Best Of

Re: Triangle Tube PT 110 after recall

Gas pressure is a BS issue, a canard, a false theory. The gas valve regulator is negative pressure. And I've tested a 175 down to about 1" w.c. propane — no problems. This gas pressure nonsense had people re-piping — all a waste. Gas pressure has never been the cause of failed or delayed ignition.

Re: Radiant under-floor system

@hot_rod: "A load calc and tube layout is helpful to assure it works properly."

You're understating the case to say they're "helpful."

We get posters here all the time with floor heat systems that don't work, have never worked, and could never work. These systems need to be designed, the biggest mistake you can make is to assume they'll "just work."

Before you lay a single foot of tubing you need to know the heating load of every room. You also need to know what behavior you want out of the floor, and what your control strategy is going to be. You need to know how much flow is required to meet that strategy. And the reason you need to figure out all of those things before you lay tubing is that the layout of the tubing is going to depend on the design, there's no layout that "just works."

Let me give an example of behavior choice. Let's say you live in Boston, where the average January/February temperature is 29F, the 99% design temperature is 13F and the mean annual minimum temperature is -6F.

Do you want a heated floor that is the sole source of heat for the room? If that's the case, it has to meet the heating load when it's -6F out. Let's say you run a surface temperature at 85F to meet that load. On an average day, when it's only 29F out, the heating load is going to be 41/76= 54% of that, so the floor only has to be 78F. Which is nice but doesn't give the toasty toes feeling. In fact, it's not really noticeable.

Let's say instead what you want is toasty toes all winter. In that case you want to run the floor at 85F on an average day. But you can't run much hotter than that, you'll need some sort of supplemental heat on the coldest days.

What are you doing for cooling? Ventilation? Those should all be integrated in the design.

Re: PMJ plc system

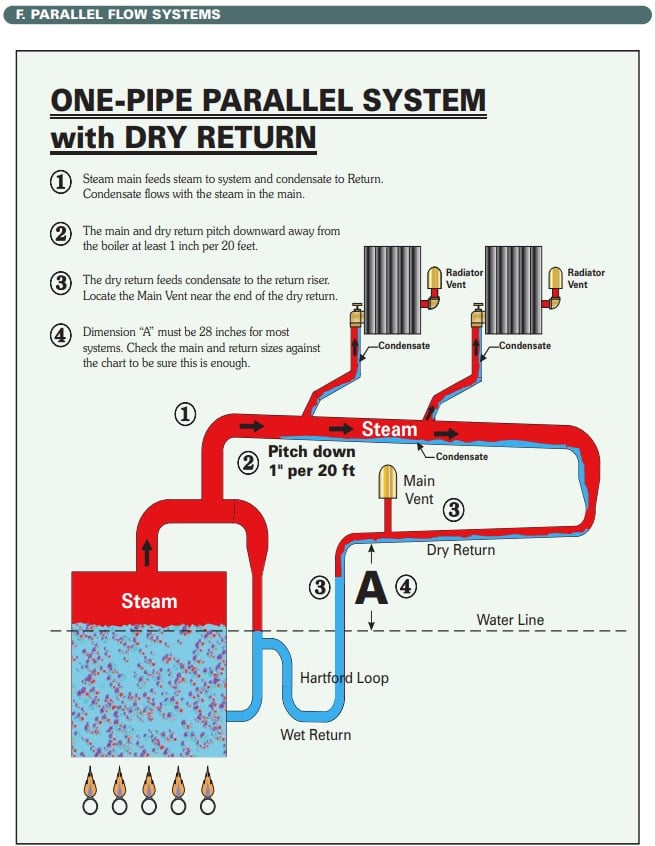

It's too small to worry about or consider. Someone who is probably dead apparently made some mistakes when consulting the fluid dynamics charts that keep getting mentioned here, and decided to tell everyone to worry about this dimension that they said should be 14"-28". Books were written about it, people designed systems based on it, diagrams were drawn showing it, and they named it Dimension A so that it could be discussed, planned around, and thought about.

That concern is unnecessary, that dimension causes zero problems, and so based on that I call "Dimension A" a myth.

Yes there is a pressure drop. It is a rounding error that is smaller than a lot of people's slope of their basement slab. And yet people keep bringing it up in threads where people are asking for help. That is wrong.

Edit: We posted at the same time, I was responding to @PMJ so I'll add this:

condensate load is a huge factor at startup or near startup.

Why do you think that condensate load is greater at startup? The exact same amount of steam is being created, therefore the exact same amount of condensate generated. Actually a little less at startup until the boiler is fully hot.

Re: PMJ plc system

And the manufacturers have to be responsible and include large factors of safety in their recommendations. I sure would not want to be a daredevil, at the risk of being told it is a bad analogy, to fly in a commercial airplane without large factors of safety built in for when things do not go according to plan.

But denying the physics helps nobody really, especially when you have seen it in your own video with your extremely low output boiler. There are people out there who have bad water and piping in very very large boilers, so we need to be careful what we advise, just like the manufacturers, and condensate load is a huge factor at startup or near startup.

Re: Similar Circulator Pumps?

Snowmelt

Snowmelt

Re: One pipe steam system main vent

Took longer to get steam to my radiators when I had main vents back at the boiler vs at the end of my mains. Had data supporting such, not just one time time measurements but year long cuft gas used vs heating degree days. Perfectly acceptable to put them in either location but my experience has been better with them at the end of the mains.

Re: A lower main from another basement

I love Jamie's response but I will give you a little more wiggle room if this system is 1-pipe (I can't tell if yours is):

If the dry return isn't well above ("well above" depends on the operating pressure — at least 14 inches, if you can operate at half a pound)

What Jamie wrote above only comes into play in a 2-pipe system. In a 1-pipe system, there is no concern about additional height requirements due to pressure. In a 1-pipe system, no matter what the pressure is, the water line will not rise either at the boiler, or at the far end of the main. But still, keep the pressure low regardless for other reasons!

Re: One pipe steam system main vent

I used to wonder about this too but I'm glad I never moved my vents from the end of the dry returns to the end of the main. You don't want an air bound dry return. Vents are supposed to remove as much air from horizontal piping that can carry steam as possible. If you didn't it would cause more back pressure and hinder flow of condensate to the returns and it might even interfere with the A Dimension and possibly result in more noise and gurgling. From one pipe steam pdf by peerlessboilers: