Best Of

Re: Main vent questions - newbie

Two #1s will likely be adequate. IMO you’ll probably see more success speeding up the venting on the far radiators and slowing it down on the near radiators than you will going crazy with the main venting.

Like others on here I’ve found the Big Mouth vents leak a lot of steam and I removed mine because I was losing 3/4 inch or so of water per week. Now I have two MOM #1s on each of my mains and lose basically nothing.

Re: Literature on Geothermal

@DCContrarian it helps to use the numbers of the project.

Total pipe length 3400'

Installed @12" OC for a field total of 3400 SQ FT.

If we are to consider the storage capacity within a foot of the tubing, that equals 6800 cubic feet.

Wet clay ( and boy was it wet when I put the bulk in February!) weighs 110 pounds per cubic foot.

So my fields have 748,000 pounds of wet clay within a foot of the tubing.

It does indeed have a capacity of about a half a BTU per pound, and cooling it from 50 to 40 would yield 3.7 million BTU.

But that is not how it works. It does have great conductivity and will keep equalizing out to a larger extent than that foot either way.

@GW I will play with alternating fields manually. I have an odd number of loops ,7.

Each of the loops is a 10 pass by 45' or so, and separated by it's neighbor by 4 feet or so. There is also a 10' wide slot I had to leave out for the side sewer.

This is important, because our observations with my brother's field, a big 30x60 with 1800 feet of tubing in the 1800SF would cold soak pretty badly deep into the season. His soils were drier and less dense and not good conductors as @DCContrarian was talking about. We did not get much edge effect and that large contiguous field got below freezing by the end of the season.

I will manually run 3 fields that are separated by idle fields and the 4' and that 10'. That will be for the very low demand fall shoulder. I will watch for the differential of entering to leaving loop water and when it drops below 10 degrees it is a good time to change up.

Then I will dog off those 3 and run the other 4. I won't know how well it will work until we get into it, but I am significantly overlooped. The common conversion is 600' of 3/4" @ 12" OC per ton. I have 3400' and a 3 ton manual J.

The idea is to let the first 3 recover based on good conductivity and run with that. I may have to tap all 7 at the worst of it. My heating degree day is 23 F and cooling degree day is 79, so yes it is very mild compared to most. The straits of Juan De Fuca are only a few miles away and moderate the temperatures considerably.

skyking1

skyking1

Re: Literature on Geothermal

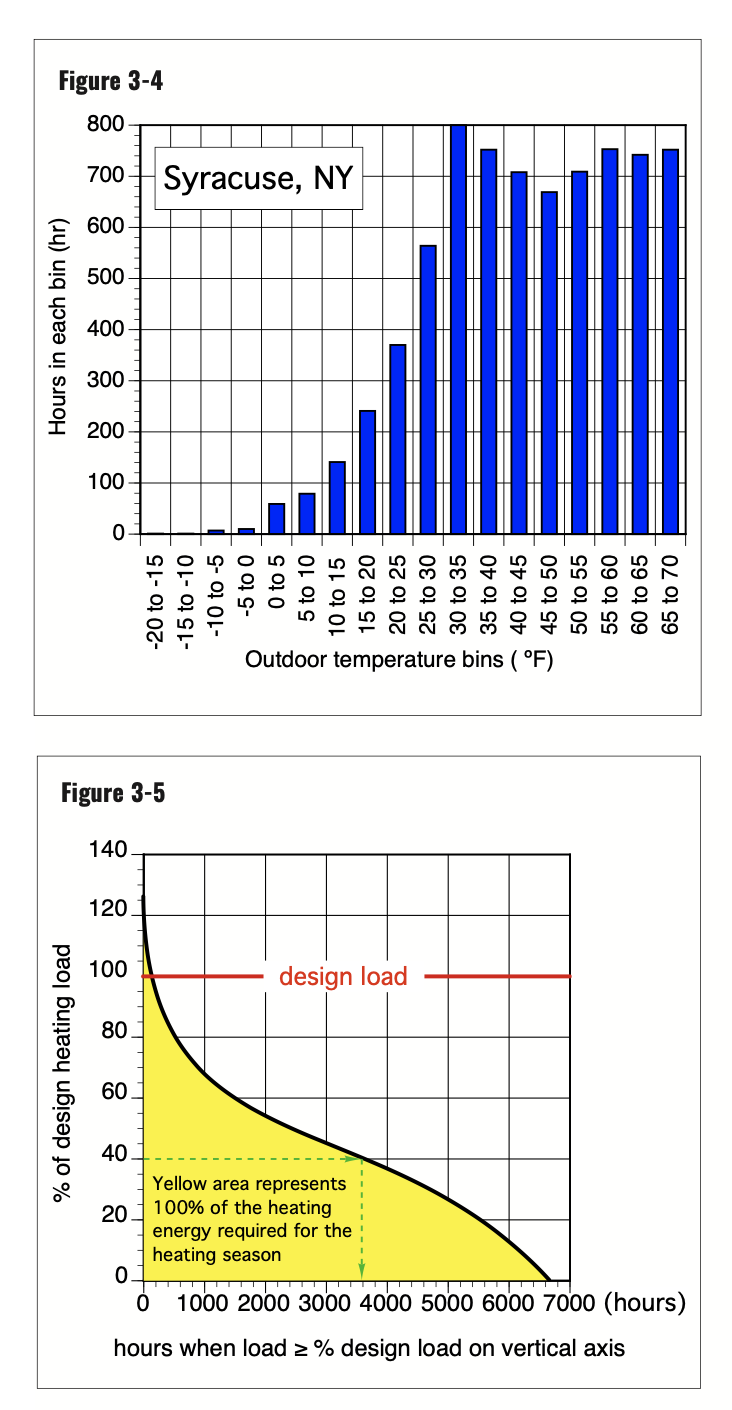

I doubt you will be at design load 31K? for more than a week or two per year. So the load on the field lessens. You can find temperature data for your location online, as an example for upstate NY. Design day there is 0-5°

I think moisture content of the soil has a lot to do with transfer, even in clay.

Really a GEO field is basically a giant solar collector/ storage. Suns energy will drive into the ground to recover the field also.

hot_rod

hot_rod

Re: Literature on Geothermal

It is 3/4"

I do want heat capacity as well as great conductivity. Gravels and sands are poor in comparison.

skyking1

skyking1

Re: Moving Olsen oil furnace to new basement and parts identification

Pretty much any Beckett burner will fit, but a newer 3450 rpm burner will have a hotter flame, irrc, and that furnace firebox might now handle it. This sounds like an older furnace, especially with that burner, so the first thing you should do is a complete inspection of the firebox/heat exchanger to make sure it isn't cracked or burnt through.

Rick

Re: Moving Olsen oil furnace to new basement and parts identification

"A penny wise and a dollar foolish " It is too old , too thin skin to spend the money on the move and new install..

Big Ed_4

Big Ed_4

Re: Moving Olsen oil furnace to new basement and parts identification

Beckett did have a model "S" which was a slow speed burner I think.

Re: Recommendation for highly reliable natural gas water heater?...

Bock is another tank built in the US. Their tanks used to be thicker steel cylinder and heads, thicker glass coating, even thicker sheetmetal jackets. You could tell by the weight listing compared to others.

hot_rod

hot_rod