Best Of

Re: Debate me Bro-3/8 inch pex 150 foot lenths AOK for high delta T radiant

fair question. dont have the tools on my cell but IIRC the pressure loss in 150' of 3/8 is still more than 300' of 1/2. so i was anticipating that i wouldnt amp up the circulator and the flow rate would be lower than target but i would be counting on high delta T to get the btus out and i have always 0referred that strategy even with 1/2 inch.

i can see from post below you share my affection dor 3/8. and they aint going broke selling it dor essentially the same price as 1/2.

and , to be fair, it is the pressure delivery at flow numbers on the plumbing side that warn folks off but i shower with 3/8 pex and im happy. i have to admit i chickened out running it on hot side to showers in 4 story building although i wanted to to cut the time to get hot to the shower head. if i would have had easier access to the chase i would have tried it .

so my occams razor take on the 'industry' is not even that they tell folks to do qhat is profitable to them but that they have given up on thinking about the best ways to so things and go the easy way for them. that includes the industry letting us down with regards to speaking out against bad regulation instead of just going along .

brian

Re: Oil Water Heater for Disabled Couple on Long Island

In the land of nearly reasonable electric rates….(thinking LI not so)…..an electric WH would seem good for an elderly couple.

Re: My three worst jobs sites. What are yours?

Aw c'mn guys. Sewage treatment plants aren't bad. I've worked several in my day, and first place you get used to the smell. Second place, personal hygiene is number one. Never washed my hands as often again. Third place, if the operator is any good at all, the place is really pretty clean… and we were really big on confined space protocols.

Oh just one more thing. Don't go for a swim…

Re: Debate me Bro-3/8 inch pex 150 foot lenths AOK for high delta T radiant

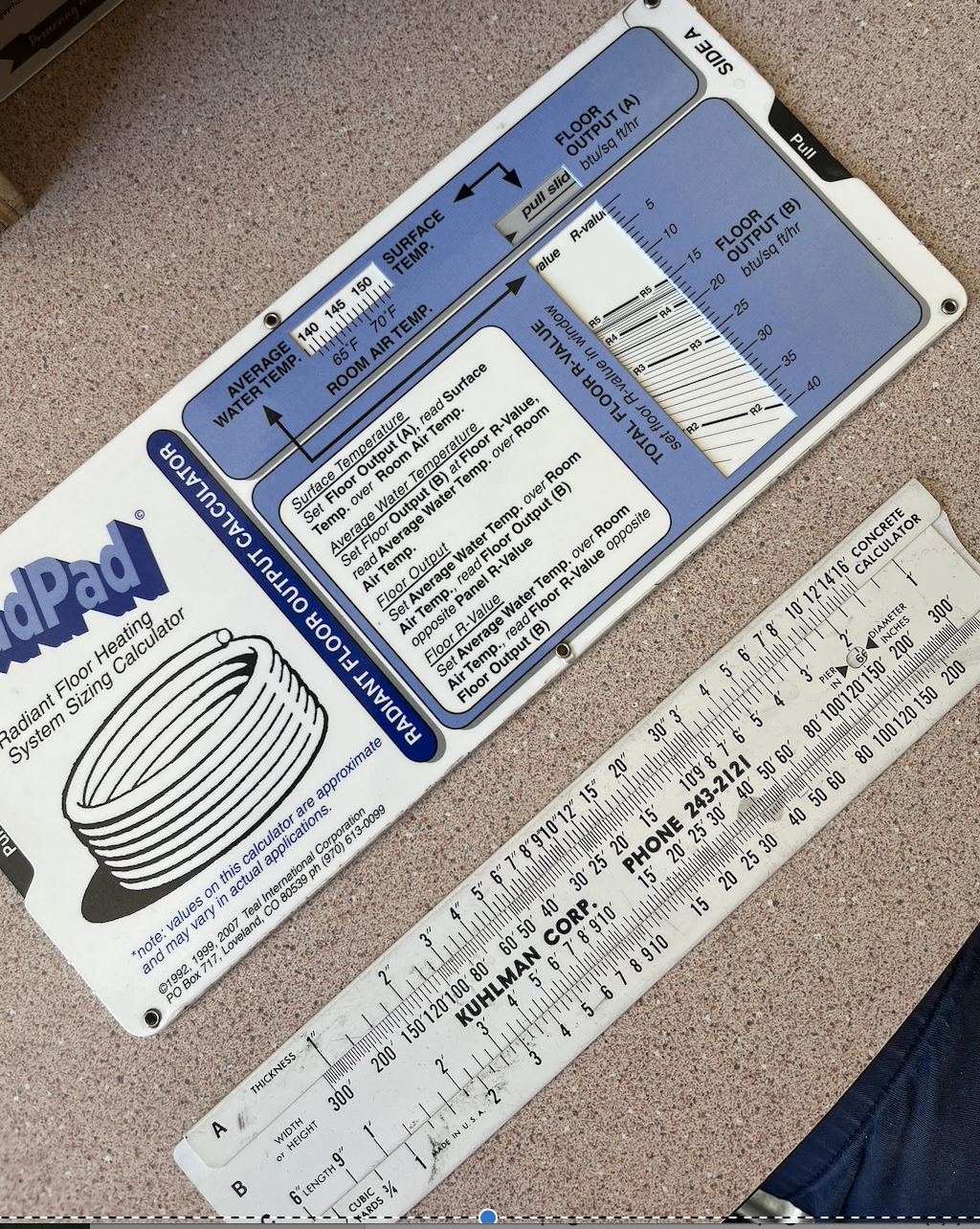

Two slide rules that I still use. I find them as fast as opening a software or app.

