Best Of

Re: Steam System sizing

Big thanks on the Whittier radiator catalog!! This is exactly what I was looking for.

Steam System sizing

Hi All,

I'm hoping for some deep in the archive help for radiator sizing. I have a total of 34x indirect radiators across 6x indirect steam heating boxes in my basement. For a long time I couldn't make out what brand / model they were, but a neighbor with the same system had one of their boxes open and I was able to snap this photo. They from Pierce's Steam Heating company, which as best I can tell merged with a couple others to form American Radiator in 1892.

According to The Ideal Fitter, American Radiator's Excelsior model had 12 sq ft of EDR per section. Similarly sized Bundy Eureka Straight models (pg. 105) have 15 sq ft of EDR per section. Does anyone have a catalog for PSH Co, or know if they kept the same radiator specs between the 1877 patent and the American Radiator branded product?

Bonus points:

I recently identified a small decorative radiator I have as a “Whittier” radiator, H B Smith Co, c.1873 (see pg. 20). I haven't been able to locate any sizing information on it yet. Has anyone seen a catalog for this company / model?

Thanks!!

Re: Spray Foam and Steam riser

That would look great too @ChrisJ

look closely at this section… Could there be a Wye Strainer that will never get cleaned?

Re: bending fuel oil line

Fill the tubing with sand. Then clear out the sand after the bend is completed.

R-22 works good for blowing out fuel lines. Oops did I say that out loud?

Re: Radiant floor does not feel warm

What size loops and how long are they. How many loops?

Typically around 1/2 gpm per 1/2" loop 250 -300' max length.

So the number of loops X 1/2 gpm = the total gpm the radiant needs.

Lets assume 10 loops, so a 5 gpm total gpm

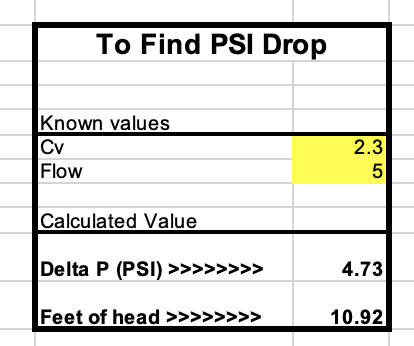

With a 2.3 Cv valve flowing 5 gpm, the pressure drop is around 11' head. That is about the high side of flow through that mixer

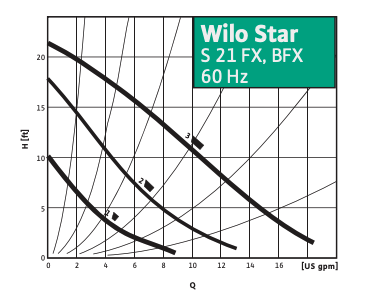

Here is the Star 21 pump curve. Enter the bottom at 5 gpm, run up to see about 17' head. So you should have plenty of pump for 5 gpm or so. If there is more restriction in the piping, that drives head up, gpm down.

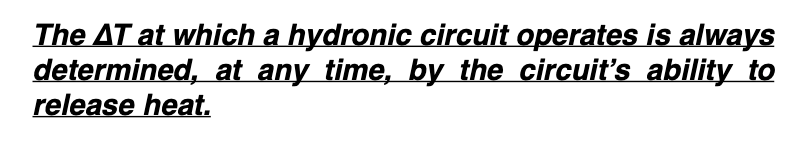

You want to measure the delta after an hour or two of continuous running. The delta will start out wide on a cold system, cold rooms, cold fluid. As the room warms the delta will close up, the load is dropping down. Somewhere in the 10- 15 delta is a common residential design delta. The system may never get to an exact ∆ number you calculate. It's the room load that drives the delta.

Here is the math if you have some accurate numbers looks like this 500 X flow X delta T

So if you are moving 5 gpm 500 X 5 X 30°= 75,000 btu/ hr being transfered to the zones.

As the room warms, delta decreases to say 10° 500 X 5 X 10= 25,000 btu/hr being delivered. Delta dropped due to the room warming, the load decreasing, see the bold printed sentence above.

But really the goal is to satisify that on/ off switch on the wall, the thermostat. If you set it to 70° and the room gets to 70° the job is done. The floors may or may not "feel" warm during this process.

If you have some stable actual data plug it into the formula.

Do you know the heat load of the system in BTU/hr?

Do you know how many gpm is needed to cover the load?

Do you know system head, based on piping loops and mix valve?

Do you have some actual ° readings after running to steady state condition.

Without a few actual pieces of data there is really know way to know if your system is operating properly, satisfactorly?

hot_rod

hot_rod

Re: Can my vintage boiler wiring be updated to modern wiring?

@TheUpNorthState88 I saved the photos of your boiler and it’s possible one will end up framed. I once pulled a 1910 Ideal coal fired water heater connected to 30 gallon tank. Kept it for years but now I just have parts of it.

Re: Can my vintage boiler wiring be updated to modern wiring?

@Steve Minnich @EdTheHeaterMan

As I have invited others, if you are ever passing through or visiting Michigan, you are welcome to see it all in person. Attic expansion tank included haha! I will happily give tours, this is a very niche group here so it not like most folks would even care to see any of this.

Re: Two boiler repipe for primary/secondary

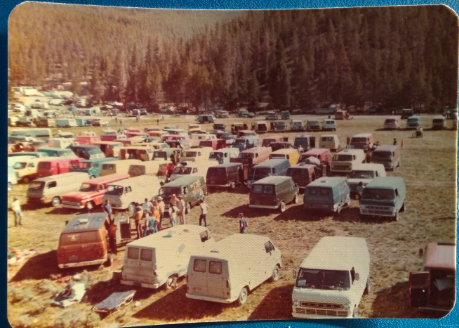

Is that your van, Ed? 66? That was a desirable model at the 1st National Truckin, 1973, Breckenridge, CO.

My red 72 Ford in the distance. Hang glider on top, two dirt bikes behind.

When too much horsepower is just enough.

hot_rod

hot_rod

Re: Can my vintage boiler wiring be updated to modern wiring?

In @TheUpNorthState88's case replacing the boiler's control wiring is a reasonable idea. It provides an opportunity for him to learn the system better, improves the quality of the wiring and to remove unused abandoned equipment. Removing the electrical clutter makes it easier should the system ever need service in the cold of the Winter.

IMO he does need the right person to do the job. I'd hate to hear that an electrician ripped it apart, got confused and then walked away, or an HVAC contractor just wants to sell a new boiler.