Best Of

Re: original circulator sized too small?

So, since 1980 it has never heated adequately?

It would be interesting to check the date code on the 007 maybe it was installed as an incorrect replacement along the way

Or it has worked fine and the system is air locked or the circ is not functioning ?

hot_rod

hot_rod

Re: My three worst jobs sites. What are yours?

any home or building that need a sewer ejector pump service or replacement

hot_rod

hot_rod

Re: Dunham valve rebuild?

I'll have to look through that document (I'm the curious type) to see if there is any typical pressures stated. Back in the day a gasoline engine has about 18-20 inches manifold vacuum at idle, probably still close to that.

Re: Repair radiant tubing in concrete

hot_rod

hot_rod

Re: Radiant flow not pushing fast enough

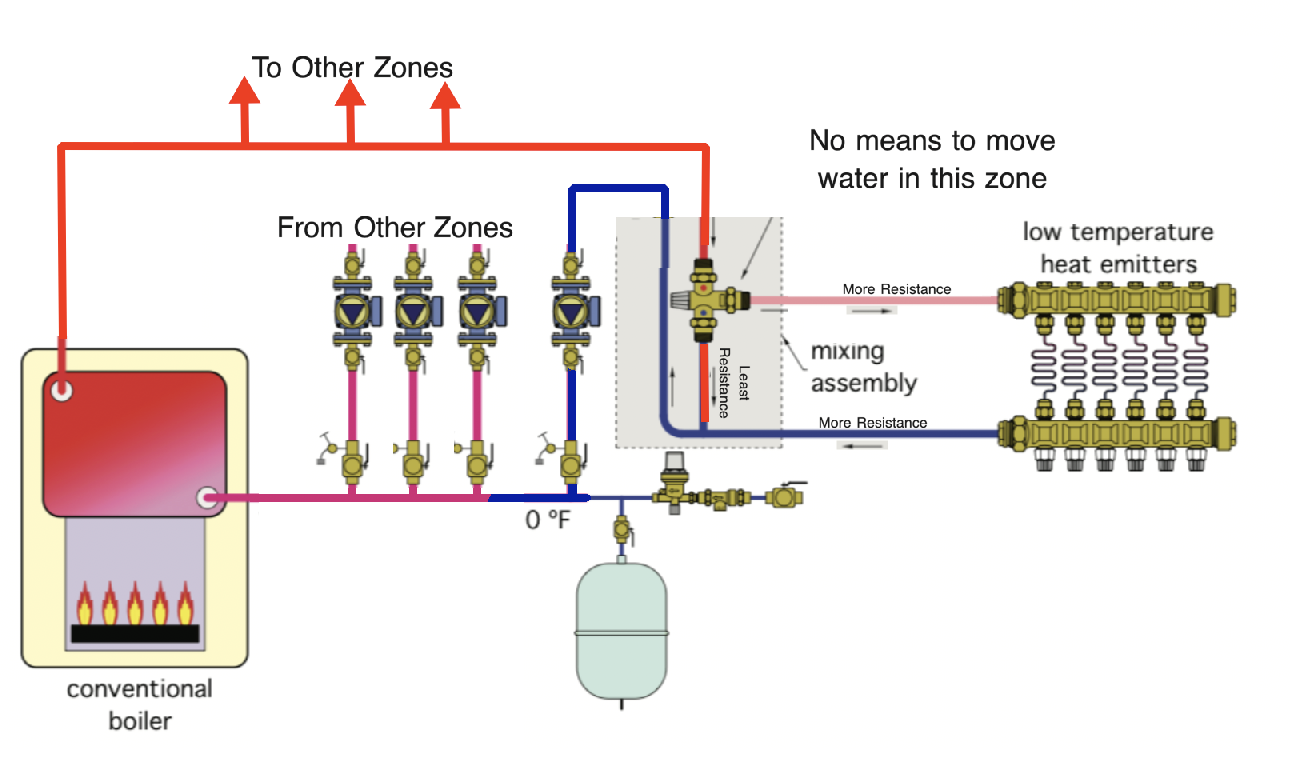

I see that circulator in your photo. This diagram is how your system might me piped:

You can see there is not a lot of pressure drop across the mixing valve when the MAIN pump is operating because is pulling equally on the cold inlet of the mixing valve and the return from the radiant floor loops. There is nothing to move the water into the cold side of the mixing valve, so all you get is what might pass thru the mix valve top the radiant loop and the rest of the flow may even go in the opposite direction on the mixing valve cold inlet port.

