.

Re: Gas boiler heating house without call for heat

@109A_5 Great Video! I believe the opposite happened to @FrankMaraschino's relay. The contacts are not open like in the video, but they are closed or welded together so they do not open when the coil is not energized.

I just thought of a fix for this that will not need any parts. If you use the 5 and 6NO on the SR501 to do what that general purpose relay is supposed to do.

Diagram to follow:

Since all the CR1 contacts on the problem relay do is connect Y to R on the Transformer terminal board, then we can just use 5 and 6NO to connect R to Y on the transformer terminal board. The SR501 is already doing what the CR2 contacts are supposed to be doing, just use the SR501 to do both jobs.

It is easy to do… Just take the wire that is connected to G on the transformer terminal board and place that wire on Y on the transformer terminal board. Very simple fix…. Just remember to leave the CR relay out of the socket.

Re: Gas boiler heating house without call for heat

For proof of concept of @EdTheHeaterMan's no parts required fix, remove the 'CR' relay and jumpering R to Y should have control of the boiler. R to Y closed boiler fires, jumper removed R to Y open the boiler shuts down. Seems promising since the boiler did not fire with the 'CR' relay removed.

Re: Cheap, Easy, And Invisible DIY Solar Thermal?

Go full passive. It's called well thought windows and and insulation and building mass.

If you're not keen on the passive solar houses which Bill Shurcliff and Norman Suanders and I were doing now some 60 years ago in New England, which still are working well — but have no sizzle, no pipes, no collectors, no pumps, no fancy valve systems (which was and remains a problem — people can't believe they work since they look verry ordinary) go visit Acoma Pueblo ("Sky City") in New Mexico. These folks had it figure out 1500 years ago.