The Rad Pad developed by Larry Drake. 1992!!

A concrete calculator.

I do have an extra RadPad somewhere if @archibald tuttle wants it

hot_rod

hot_rod

Re: Ruud Monel Water Heater

where is it leaking? unless it is a connection it is done. those have a gas valve that is questionable at best and i believe have the inlet and outlet tubes routed in such a way that you can't put a modern t& p valve on them.

Re: Why purge valve above boiler? Pumping Away.

you turn off the “service” valve , open the fast fill function

So water can only go around thru the system, it pushes air as it goes, up through the boiler to the “drain” valve purge point

With this method everything including the boiler gets purged from one point

hot_rod

hot_rod

Re: Repiping monoflo returns, how does this look?

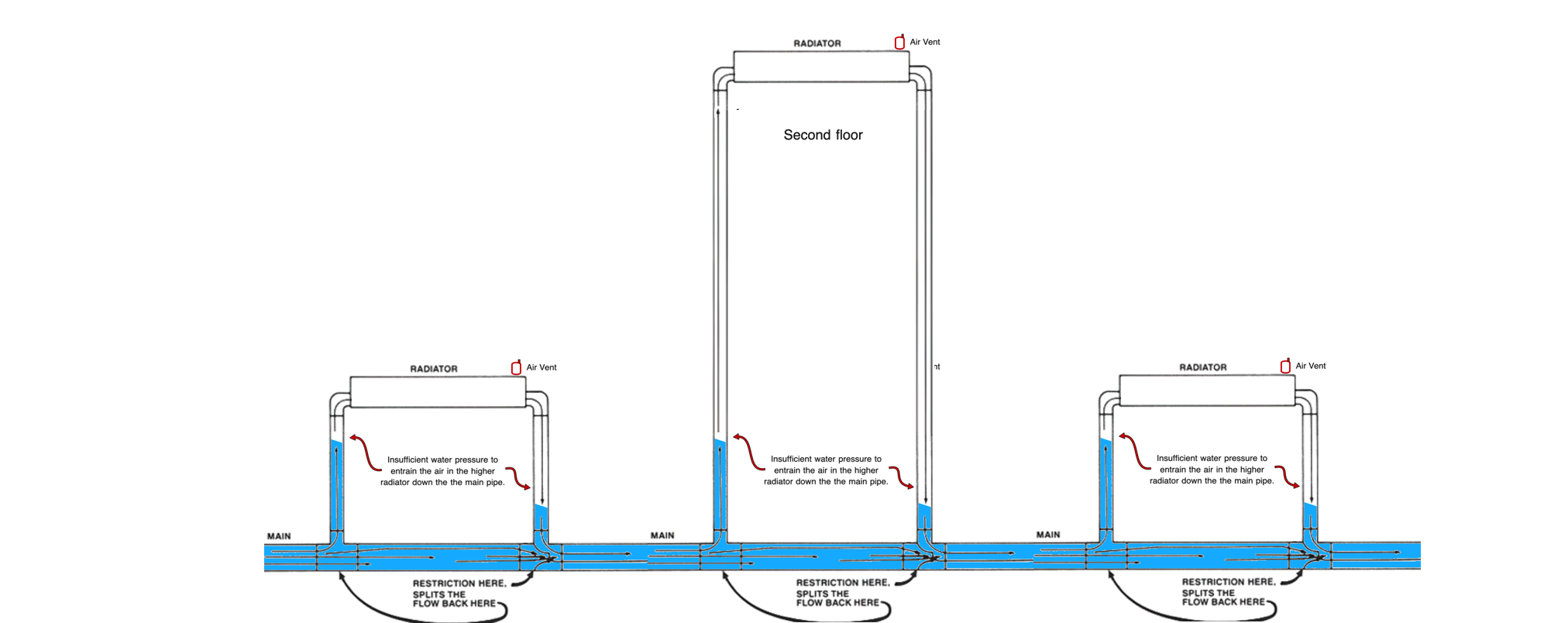

This is what purging might look like in your Monoflo® system:

You will be able to get air out of the main pipe however the risers, especially to the second floor,

will be impossible to PURGE…. they must be VENTED.