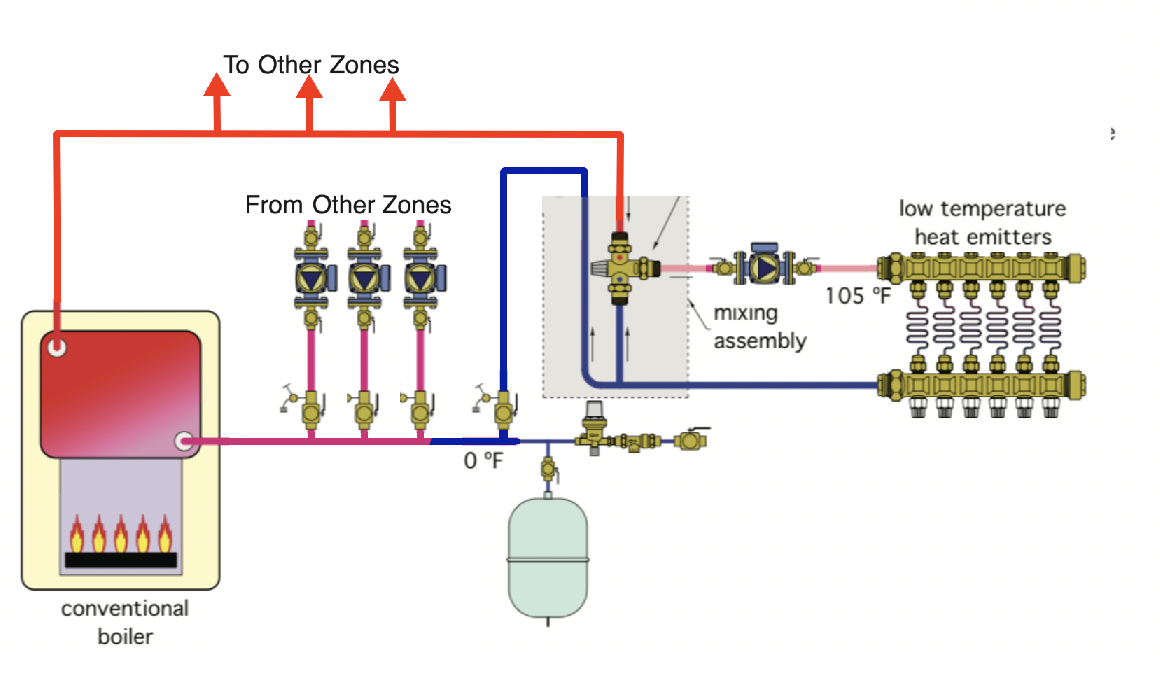

This next illustration indicates the circulator in the proper location.

The pump will pull water from both the hot and the cold ports to get the proper water temperature and move it thru the radiant floor tubes. I have also learned that you do not need the circulator pump where you actually have it located. That is because the mixing valve will pull the water from the boiler as needed to maintain the "MIX" temperature you set it for. If it needs more or less hot water that valve will compensate automatically.

Re: My three worst jobs sites. What are yours?

This post makes me smile. Vacuum pumps are used in rendering plants, so yes, been in lots of those. Edible oil and shortening plants are slippery too. Really had to be careful climbing the stairs.

Sewage treatment plants too. They're not that bad, really.

Poultry processing plants use vacuum pumps for evisceration. Really nice when we'd get one in for repair that had been baking in a hot enclosed semi trailer for a day or 2.

Re: My three worst jobs sites. What are yours?

Went into a crawlspace to fix a floor furnace. After I got in there and was laying in some wet muddy crawlspace floor, someone flushed the toilet and I found out quickly that the sewage piping was broken, got out fast and went home to shower and change clothes. Never went back to that house.

Re: Gas Floor Furnace quit working

Hi @mattmia2 , I'm very careful with referrals. I'm of the "go slowly and do it well, and just once" bent. Too many are of the "go fast and mess up" approach. I don't want my name attached to that. And, although I don't mind crawlspaces, just guessing I'm in the minority. 🤠

Yours, Larry

Re: 1930's Hydronic System help understanding

The Low Water Cut Of Switch should be installed in one of the tapping's in the side of the new boiler and it should be wired as the first electric control to protect the boiler in the event of a water loss as it will immediately cut the power to the boiler if the LWCOS senses no water.

About the steel compression tank; it would be better and more effective keeping this tank for air management as it has a much greater capacity to create and maintain the point of no pressure change. The steel compression tank creates a huge air cushion to provide the Point Of No Pressure Change and quickly removes air bubbles and microbubbles as long as an In Line Air Separator and Airtrol valve is installed correctly.

Once the boiler, steel compression tank and system is filled with water the water feed valve is shut off completely and the boiler started the remaining air in the system will migrate to the steel compression tank dissolve from the water and will remain in the air blanket above the water in the steel compression tank to maintain the Point Of No Pressure change and keep the circulator flooded.