But I'm tired of preaching passive solar, so…

Re: Radiant flow not pushing fast enough

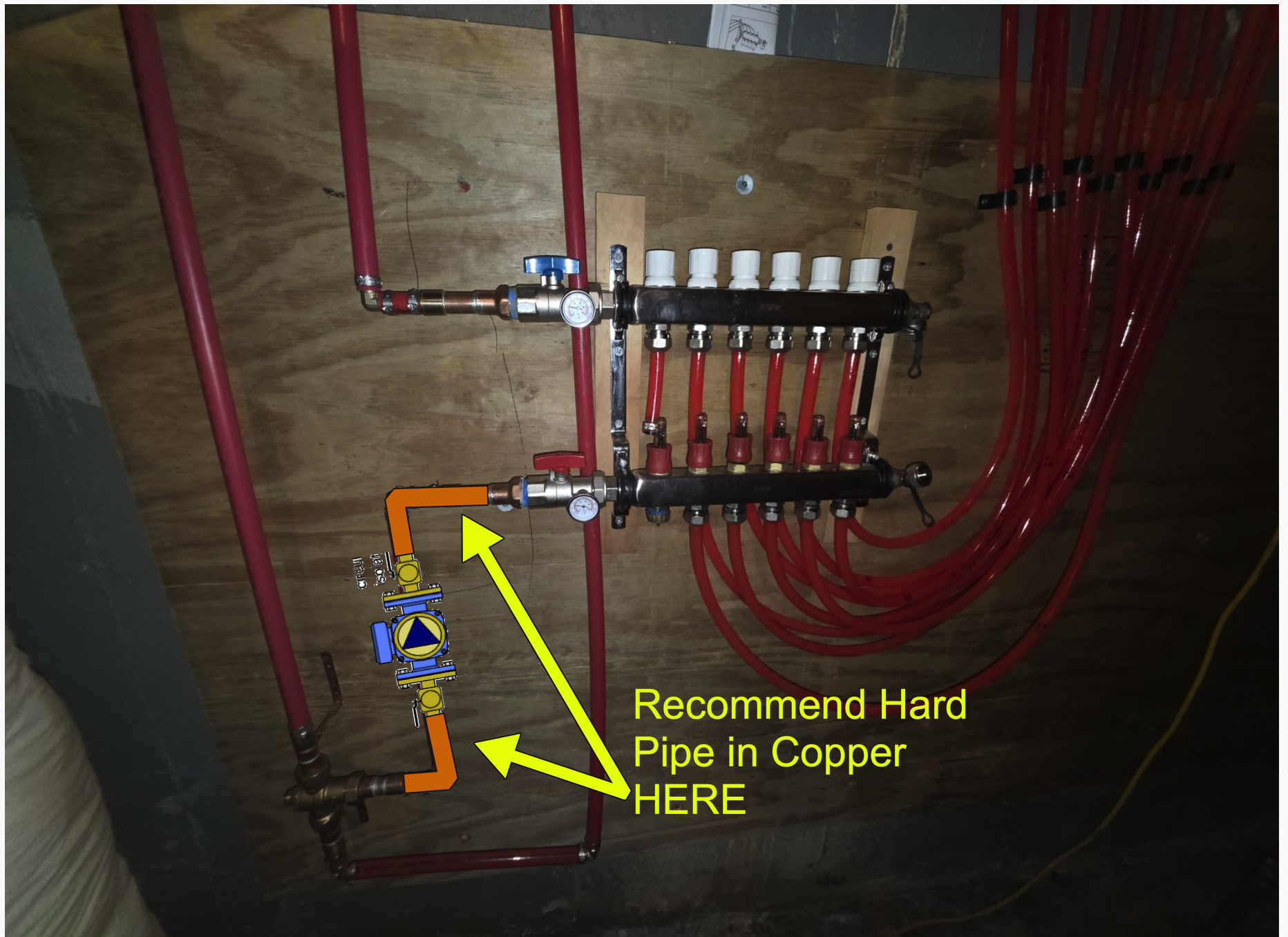

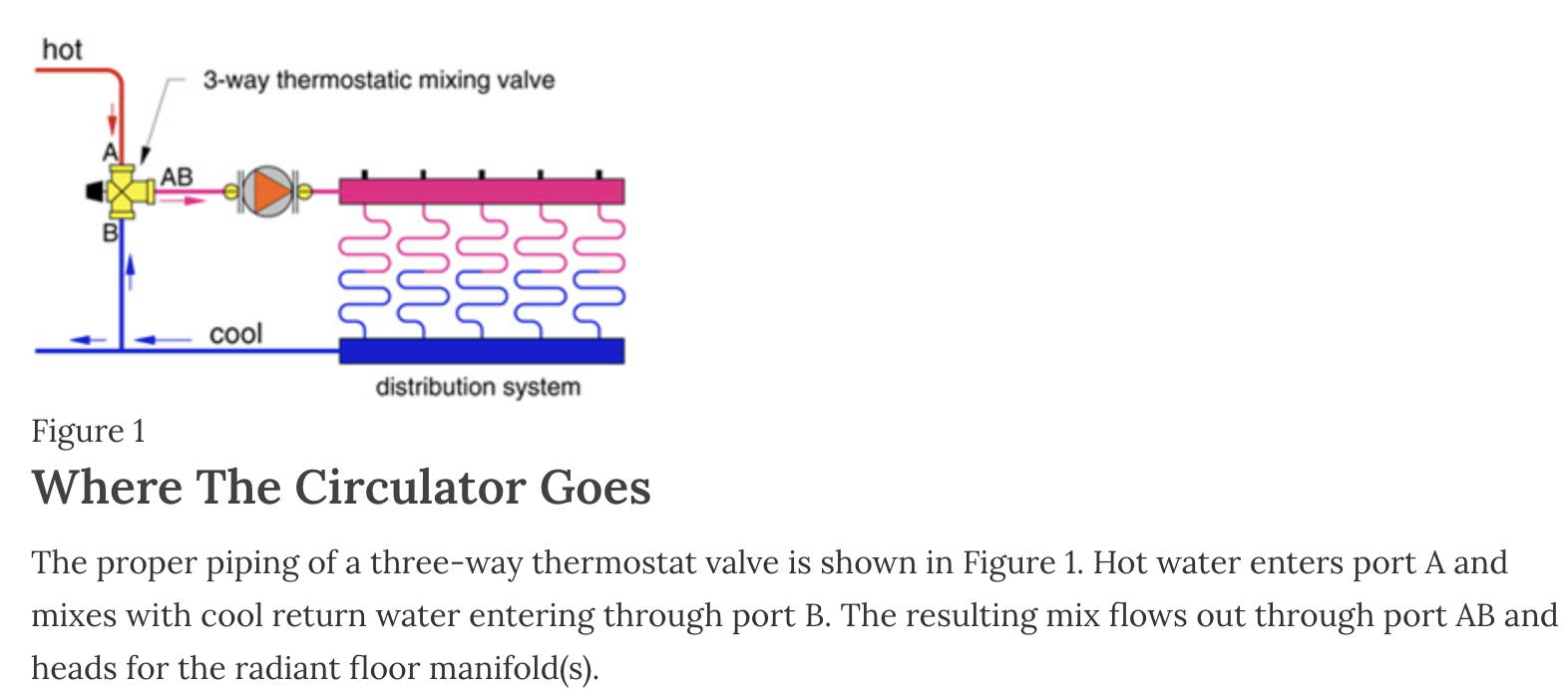

Where is the circulator for the Radiant floor zone located? It should be here (see Photo)