Re: Debate me Bro-3/8 inch pex 150 foot lenths AOK for high delta T radiant

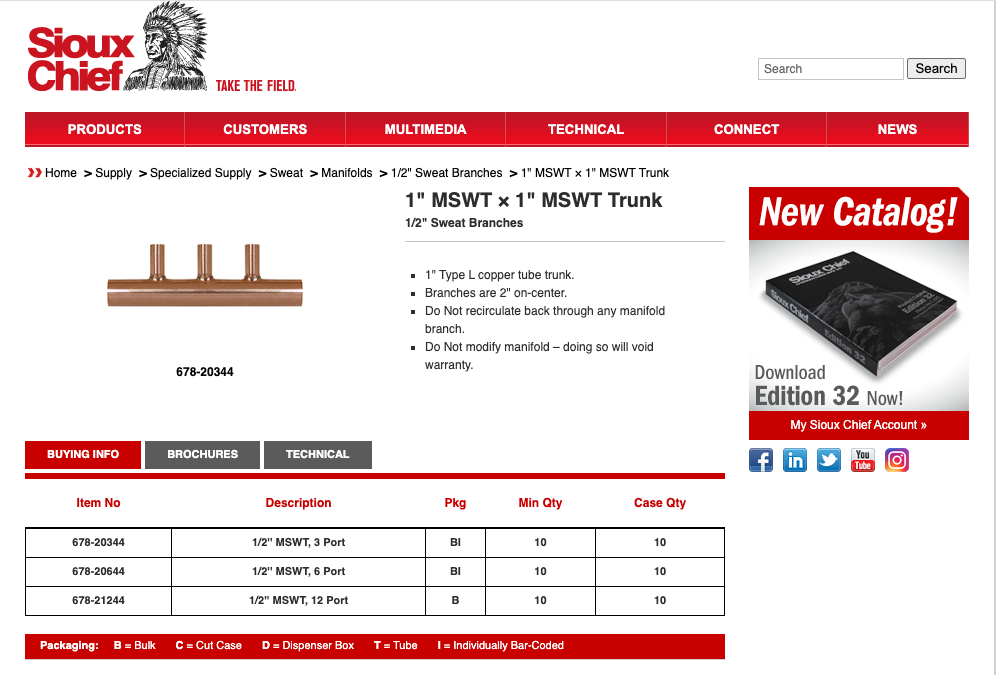

You can still get manifolds with 1/2" sweat stubs, add your own pex adapter.

hot_rod

hot_rod

Re: Top draw Roth problem

@BDR529, please follow site rules and be respectful of others. Thanks.

Re: Top draw Roth problem

Not nice. This is called HeatingHelp.com. I don't see how your statement helps

Tom indicated that there are some different possibilities …and some others.

- Dirt fell into the fuel line during assembly

- Leaking flare connection

- Leaking pipe thread connection

- The draw tube inside the Roth tank is not below the liquid and is just drawing air.

- There is no draw tube inside the Roth tank

- The Roth tank valve (that looks like a miniature hand pump handle) is in the off position.

- There is a pinhole in the copper tubing between the tank and the tigerloop.

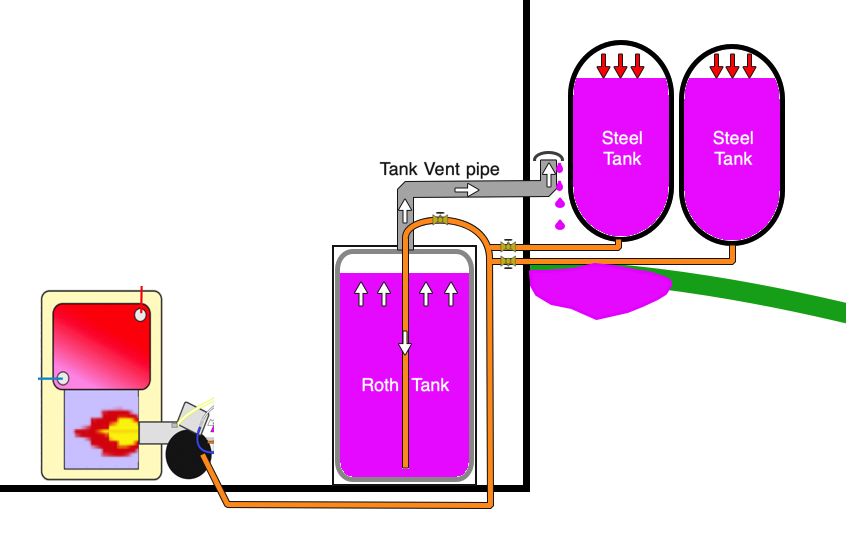

I have a concern about your three tank descriptions. This could be a recipe for disaster. You may have it under control, but some day you may be on vacation, or in the hospital or just too old, and someone will “do you a favor” that does not understand how you have the tanks arranged. They will open a valve and you will have all the oil from the outside tanks siphon into the roth tank. Please tell me “that all the tanks are at the same level” otherwise you may have this condition:

Of course if you have this setup, you are smart enough to never have all three fuel line valves open so the oil in the higher tanks can gravity flow into the lower tank then spill out thru the vent onto the ground. I just wonder if your helpers will know that if you are not there for some reason when they do you a big favor and order two full tanks of oil so your pipes don't freeze while you are hospitalized …. you know what they say about no good deed