Best Of

Re: Leaning B Vent

As long as its not leaking, I'm more concerned about the distance/height to that window...Mad Dog

Re: Cast iron boiler replacement with Navien High Efficiency Condensing Boiler NFB 200H

At the very least count up the heat emitters in each unit

If you have 50’ of fin tube in each unit X 550 per foot you can only put 110,000 into the units

Even a 1 million btu/hr boiler would not add more heat The heat emitters are what you might size to, if they have been adequate in the past

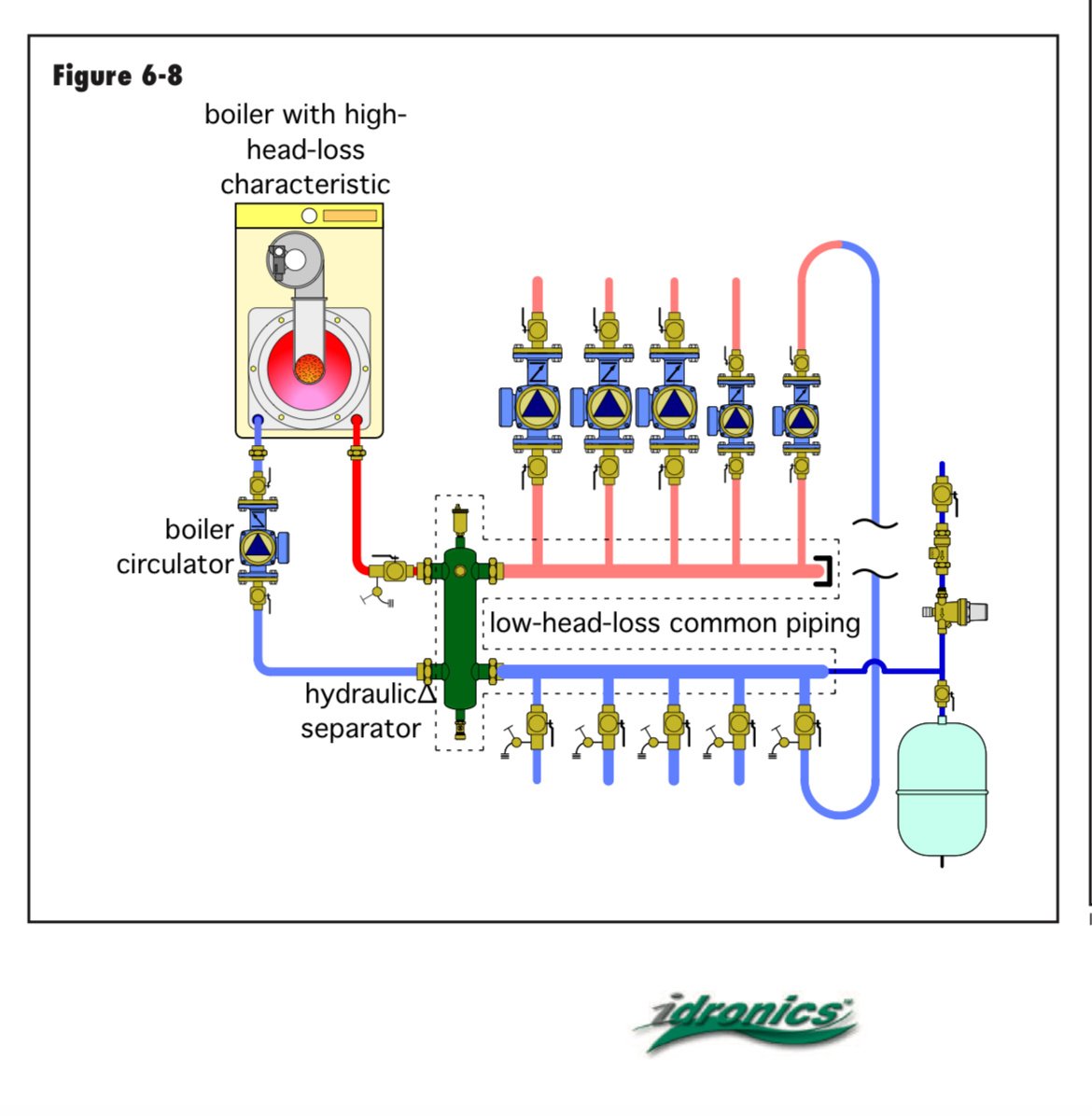

Here is a multi function hydraulic separator, Sep 4

It does air, dirt, magnetic and hydraulic separation in one unit

This shows zone pumps, it could be one pump and 4 zone valves

hot_rod

hot_rod

Re: Cast iron boiler replacement with Navien High Efficiency Condensing Boiler NFB 200H

Sometimes it's better not to take on a job and walk vs be married to a problem. Why risk your reputation where sizing or equipment will be a headache for you.

Re: Gas boiler heating house without call for heat

Got it. So it's an either/or thing.

So, update: the new relay arrived from Supply House during dinner. I got a dispensation from the lady of the manor to interrupt dinner and quickly head downstairs along with two very excited kids to install it. After I plugged the new relay in, I returned power to the boiler and the damper opened. That was it.

My 8-year old: "Nothing's happening."

I turned to my 12-year old and told him to go upstairs, set the thermostat to Heat, hold the up arrow until it flashed above the room temperature, then press the up arrow repeatedly until it was 2 degrees higher than the room temperature.

My 12-year old: "But you said never touch the thermostat."

Me: "This is an exception."

My 8-year old: "How come he gets to do it?"

Me: "You can both do it." I told the 12-year old to let his brother do it, and "supervise." They ran up the basement stairs.

I expected the next sounds I heard to be kids fighting in the living room but after a half a minute or so, I heard the boiler click and the burners fire up. Then two kids stampeding down the basement stairs.

"Did it work?" the 8 year old asked.

I told him it did.

Thank you to everyone who pitched in to help us out. It's very kind of you all to offer your time and your expertise to help strangers. My wife wanted me to extend her gratitude as well. I've learned a lot. This site is a great resource. I'm sure I'll have more questions in the future.

Re: Gas boiler heating house without call for heat

@EdTheHeaterMan posted the 'CR' bypass back on page 2 when we started to have a discussion about that method. Color image with B&W image in the Lower Left corner and his annotations as what to change. At this point I'd put the replacement relay in as proof that it all works as expected. You can always change it later if you want to.

Re: Cast iron boiler replacement with Navien High Efficiency Condensing Boiler NFB 200H

EEEK. Is that poor boiler really sitting in a pit? Asking for trouble.

Step 1. Make sure you have the sizing right. Mod/cons are wonderful gadgets, but they do need to be sized correctly for the load. So… a building heat loss is in order.

I'm curious. Why two pumps in series like that? That makes no sense at all. You are going to be running primary/secondary, I hope, so two pumps will be needed — but not in series as you suggest.

Re: Cast iron boiler replacement with Navien High Efficiency Condensing Boiler NFB 200H

how many zones ? Is it easy to vent to outside ?

Snowmelt

Snowmelt

Re: Cast iron boiler replacement with Navien High Efficiency Condensing Boiler NFB 200H

the boiler you have is a 135,000, 107,000 output. If that has been been adequate, why are you considering a 200?

hot_rod

hot_rod

Re: New Century House with Two Pipe Steam - Questions

That's called a "lock-shield" valve. And the part you're holding in the pic is the key.

Re: Draft inducer motor for gas boiler

We all first tried just replacing the motor , learn from our mistakes .. :)

Big Ed_4

Big Ed_4