You may not need the circulator on the boiler side of the mixing valve as indicated by @hot_rod

Re: Radiant flow not pushing fast enough

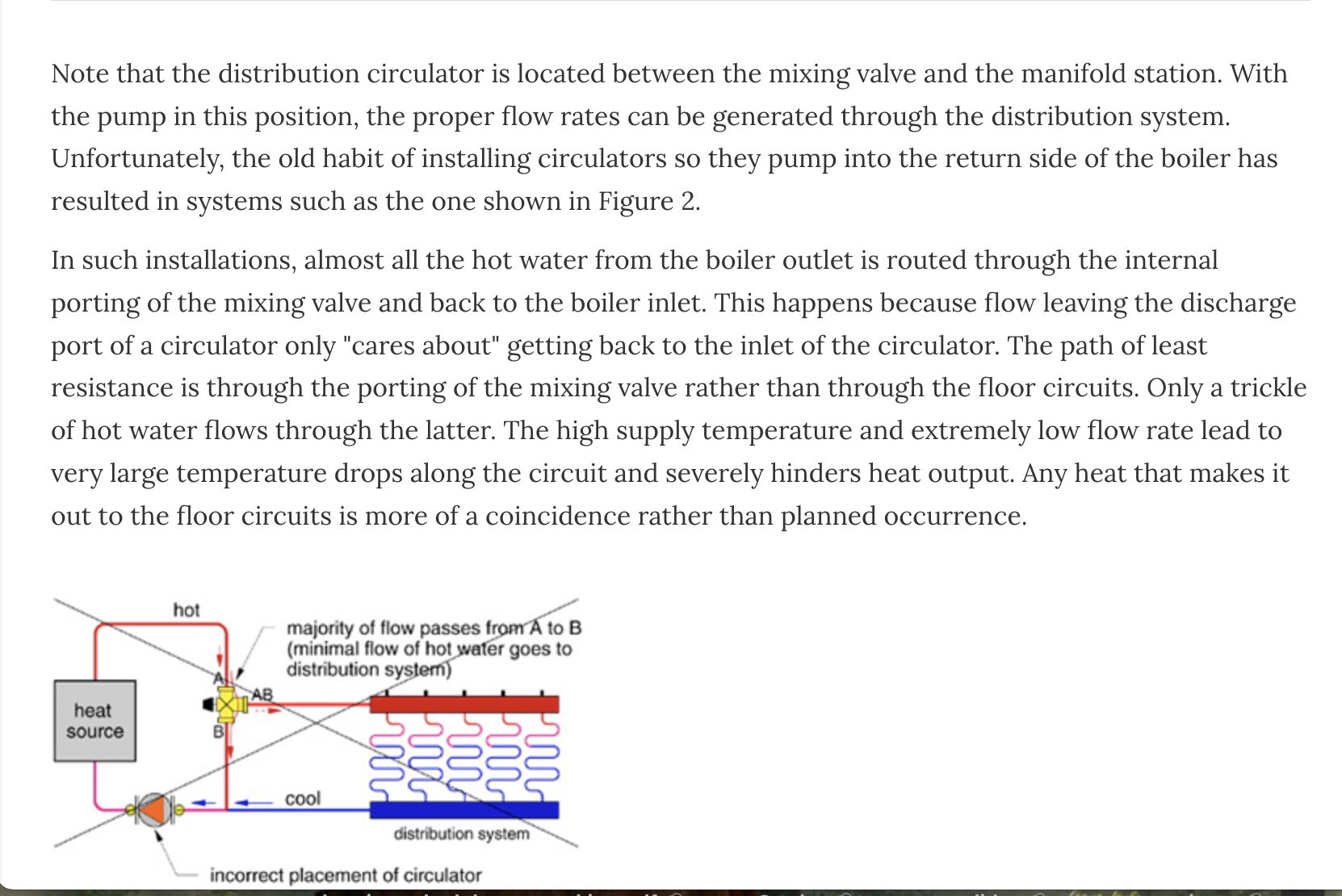

I suppose it depends on the design of the valve, not all valves shut off the hot port 100%. ASSE listed scald protection valves can shut off the hot 100%.

You should pipe up a few demos and report back :)

Regardless, this is how most if not all three way thermostatic manufacturers require a 3 way thermostatic to be piped, for hydronic mixing use. Piped this way it will work, piped in any other configuration you may not always get the results you expect.

hot_rod

hot_rod